Manufacturing systems are becoming faster, more connected, and increasingly data-driven. But none of it matters if the system isn’t able to respond quickly when conditions change.

Closed-loop manufacturing addresses this need by linking data collection, analysis, and control. Sensors on the line feed live information into integrated systems. Deviations trigger immediate actions like adjusting machine settings, updating schedules, or flagging quality issues before they escalate.

This continuous feedback loop supports better decisions, fewer delays, and more predictable outcomes. It also lays the foundation for smart manufacturing, where MES, SCADA, ERP, and IoT platforms work together in real time.

In this article, we’ll break down how closed-loop manufacturing works, how it compares to open-loop systems, and why it’s becoming essential for modern production.

- What is Closed-Loop Manufacturing

- How Closed-Loop Systems Work in Manufacturing

- Benefits of Closed-Loop Manufacturing

- Closed-Loop Manufacturing vs Open-Loop Systems

- Closed-Loop Quality Control in Smart Factories

- Role of IoT in Closed-Loop Manufacturing

- Steps to Implement a Closed-Loop Production Process

- Challenges and Considerations

- Kladana: Built for Connected Manufacturing

- FAQs on Closed-Loop Manufacturing

- List of Resources

What is Closed-Loop Manufacturing?

Closed-loop manufacturing is a production method that uses real-time data to automatically monitor and control processes on the factory floor. It creates a continuous feedback cycle between machines, sensors, control systems, and business platforms, allowing for fast, accurate adjustments during production.

The goal is simple: spot deviations as they happen and correct them immediately. This reduces waste, improves quality, and cuts down on downtime.

