Tracking maintenance work every day becomes easier when you use a structured daily maintenance report format in Excel. Instead of relying on handwritten notes or unorganized files, you can log every inspection, repair, and downtime in one place using an Excel maintenance tracker. These read-to-use templates help your team record equipment details, parts used, and preventive tasks clearly for each shift.

In this guide, you’ll find free maintenance log sheet Excel formats you can download and tailor to your plant, facility, or workshop. You’ll also learn how to customize your equipment maintenance report template with formulas, dropdowns, and summaries to standardize your reporting process and improve overall efficiency.

- What Is a Daily Maintenance Report?

- Why Use Excel For Daily Maintenance Reports?

- Core Fields In The Excel Format

- Types of Daily Maintenance Reports

- Comparison Table: Types Of Daily Maintenance Reports

- Build It In Excel (Step-by-Step)

- Excel Templates for Daily Maintenance Reports

- Best Practices For Using Excel Maintenance Reports

- To Sum Up

- Frequently Asked Questions on Daily Maintenance Report

What Is a Daily Maintenance Report?

A daily maintenance report is the record you use to capture every maintenance task completed during a shift. It gives you a clear view of what work was done, which machines were serviced, and how much downtime occurred. When you use a daily maintenance report format in Excel, you can store all this information in a structured way that’s easy to review, share, or analyze later.

In maintenance operations, this report is one of your most reliable tools for preventive care and accountability. It helps you verify that technicians have followed the preventive checklist. You can store all this information in a structured way that’s easy to review, share, or analyze later.

A daily maintenance report also connects short-term activities to long-term asset management. It feeds data into weekly or monthly summaries, making it easier to measure performance metrics such as Mean Time to Repair or downtime trends. Compared to broader reports, this daily version focuses on Immediate action, such as what was fixed today, which equipment needs follow-up, and what preventive tasks are pending.

Why Use Excel For Daily Maintenance Reports?

Using a daily maintenance report format in Excel makes tracking easier, faster, and more accurate. Here’s why most maintenance teams rely on it:

1. Simple and low-cost solution: Excel is already available in most workplaces, so you don’t need new software or extra training. You can start using it immediately to record daily inspections, repairs, and downtime.

2. Easy to customize: You can edit your maintenance log sheet Excel to match your setup, such as machines, facilities, or fleet vehicles. Add or remove columns for work orders, parts used, shift details, or remarks, giving you complete control over your reporting process.

3. Build for trend tracking: With formulas like COUNTIF, SUMIFS, and Excel charts, your Excel maintenance tracker can show performance trends such as total downtime, number of completed tasks, and preventive maintenance completion rate.

4. Integrates with other systems: Excel seamlessly integrates with other digital systems like CMMS or ERP. You can easily import or export your equipment maintenance report template, keeping your maintenance data in sync across teams.

5. Supports preventive planning: When linked with your preventive maintenance checklist Excel, the daily sheet helps ensure recurring inspections and safety checks are always completed on schedule.

Core Fields In The Excel Format

When you build your daily maintenance report format in Excel, it’s important to include the right fields. Each section of the sheet captures essential information to help you analyze work performance, downtime, and preventive compliance.

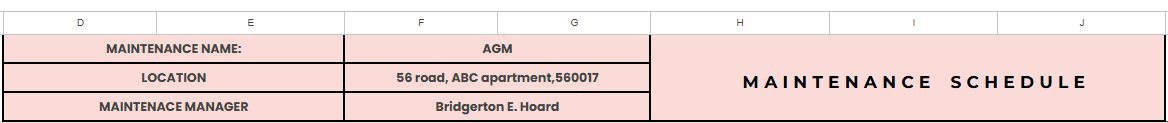

1. Header

Start your sheet with clear identifiers so that every report is easy to trace. You should include:

