Manufacturing businesses often face lengthy sales cycles, intricate distributor networks, and ongoing after-sales demands. Choosing the right CRM in the manufacturing industry can help you centralize customer data, align sales with production, and make forecasting more accurate.

As CRM platforms evolve from sales tools into business operating systems, they have become indispensable across industries. Fortune Business Insights values the Global CRM software market at $101.41 billion in 2024, projected to reach $112.19 billion in 2025. For manufacturers, this signals a transformation. Customer management is now directly tied to production efficiency and long-term competitiveness.

For manufacturers, this shift marks a clear transformation. Customer engagement is now directly tied to production efficiency and long-term competitiveness.

Choosing the right system begins with understanding the role of CRM in the manufacturing industry, exploring the best CRM solutions for manufacturing, and comparing leading CRM software for the industry based on features, scalability, and integration capabilities. This guide helps you identify what matters most before you make an investment.

- What Is CRM in The Manufacturing Industry?

- Benefits of CRM in Manufacturing

- Key Features to Look for in Manufacturing CRM

- Challenges of CRM Adoption in Manufacturing

- Best CRM Software for Manufacturing Companies

- How to Choose the Right CRM for Manufacturing

- CRM vs ERP in Manufacturing

- Kladana Integration Solution Focused

- To Sum Up

- Frequently Asked Questions on CRM in the Manufacturing Industry

- List of Resources

What Is CRM in The Manufacturing Industry?

A CRM in the manufacturing industry is a system built to manage and strengthen relationships with customers, distributors, and partners across the production and sales cycle.

Unlike generic CRMs that focus only on lead tracking, manufacturing CRMs connect customer data with production planning, order management, and after-sales support to ensure that every department operates from a unified source of information.

Clarifying CRM vs General Software Confusion

In manufacturing, the word CRM is often used loosely. Many tools described as a CRM for warehouses or a CRM for production are actually broader operational systems, such as ERPs or order management software. The key is to understand what software does rather than how it’s labeled.

| Term Used | What It Usually Refers to | Core Focus in Manufacturing Context | Examples |

| CRM | Software for managing customer and distributor relationships, leads, and service data | Sales pipeline tracking, communication history, after-sales, and warranty management | Zoho CRM, Hubspot, Salesforce |

| ERP | Integrated platform for managing production, inventory, procurement, and finance | Shop floor control, material planning, costing, and accounting | Kladana, SAP, Business One, etc |

| CRM for warehousing / production | Often, general management software or ERP modules are marketed as CRM | Operational coordination, order processing, and internal task tracking | Odoo, Marg ERP, etc |

Why Manufacturers Need CRM Beyond Sales

The use of CRM in the manufacturing industry goes far beyond sales management. It brings visibility across departments, connects forecasting with production planning, and simplifies distributor communication.

With all customer and order data in one place, you can identify repeat patterns, respond faster to service issues, and make more accurate production decisions.

Recent data from HG Insights shows that global spending on CRM solutions is expected to reach $53 billion within the next 12 months.

This reflects how businesses are now treating CRM systems as part of their core operations, helping manufacturers coordinate sales, service, and production in one centralized location, rather than relying on disconnected tools.

Benefits of CRM in Manufacturing

A CRM in the manufacturing Industry gives you visibility across sales, production, and after-sales operations. It helps you connect departments that often work in silos, bringing efficiency and predictability to your customer management process.

1. Centralized Customer & Distributor Data

All customer and distributor information stays in one place, accessible to every team that needs it. When sales teams update customer requirements or production schedules change, everyone from operations to service works with the same data. This ensures transparency, reduces communication gaps, and facilitates smoother handoffs between departments.

2. Better Demand Forecasting & Sales Pipeline

By combining historical sales data with live inquiries, the CRM software for the manufacturing industry helps you to forecast demand more accurately. You can identify top-performing products, anticipate order spikes, and align your production schedules with actual sales opportunities rather than assumptions.

IDC’s 2025 research on the digital customer journey for manufacturers found that companies integrating customer and operational data expect a 23.8% increase in online sales within two years. This shows that connected CRM systems do more than track deals. They directly influence revenue by aligning production with demand.

