Walk into any warehouse that runs on spreadsheets and handovers. Chances are, you’ll find the same signs: pallets parked in the wrong zones, delayed dispatches, stock mismatches, and staff rechecking the same order twice.

It’s not because the teams aren’t working hard. But it can be due to issues in mapping the flow. It’s often not mapped, tracked, optimized, or automized.

According to Statista, the warehouse automation market is projected to grow to $41 billion by 2027.

A proper Warehouse Management System (WMS) automates warehousing procedures, building a live, trackable process across inbound, storage, and outbound operations.

No loose ends. No mental checklists. Just operational clarity. And that’s exactly what we’ll explore ahead. Read on to have a clear breakdown of how WMS process flows work, the SOPs behind them, and real examples you can apply right away.

What is a Warehouse Management System (WMS)?

A WMS is a software that reflects your warehouse on screen to have a quick, comprehensive view of every incoming box, every shelf position, and every outgoing shipment.

You don’t just track but get to set the pace, prevent manual misses, and leverage control over how goods move from point A to point B.

How a WMS supports your day-to-day

- Inbound receiving: Auto-checks POs and flags quantity mismatches.

- Putaway logic: Finds best-fit locations based on volume, item type, or zones.

- Storage updates: Logs where each SKU sits and how much is left, in real time.

- Order picking: Assigns pickers based on routes, zones, or speed logic.

- Packing & shipping: Pulls the right label formats and carrier details instantly.

- Returns & restocks: Marks condition, triggers inspection, routes back to bins or quarantine.

