Daily production tracking helps factories avoid delays, reduce waste, and meet their goals. But without a fixed format, this data often gets lost or misunderstood. A daily production report is a simple tool that solves this problem. It collects key details from the shop floor — what was made, how much, and what went wrong — into one clear document.

Many small manufacturers still use notebooks or scattered spreadsheets. This slows down shift handovers and makes audits hard. A good production report template helps teams follow the same format every day. It also shows gaps between the production plan and the actual output.

In this article, you’ll find a free Excel daily production report template, ready to use. It works for shift‑wise, machine‑wise, or plan vs. actual reporting. You’ll also learn how to fill it in and use it to improve your workflow—manually or with tools like ERP.

- What Is a Daily Production Report?

- Why Use a Standardized Production Report Template?

- What Should Be Included in a Daily Production Report?

- Downloadable Daily Production Report Templates (Free)

- How to Use These Templates in Your Manufacturing Workflow

- Manual vs. Automated Production Reporting

- Final Thoughts: Start Simple, Scale Smart

- FAQs on Production Report Template

What Is a Daily Production Report?

A daily production report is a document that records what happens on the shop floor during a work shift or a full day. It includes data about what was produced, by whom, on which machine, and how many units were planned versus how many were actually made. It also notes if there were any issues — like machine breakdowns, defects, or delays.

This report helps factories stay organized. It brings structure to the daily routine and makes it easier to track performance and solve problems quickly.

Who Uses It

The main users are floor supervisors, production heads, and plant managers. Floor supervisors fill out the reports during or after each shift. Production heads review them to compare different shifts or machines. Plant managers use the data to prepare reports for management or clients. In small teams, even the business owner might fill out or check the daily production sheet.

How It Helps

A manufacturing production report shows the difference between the plan and the actual output. This makes it easier to spot if the team is falling behind. It also helps detect bottlenecks — like a slow machine or frequent changeovers.

These reports support daily team updates. Managers can look at yesterday’s numbers, see what went wrong, and adjust the plan for today. Teams that use reports regularly tend to solve problems faster and waste less time and material.

Over time, collecting this data every day builds a clear history. This helps in monthly planning, costing, and forecasting. That’s why a clear production report template is important — even if you’re just starting with Excel or paper‑based tracking.

Why Use a Standardized Production Report Template?

A standardized production report template helps make daily reporting easier, faster, and more accurate. When all team members follow the same format, it becomes simpler to collect, compare, and understand production data.

Reduces Manual Errors

Without a fixed format, team members may forget to fill in some data. Or they may use different terms and layouts. This leads to confusion and mistakes. A clear production report format Excel file reduces such errors. It tells the operator exactly what to fill in and where.

Easier Shift Handovers

When shifts change, the new team needs to know what happened before them. If the data is missing or unclear, mistakes happen. A well‑made daily production sheet makes handovers smooth. Everyone follows the same layout, so no time is wasted explaining notes.

More Consistent Reporting Across Teams/Factories

Standard templates are useful when you have multiple teams or locations. Each person may have a different style of writing reports. But with a common daily production report template, everyone records data the same way. This makes it easier to compare performance and spot trends.

Helps with Monthly Summaries and Audits

Daily reports add up quickly. When the format is always the same, monthly reviews are faster. It’s also easier to prepare for audits. All the data is already sorted in a clean, uniform format. You don’t need to spend extra time reformatting or correcting past reports.