3. After-Sales Service & Warranty Tracking

Manufacturing relationships don’t end with product delivery. A CRM helps you track service requests, complaints, and warranty claims, maintaining a complete record of customer interactions. This enables faster service response times and builds trust with your distributor and end customers.

4. Integrations with ERP & Production Systems

When your CRM integrates with ERP or production systems, you gain a single, unified view of your operations, from quote to dispatch. Sales data automatically syncs with inventory and production modules, reducing manual entries and errors while improving coordination between departments.

Key Features to Look for in Manufacturing CRM

When comparing different CRM software solutions for the manufacturing industry, focus on how each platform supports your sales, production, and customer service workflows. The right system should simplify coordination across teams, not just manage contacts or leads.

1. Lead & Pipeline Management

A strong CRM in the manufacturing industry enables you to capture leads from multiple sources, including trade shows, distributor networks, and online inquiries, and track their progress through each stage of the sales process.

You can assign opportunities to your sales representative, set reminders for follow-ups, and forecast potential revenue with greater accuracy.

2. Integration with Inventory and ERP Systems

Your CRM should work in sync with your inventory and ERP platforms to avoid duplicate data entry and manual updates.

Integration ensures that when a deal is confirmed, the system automatically checks stock levels, triggers production orders, or updates dispatch schedules. This is critical for aligning sales commitments with production capacity.

📘 Recommended Read: ERP vs CRM. Which Solution is Best for Streamlining Your Business?

3. Mobile Access for Sales Representative

Manufacturing sales teams are often on the move, such as meeting clients, visiting distributors, or attending industry trade shows and exhibitions.

A mobile-friendly CRM for manufacturing companies allows sales representatives to access customer data, update deal status, or check inventory availability directly from their mobile devices. This keeps your pipeline up to date in real-time.

4. Reporting & Analytics

Data-driven insights are essential for long-term planning. Look for a manufacturing CRM solution that offers dashboards and detailed reports on customer activity, order history, and regional performance. These analytics help you identify top-performing territories, understand seasonal trends, and make smarter production and sales decisions.

Challenges of CRM Adoption in Manufacturing

Even the best CRM software for the manufacturing industry can fall short if it’s not implemented correctly. Many manufacturers face hurdles that are less about technology and more about people, processes, and alignment. Recognizing these challenges early helps you plan a smoother adoption.

1. Staff Training and Cultural Barriers

Introducing a CRM often requires a shift in how teams record data and communicate. Employees accustomed to manual tracking or spreadsheets may resist change, perceiving the system as an additional workload.

To ensure success, you’ll need a structured onboarding process, regular training sessions, and transparent internal communication on how the CRM benefits each department, from sales to service.

2. Data Migration Issues

Migrating customer and distributor data from legacy systems to a new CRM in the manufacturing industry can be a complex process. Missing fields, duplicate records, or inconsistent formats can lead to data loss. It’s essential to clean and standardize your data before migration and run pilot tests to validate accuracy before going live.

3. Aligning CRM with Production Workflows

A CRM that doesn’t reflect your actual production and order processes can cause confusion instead of clarity.

For example, if your sales cycle doesn’t sync with production lead times or order approvals, teams may end up working with outdated information.

Choose a CRM that can adapt to your workflows or integrate easily with ERP tools to maintain alignment across operations.

📗 Recommended Read: CRM for E‑Commerce: What to Look For at Every Stage of Growth