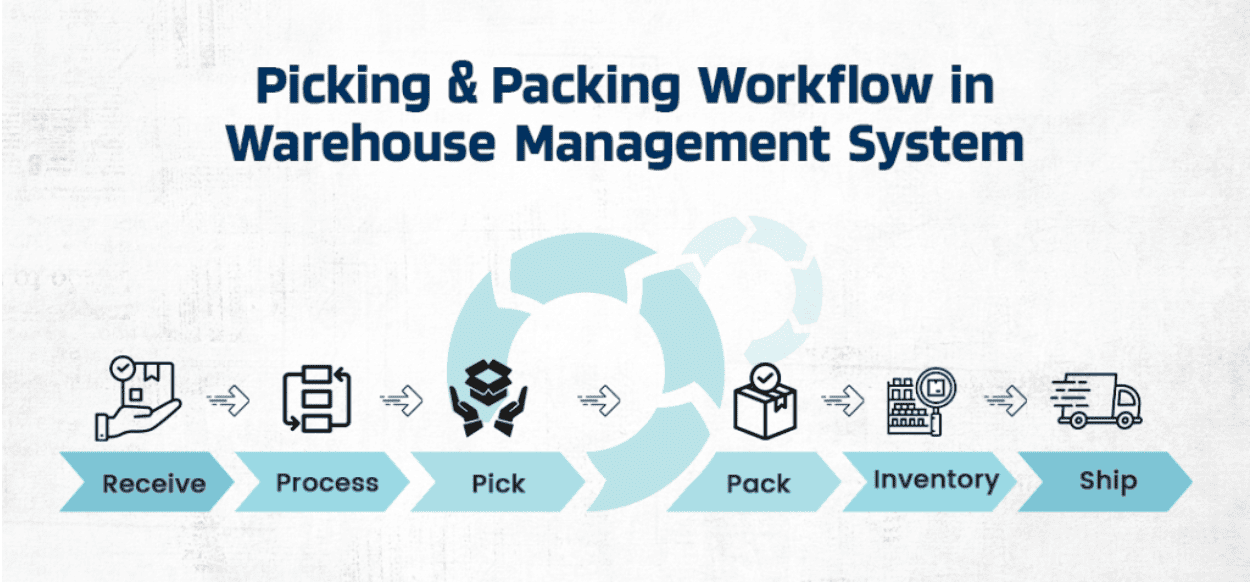

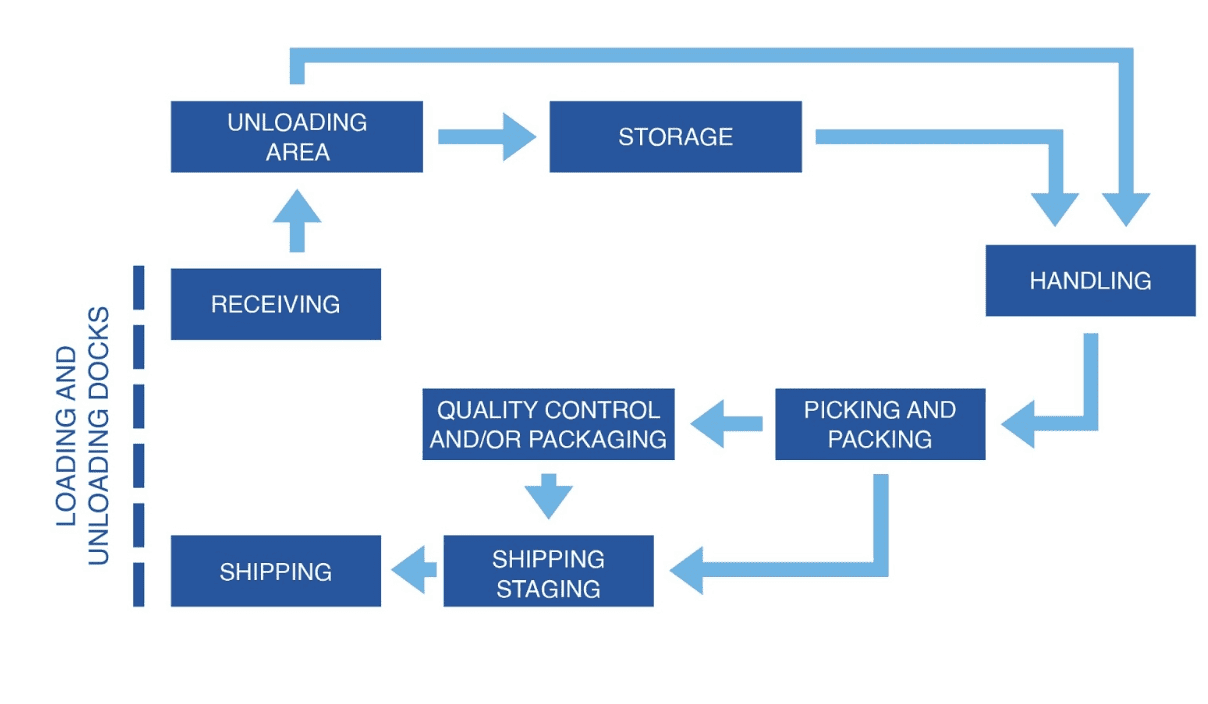

Complete Warehouse Management System Process Flow

A warehouse functions like a circuit where every order, return, or pallet movement is a signal. If the circuit isn’t well-mapped, things misfire: delays creep in, wrong SKUs go out, and stock reports start lying.

Here’s a more detailed look at the steps involved in the warehouse management system.

1. Receiving and Inspection

Your team scans arriving pallets or cartons against purchase orders.

The WMS logs quantities and flags mismatches on the spot. Damaged or incorrect items can be quarantined before they clog your system.

How it works:

- Match goods against purchase orders (POs) using barcode scans.

- Flag discrepancies in quantity or damaged goods.

- Create GRNs (Goods Received Notes) for accepted items.

- Update the system with the received SKU count + condition.

A modern WMS can link this directly to suppliers and inventory, so what you scan is what you stock.

