As a founder or operations head, you’re under constant pressure to scale quickly while keeping costs under control. Setting up production in-house requires significant capital, lengthy timelines, and ongoing management challenges that can hinder your progress. At the same time, you can’t afford to compromise on product quality or delivery commitments.

That’s why more businesses are reevaluating their production sourcing strategies. Instead of only chasing cost cuts, many are rebuilding outcome-based outsourcing relationships that focus on speed, flexibility, and value creation. In fact, Deloitte’s Global Outsourcing Survey 2024 found that 67% of executives have already shifted to outcome-driven partnerships. Demonstrating that outsourcing is no longer just about saving money, but about staying competitive.

This guide gives you a clear view of your options. You’ll learn the advantages and risks of outsourcing, how OEM, ODM, and contract manufacturing models differ, what to check before choosing a partner, and how to manage the relationship with the right systems. You’ll also see where India’s manufacturing landscape is headed and how digital tools like ERP/MRP platforms help you stay in control.

- What Is Contract Manufacturing?

- Benefits & Risks

- Contract Manufacturing Models & Examples

- OEM vs ODM vs CM — What to Choose

- How to Select a Contract Manufacturer

- Managing the Relationship

- Digital Backbone: ERP/MRP for BOMs, Revisions, Work Orders, GRNs, ASN Tracking

- India Outlook

- Kladana Integration: Run Contract Manufacturing Smoothly

- To Sum Up

- Frequently Asked Questions on Contract Manufacturing

- List of Resources

What Is Contract Manufacturing?

When you hear the term ‘contract manufacturing, ‘ think of it as outsourcing the production of your product to a specialized manufacturer. You still own the brand, the design, and the intellectual property. However, the actual production of the product occurs outside your factory.

To understand it better, you need to see how it fits alongside other models:

- Contract manufacturer (CM): Produces your product strictly according to your design and specifications

- OEM (Original Equipment Manufacturer): Manufactures your design under your brand, often adding their production expertise

- ODM (Original Design Manufacturer): Not only manufacturers, but also designs products that you can sell under your brand name

Here’s a simple way to differentiate them:

- With a CM, you bring the design, they bring the machines

- With an OEM, you control the product design, but they execute it end-to-end

- With an ODM, you buy both the design and the production service as a package

Benefits & Risks

When you outsource production, you open the door to lower costs, faster scale, and access to new capabilities. At the same time, you also take on risks around quality, IP, and supply dependence. Here’s a side-by-side view that helps you weigh the trade-offs clearly.

And this isn’t just theory. Grand View Research estimates that the Global Pharmaceutical contract manufacturing market was valued at $129 billion in 2024 and is expected to nearly double by 2030. This growth underlines how even highly regulated industries rely on contract manufacturers to scale more quickly and remain competitive.

| ✅ Benefits | ❌ Risks |

| Lower CapEx: No need to invest in costly machinery or facilities | Quality drift: Product quality may slip without strict monitoring. Clear standards and regular checks avoid this |

| Faster time-to-market: Start production quickly instead of waiting months to set up your own line | IP leakage: Sensitive designs may be copied or leaked |

| Scalability: Ramp up or down based on demand | Supply dependence: Relying on just one contract manufacturer creates vulnerability |

| Focus on core strengths: You concentrate on design, marketing, and customers | Logistics risks: Delay due to trade, customs, or transport issues |

| Access to advanced tech & certifications: Benefit from specialized equipment and expertise | Custom creep: Hidden charges or poor cost transparency |

Contract Manufacturing Models & Examples

Contract manufacturing isn’t one-size-fits-all. The type of partner you choose depends on what you’re producing, the complexity of the production, and the applicable compliance requirements.