Explore Kladana for Production Reporting

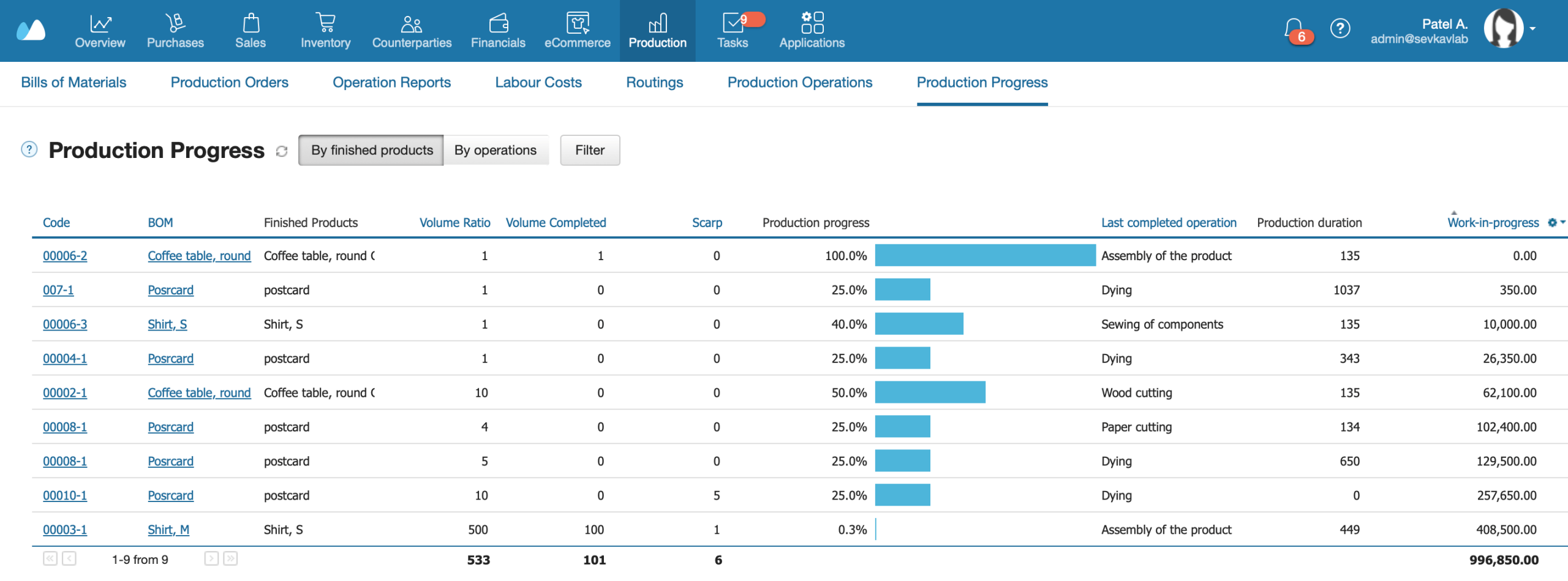

The Production Progress report shows how each production task is moving forward and how ready the products are at each stage.

You can track production progress by finished products or by operations:

✅ Production Progress by Finished Products

This view shows how much of each finished product has been completed based on its Bill of Materials (BOM). It helps production managers quickly assess how close they are to fulfilling production targets for each item.

The report shows key details for each item:

- Code — Item number in the Production Order

- BOM — Bill of Materials used

- Finished Products — Item name

- Volume Ratio — Planned quantity

- Volume Completed — Quantity produced

- Scrap — Defective output so far

- Progress — Completion %

- Last Operation — Most recent step finished

- Duration — Days in production

- WIP — Cost of uncompleted items

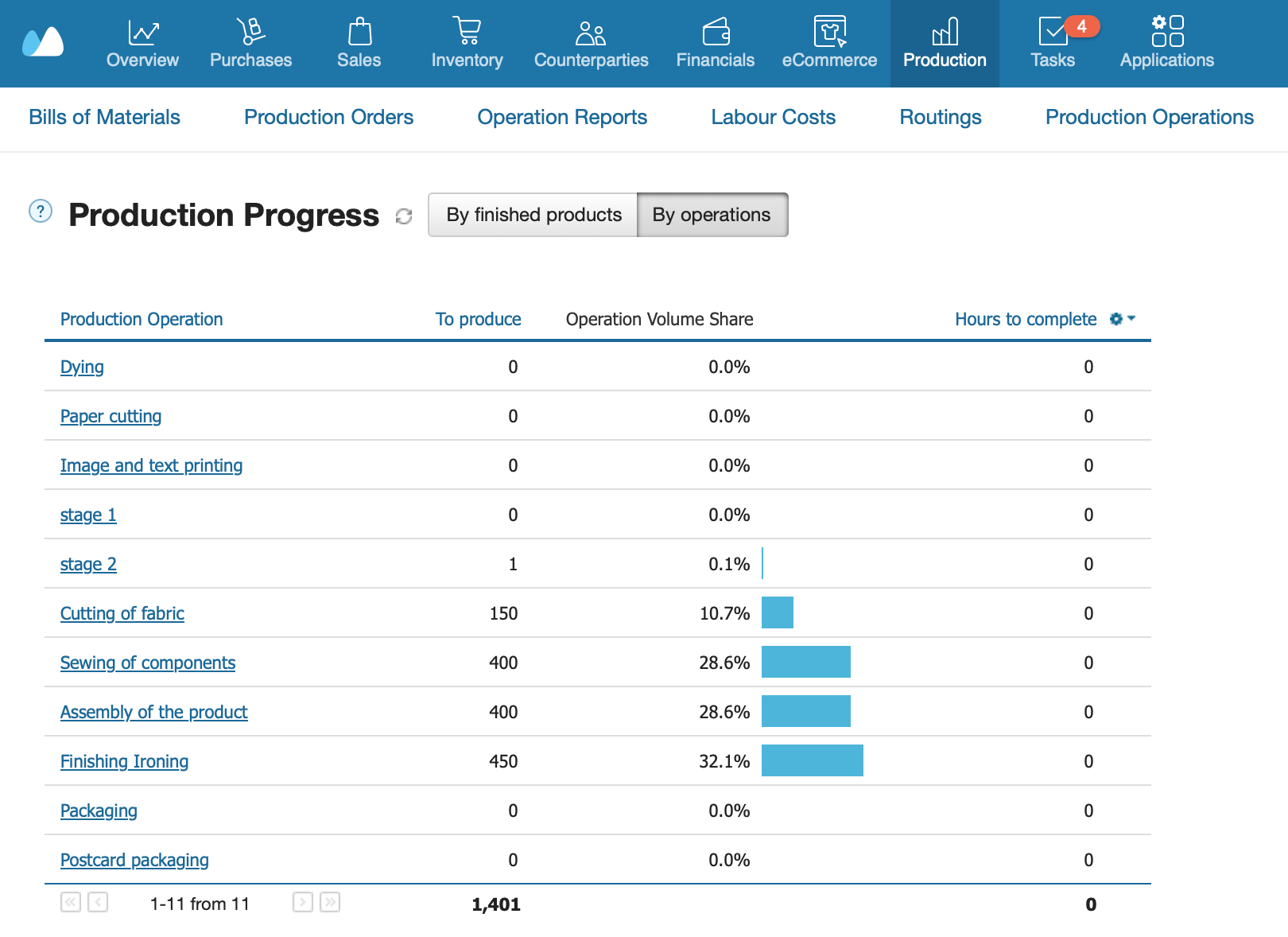

🛠️ Production Progress by Operations

This view breaks down the status of each manufacturing operation — like cutting, stitching, or assembly. This makes it easy to identify bottlenecks or delays at specific steps in the production process.

The report shows for each operation:

- Operation — Stage name

- To Produce — Remaining quantity

- Volume Share — % of total workload

- Hours Left — Planned time to finish

What Should Be Included in a Daily Production Report?