Best CRM Software for Manufacturing Companies

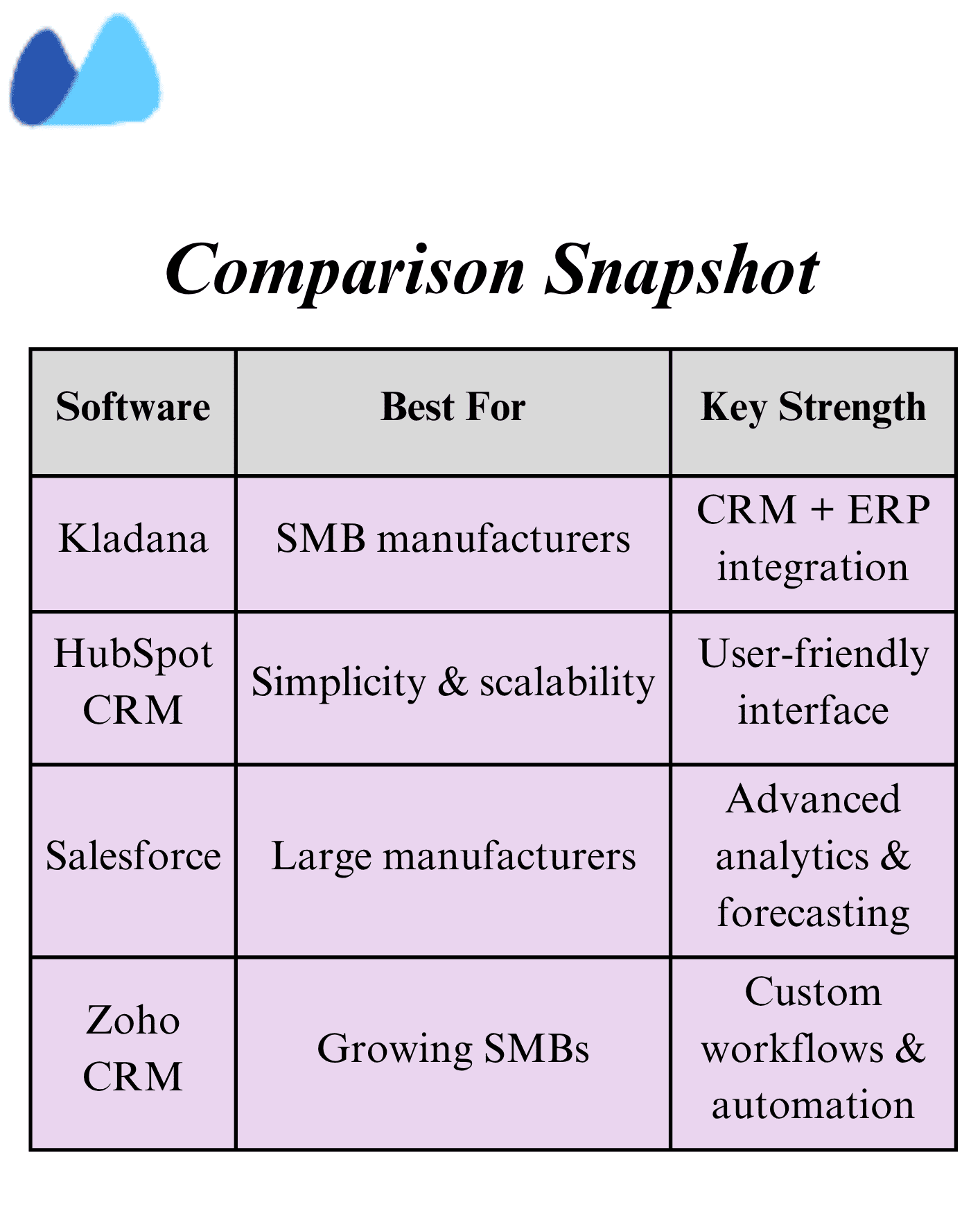

With dozens of options available, choosing the best CRM for the manufacturing Industry depends on your company’s size, complexity, and integration needs. Below is a comparison of some leading platforms trusted by manufacturers for managing sales, customer data, and after-sales service.

1. Zoho CRM

Zoho CRM is recognized for its flexibility and affordability, making it an ideal fit for small to mid-sized manufacturers. It supports lead tracking, workflow automation, and integration with Zoho inventory or books for order and finance management.

- Best for: SMB manufacturers with growing sales teams

- Key Strengths: Custom workflows, email automation, regional sales tracking

- Pricing: Starts around: $8–2400 per user/month

2. Hubspot CRM

HubSpot offers an intuitive interface and modular setup. Its free version covers basic contact management, while paid plans add analytics, automation, and forecasting. Integration with HubSpot Operations Hub allows limited synchronization with inventory systems.