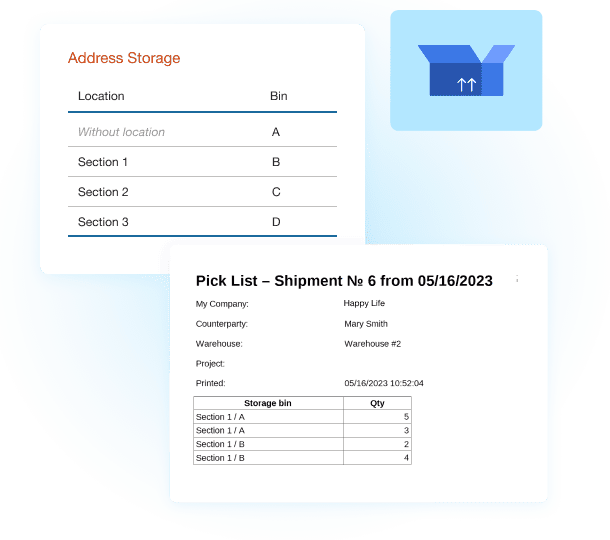

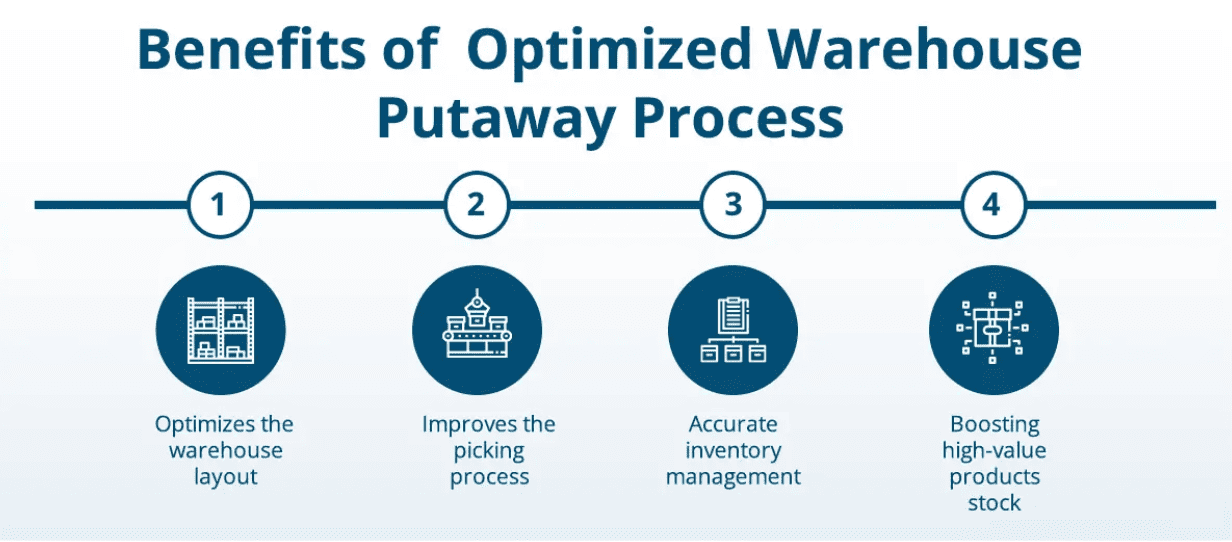

2. Putaway

The system suggests optimal storage based on item size, weight, and slot availability.

Your staff picks up a scanner, follows the putaway route, scans the bin, and moves the item. The WMS marks that bin as occupied and adjusts the inventory in real time.

Key action items for this step:

- Use dynamic slotting rules (weight, size, frequency) to assign ideal bins.

- Show staff optimized routes via handheld devices.

- Auto-update inventory location in real-time.

- Trigger restock flags if overflow areas are used.

3. Inventory Storage

Once goods land in bins or racks, the system keeps track.

Real-time data tells you exactly how much stock is left. You don’t need manual counts. Instead, cycle counts become quick spot checks, not full-blown disruptions.

Here’s what goes on:

- Maintain real-time location mapping of every SKU.

- Track bin utilization and flag congestion zones.

- Schedule cycle counts instead of full shutdown stocktakes.

- Use system alerts for expiry, FIFO/LIFO compliance, or reorder points.

4. Order Picking

When a new order arrives, the WMS divides it into picking tasks based on zones or batch logic.

Pickers grab mobile scanners, follow the route, scan each item, and confirm picks in one seamless workflow. A WMS guides pickers to the right locations with the right lists, reducing foot travel and order errors.

The work involves:

- Assign picklists using zone-based or batch picking logic.

- Use barcode scanners or mobile devices for guided navigation.

- Trigger real-time stock deductions with each scan.

- Prioritize urgent or multi-channel orders with system rules.

5. Packing

Here, picked items are verified, grouped, and prepared for dispatch.

At this stage, the items go to the packing station where WMS pulls the right packaging specs, prints labels, and triggers any custom paperwork.

What work goes into here:

- Match scanned SKUs against customer orders.

- Generate auto-printed packing slips and labels.

- Apply carrier-specific packaging rules (e.g., DHL vs. FedEx).

- Trigger weight checks or volume validation via integrated devices.

6. Shipping

The system generates shipping labels, book carriers, and records tracking numbers.

As soon as the package leaves the dock, the WMS updates inventory, ends the order cycle, and feeds data to your ERP system or ecommerce portal.

Major action items at this stage:

- Allocate shipments based on carrier rules or SLAs.

- Print shipping labels, bills of lading, and manifests automatically.

- Push order tracking info to customers and platforms.

- Hand off to the carrier with proof of shipment scan.

7. Returns and Replenishment

Returned units get scanned at the receiving dock and routed based on status. If restockable, the WMS places them back into available bins.

How it works:

- Scan returned items and verify against RMA (return) tickets.