- Site or production line name

- Date and shift details

- Equipment or machine ID

- Supervisor and technicians’ names

This makes it easier to track who performed which task and when

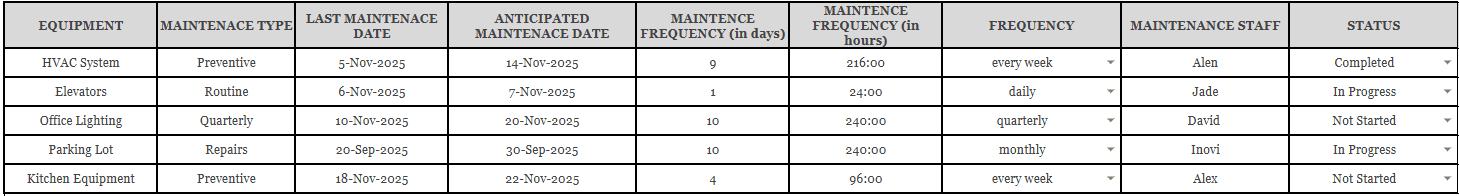

2. Work Log

This is the main section of your maintenance log sheet Excel.

Here you record:

- Work Order number

- Type of maintenance (routine, preventive, or corrective)

- Task performed (inspection, lubrication, replacement, calibration, etc.)

- Labor hours and spare parts used

- Task status (Completed or Pending)

Your Excel maintenance tracker can automatically calculate total labor time or highlight overdue work using conditional formatting.

3. Downtime

In this section, you track interruptions and their causes. Include:

- Machine or asset name

- Downtime start and end time

- Cause code or reason (mechanical, electrical, operator, etc.)

- Total duration (use the Excel formula = TEXT (end-start, (h): mm))

➡️ This helps you measure MMTR and identify recurring breakdowns over time.

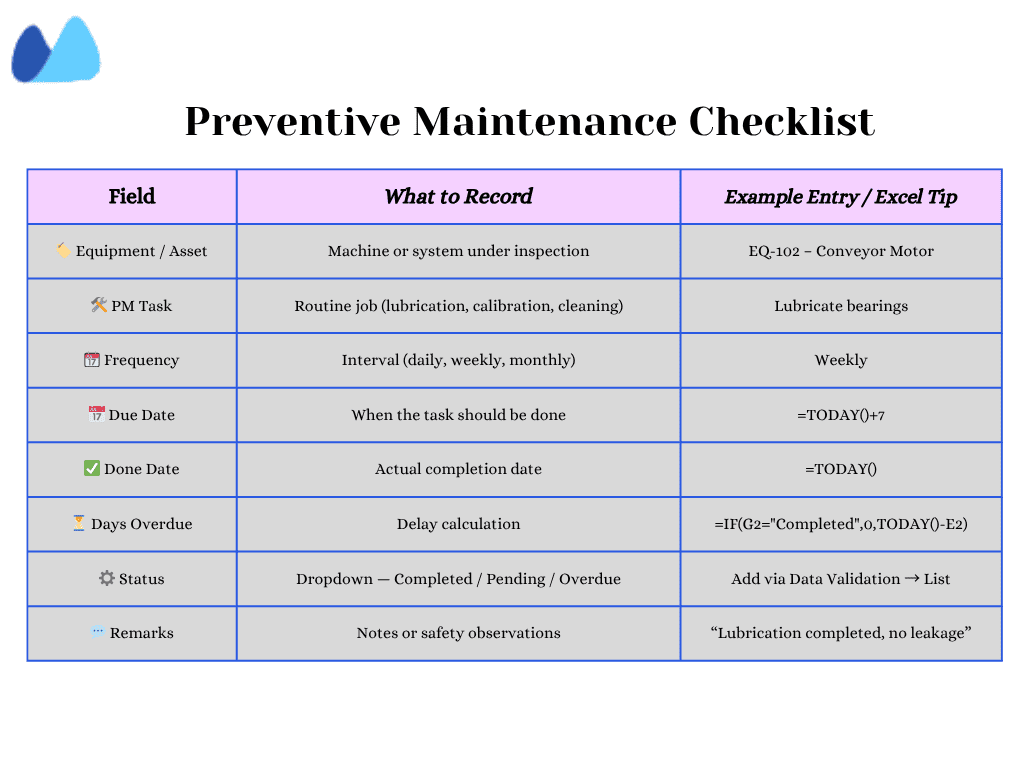

4. PM & Safety Checks

This part connects your daily log to the preventive maintenance checklist Excel file.