- Best for: Companies looking for a simple, scalable CRM

- Key strengths: Ease of use, strong reporting tools, cloud accessibility

- Pricing: Free core CRM, paid tiers start from $30 per user/month

3. Salesforce Manufacturing Cloud

Salesforce is among the most powerful CRM solutions for the manufacturing sector. Its manufacturing cloud provides real-time sales agreements, demand forecasts, and production visibility. However, its advanced features come with higher setup and customization costs.

- Best for: Enterprise with dedicated IT support and multi-region operations

- Key strengths: Deep customization, analytics, and AI-powered forecasting

- Pricing: Custom quotes, generally higher-end plans

4. Kladana

Unlike generic CRMs, Kladana offers an integrated CRM + ERP approach tailored for SMB manufacturers, along with lead and sales tracking. It connects directly with inventory production and order management. It is ideal for companies needing complete visibility from lead to dispatch.

- Best for: Small and medium manufacturers wanting CRM and ERP in one system

- Key strengths: Real-time order sync, after-sales tracking, and inventory integration

- Pricing: Flexible monthly plans, free trial available

🚀 CRM that understands manufacturers. Start with Kladana free

Purpose-built for production-first teams that need simplicity, not spreadsheets

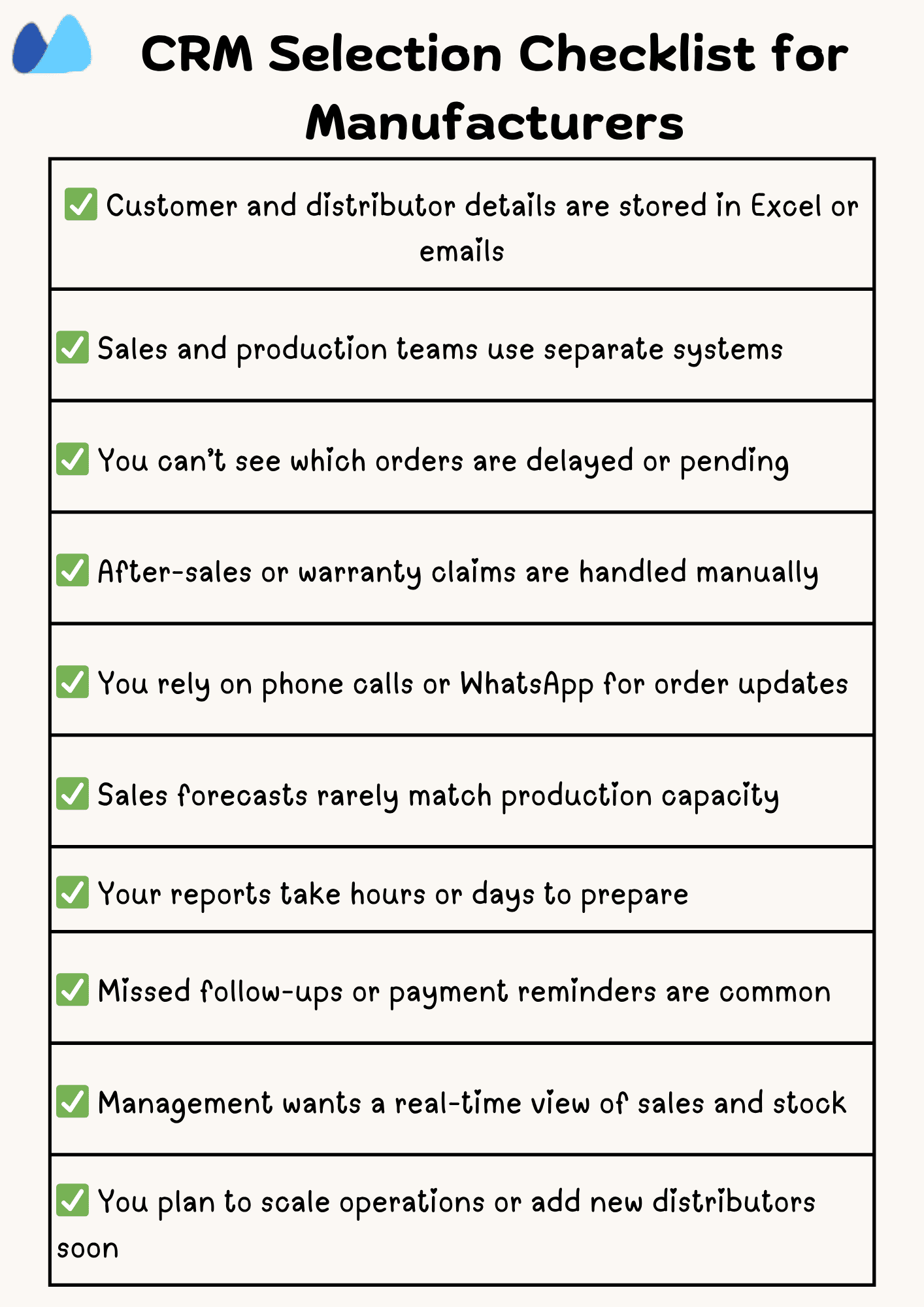

How to Choose the Right CRM for Manufacturing

Selecting the best CRM for a manufacturing business depends on your company’s structure, sales process, and operational complexity. The right system should simplify your workflows, not add extra steps. Here’s what you should consider before deciding.

1. Company Size and Budget

Small and mid-sized manufacturers often benefit from CRMs that combine core sales management with inventory or ERP integration at an affordable cost. Larger organisations may need more customization and advanced automation. Define your budget early and consider additional fees for setup, training, or API integrations.

2. Integration Needs

A CRM for manufacturing companies should integrate smoothly with your existing software stack. Whether it’s ERP, inventory, or accounts, look for systems that can sync data in real-time between departments, ensuring every team works from the same information. Integration eliminates duplicate work and reduces errors in order management and forecasting.

3. Future Scalability

Your CRM should support business growth over time as you expand product lines or add new sales channels. You’ll need the system to scale with you. Select software that enables flexible customization, additional user seats, and advanced modules without necessitating a complete migration later.

CRM vs ERP in Manufacturing