- Trigger QA checks or sort for repair/discard.

- Auto-update restockable inventory bins.

- Notify replenishment if the stock dips below safety levels.

A ready reckoner below can be handy when following a WMS process.

| Stage | Key Actions | WMS Automation/Support |

1. Receiving |

– Match goods to Pos |

– Barcode scan POs |

2. Putaway |

– Assign storage zones |

– Smart slotting logic |

3. Inventory Storage |

– Monitor SKU locations |

– Live location mapping |

4. Picking |

– Generate picklists |

– Zone/batch logic |

5. Packing |

– Match picks to orders |

– Auto label print |

6. Shipping |

– Allocate to the carrier |

– SLA-based carrier rules |

7. Returns & Replenishment |

– Scan returns |

– RMA scan |

Managing a warehouse is more than moving stock. It’s about tracking every item from arrival to dispatch with zero blind spots. Kladana’s warehouse management features are designed to mirror real-world workflows, making it easy for your team to scan, store, pick, pack, and ship with accuracy and speed.

Recommended read: Revolutionizing WMS Efficiency: Smart Warehouse Barcoding — Upgrade your WMS with barcoding. Discover why just 10% of items are barcoded, explore barcode drones and wearables, and follow a clear step-by-step guide.

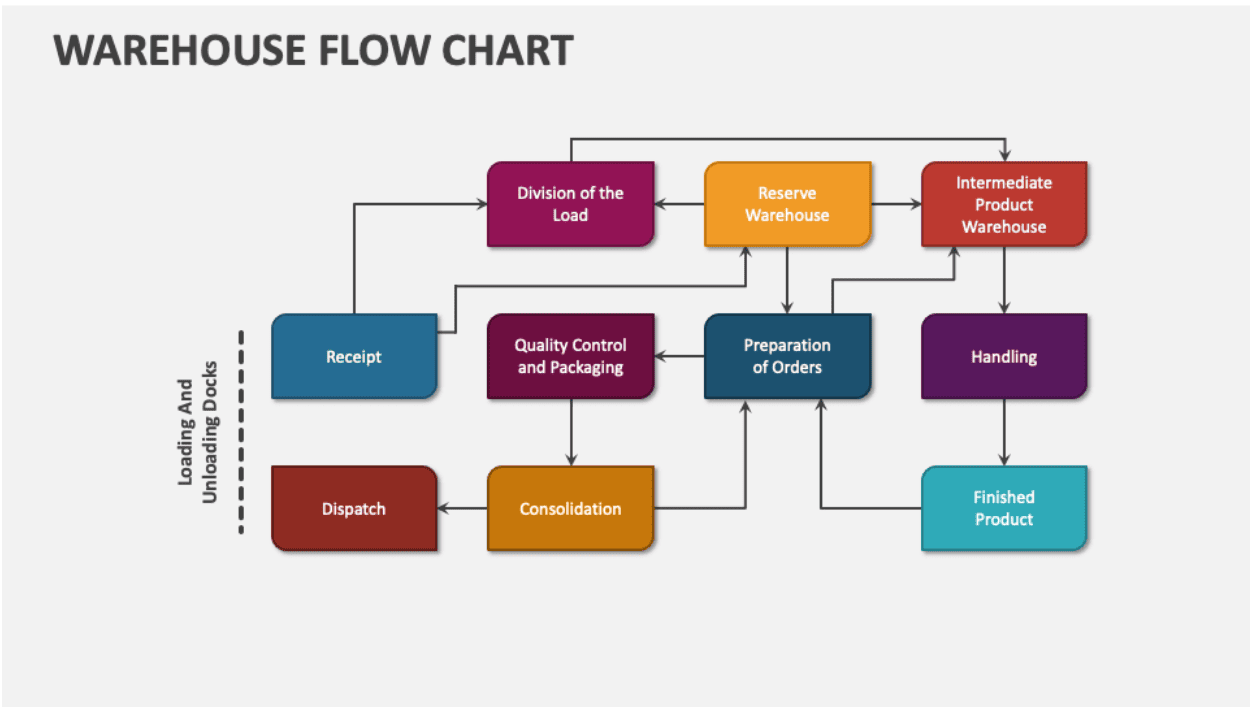

Warehouse Process Flowchart Example

Let’s see what a warehouse flowchart looks like. This is needed for quick decision-making so that teams can map movement, identify bottlenecks, and assign roles.

Receipt (Blue)

Incoming goods land here so that teams can verify quantities and conditions before progressing.