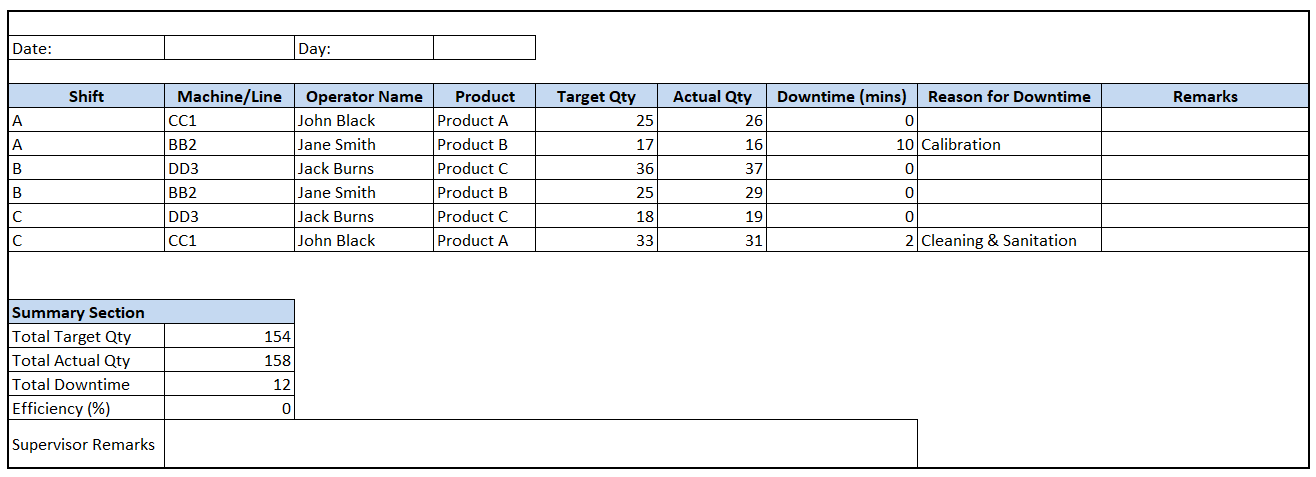

A good daily production report collects all the key data from the shop floor in one place. This makes it easy to track what was planned, what was completed, and what went wrong. Below is a list of fields every production report template should have.

- Date & shift

Start with the date and specify the shift (morning, afternoon, or night). This helps track production across different times of the day. - Operator name / machine ID

Write the name of the operator or the machine used. This is useful for tracking performance and identifying repeat issues. - Item produced / SKU / batch

Mention what was produced. Include the item name, SKU, or batch number if possible. This keeps the records clear and avoids mix‑ups. - Planned quantity vs. actual

Add the number of units planned and the number actually made. This shows whether the team met the goal or not. - Downtime (reason, duration)

Record if the machine stopped working or there was a delay. Include the reason and how long it lasted. This helps identify bottlenecks. - Defects/rework

Note how many pieces had defects or needed rework. This helps track quality problems. - Remarks or issues

Leave space for notes. Supervisors can mention issues, observations, or anything unusual during the shift.

Free Downloadable Daily Production Report Templates

You don’t need to create your own report from scratch. We’ve prepared free daily production report template files in Excel and Google Sheets. These are easy to copy, print, or fill out online. No need to fill out the form to get access to our templates.