Manufacturers often rely on both CRM and ERP systems to manage their operations. While both store and organize business data, their functions differ significantly. A CRM in the manufacturing industry focuses on relationships and sales visibility. An ERP system manages your production, procurement, and financial activities. Understanding how the two complement each other helps you make informed investment decisions.

Deloitte’s 2025 smart-manufacturing survey notes that 92% of manufacturers believe digital and smart manufacturing will define competitiveness in the next three years.

So, integrating CRM and ERP supports that goal by linking customer demand with operational capacity, ensuring every order moves seamlessly from quote to delivery.

| Aspect | CRM | ERP |

| Primary purpose | Builds and manages customer, distributor, and service relationships | Plans and controls manufacturing, inventory, and accounting operations |

| Core data managed | Customer profiles, inquiries, leads, quotations, and after-sales activities | Raw materials, BOMs, production orders, purchase and sales invoices |

| Main users | Sales, marketing, customer service, and distributor managers | Production, warehouse, procurement, and finance teams |

| Typical use case | Track leads, follow up with distributors, forecast demand, and manage warranties | Plan production schedules, manage stock levels, process vendor POs, and generate financial reports |

| Output focus | Higher sales visibility, improved forecasting, and better customer experience | Efficient production flow, accurate costing, and real-time stock control |

| Integration advantage | Connects with ERP to share order data and customer information automatically | Receives confirmed orders and forecasts from CRM to trigger production and procurement activities |

When to Use Each

Suppose your primary goal is to organize leads, strengthen distributor relationships, and gain a 360-degree view of customer interactions.

In that case, a CRM software specifically designed for the manufacturing industry is ideal for your needs. It helps your sales and service teams respond more quickly, close deals sooner, and enhance customer retention.

However, if your focus is on operational control, managing stock, purchase orders, or manufacturing costs, then an ERP system provides deeper visibility into day-to-day processes.

For long-term growth, integrating CRM and ERP systems in manufacturing provides the best of both worlds. It aligns sales demand with production capacity, ensuring every confirmed order moves smoothly from quotation to dispatch without manual coordination.

Kladana Integration Solution Focused

When evaluating a CRM in the manufacturing industry, a key factor is how well it connects front-end sales and service with back-end production and inventory management. Kladana illustrates what this integration looks like in practice for a CRM and ERP hybrid designed for small to medium-sized manufacturers.