Division of the Load (Pink)

Bulk shipments get split based on product type, destination, or handling needs.

Reserve Warehouse (Yellow)

Stock that isn’t needed right away goes here.

Intermediate Product Warehouse (Red)

Used for semi-finished or high-turnover goods that need quick access.

Preparation of Orders (Dark Blue)

Pulls SKUs needed for each order. May involve batch picking or zone picking strategies.

Quality Control and Packaging (Pink)

This is to make sure that each order meets standards for boxing, labeling, sealing, etc.

Handling (Purple)

Highlights the movement between zones that involve conveyors, forklifts, or manual carry.

Finished Product (Teal)

Final packed goods marked as ready for dispatch.

Consolidation (Orange)

Combines items from different orders or suppliers before final shipment.

Dispatch (Dark Red)

Final loading for outbound logistics. Links to delivery tracking and carrier pickups.

Color-Coding Logic

Each color signals the type of operation:

- Blue/Dark Blue: Start/end points (receipt, picking)

- Pink: Quality or manual checkpoints

- Yellow: Long-term storage

- Red: High-priority or fast-moving storage

- Purple: Internal movement/handling

- Teal: Finished goods ready for outbound

- Orange: Transition stages

- Dark Red: Final dispatch/exit point

Warehouse SOP Flowchart

Standard Operating Procedures (SOPs) for the warehouse help everyone from new joiners to warehouse veterans follow the same playbook.

The SOP flowchart provides step-by-step instructions that assign clear responsibility at every stage.