You can list:

- Inspection or lubrication tasks scheduled for the day

- Safety permit or checklist references

- Pass/fail column for each task

- Remarks for missed or failed checks

➡️ Adding drop-downs for Pass/Fail and color-coding incomplete tasks gives you a clear visual summary of preventive work.

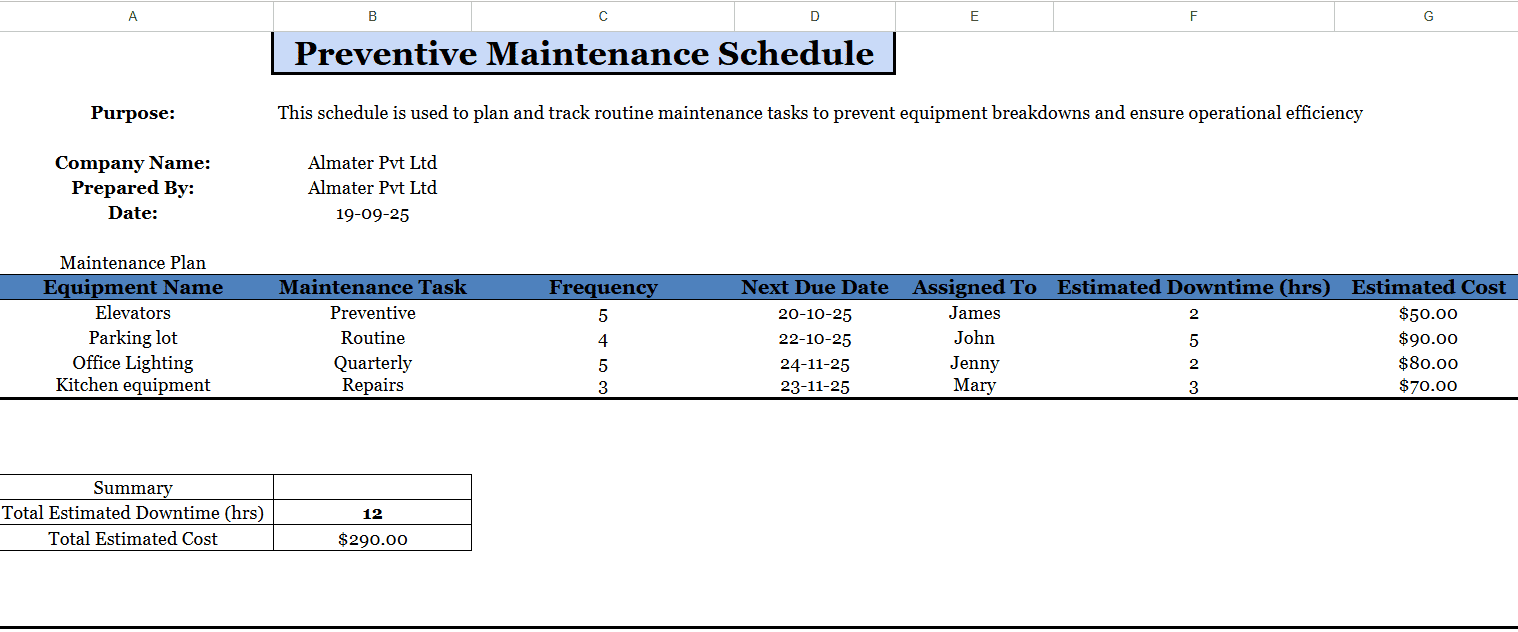

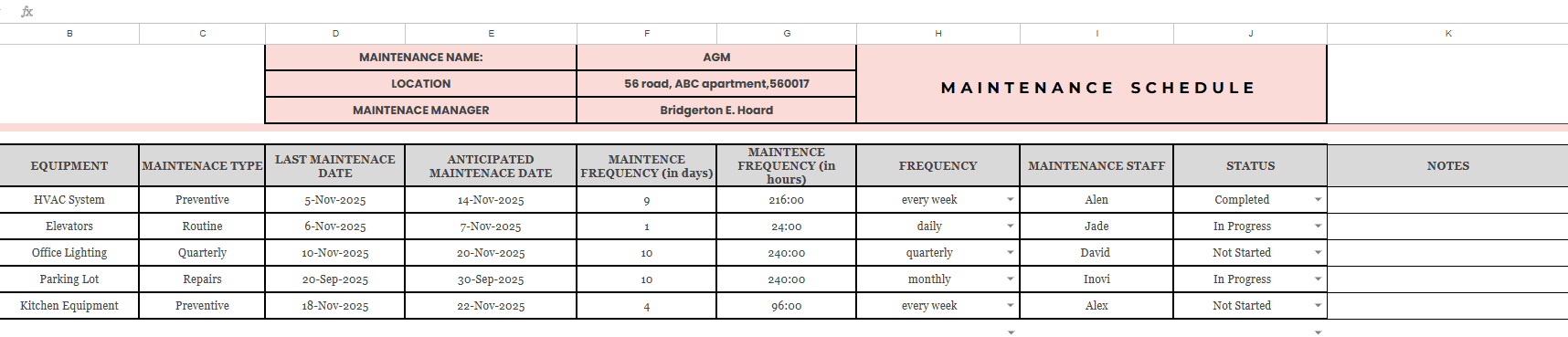

Summary

At the end of the sheet, add an automatic summary area. Your equipment maintenance report template can display:

- Total number of completed work orders

- Pending jobs or backlog

- Total downtime minutes

- Average repair time (MTTR)

- Parts used or cost summary

➡️ This summary gives your team and management an instant snapshot of daily performance without manual calculation

Types of Daily Maintenance Reports

Every workplace handles maintenance differently, so your daily maintenance report format in Excel should match the type of work you manage. Here are the most common variations you can create or download:

1. Equipment Maintenance Report Template

Use this when you track individual machines or assets. Each sheet lists equipment ID, issues found, parts replaced, and repair time. Ideal for manufacturing and workshop environments.

2. Plant Maintenance Report Format

Designed for large-scale operations with multiple production lines. It summarizes total downtime, shift-wise performance, and preventive tasks in every area of the plant.

3. Preventive Maintenance Checklist Excel