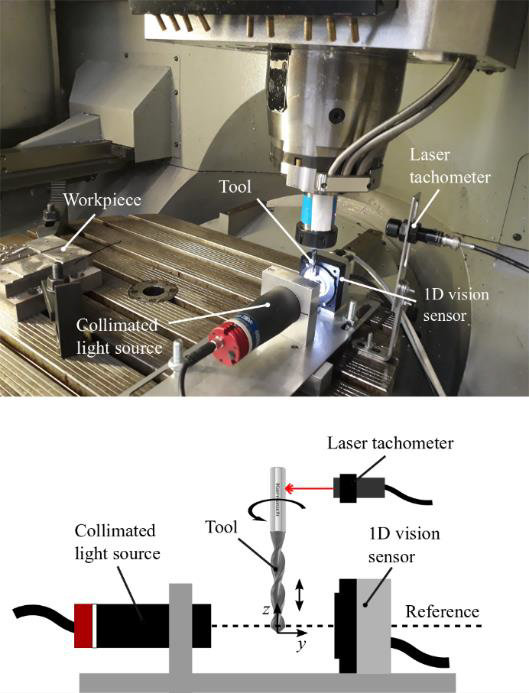

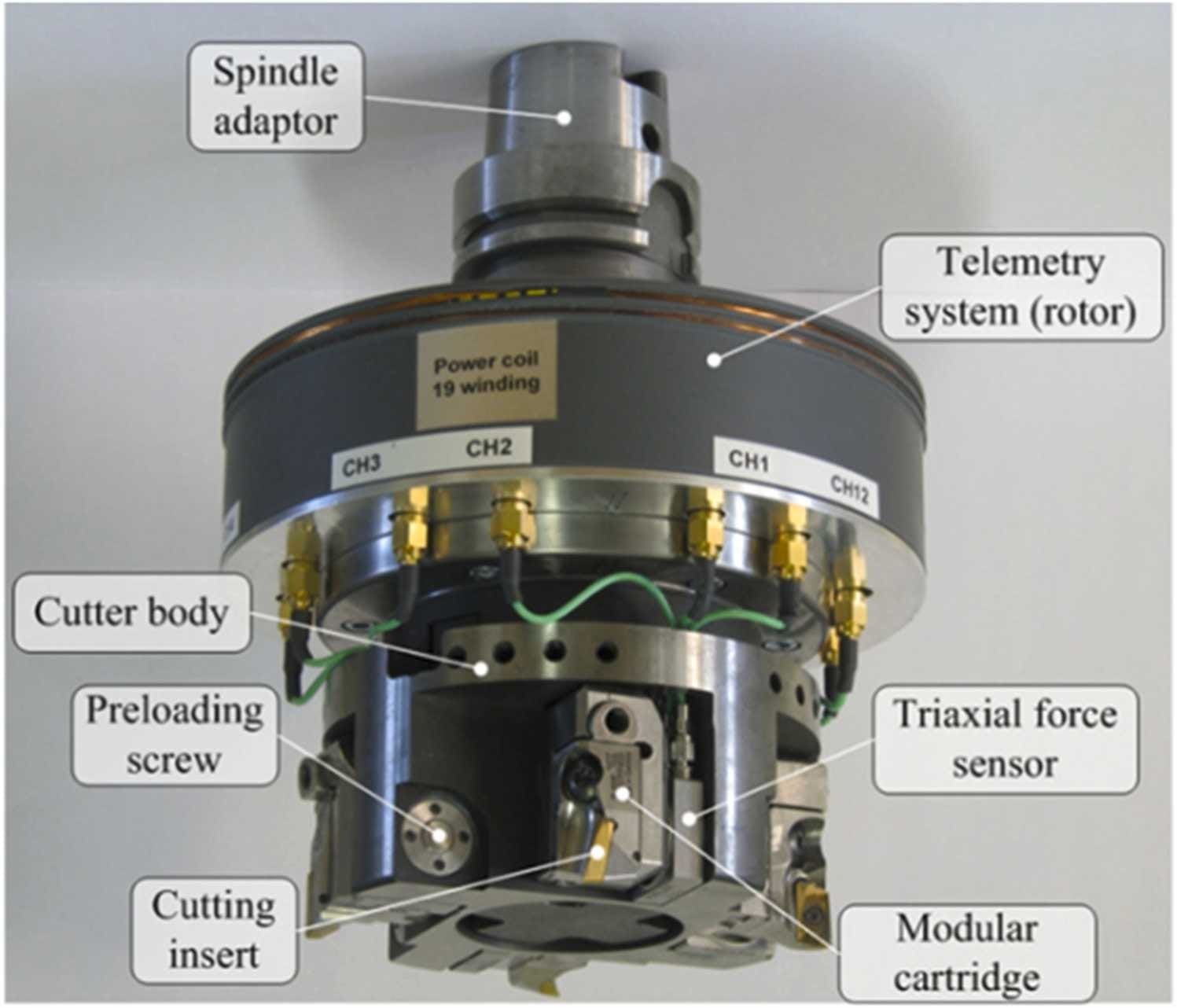

Let’s take an example. In a CNC machining setup, if a tool wears down or cuts outside tolerance, sensors detect the shift. The control system adjusts speed or pressure on the fly, ensuring the part stays within spec. There’s no need to stop the line or wait for end-of-line inspection.

The Role of Real-Time Data Feedback Systems

At the heart of closed-loop manufacturing is real-time data feedback. This system continuously collects data from equipment, processes it instantly, and triggers automated responses.

It typically includes:

- Sensors and edge devices: Installed on machines to monitor temperature, vibration, torque, flow rate, etc.

- Data platforms: SCADA, MES, or IoT gateways that process sensor data and determine corrective action.

- Control systems: PLCs or industrial PCs that execute adjustments based on the feedback received.

With this setup, operations teams have stronger control over tolerance, energy use, and quality without any human intervention. Consider its implementation for a chemical processing plant, where real-time pH or viscosity readings can trigger automated changes to flow rates or temperatures to keep the batch quality consistent.

