You can unlock 30% gains in operational efficiency by simply fine-tuning your production planning. Often, manufacturers overlook downtime as a maintenance issue. But it’s a scheduling one that arises due to poor slotting, late material calls, and overloaded machines.

That alone costs most manufacturers at least 5% of their total productive capacity, with some bleeding closer to 20%.

Stack it up across shifts, and you’ll have jobs running late, teams on hold, and orders chasing the clock. A reasonably good production schedule in manufacturing will shrink those gaps and maximize productivity during every shift.

So if you’re struggling with bottlenecks, fire-drill reschedules, or machines sitting quietly while orders pile up, it suggests a production scheduling problem.

This guide breaks it down from the ground up.

- Production Schedule: What Is It, and What’s the Role of PPC?

- What are the Benefits of Effective Production Scheduling

- Production Scheduling Process: Steps and Inputs

- Methods & Techniques

- Just-in-Time (JIT) Scheduling

- Production Scheduling Tools & Software

- Challenges & Best Practices

- How Kladana Helps Solve Challenges

- FAQs on the Production Scheduling

- List of Resources

How Kladana Simplifies Production Scheduling

✅ ERP + MRP in One Place — Plan production in sync with inventory, procurement, and sales. MRP runs in the background to make sure materials are ready before a job starts.

✅ Live View of Every Task — See each job’s material status, assigned operator, and target delivery date — no more guessing or running to the shop floor for updates.

✅ Automatic Job Assignment — Match work orders to available machines and teams based on priority, skill, and shift capacity. The system handles the heavy lifting.

✅ Flexible Timelines — Adjust production routes, reassign operators, or shift delivery dates in seconds — all without digging through multiple files.

✅ Early Bottleneck Alerts — Spot issues before they slow you down and reroute work instantly to keep schedules intact.

✅ Purchasing Built In — Trigger purchase orders for low-stock materials directly from the production plan so you never miss a deadline.

✅ Status at a Glance — Color tags show whether a job is ready, in progress, or blocked — updated automatically from real-time shop floor inputs.

✅ No Complex MES Needed — Get the clarity and control you need without investing in a heavy, expensive execution system.

Production Schedule: What Is It, and What’s the Role of PPC?

A production schedule in the manufacturing industry is a time-bound plan that lays out, in detail, what to make, when, and how resources line up to get each job done.

It offers a schedule that maps jobs to machines, people, and time blocks so that everything flows without pileups, missed deadlines, or last-minute chaos.

To prepare one, you can choose from our free production schedule templates and get started.

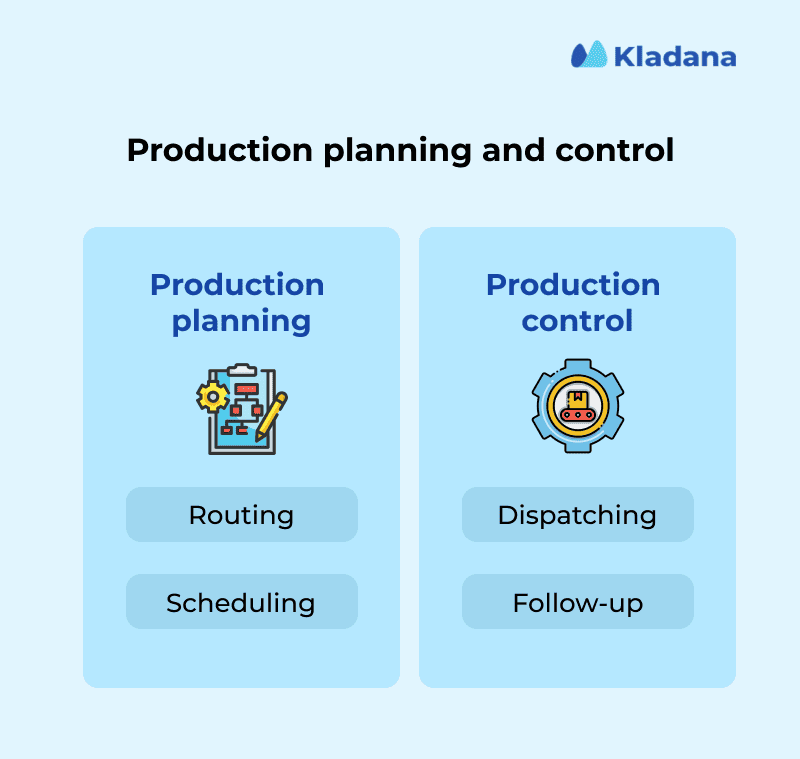

Role in PPC (Production Planning and Control)

Production scheduling is one of the few moving parts in PPC that directly touches execution, as this is where the big-picture strategy meets daily operations.

PPC helps in:

- Planning and setting up long-range goals of what to produce, when, and in what volume.

- Routing that defines the exact steps each product will take through machines and stations.

- Scheduling, which converts routing into time-based task allocation of who does what, when, and on which machine.