For example, producing electronic devices is very different from bottling a new drink or machining auto parts. By understanding the main models, you can decide which one best fits your product and avoid mismatched expectations.

| Model/Industry | What It means | Example |

| Electronics Manufacturing Services | Produces electronic assemblies such as printed circuit boards, wiring, and device assembly | A consumer tech brand designs a smart gadget but outsources Printed Circuit assembly and device testing to an Electronic manufacturing Services |

| Plastics Molding | Creates plastic parts or packaging using injection or blow molding | A skincare company develops a new product line and relies on a plastics molder to make bottles, jars, and caps |

| Precision machining | Manufacturers’ metal parts that require exact dimensions and finishes | An industrial tools SME designs a pump but outsources Computer Numerical Control-machined impellers and shafts to a machining supplier |

| Medical Devices & Pharma (CDMO) | Specializes in the regulated production of medicines, supplements, or medical devices under strict quality standards | A nutraceutical brand formulates a probiotic but hires a CDMO to fill capsules and package them under Good Manufacturing Practices compliance |

| Food & Beverage Co-Packing | Handles large-scale preparation and packaging of food or beverages | A new beverage label creates its recipe but works with a co-packer to brew, bottle, and label drinks ready for supermarkets |

OEM vs ODM vs CM — What to Choose

OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and CM (Contract Manufacturer) are not interchangeable. The right choice depends on how original your product is, how fast you need to launch, how much budget you can commit, and how much control you want to keep.

| Design Factor | OEM | ODM | CM |

| Product novelty | Works well if you already have a finished design and need production expertise | Suitcases when product originality doesn’t matter, and you want a quick standard solution | Best for highly original products where you want to keep design and want full ownership and IP |

| Speed to market | Suitable if you can allow some setup time for tooling before launch | Ideal for the fastest launch since designs are already developed | It is best when you can balance speed with complexity, suited for gradual but controlled scaling |

| Budget | Fits businesses with Medium-high budgets that can cover tooling and production costs | Fits tight budgets like the lowest upfront cost, as Research & Development is avoided | Fits when you want to avoid heavy CapEx but are fine covering transfer and alignment costs |

| Control | Good for keeping firm control over specs and branding with vendor support | It’s good if limited control is acceptable and speed or cost matters more | It’s best if you need maximum control over design, quality, and process |

💡Outsourcing parts? Keep BOMs, POs, and GRNs in sync with Kladana

Keep your contract manufacturer aligned with the latest BOMs, POs, and delivery records to stay error-free and up to date

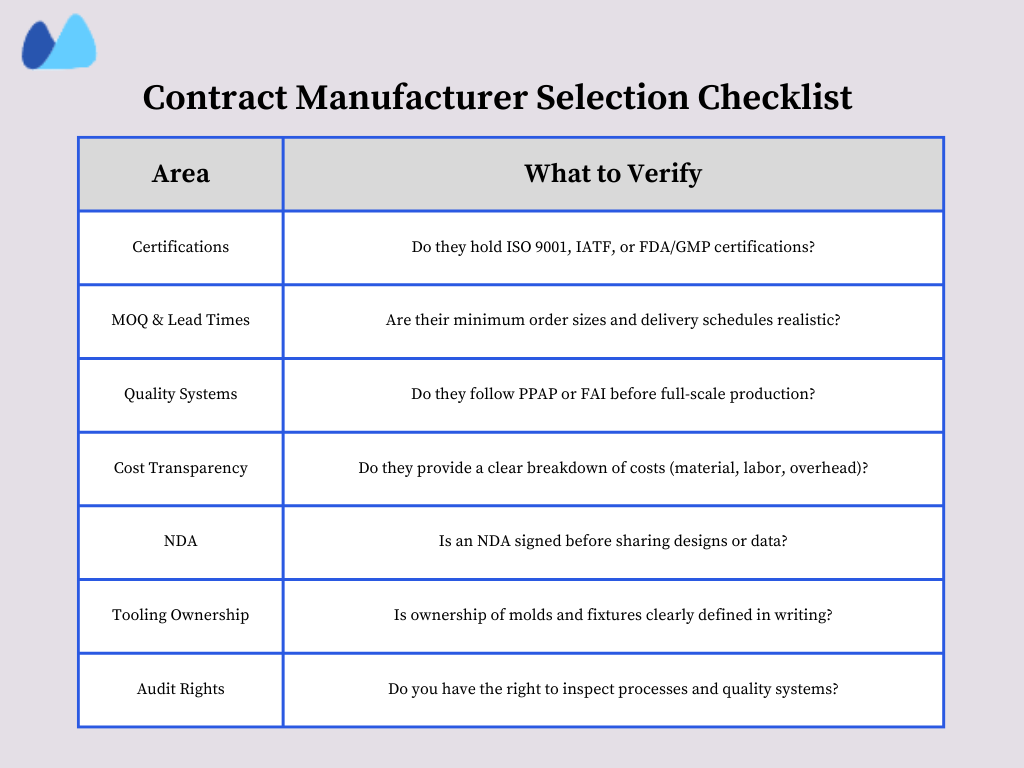

How to Select a Contract Manufacturer

Selecting a contract manufacturer is about more than who can make your parts at the lowest price. You’re choosing a partner who will impact your quality, speed, and margins. A structured approach makes the evaluation process clearer and helps you avoid risks in the future.