Focused on recurring tasks such as lubrication, calibration, or safety inspection. It helps you confirm that every scheduled job has been completed and signed off.

4. Breakdown or Corrective Maintenance Report

Used when an unplanned failure occurs. You log downtime duration, cause code, and actions taken to restore equipment, then analyze patterns later through your Excel maintenance tracker.

5. Facility or Fleet Maintenance Log Sheet Excel

Suited for property managers or transport supervisors. You can record repairs, servicing dates, and condition updates for buildings, utilities, or vehicles.

Comparison Table: Types Of Daily Maintenance Reports

| Report Type | Tracks | Best For |

| Equipment Maintenance Report | Machine Issues, parts used, repair time | Workshops or manufacturing lines |

| Plant Maintenance report | Downtime and shift-wise performance | Large factories or multi-line plants |

| Preventive Maintenance Checklist | Scheduled inspections and lubrication | Routine maintenance tracking |

| Breakdown report | Unplanned failure and causes | Analyzing recurring breakdowns |

| Facility/Fleet Log Sheet | Repairs and servicing details | Buildings, utilities, or vehicles |

Build It In Excel (Step-by-Step)

You can easily create your own daily maintenance report format in Excel with formulas, dropdowns, and automatic summaries. Follow these steps to build a clean and functional tracker:

1. Create The Basic Layout

- Open a new sheet and set up sections for Header, Work Log, Downtime, PM & Safety Checks, and Summary