Kladana is Built for Closed-Loop Manufacturing

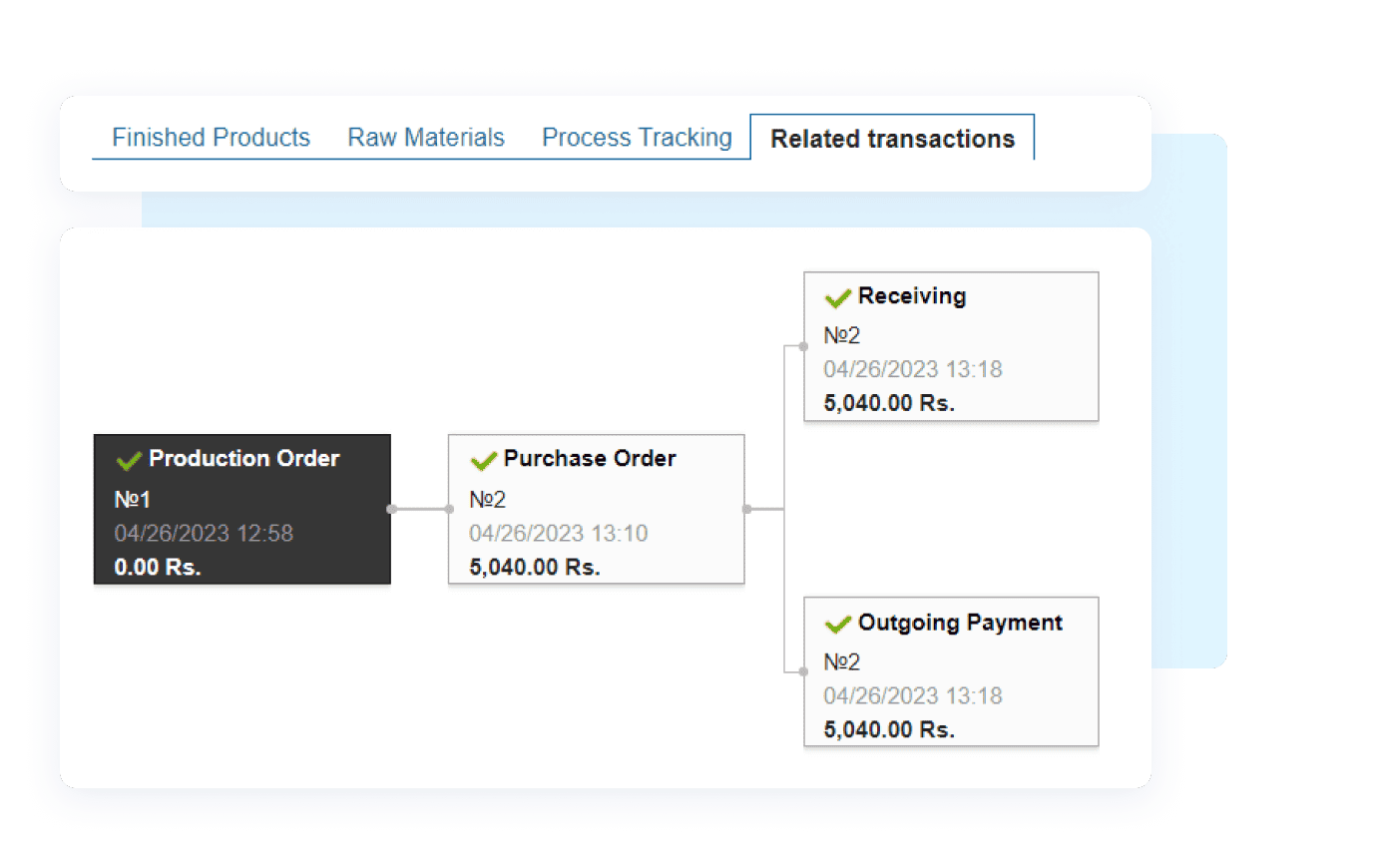

✅ Live Order and Production Tracking — Monitor every production run, stock movement, and material issue in real time. Kladana keeps your BOMs, work orders, and inventory always in sync.

✅ Shop Floor to ERP Connectivity — Link machines, operators, and systems with a centralised ERP that updates instantly. No delays, no manual uploads, no batch processing.

✅ Multi-Level BOM Support — Create, manage, and update complex BOMs with linked raw materials, semi-finished goods, and routing. Track material flow across stages without losing visibility.

✅ Real-Time Stock Allocation — Know exactly what’s been consumed, what’s available, and what’s pending in production. Avoid shortages, overproduction, or stockouts.

✅ Integrated Quality Checks — Log inspections and non-conformance events as part of the production process. Trigger corrective actions and trace them across batches or SKUs.

✅ IoT and Barcode Integration Ready — Pair with sensors, barcode scanners, and smart tools to enable live feedback across lines. Ideal for fast-paced, feedback-driven environments.

✅ Flexible Reporting and Audit Trails — Access real-time reports on WIP, production variance, consumption history, and more with full traceability down to the transaction.