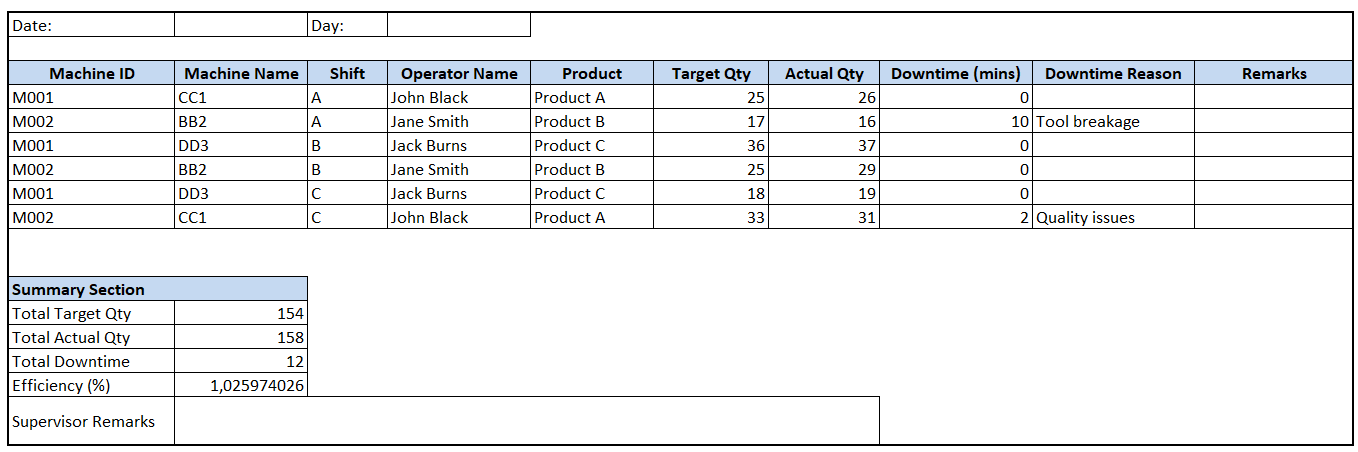

Shift‑wise Report (Excel, Google Sheets)

This template helps teams track output for each shift — morning, afternoon, or night. It includes fields for operator name, machine ID, items produced, and downtime. Use it when multiple teams work on the same machine.

OR

Machine‑wise Report

If your factory uses many machines at once, this template helps monitor output by machine. It’s useful to compare performance across machines or spot problems like frequent breakdowns.

OR

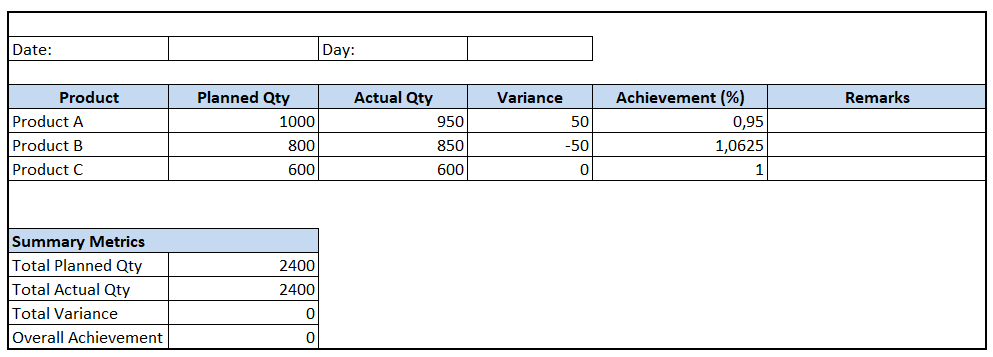

Plan vs. Actual Summary Report

This manufacturing report compares planned output with actual results. It shows gaps in production and helps teams adjust future plans based on real data.

OR

How to Use These Templates in Your Manufacturing Workflow

You can start using the daily production report template in a few simple steps. Choose what works best for your team — printed forms, Excel on desktop, or Google Sheets on mobile.

Step‑by‑step: Printing, Digital Entry, Mobile Access

Print the template if you prefer paper‑based reporting. Keep a file at each workstation. For digital entry, use Excel on your factory computer or share a Google Sheet with your team. Teams with tablets or mobile phones can fill it in directly during or after each shift.

Who Fills Them, When, and How to Review

Operators or floor supervisors usually fill out the report during or at the end of their shift. The production head collects and reviews the sheets daily. You can also hold quick morning meetings to review the previous day’s data. This helps spot missed targets, machine issues, or quality problems.

How to Digitize This with ERP

Once you get used to daily tracking, you can move to a smarter tool. An ERP like Kladana helps record this data automatically. It connects production, inventory, and costing in one place. You don’t need to calculate output or costs by hand — unit cost, WIP, and materials are updated in real time. This saves hours of manual work every week.