1. Sales Pipeline Tracking

Kladana’s CRM module captures leads, quotations, and orders in a single dashboard. Each deal moves through defined stages, with built-in reminders and task assignments. When a sales order is confirmed, it automatically checks stock availability and production schedules to prevent over-commitment.

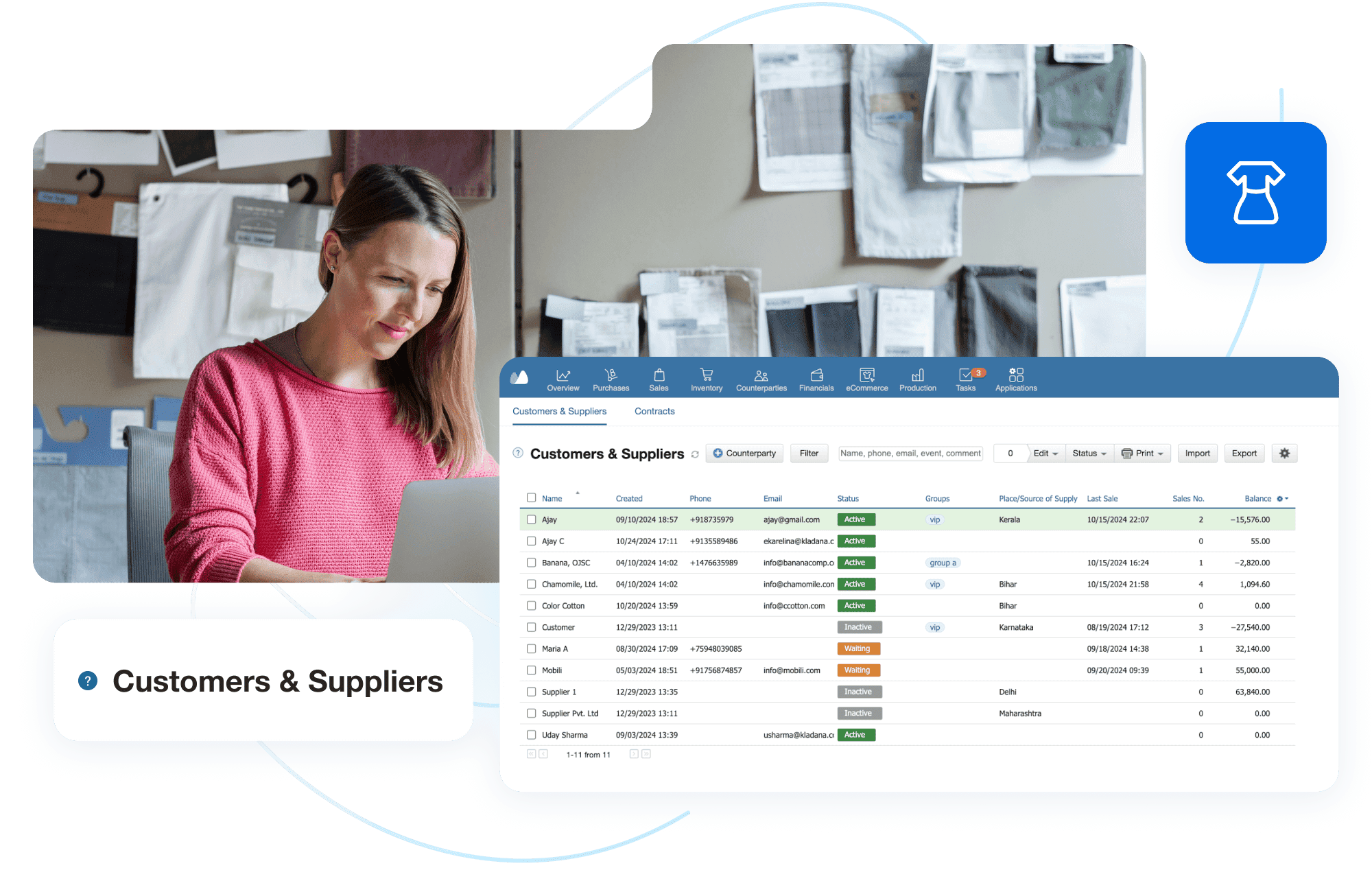

2. Customer Management

All customers, distributors, and suppliers are maintained in one system, which includes complete transaction histories, unpaid invoices, discounts, and communication records. Each client profile displays contact details, recent activities, and comments, so every team member has the necessary context before engaging.