Closed-Loop vs Open-Loop: Key Differences

Open-loop systems operate on preset parameters. Once the process starts, it runs without evaluating output in real time. Any adjustments are made after the fact, usually based on scheduled checks or quality audits.

Closed-loop systems, on the other hand, evaluate output constantly and make adjustments during production. This enables faster response times, fewer defects, and stronger process control.

| Feature | Closed-Loop | Open-Loop |

Feedback Mechanism |

Continuous, real-time feedback |

No feedback during operation |

Control Method |

Adaptive, based on live data |

Fixed, based on setpoints |

Response Time |

Instant, automated |

Delayed, manual |

Quality Control |

Ongoing, integrated in the process |

Periodic, post-production |

Suitability |

High-precision, dynamic environments |

Stable, low-variation processes |

In modern production environments where complexity, customization, and speed are growing demands, closed-loop systems offer clear operational advantages.

How Closed-Loop Systems Work in Manufacturing

You now understand that closed-loop systems rely on an integration between machines, sensors, control platforms, and business systems. Let’s dive deeper into how all these components play their part.

Sensors and Data Collection at Machine Level

Everything starts on the shop floor. Sensors are installed on machines to measure variables like speed, temperature, pressure, torque, vibration, and part dimensions. These sensors collect high-frequency data in real time and send it to controllers or edge devices for immediate analysis.

Example: In a plastic injection molding machine, temperature and pressure sensors monitor the material flow. If the temperature drops below the required threshold, the controller adjusts the heater settings immediately.