Technical Capabilities

1. Certifications: Ask for ISO 9001, IATF 16949, or FDA/GMP, depending on your industry. These confirm that the manufacturer meets international standards.

2. Minimum order quantity & lead times: Check whether their minimum order quantities and delivery timelines match your demand pattern.

3. NPI support: Ensure they can run pilot lots and support smooth new product introduction.

4. Quality systems: Look for structured processes like PPAP (Production Part Approval Process) and FAI (First Article Inspection) to validate parts before full-scale production.

5. Cost model transparency: Ask for a detailed breakdown of material, labor, and overhead, not just a lump sum.

6. Data sharing & change control: Verify how they provide production data and how they manage design or supplier changes.

IP & Compliance

1. Non-disclosure agreement (NDA): Must be signed before sharing designs or specifications.

2. Tooling ownership: Define in writing who owns molds, jigs, or fixtures used for your product.

3. Escrow: Use escrow agreements for critical IP, software, or design files.

4. Audit rights: Reserve the right to audit processes and suppliers to ensure compliance.

Managing the Relationship

Working with a contract manufacturer is not a long-distance handoff. It’s a relationship that depends on visibility, performance tracking, and disciplined processes. The proper structure ensures you deliver consistently on quality, timelines, and cost, while protecting your margins and reputation.

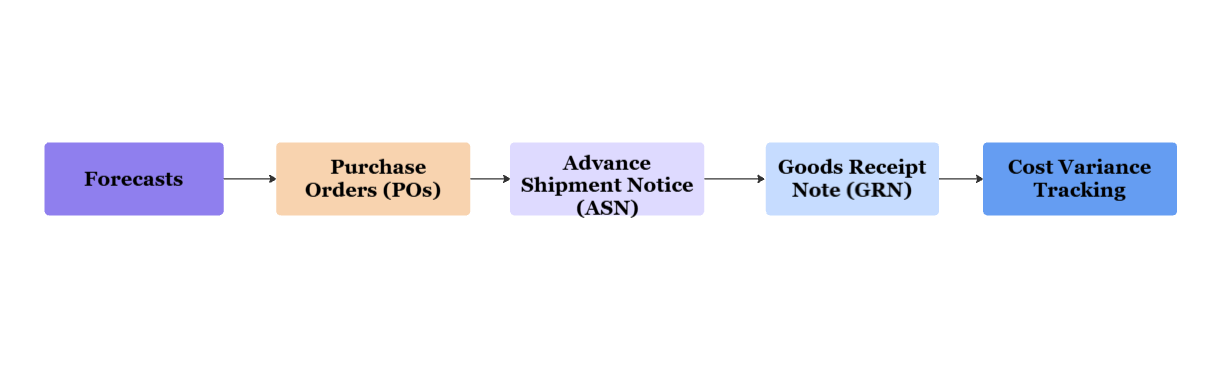

Forecasting & Purchase Contracts

1. Share rolling forecasts that look ahead 3–6 months. This helps your manufacturer plan raw materials, labour, and machine capacity in advance.

2. Convert forecasts into firm purchase contracts. Contracts secure production slots, stabilize pricing, and create accountability on both sides.

3. Review forecast accuracy regularly. The more predictable your signals, the more likely your manufacturer is to prioritize your orders.

VMI/Consignment Options

➽ Vendor-managed inventory (VMI): Your manufacturer monitors demand and maintains agreed stock levels. This reduces administrative effort and minimizes the risk of shortages.

➽ Consignment stock: Materials or finished goods are stored in your warehouse but remain the manufacturer’s property until consumption. This keeps your working capital free while ensuring product availability.

➽ Both approaches improve supply reliability and reduce the financial burden of holding inventory.