3. ERP Integration

Unlike standalone CRMs, Kladana links sales directly with production, inventory, and purchasing modules. Confirmed sales orders can trigger production or procurement workflows, ensuring real-time coordination between departments and eliminating duplicate entries.

4. After-Sales Service & Automation

Tasks, reminders, and workflows help the team follow up on deliveries, payments, and warranty issues. Custom document templates such as quotes, invoices, or work orders. It makes it easy to standardize communication and reduce manual effort. Internal notes and role-based access keep collaboration structured and secure.

Together, these capabilities demonstrate how an integrated CRM and ERP platform can unify customer relationships with operational control, helping manufacturers transition from fragmented tools to a single, connected system.

To Sum Up

As manufacturing becomes more connected and customer expectations rise, CRM systems have evolved from simple sales tools into the backbone of coordination between sales, service, and production.

When your teams share the same information, you reduce errors, improve planning, and respond faster to market changes.

A connected CRM helps you turn every interaction into insight and every order into opportunity. It provides your business with the consistency and speed that modern manufacturing demands.

💡 From leads to after-sales — manage it all in Kladana

Track customers, orders, and production in one connected dashboard

Frequently Asked Questions on CRM in the Manufacturing Industry

What is CRM in the manufacturing industry?

CRM in manufacturing refers to systems that help manage and analyze interactions with customers, distributors, and service partners, specifically tailored to the longer cycles, complex quoting, and after-sales support inherent in the manufacturing industry.

Why do manufacturers need CRM software?

It is becaue manufacturers have multi-stage sales pipelines, distributor networks, and after-sales obligations. A CRM helps centralize data, reduce errors, improve forecasting, and strengthen customer relationships.

How is CRM different from ERP for manufacturers?

CRM handles front-end functions, such as customer interactions, sales, and service. At the same time, ERP handles back-end operations like inventory, production, and finance — the two work best when integrated.

What features should a manufacturing CRM include?

Key features include:

- Lead & pipeline management

- Integration with ERP/inventory

- Mobile access

- Robust reporting

Which is the best CRM for small manufacturing companies?

The best depends on your workflows, budget, and integration needs. For small manufacturers, look for CRMs that are flexible, easy to adopt, and integrate well with your current systems.

Can CRM improve demand forecasting for manufacturers?

Yes. By aggregating historical orders, sales pipeline data, and real-time leads. A good CRM helps align production and procurement decisions more accurately.

How much does CRM software for manufacturing cost?

The cost depends on your subscription fees per user, as well as setup/integration costs. For manufacturing-specific or integrated CRMs, costs tend to be higher due to the complexity involved.

How do CRMs integrate with production or inventory systems?

It integrates through APIs, middleware, or native connectors. Integration enables automated data flow by eliminating duplicate entry and reducing errors.

Is cloud CRM safe for manufacturing data?

Yes. Most reputable CRMs utilize encryption, role-based access controls, regular backups, and secure data centers to ensure the protection of sensitive data. Always check vendor compliance, data residency, and security certifications.

What are the adoption challenges manufacturers face when deploying CRM?

Common challenges include staff resistance to change, inconsistent data formats during migration, aligning CRM workflows with production schedules, and providing training across departments.

List of Resources

- Fortune Business Insights: Customer Relationship Management Market Growth

- HG Insights: CRM Market Report

- Deloitte: 2025 Manufacturing Industry Outlook

- IDC: Digital Customer Journey report for Manufacturers

Read‑alikes

How to Estimate Manufacturing Costs: Methods, Tools, and Best Practices

Production Scheduling in Manufacturing: Methods, Tools, and Best Practices

Revolutionizing Manufacturing: The Impact of Automation in Manufacturing on Production Processes

Manufacturing Execution System (MES): The Smart Transformation Your Factory Needs