- Dispatching & Control involves executing the schedule, monitoring it, and feeding adjustments back into the loop.

What are the Benefits of Effective Production Scheduling

The benefits below highlight why effective production scheduling is a game-changer for manufacturers.

1. Lesser Downtime and Bottlenecks

A manufacturer may face unplanned gaps and pileups due to scheduling blind spots. But a production schedule can enable machines to operate with tighter transitions, with smoother handoffs and clear priorities to cut off unnecessary wait times.

What makes it work:

- Jobs are grouped to reduce frequent changeovers

- Idle time is visible ahead of time, not after

- Rescheduling happens fast when dependencies shift

2. Effective Use of Resources

Production scheduling in manufacturing can bring absolute clarity to task assignments and prevent overloaded teams and underused equipment. It provides manufacturers with balanced workloads and steady output.

How it gets done:

- Work remains balanced across available machines and shifts

- Operators need not wait for unclear priorities

- The setup time is reduced by sequencing jobs logically

3. On-Time Delivery and Customer Satisfaction

Production planning and scheduling make sure that the final package is ready for movement on time. It helps provide customers with a clear schedule, as you can track progress on the floor. In turn, this increases their faith in your business and vis-à-vis satisfaction.

What changes with better scheduling:

- Job timing reflects material readiness and real capacity

- Rush orders are slotted without breaking flow

- Sales and production stay synced on order status

Production Scheduling Process: Steps and Inputs

The production scheduling will require you to consider the key functions on the floor: jobs, targets, and priorities.

Here’s a detailed process with the necessary inputs on how to schedule the production planning.

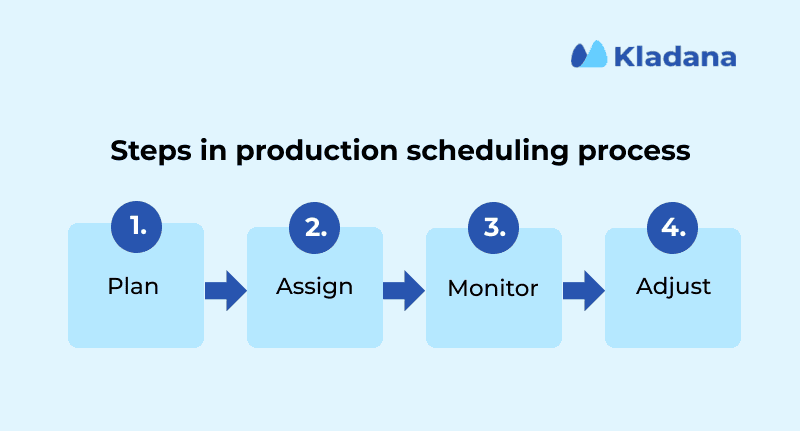

A. Steps in the Production Scheduling Process

Each step in the production scheduling process below involves making choices to prevent slowdowns before they become bottlenecks that you can’t outrun.

1. Plan

Apart from sequencing, the planning requires adding routing rules, operation timing, overlapping job dependencies, and material checkpoints before a single task hits the floor.

It unlocks:

- Visibility into work centers that will get overloaded

- Clear routing so no task ends up at the wrong station

- Buffer settings for the machines with higher failure rates

2. Assign

The production schedule becomes functional when there’s a sufficient number of tasks. In essence, matching jobs with machines and assigning the same to team members to run it smoothly.

The assignment stage makes sure you:

- Prevent double-booking resources by accident

- Sequence high-priority jobs without breaking mid-priority flow

- Don’t need a part that arrives two days late

3. Monitor

Track the jobs that are happening right now with the ones that are stalling, along with the lag (in time).

In a production schedule, you’ll mainly track:

- Tasks running longer than estimated before they derail the next shift

- WIP stacking up in areas that should’ve been cleared

- Idle machines with assigned jobs that haven’t started yet

4. Adjust

What if, on a given day, an issue arises with the spindle motor, or a supplier sends the wrong gauge?

It’s here that your planning must adjust on the fly. Otherwise, you’ll end up manually chasing updates for the next three days.

Some of the key adjustments are:

- Re-slotting urgent jobs without breaking batch runs

- Rebalancing machines when one goes down mid-cycle

- Holding dependent tasks until missing materials arrive

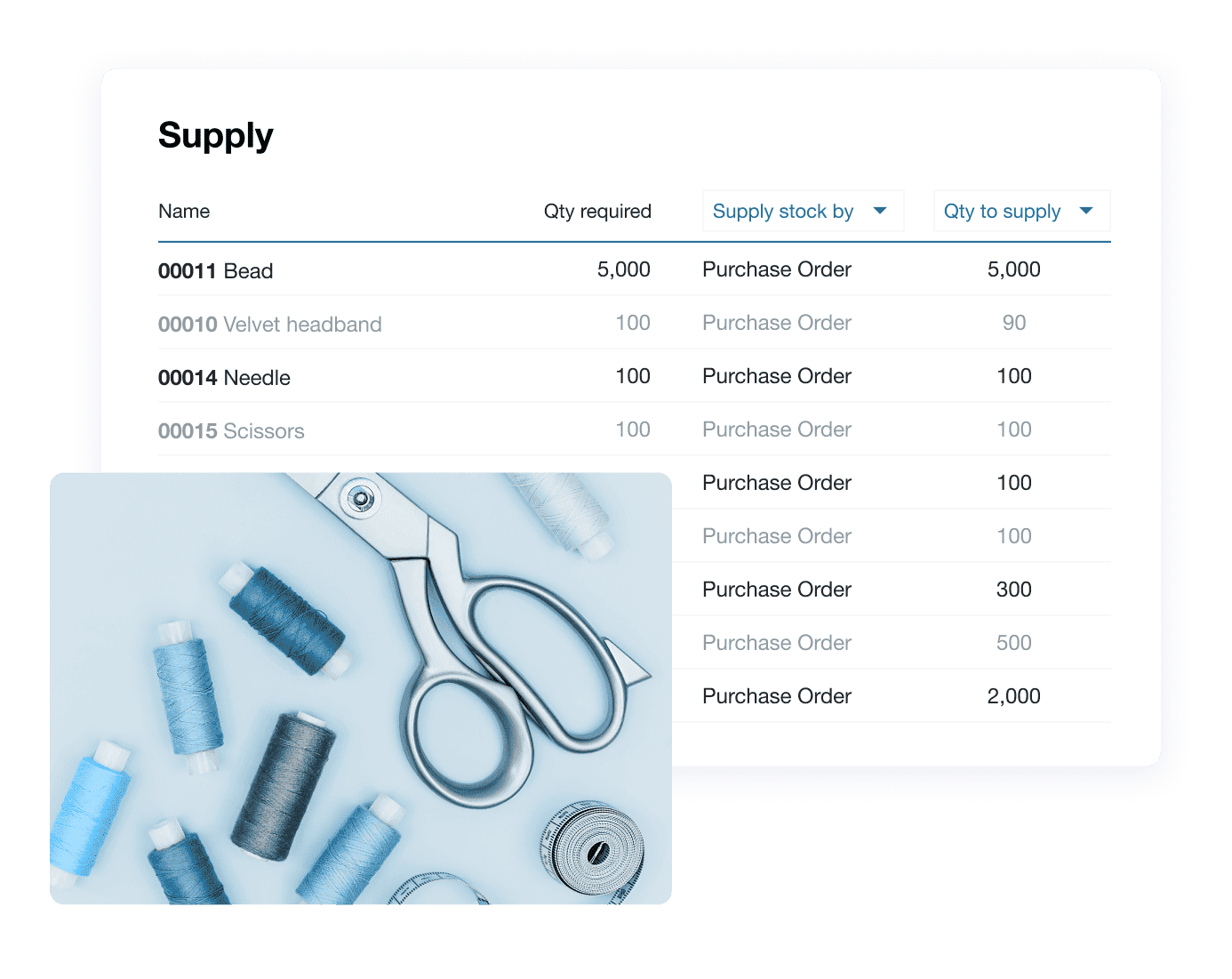

B. Inputs for Production Scheduling Process

To bring agility into production, you need to determine inputs with enough consideration of process hiccups.

Below are the three key areas where you could plug into the system for input.