📖 Recommended Read:

Performance KPIs

1. On-time delivery (OTD): Measure whether shipments arrive as promised. A high OTD rate signals reliability.

2. Parts per million (PPM) defect rate: Quantifies quality performance. A low PPM shows effective process control.

3. First-pass yield: Tracks the percentage of units produced correctly the first time, without rework. High yield indicates stability and efficiency.

4. Reviewing these KPIs in joint sessions makes performance transparent and creates a culture of continuous improvement.

S& OP Cadence

- Integrate your manufacturer into your sales and operations planning (S& OP)

- Monthly or quarterly S& OP sessions align demand forecasts, production schedules, and material availability

- This cadence prevents last-minute firefighting and ensures both teams respond proactively to demand or supply shifts

Digital Backbone: ERP/MRP for BOMs, Revisions, Work Orders, GRNs, ASN Tracking

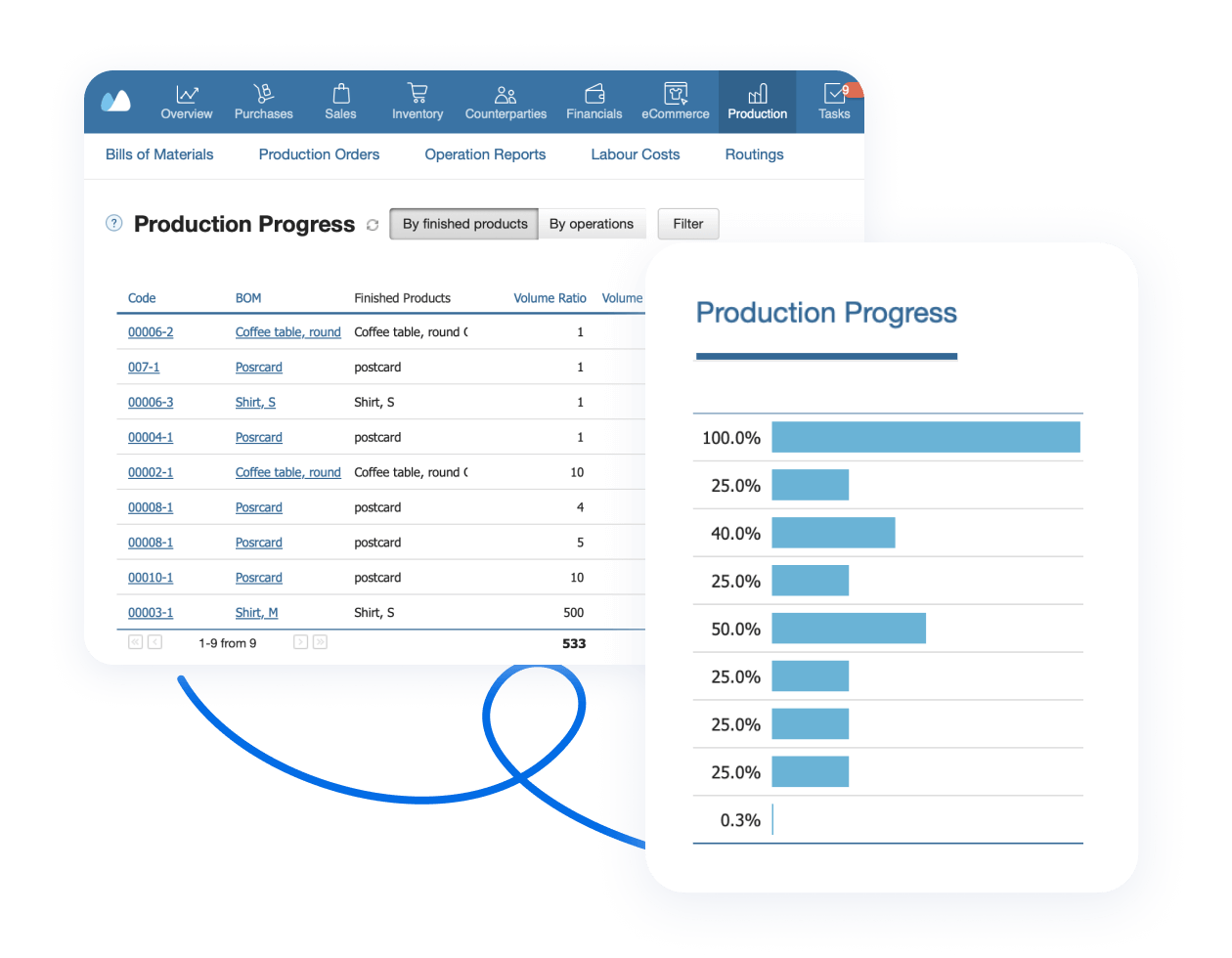

Managing all these emails and spreadsheets often leads to errors, missed updates, and version mismatches. A strong ERP/MRP system helps you process transparently everything for you and your manufacturer.

Maintain Bills of Materials (BOMs) revisions inside the system so that the manufacturer always works with the latest version. Kladana supports multi-level BOMs with full revision tracking.

➡️ Link production orders and work orders directly to sales forecasts and purchase orders. In Kladana, you can convert forecasts into plans automatically, reducing manual steps.

➡️ Record Goods Receipt Notes (GRNs) when shipments arrive and capture any defects or discrepancies on the spot.

➡️ Use Advance Shipment Notices (ASNs) to know what is in transit before it arrives, improving warehouse and labor planning.

➡️ Track cost variances by comparing planned vs actual material, labor, and overhead costs. Kladana’s costing tools give you early warning when margins are at risk.

➡️ Manage outsourced operations by assigning tasks to your CM, recording their work, and integrating their output into your production workflow.

➡️ Oversee multi-location stock with raw materials, WIP, and finished goods across your own site and CM’s site, all visible in one dashboard.

With these capabilities, Kladana ERP becomes your digital backbone. It doesn’t just store data. It coordinates processes, enforces revision discipline, and protects profitability in outsourced manufacturing.

📖 Recommended Read:

India Outlook

The landscape of contract manufacturing in India is expanding quickly. For SMEs, hardware startups, and D2C brands, this shift means more reliable options for outsourcing locally, rather than relying solely on global supply chains.