- Use bold headings and borders to make each section easy to identify

- Freeze the top row so your headers stay visible while scrolling

📋 Tip: Keep the column width uniform for quick data entry

2. Add-Drop-Down Lists Using Data Validation

- Use Data > Data Validation to create dropdowns for fields like status completed, Maintenance Type, or Cause Code

- This keeps your maintenance log sheet Excel clean and error-free

3. Insert Formulas For Calculations

- Use = TEXT (end-start, “[h]: mm”) to calculate or downtime duration

- Apply COUNTIF and SUMIFS to total completed jobs, pending tasks, and downtime hours

- Display these KPIs in your Excel maintenance tracker summary area

4. Apply conditional formatting

- Highlight overdue or failed checks in red, and completed work in green

- Use icon sets or color scales to make your equipment maintenance report template visually clear

💡Tip: Add rules that automatically flag downtime above a specific limit.

5. Set Print Area and PDF Export

- Go to Page Layout > Print Area > Set Print Area to define what prints

- Use File > Export > Create PDF/XPS for one-click sharing after each shift

- This makes your daily maintenance report format in Excel easy to circulate among teams or attach to emails

6. Protect Formula Cells

- Lock calculation fields while keeping entry fields editable

- Go to Review > Protect Sheet and enable only necessary actions

- It prevents accidental formula deletion and keeps your tracker consistent across shifts

Excel Templates for Daily Maintenance Reports

To save time, you can download ready-to-use templates instead of building everything from scratch. The easy daily maintenance report format in Excel below is fully editable and designed for real-world use.

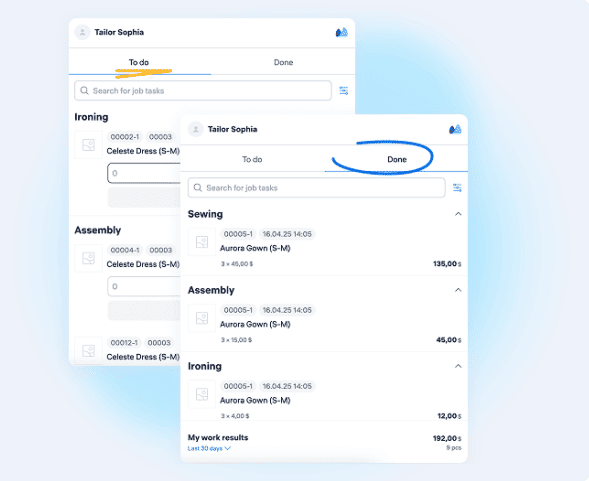

V1 — Simple Daily Maintenance Log Sheet Excel

- Best for small teams or single-equipment tracking

- Includes fields for task, technician, start-end-time, and status

- Auto-calculates total labor hours using Excel formulas

- Works well for daily shift entries or facility maintenance updates

📍Use it when: You want a basic structure that records completed and pending work with minimal setup.

V2 — Advanced Excel Maintenance Tracker

- Adds sections for the preventive maintenance checklist, Excel, and parts ledger

- Includes formulas for downtime, MTTR, and PM compliance

- Built-in, color-coded KPIs highlight overdue maintenance teams

- Ideal for manufacturing plants or multi-line maintenance teams

📍Use it when: You need detailed tracking, preventive logs, and automatic summaries for weekly reviews.

Best Practices For Using Excel Maintenance Reports

Once you start using the daily maintenance report format in Excel, following a few best practices can make it more reliable and easier to manage across shifts.

1. Standardize your codes and naming conventions

Use consistent asset IDs, cause codes, and status labels in your Excel maintenance log sheet. It helps you avoid confusion when analyzing reports or creating summaries.

2. Train your team for consistency

Ensure every technician knows how to update the sheet correctly. Even simple data-entry mistakes can affect totals and KPIs in your Excel maintenance tracker.

3. Attach supporting documents.

Link inspection photos, work permits, or service records to your equipment maintenance report template. This improves traceability and helps with safety audits.