Data Processing and Automated Control Actions

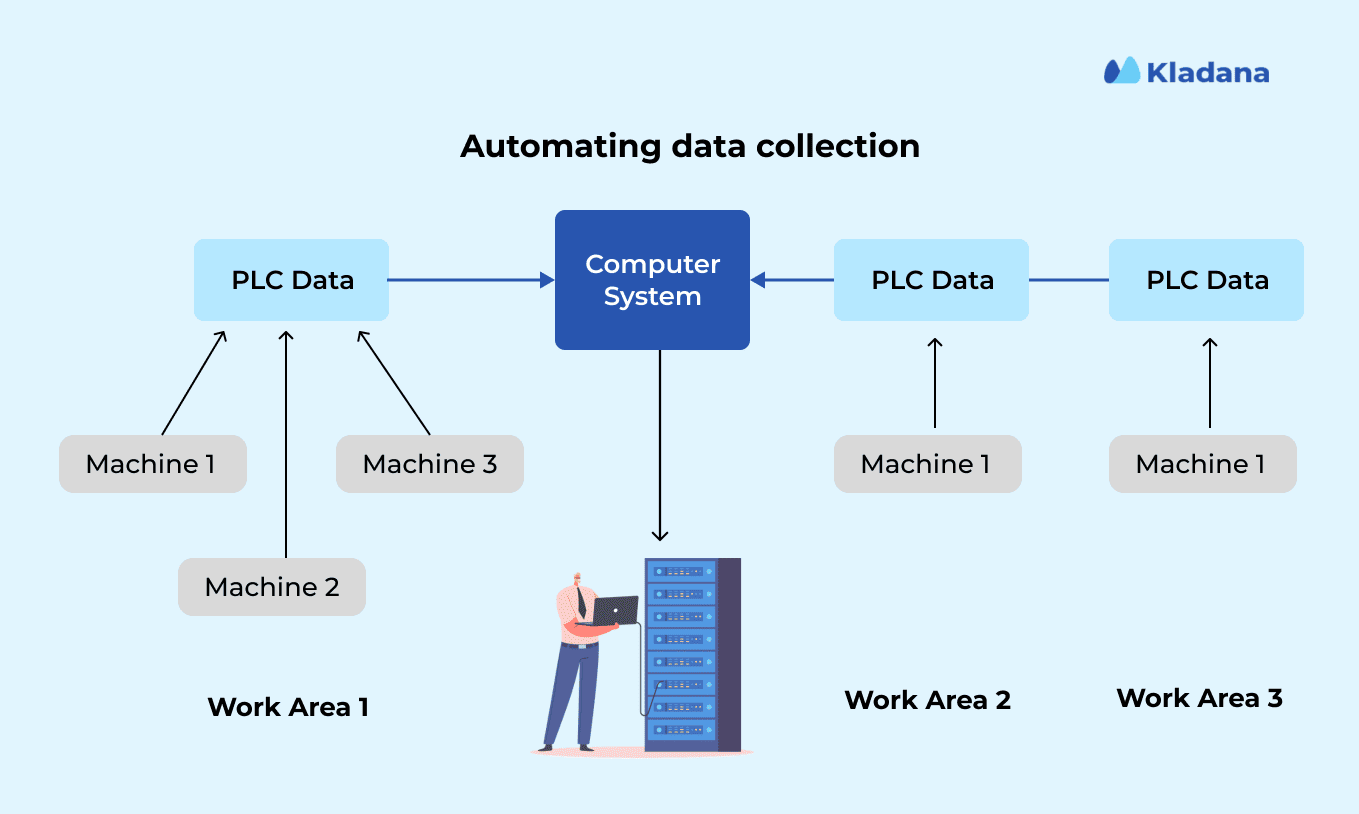

The collected data is sent to local controllers (PLCs or industrial PCs) or cloud-based platforms, depending on system architecture. These platforms compare real-time values against defined thresholds or setpoints.

If the system detects a deviation, it automatically adjusts machine settings, sends alerts, or pauses the process to prevent defects.

Take precision grinding, for example. If surface roughness exceeds tolerance, the controller slows the feed rate and adjusts pressure, ensuring the next part is machined correctly. This automated response loop happens in milliseconds, reducing the need for manual intervention and preventing issues before they affect output.

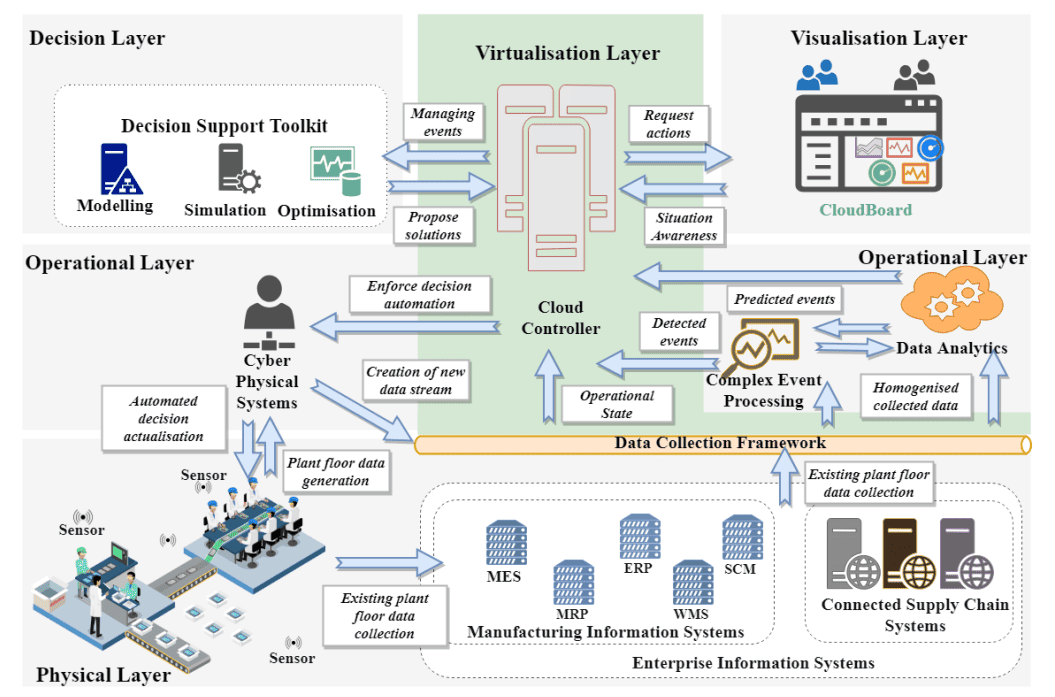

Integration with MES, SCADA, and ERP Systems

Closed-loop systems don’t operate in isolation. For maximum efficiency, they are integrated with higher-level platforms like:

MES (Manufacturing Execution System): Tracks work orders, machine status, and production flow.

SCADA (Supervisory Control and Data Acquisition): Monitors real-time plant data and allows supervisory control.