According to KPMG’s 2025 FMCG Contract Manufacturing Industry Outlook, India is seeing accelerated growth in contract manufacturing, supported by policy incentives and industry consolidation. This signals a stronger ecosystem for smaller brands that want to outsource locally without compromising on scale or compliance.

Growth Pockets

1. Devices and electronics: India’s electronic manufacturing services providers are scaling to meet rising demand in smartphones, wearables, and IoT hardware. This is one of the strongest growth pockets in the market.

2. Pharma and CDMO: India has long been a hub for generics, and now contract development and manufacturing organisations (CDMOs) are gaining ground as global players look to India for both cost and capacity advantages.

3. Automotive components: Global OEMs are sourcing more from India as part of their localization strategies. Tier 1 and Tier 2 suppliers increasingly use contract manufacturing in India to expand quickly.

4. Food and FMCG co-packing: D2C food and FMCG brands use local co-packers to bottle, label, and package products, speeding time-to-market without heavy investment.

Policy Push

1. Programs like Make In India and PLI (Production Linked Incentive) are fueling expansion, giving manufacturers the incentives to add capacity.

2. A more streamlined GST framework and new logistics infrastructure are reducing bottlenecks in supply and distribution.

3. National priorities around reducing import dependence in electronics, defense, and renewable energy are creating new opportunities for SMEs to collaborate with Indian contract manufacturers.

What It Means for SMEs Outsourcing Locally

- By outsourcing locally, SMEs reduce lead times and decrease their reliance on overseas suppliers.

- Access to advanced manufacturing technology and certifications becomes easier without making significant capital investments.

- With the policy push driving certified and capable contract manufacturers into the ecosystem, SMEs now have better choices than ever before when it comes to local outsourcing.

Kladana Integration: Run Contract Manufacturing Smoothly

Managing a contract manufacturer means staying on top of forecasts, quality, and costs, not just placing orders. Kladana ERP gives you the digital backbone to coordinate all of this in one system:

1. Tie forecasts to POs & jobs: Convert sales forecasts into purchase and production plans for your contract manufacturer. Track confirmations and Advance Shipment Notice directly inside Kladana.

2. Receivings & quality: Record Good Receipt Note from CM deliveries, log defects or returns, and reconcile against purchase orders.