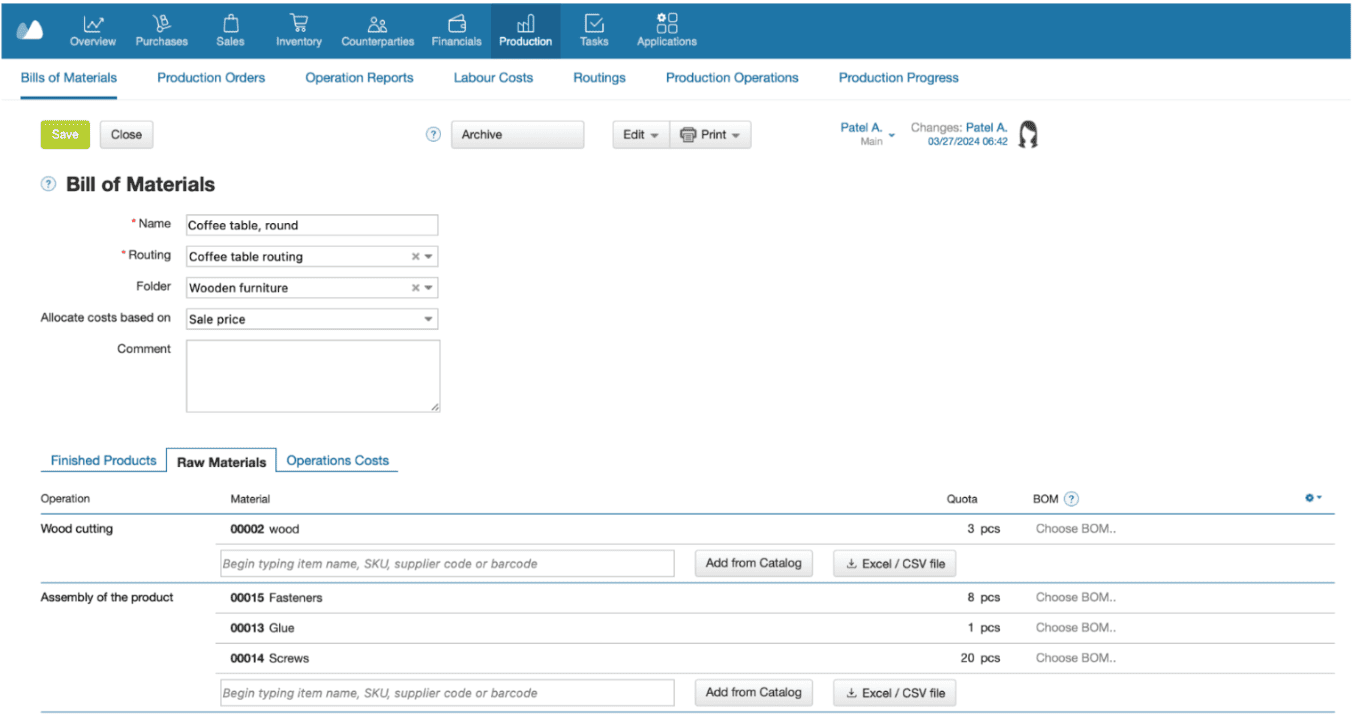

1. Bill of Materials (BOMs)

BOM defines the material prerequisites.

If not met, the job cannot proceed, regardless of the availability of machines or labor.

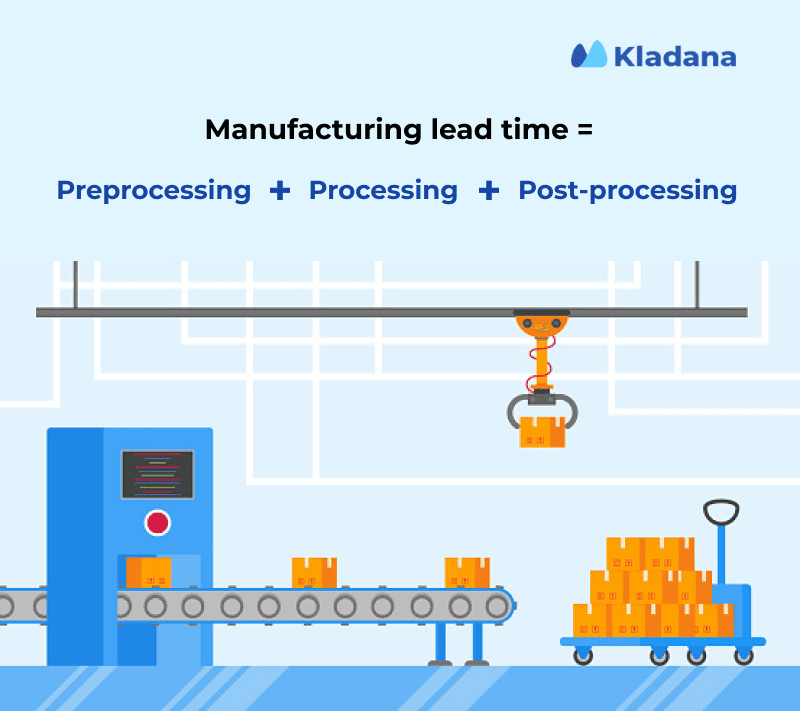

2. Lead Times

Lead times lock in the earliest possible start for each task, including suppliers and internal operations.

The production space will open based on when materials arrive and are ready for use, rather than the order data.

3. Labor Availability

Every task in the production schedule depends on the team assigned to it. So, you’ll factor in the people available in the shift and the visibility into their skill levels, current workloads, and coverage across stations.

Methods & Techniques

These are the three highly used approaches in production scheduling as follows.