ERP (Enterprise Resource Planning): Aligns production with business functions like inventory, purchasing, and demand planning.

Together, these integrations ensure that feedback from the shop floor informs upstream decisions and downstream processes.

If a packaging line detects recurring seal faults, the MES can log the issue, and the ERP can automatically trigger a maintenance ticket and pause raw material procurement until the fault is resolved.

This seamless flow of data, from machines to business systems, is what allows closed-loop manufacturing to support real-time decision-making and continuous improvement at scale.

Benefits of Closed-Loop Manufacturing

Closed-loop systems help manufacturers move from reactive problem-solving to proactive control. Here are its most prominent benefits:

Improved Product Quality Through Feedback Loops

With live sensor data feeding directly into control systems, quality checks happen in real time. If a dimension goes out of spec or a machine starts to deviate, adjustments are made immediately. This ensures defects are caught early and prevents entire batches from going bad.

Faster Response to Process Deviations

Closed-loop systems monitor key variables constantly. If a temperature spike, pressure drop, or machine vibration crosses a critical limit, the system reacts instantly by slowing production, adjusting parameters, or alerting technicians.

This rapid response helps avoid unplanned downtime and costly rework.

Waste Reduction and Cost Efficiency

Mistakes are expensive. Whether it is raw materials, energy, or labor, every wasted input adds to production cost. Closed-loop systems reduce these expenses by preventing overcorrection, overproduction, and unnecessary machine wear.

Predictive and Adaptive Control Capabilities

Closed-loop systems don’t just respond to current conditions. When paired with machine learning or trend analysis, they can predict future problems and adapt in advance.

Over time, the system learns how different factors like humidity, wear, or seasonal input changes affect production. It then adjusts control settings before these variables impact output.

Closed-Loop Manufacturing vs Open-Loop Systems

Both closed-loop and open-loop systems are used in manufacturing, but they operate very differently. Understanding the gap between the two helps you decide which system fits your process, especially as factories shift toward more connected and responsive operations.

Feedback Mechanism

Closed-loop systems depend on feedback. Sensors measure variables continuously, and control systems adjust settings instantly. This loop allows for consistent, real-time corrections.

In open-loop systems, there is no feedback. Machines run based on preset parameters, regardless of output changes. Deviations are only caught later, often through inspections or customer complaints.

Automation Level

Closed-loop setups are built for automation. They use logic controllers, real-time software, and integrated platforms that keep everything aligned without waiting for human decisions.

Open-loop systems rely more on manual monitoring and adjustment. Operators watch for signs of drift and make changes themselves, often after noticing a pattern or a quality issue.

Quality Control

With closed-loop systems, quality is monitored during production. Sensors and cameras catch issues early, and corrections happen on the fly.

Open-loop systems depend on sampling or post-process inspections. If problems are found late, entire batches may need rework or scrapping.

Efficiency

Efficiency in closed-loop systems comes from faster response times, better use of materials, and fewer line stoppages. The process is stable and repeatable, even in complex environments.

Open-loop systems are more reactive. Efficiency drops when issues go unnoticed, requiring downtime or manual fixes to recover.

| Feature | Closed-Loop | Open-Loop |

Feedback Mechanism |

Yes: Uses sensor data to adjust in real time |

No: Runs on fixed inputs without feedback |

Automation Level |

High: Systems respond without manual input |

Moderate: Operators intervene as needed |

Quality Control |

Continuous and in-process |

Manual or post-process |

Efficiency |

Optimized through real-time corrections |

Reactive. Depends on periodic checks |

If you’re running a process that needs precision, speed, or continuous output, closed-loop systems provide better control and predictability. Open-loop setups may still work in low-risk environments or legacy operations, but the trade-offs are clear as production demands grow.

Closed-Loop Quality Control in Smart Factories

We will now look at how closed-loop quality control supports manufacturing operations in smart factories:

Data-Driven Manufacturing Feedback

Closed-loop manufacturing starts with data. Live sensor inputs track what the process is doing as it runs. That data feeds into the control system and triggers adjustments on the spot. The goal is simple: fix problems before they turn into defects.

For example, in plastic injection molding, cavity pressure sensors measure how resin fills each part. If the material begins to flow too quickly due to a drop in viscosity, the system reduces injection pressure on the next cycle. That keeps the part’s dimensions within spec.