3. Cost tracking: Compare planned vs actual costs, including materials, labour, and waste, to protect your margins.

4. Visibility: View stock and WIP across multiple locations, such as your own site, plus the CM’s warehouse or shop floor, all in one single dashboard.

5. Custom workflows & statuses: Use configurable statuses, custom print forms, and adapt the production flow to match your CM partner’s operations.

6. Supply & Inventory alignment: Use MRP to plan material orders, adjust raw material usage, or finished outputs mid-process if there’s variation.

With these capabilities, Kladana becomes more than an ERP. It provides you with end-to-end visibility and control over outsourced production, allowing you to scale with confidence by avoiding chaos.

🚀 Scale with CMs minus chaos — forecasts, costs, and QA in one place

From forecasts to quality checks, manage every step of outsourced production in Kladana ERP and keep your growth under control

To Sum Up

Contract manufacturing provides a way to scale without incurring significant investments in factories or equipment. By outsourcing production, you can focus on your core strengths while still accessing advanced technologies and certifications.

At the same time, using a strong digital backbone ensures that BOM revisions, purchase orders, shipments, receipts, and costs stay aligned across both your site and the contract manufacturer’s.

If you’re running an SME, hardware startup, or D2C brand, the takeaway is simple. Contract manufacturing can help you grow faster, but only if you maintain control over quality, cost, and visibility.

Frequently Asked Questions on Contract Manufacturing

What is Contract Manufacturing?

Contract manufacturing is when you outsource production to a specialist company that makes your product based on your design and specifications. You keep ownership of the brand and intellectual property, while the manufacturer provides the facilities, equipment, and labour.

How is OEM different from manufacturing?

With OEM, the manufacturer produces your design under your brand but may influence production methods and materials. In contract manufacturing, the partner only follows your detailed specifications, giving you more control over the final product.

What are the top benefits of contract manufacturing for SMEs?

The most significant benefits included reduced capital investment, faster time-to-market, scalable production capacity, access to advanced technology and certifications, and the ability to focus on core strengths such as design and marketing.

What are the most significant risks, and how can they be managed?

Risks include quality drift, intellectual property leakage, supply dependence on a single partner, and hidden costs. These can be managed with clear agreements, quality audits, strong IP protection, and by working with more than one manufacturing partner.

Which industries commonly use contract manufacturers?

Industries like electronics, automotive components, plastics molding, medical devices, pharmaceuticals, and FMCG/food brands rely heavily on contract manufacturers to scale production quickly and cost-effectively.

What should be included in a manufacturing contract?

A good contract should include service-level agreements, a clear quality control plan, defined ownership of tooling and molds, IP protection terms, processes for design changes, cost transparency, and audit rights.

How do OEMs ensure quality at a CM site?

OEMs often utilize structured quality systems, such as APQP (Advanced Product Quality Planning) and PPAP (Production Part Approval Process), as well as on-site audits, to verify that the manufacturer meets agreed-upon standards before and during mass production.

What’s the difference between EMS, ODM, and CM?

- EMS focuses on assembling electronic products like Printed Circuit Boards and devices

- ODM provides ready-made product designs that you can brand with limited customization

- CM produces your own design with complete control over specifications and IP

Does contract manufacturing always reduce time-to-market?

It often accelerates launches because you avoid setting up your own factory. However, it may not save time when complex tooling, regulatory approvals, or long product validation cycles are required before it can start.

What is the outlook for contract manufacturing in India?

India is emerging as a strong hub for contract manufacturing, with growth in electronics, pharma/CDMOs, auto parts, and FMCG co-packing. Government initiatives like Make in India and PLI schemes are pushing expansion, creating more reliable local options for SMEs.

List of Resources

- Grand View Research: Pharmaceutical Contract Manufacturing Market

- Deloitte: Global Outsourcing Survey 2024

- KPMG: Contract Manufacturing Overview

Read‑alikes

How to Estimate Manufacturing Costs: Methods, Tools, and Best Practices

Closed-Loop Manufacturing: How Real-Time Data is Powering Smart Factory Operations

Production Control Plan: from Prototype to Production with Templates & Compliance

23 Best ERP Software for Manufacturing in India: 2026 Update

Revolutionizing Manufacturing: The Impact of Automation in Manufacturing on Production Processes