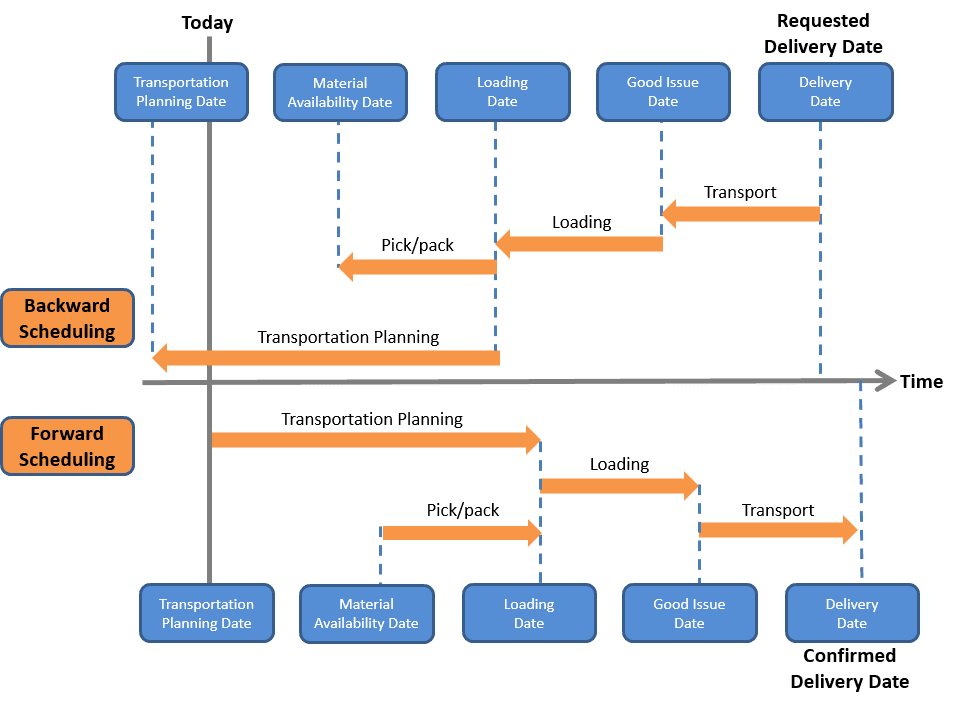

Forward and Backward Scheduling

Forward scheduling: The production is planned from the earliest possible date. Subsequently, each job is pushed forward. The capacity is filled up quickly to create more buffers, often leading to earlier-than-needed completion.

Backward scheduling: It works in reverse because the manufacturing begins from the deadline and works backward by fitting jobs into the latest available slots that still meet delivery deadlines.

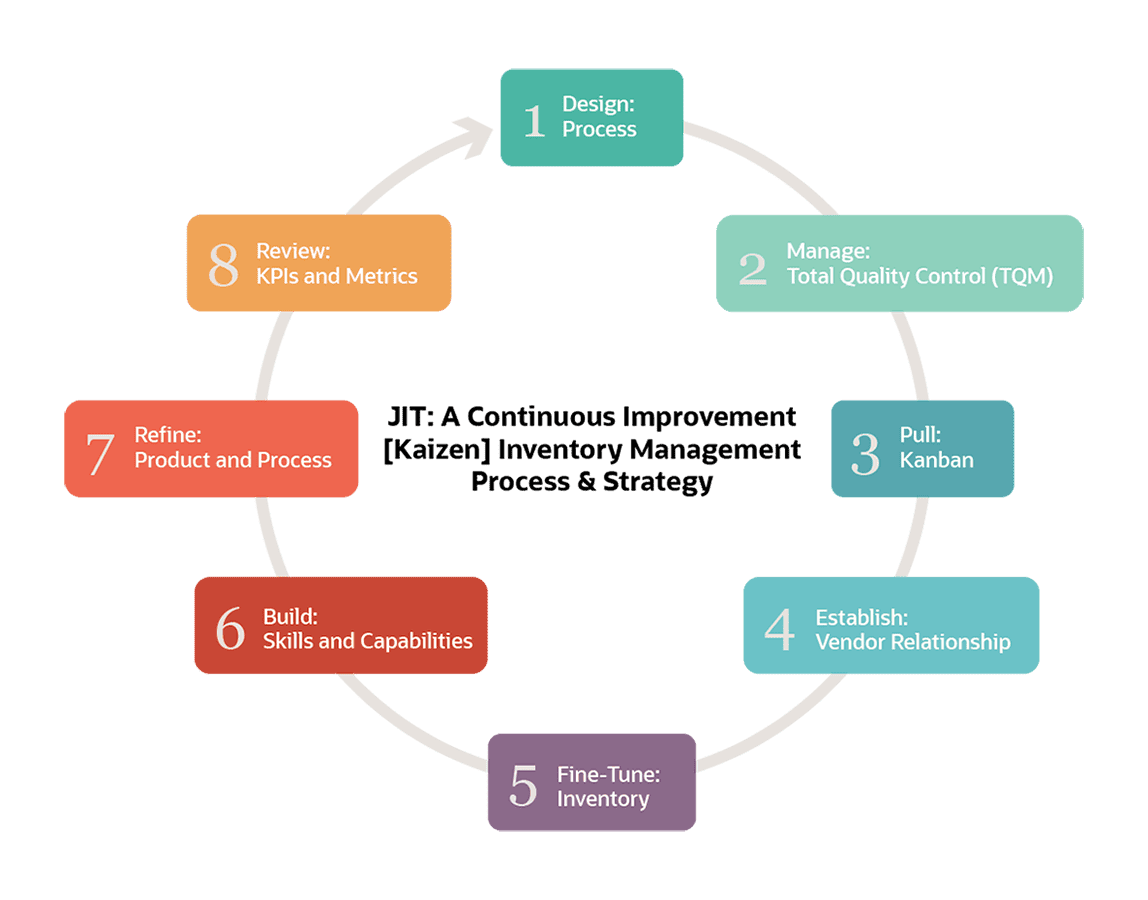

Just-in-Time (JIT) Scheduling

This method focuses on producing only when required, using precisely the materials needed, with zero excess in stock. The schedule is designed to trigger jobs based on real demand, not forecasts.