Continuous Quality Assurance

Sampling a few units per shift is no longer enough. With shorter lead times and tighter output requirements, quality needs to be checked continuously, not occasionally. Closed-loop systems make that possible by embedding inspection into the production process itself.

Consider a scenario of PCB assembly, where high-resolution cameras inspect every board for solder placement, pad alignment, and bridging as the machine places each component. If the system detects a drift in placement or joint quality, it recalibrates before the next board is assembled.

Role of AI and Machine Learning in Adjustments

AI and machine learning are changing how closed-loop systems respond. Instead of reacting to fixed thresholds, the system learns how the process behaves over time. It begins to understand when, how, and why things deviate from the set standards and adjusts before issues surface.

In automotive assembly, Ford uses AI-enabled cameras called AiTriz and MAIVS. They’re deployed across dozens of stations and catch faults that used to pass undetected.

These cameras detect small deviations in headlight placement or panel gaps that used to be hard to catch. When the system notices a recurring shift on one side of the vehicle, it recalibrates the robot’s movement path immediately. This reduces misalignment issues and helps avoid costly rework further down the line.

Role of IoT in Closed-Loop Manufacturing

IoT is what makes closed-loop manufacturing truly scalable. Without connected sensors, devices, and data systems, feedback stays isolated at the machine level. We’ll now see how they all come together.

Connecting Devices, Sensors, and Cloud Systems

At its core, IoT provides the infrastructure for data flow in closed-loop systems.

Sensors embedded in machines measure process variables like pressure, torque, flow rate, or product dimensions.

These sensors send signals to edge devices or PLCs, which process critical data locally for immediate response. The same data is also transmitted to central systems or cloud platforms for deeper analysis, pattern detection, and cross-site optimization.

Bosch Rexroth’s smart factory network is a great example. It connects hundreds of CNC machines via IoT gateways to a central MES. When a spindle vibration sensor detects imbalance, the edge controller adjusts the spindle speed in real time. Meanwhile, the cloud platform logs the event, compares it against historical data from other machines, and updates the maintenance schedule across the entire fleet.

Real-Time Monitoring in Manufacturing Environments

IoT enables a live, unified view of production conditions. Instead of operators physically checking gauges or reviewing periodic reports, connected sensors feed a constant stream of data into MES, SCADA, or IoT analytics dashboards.

This allows multiple stakeholders like operators, quality engineers, and maintenance teams to monitor the same live information, even from remote locations. More importantly, the system can compare these readings against control limits and trigger corrective actions without delay.

One of the prominent examples is Siemens’ MindSphere platform. It links IoT sensors in electronics assembly lines to cloud analytics. If a reflow oven’s temperature begins to drift outside the target profile, the local controller adjusts heater power instantly, while the deviation is flagged for review. Quality teams in another facility can view the same data, ensuring consistent standards across plants.

Industrial Automation Feedback Control and Alert Systems

Along with collecting and displaying the readings, IoT enables machines to act on those readings automatically. In a closed-loop context, that means the system can both execute corrective actions and send targeted alerts when human intervention is necessary.

For routine variations, the control system responds directly. For more complex or safety-critical issues, the IoT platform escalates alerts to the right personnel, complete with diagnostics and suggested actions.

In General Electric’s Brilliant Factory program, torque sensors on jet engine assembly tools send readings to a central IoT system. If torque falls outside tolerance, the tool recalibrates before the next fastening cycle. If recalibration fails, the IoT system locks the tool and sends an alert to maintenance, preventing the defect from propagating further down the line.

Steps to Implement a Closed-Loop Production Process

Closed-loop manufacturing works when data, controls, and people move in sync, and the steps below help you to implement it:

Step 1: Identify Key Feedback Points in Production

Map the line from raw input to finished unit. Mark the moments where a small change affects quality, speed, or safety. These are the points where sensors and checks matter most.

Practical places to start:

- Material prep and dosing, where mix ratios or temperatures shift

- Forming or machining, where tool condition and force readings change the outcome

- Assembly and fastening, where torque and position must match the set range

- Finishing and packaging, where fill level, seal strength, and label position matter

Step 2: Choose Compatible Hardware and Software Platforms

Pick sensors, controllers, and software that are compatible with each other. Confirm accuracy, speed, and protocol support before you buy.