4. Use summary dashboards for quick insights.

Create a top sheet showing total downtime, backlog, and preventive completion rate. It saves time when reviewing your plant maintenance report format with managers.

5. Review and back up reports regularly

Keep a digital archive of your daily files by week or month. This helps you monitor long-term trends and keep your preventive plan up to date.

6. Keep your preventive maintenance checklist Excel updated

As your assets age or equipment changes, refresh the checklist items to reflect new schedules, parts, or inspection standards.

📖 Recommended Reads

1. Free Excel Inventory Management Template With a Full Guide — Learn how to track spare parts and stock levels using a ready-to-edit Excel file

2. 4 Free Purchase Order Templates with a Step-By-Step Guide — Create and manage part orders directly from Excel to streamline your maintenance workflow

💡Go From Repairs to Results — Download Your Free Excel DMR Tracker

Simplify daily logs and prevent missed tasks with one Excel Sheet

To Sum Up

Using a structured daily maintenance report format in Excel helps you stay organized, reduce downtime, and maintain full visibility of your operations. Instead of scattered notes or incomplete entries, you get a single, consistent record that shows what work was done, which equipment was serviced, and how much time was spent.

With formulas, dropdowns, and summaries, your Excel maintenance tracker becomes more than a log. It’s a tool for continuous improvement. Whether you manage machines, facilities, or fleets, the same format keeps your maintenance log sheet Excel accurate and easy to review.

Once you standardize your reporting, you’ll notice better preventive scheduling, faster analysis, and smoother shift handovers every single day.

Frequently Asked Questions on Daily Maintenance Report

What must a daily maintenance report include?

Your daily maintenance report format in Excel should have fields for date, shift, asset name, maintenance type, task description, downtime, technician name, and status. A summary of total jobs and downtime completes it.

How do I calculate downtime automatically in Excel?

Use the formula = TEXT (EndTime − StartTime, “[h]: mm”) to calculate duration in hours and minutes. You can also use SUMIFS to calculate total downtime across all assets in your Excel maintenance tracker.

Can I track PM completion vs plan daily?

Yes. Add a preventive maintenance checklist Excel with a “Scheduled vs Done” column. You can use COUNTIFS to calculate your daily or weekly completion rate.

How do I summarize by asset, line, or shift?

Insert a PivotTable to group your data by machine name, line, or shift. It helps you see which areas have the most downtime or pending work in your Excel maintenance log sheet.

What’s the best way to log parts used and cost?

Add a “Parts Used” column with unit price and use=Quantity x Rate to auto-calculate cost. You can then total it at the bottom of your equipment maintenance report template.

How do I color-flag overdue or failed tasks?

Use conditional formatting > New rule > Text contains and assigns colors red for overdue, orange for pending, green for completed. It gives your maintenance report format in Excel a quick visual status check.

Can I import Work Order (WO) IDs from another sheet or system?

Yes. Use the VL00KUP or XL00KUP function to pull WO numbers and task details from your master list or CMMS export file directly into your Excel report.

How do I export to PDF with proper page breaks?

Go to Page Layout > Breaks > Insert Page Break before each shift section, then use File> Export> Create PDF/XPS. This keeps your pages clean when printing or sharing reports.

How do I adapt it for facilities vs production equipment?

For facilities, rename asset columns as “Area or System,” and for production, keep machine IDs and cause codes. The same plant maintenance report format can be reused with minor edits.

How do I turn daily logs into weekly or monthly KPIs?

Use formulas like AVERAGEIFS and SUMIFS to pull totals from multiple daily files. You can then track downtime, backlog, and PM compliance trends in a separate KPI dashboard.

Read‑alikes

4 Free Purchase Order Templates with a Step‑By‑Step Guide: Excel, Word, and Google Sheets Format

Invoice Templates for Excel: Free Downloads, Formats & When to Use Them

Free Labour Contractor Bill Format in Excel: Templates and How to Create Yours

Fixed Assets Register Format in Excel: Free Templates & Complete Guide