Running JIT will require teams to respond fast, keep changeovers tight, and suppliers on their toes.

Finite vs Infinite Scheduling

Finite scheduling: If a resource is booked, it won’t schedule anything else into that time block. It avoids overlaps and overloads but can leave small idle gaps that need follow-up smoothing.

Infinite scheduling: This method ignores capacity and fills the schedule based on when jobs are due or planned. For example, assigning three jobs to the same machine at the same time.

Production Scheduling Tools & Software

The production scheduling runs on two types of systems: manual tools and automated software.

Manual Systems: Whiteboards, Excel, and Paper

Typically, a planner updates a spreadsheet, pins routing charts to a board, or maps jobs on paper. It works when the job count is low and changes are rare. However, in cases of shift overlaps or when machines are running at full load, the manual systems may become brittle.

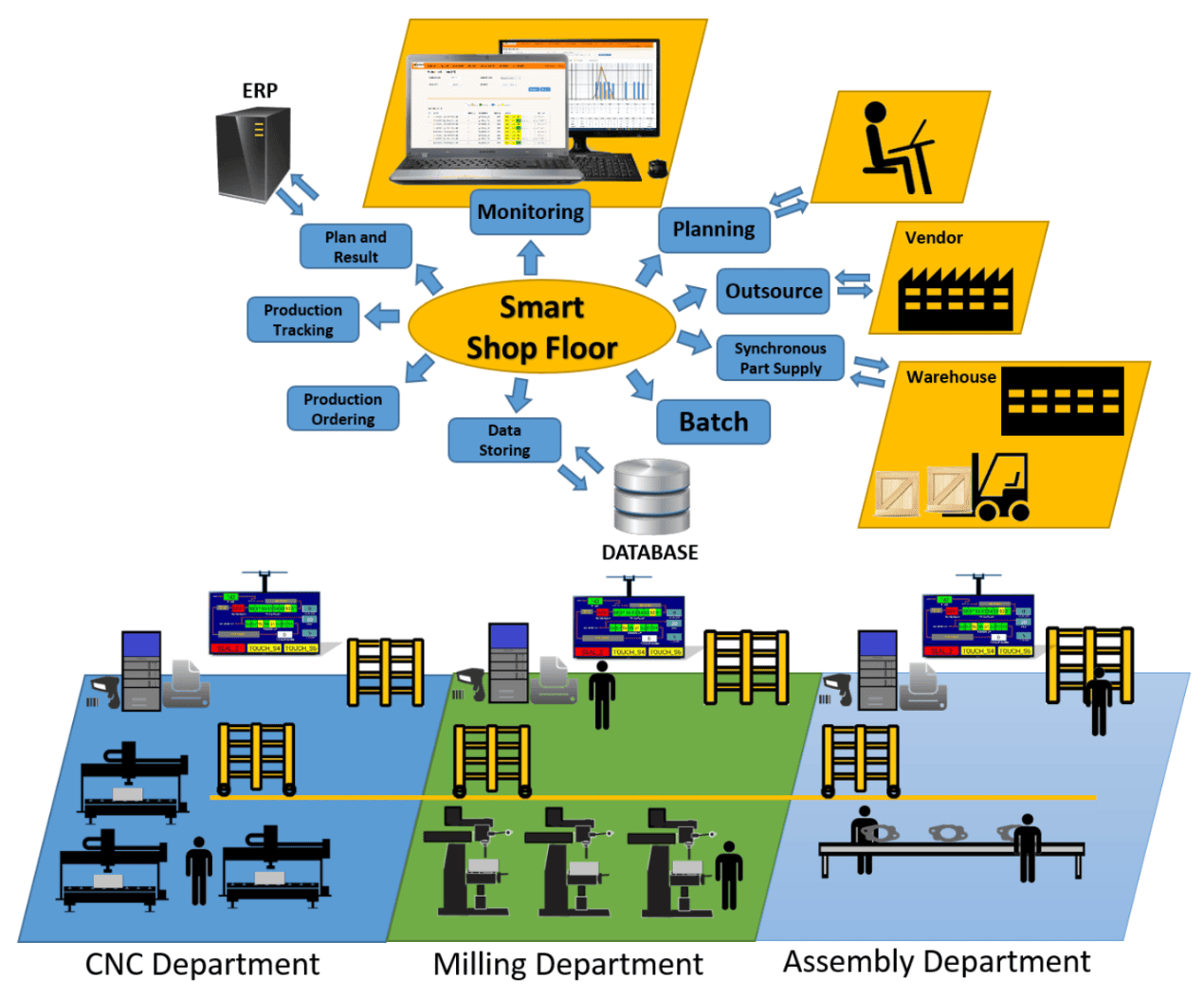

Automated Systems: ERP and MRP Software

An ERP (Enterprise Resource Planning) system acts as the backbone for automation. It can sync production with business functions like finance, procurement, and sales.