🎁 Kladana Free Templates Collection

Check out our free templates in different formats for almost every business occasion: from production scheduling to price quotation and invoicing.

Download them, customize, add your company details and logo, print, and use them for your needs.

- Production Schedule Templates — Plan your production operations and organize the production orders

- Bill Books — Printable collections of standard bills, mobile formats, and tax-compliant invoices

- Inventory Management Template in Excel — Make your first steps in keeping your inventory in order without notebooks

- Proforma Invoice Templates — Outline estimated costs before the final invoicing

📌 No need to fill out forms or share your phone number. Just download the template or make a copy.

Manual vs. Automated Production Reporting

Many small factories start with Excel or paper‑based daily production sheets. It’s a good first step, but it has limits as your business grows.

Limitations of Excel

Manual reports take time to fill out. It’s easy to forget data or make mistakes. Excel files are not always updated in real time. They can get lost or saved with the wrong version. If you want to check past data, you may need to open many files.

Also, Excel doesn’t connect to your stock, sales, or costing. You have to enter everything again in different sheets or systems.

Benefits of Connecting Your Reports to Stock, Purchase, Cost

With ERP, your production report template becomes part of a larger system. Output is linked to stock levels. When you finish a batch, the stock is updated. If you use raw materials, the system subtracts them from inventory. You can also track material costs and production time.

📍 Need to master manufacturing control & planning? Read our detailed blog article: A Practical Guide to Manufacturing Control Plans and Manufacturing Planning Strategies, Tools, and Technologies

Final Thoughts: Start Simple, Scale Smart

A clear daily production report is a small but powerful tool. It helps teams stay organized and spot problems early. If your factory is still using notebooks or scattered files, templates are a great way to begin.

Templates Are the First Step

Starting with a production report template gives structure to your workflow. Everyone follows the same format. It saves time, avoids confusion, and builds a habit of daily tracking. This makes it easier to measure performance and improve over time.

Move to Integrated Tools When Ready

As your operations grow, manual reporting may slow things down. Switching to a connected system helps you manage production faster and with fewer errors. You can link reports with stock, costs, and suppliers in real time.

What else Kladana can give manufacturers?

Kladana offers an affordable ERP solution for small and medium manufacturers. It connects your manufacturing report, inventory, and costing in one place. It calculates unit cost, tracks WIP, and manages your BOM automatically.

FAQs on Production Report Template

What is a daily production report?

A daily production report is a document used to track what was produced during a shift or a full day. It includes details like quantity, operator, machine, defects, and downtime.

What should be included in a production report template?

A good production report template should include the date, shift, operator name, machine ID, item or SKU, planned vs. actual output, downtime, defects, and remarks.

Is there a free Excel template for daily manufacturing reports?

Yes. You can download a free daily production report template in Excel or Google Sheets from this article. It’s easy to edit, print, or use online.

How do I create a production report in Excel?

Start with a simple table. Add columns for date, shift, machine, operator, item name, planned and actual quantity, defects, downtime, and notes. Or use our ready‑made template.

What’s the difference between a production report and a production schedule?

A production schedule shows what should be done. A daily production report shows what was actually done.

Can I use Google Sheets for production tracking?

Yes. Google Sheets works well for small teams that need to track production daily and collaborate in real time.

What are common KPIs tracked in production reports?

Key metrics include planned vs. actual output, downtime, defect rate, rework quantity, and machine efficiency.

How often should I update my production report?

Most factories update reports after every shift or at the end of the day. This keeps the data fresh and useful.

Can production reports be automated in ERP software?

Yes. ERP software like Kladana can automate production data entry and calculate unit cost, WIP, and material use.

Are there industry‑specific formats for production reporting (e.g., garment, food)?

Yes. The format may change slightly. Garment units may track styles or sizes, while food factories may record expiry dates or hygiene checks. But the structure is usually similar.