What to verify:

- Sensor specs match the process range and response time

- PLC or edge device supports required protocols (OPC UA, MQTT, Modbus TCP)

- MES or SCADA can read tags, write setpoints, and store records against work orders

- Cybersecurity basics are in place (network zones, user roles, audit trails)

Step 3: Integrate Data into MES and Quality Control Systems

Shop-floor data should not be siloed. Route readings to MES and quality systems so actions are logged, traced, and linked to orders and batches.

Make integration useful:

- Tie alarms and corrections to the specific job, tool, and station

- Store before and after values for each correction

- Auto-create rework tasks when a rule fails, then close the loop with sign-off

- Use dashboards for shift reviews, not just real-time views

Step 4: Train Staff to Act on Real-Time Data

People make the system reliable. Teach operators how to read signals, when to trust automation, and when to step in.

What to include:

- Short playbooks for common alerts, with clear next steps

- Simulator sessions on a test line, not only slides in a room

- Shadowing for new hires during live runs

- Weekly reviews of a few real events, what happened, and how to respond faster next time

Challenges and Considerations

Closed-loop manufacturing offers major gains, but success depends on navigating a few common roadblocks. These are the areas that most often slow teams down during implementation.

Data Overload and Processing Speed

Sensors can generate thousands of data points per second across machines, lines, or plants. If the system isn’t built to prioritize what’s critical, or if edge processing isn’t used, delays can occur in triggering actions or logging events. This affects both real-time control and long-term analytics.

Legacy System Integration

Many factories still rely on older PLCs, manual stations, or machines that lack connectivity. These assets don’t support direct integration with modern MES or IoT platforms, which creates gaps in the feedback loop. Teams often need protocol converters, retrofitted sensors, or edge devices to bridge this divide.

Change Management and Operational Buy-In

Closed-loop systems shift control from manual checks to automated actions, which can feel unfamiliar or risky to line operators and supervisors. If the team doesn’t trust the alerts or understand what’s being adjusted, they may override the system or revert to old workflows. Adoption requires hands-on training, clear escalation paths, and visible wins to build confidence.

Kladana: Built for Connected Manufacturing

To support closed-loop operations, you need an ERP that connects inventory, production, and quality control in real time.

Kladana helps modern factories sync data from the shop floor to the office. It tracks materials, automates order flows, and gives full visibility across BOMs, work orders, and stock levels.

Whether you’re running a batch job or continuous line, Kladana ensures that every movement is recorded, traceable, and ready for decision-making.

Shift from traditional to closed-loop manufacturing with Kladana

Kladana connects your production, inventory, and quality systems in one platform so you can make faster decisions, reduce delays, and scale your operations with confidence.

FAQs on Closed-Loop Manufacturing

Let’s answer some of the common and technical queries around closed-loop manufacturing:

What is an example of a closed-loop manufacturing system?

A closed-loop system in manufacturing uses real-time data from sensors to automatically control and adjust a process while it’s running. For example, a filling machine that measures liquid level and adjusts valve timing on each bottle is a typical closed-loop setup.

How does a closed-loop system improve production?

It improves accuracy, reduces waste, and minimizes downtime by making instant corrections during the process. This keeps output consistent, even when inputs or conditions change mid-run.

What’s the difference between closed-loop and open-loop manufacturing?

In a closed-loop system, sensors provide real-time feedback to the controller, which adjusts operations automatically. An open-loop system runs on preset parameters with no live feedback or automatic correction.

How does IoT support closed-loop manufacturing?

IoT connects sensors, machines, and software systems so data can move freely and be acted on quickly. It enables remote monitoring, faster control decisions, and better integration between shop floor operations and enterprise systems.

List of Resources

- 3ERP — CNC Machining Parameters: 11 Types, Setup and Adjustment

- Inductive automation — PLC: Programmable Logic Controller

- Business Insider — Ford’s AI cameras are catching hard-to-spot manufacturing errors. It could solve the company’s costly recalls

- Industrial Machinery Digest — Bosch Rexroth’s CNC System MTX with New Hardware

- Engineering Industries eXcellence — Siemens Insights Hub (MindSphere)

- GE Aerospace — A stroke of brilliance: Making factories and facilities smarter