Also, the MRP (Material Requirements Planning) module can help align material supply with production needs and typically runs within or alongside the ERP.

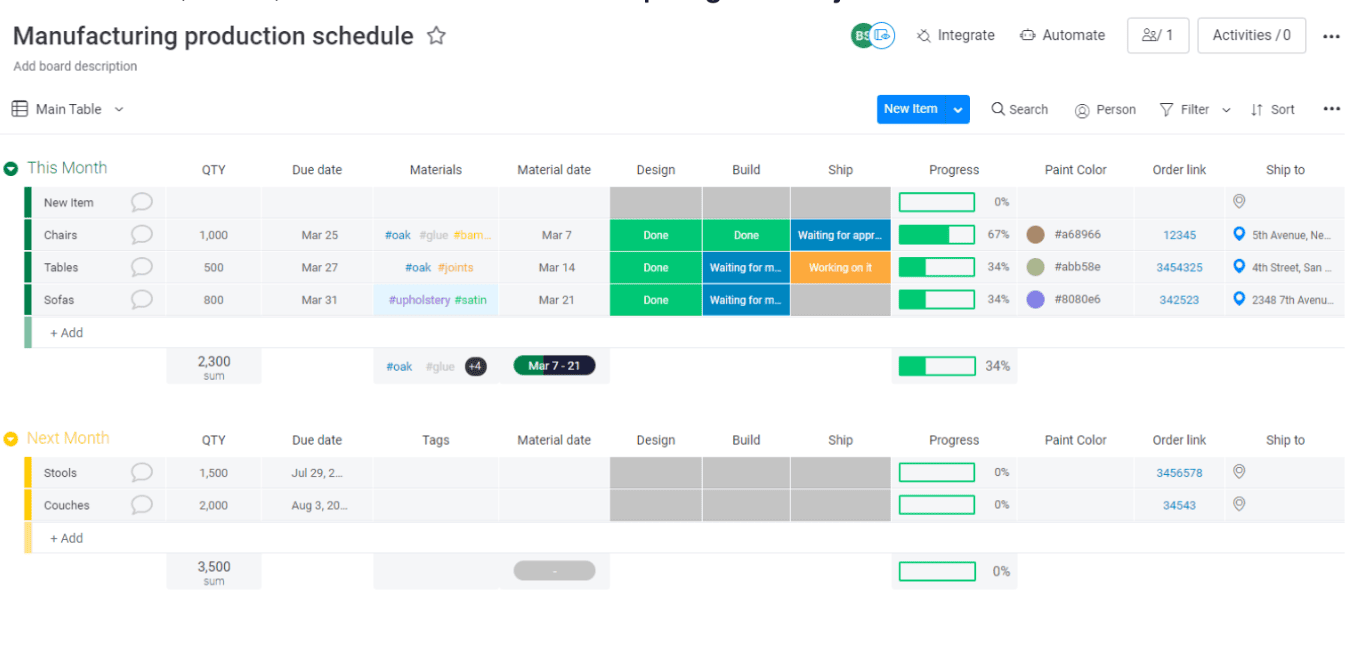

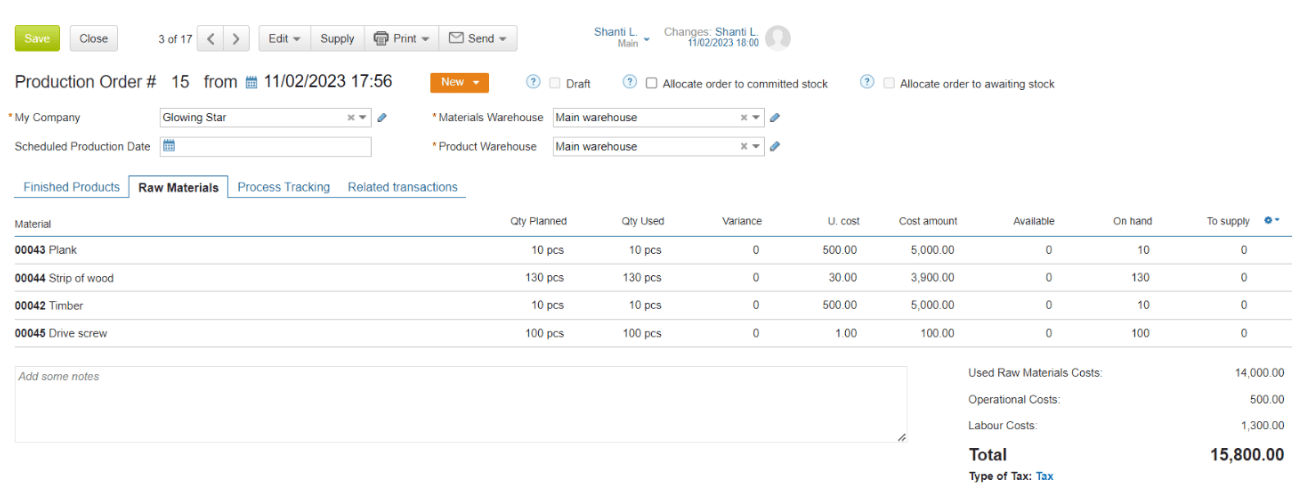

Example: Scheduling in Kladana ERP

For production managers, Kladana offers a clean interface that assigns jobs, tracks progress, and shifts timelines without opening ten files. Each task appears with its material status, assigned operator, and target delivery.

You can view bottlenecks before they form and adjust routing directly from the dashboard.

Using Kladana as an automation layer for manufacturing can:

- Show real-time material readiness right inside the production schedule

- Auto-allocate jobs to available machines and teams based on priority and shift capacity.

- Trigger purchase orders for low-stock items directly from the production plan

- Provide deeper visibility into pending, running, and delayed tasks in one view

Challenges & Best Practices

There are a couple of big challenges in adopting the production schedule, which you can overcome by implementing the best practices.

Dealing with Rush Orders

Rush orders can disrupt the flow of your production. A high-priority job landing without warning may compel re-sequencing and reshuffling the work in progress. Also, it may require pulling off materials from already planned tasks.

Best practice:

Start leaving open slots in the calendar intentionally during each shift to absorb urgent requests. Instead of overwriting current tasks, you fit the rush in without breaking your batch runs.

Pro tip: If you’re using ERP, tag rush orders with a unique job type to auto-prioritize material staging and floor assignments.

Integrating Shop Floor Feedback (IoT)

The real-world variables start kicking in once the job hits the floor. There can be tools that wear out mid-run, machines that slow down after long cycles, and there can be environmental shifts like heat or humidity that impact tolerances.

Now, if all these are part of daily operations, then you absorb this feedback in real-time.

Best practice:

Connect IoT feedback directly into your scheduler. Systems can pull data from sensors, operator tablets, or machine logs that can flag delays early.

In Kladana, for instance, floor data shows up in live status tags like “In Progress,” “Paused,” or “Delayed,” keeping your view accurate without manual check-ins.

How Kladana Helps Solve Challenges

Kladana provides manufacturers with a lightweight yet powerful solution to keep production grounded in reality, eliminating the need for a complex MES setup. Each production order in Kladana comes with a status trail.

You know exactly when a job starts, which stage it’s in, and what’s holding it back.

Color-coded tags like “Ready,” “In Process,” or “Blocked” update based on material status, operator activity, or machine inputs.

The features in Kladana ensure the following:

- Eliminating the need for the shop floor to check job status

- Drives easy visibility across all active and pending work orders

- Enable faster response to delays without chasing paperwork

Chasing updates across files, emails, and the shop floor? That ends here.

Kladana brings your production schedule, material tracking, and task updates into one clean view, so you can spend less time coordinating and more time delivering.

FAQs on the Production Scheduling

There may be questions on planning the production schedule and activities related to it. We’ve answered it!

What is a production schedule in manufacturing?

The production schedule is a time-bound plan that maps jobs to be done on machines, by people in the factory, and within their shifts, ensuring delivery targets are met without delays or resource conflicts.

How is production scheduling different from planning?

Planning sets the goals and timelines. But the production scheduling breaks them into task-level execution with real-time resource alignment.

What are the primary methods of production scheduling?

The three typical approaches include forward scheduling, backward scheduling, just-in-time (JIT), and finite/infinite scheduling.

How do you create a production schedule?

Start by defining tasks, checking for material and labor availability, assigning jobs to machines, and making adjustments based on real-time floor feedback.

What is forward vs backward scheduling?

Forward scheduling begins from the day of the plan and schedules the future. Backward will start from the deadline and work in reverse to fit the timeline.

What software is best for production scheduling?

Cloud ERPs like Kladana offer live job tracking, drag-and-drop scheduling, and resource control suited for small and mid-size factories.

Can small manufacturers automate scheduling?

Yes. ERP and MRP solutions make it easy to digitize scheduling without high setup costs or complexity.

How does production scheduling reduce downtime?

By sequencing tasks logically, assigning resources smartly, and reacting fast to delays, it keeps machines running and workflows smooth.

What’s the role of ERP/MRP in production scheduling?

ERP ties scheduling to sales, inventory, and procurement. MRP ensures material availability aligns with job timelines.

How do you handle last-minute order changes in scheduling?

With a responsive system, you can re-slot tasks, adjust resource loads, and update floor teams without breaking the workflow.

List of Resources

- PPCexpo — Production Planning in Manufacturing Industry: Key Insights

- The International Society of Automation — How Much Is Plant or Facility Downtime Costing You?