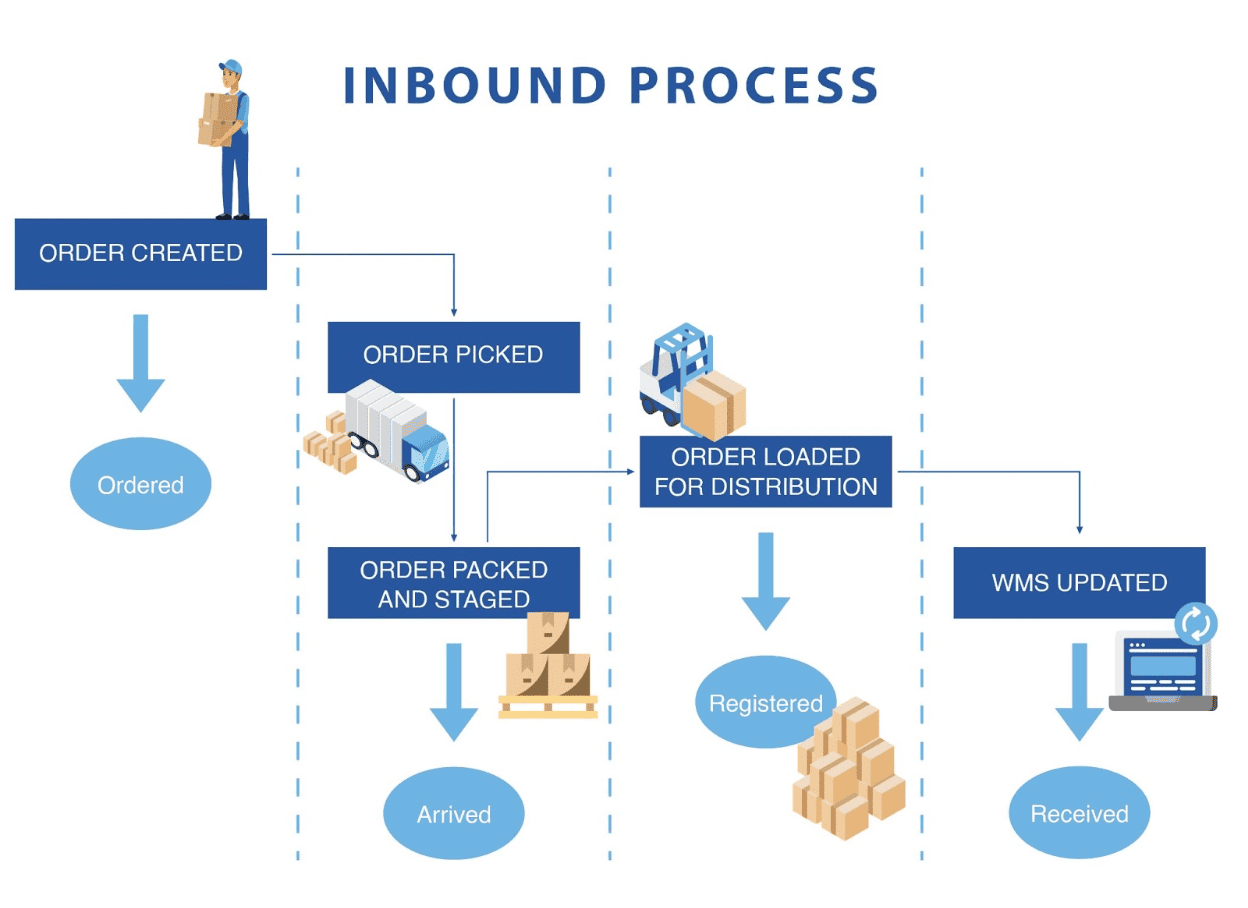

Example SOP flow for inbound and outbound tasks

Let’s take a closer look at how the SOP flowchart is prepared for inbound and outbound tasks through an example.

Example: Inbound SOP Flow

Each step flows into the next, with defined owners and WMS triggers at the right checkpoints.

Here’s how an inbound shipment SOP might look:

- Gate Entry & Document Check — Security Guard

- GRN Verification — Receiving Team

- Barcode Scanning & Item Count — Warehouse Associate

- Damage Check & Flagging — Quality Control

- Putaway Instructions — WMS System

- Putaway Execution — Floor Staff

Example: Outbound SOP Flow

This SOP flow is to keep the accountability high and trace back delays or mismatches to the exact steps.

For a typical outbound process:

- Sales Order Generation — Sales Ops

- Picking Task Assignment — WMS

- Order Picking — Picker

- QC Scan & Match — QA Associate

- Packing & Labeling — Packing Staff

- Handover to Carrier — Dispatch Team

Benefits of Mapping WMS Process Flow

When warehouse teams can see their entire workflow on screen, they work with more clarity and fewer errors.

Mapping the WMS process brings the hidden gaps to light and creates a visual guide for what should happen, when, and by whom.

Here’s how that helps day to day:

Fewer manual errors

Mapped processes help eliminate the guesswork so that the staff doesn’t have to rely on memory or verbal instructions.

That alone cuts down on duplicate scans, misplaced stock, or skipped checks.

Improved accountability and consistency

When everyone’s role is visible, the team members know where their part starts and ends, so there’s less room for crossed wires or delays in handovers.

It’s because each step is linked to a specific role, and there’s no back-and-forth over “who was supposed to do what.”

Faster onboarding and scaling

New hires get a visual guide to learn from without shadowing subordinates for weeks.

As the business grows, that same map helps you scale operations without reinventing how the warehouse runs.

Optimizing the WMS Flow with Automation

If you’re only dealing with the manual WMS flow, then even a well-documented process won’t deliver speed or scale. But then, adopting automation does not replace people but takes repetitive tasks off their hands, enabling them to work with speed and certainty.

Here’s how you can optimize the way WMS functions with automation.

1. Use of scanning tools to eliminate friction

Barcode scanners, RFID tags, and handheld mobile devices do more than just track inventory. They actively influence the speed and accuracy of inventory management in the following ways:

- RFID or barcodes spare you from manually entering SKUs or locations.

- Mobile scanning tools also reduce the physical movement of workers.

2. Integration bridges the warehouse and the back office

Integrated systems remove the lag between warehouse activity and backend updates. The inventory can thus get updated in real-time because of:

- A WMS syncs with ERP and inventory platforms to make sure that any update (received pallet or a packed order) is instantly reflected across systems.

- Auto-generated alerts keep teams in sync with low stock trigger restock, confirmed picks, close orders, and more.

3. Dashboards turn movement into insight

Dashboards aid live decisions, giving warehouse leads a top-down view of incoming loads, pending picks, and stuck shipments.

The decision-makers get a floor-wide lens and the data due to the following reasons:

- Picking rates are tracked along with zone congestion and stalled orders.

- Visual cues like color-coded delays or fast-moving SKUs help managers redeploy staff or tweak priorities mid-shift.

FAQs on the Warehouse Management System Process

Let’s address some of the key questions around the warehouse management system process flow.

What is the standard process flow in a warehouse?

A typical process flow involves receiving, inspection, putaway, storage, picking, packing, shipping, and handling the returns.

How do WMS systems improve process flow?

They automate routine tasks, track inventory in real time, and remove manual steps that cause delays or errors.

Can I customize the warehouse SOP flowchart?

Yes, SOPs should reflect your team structure, layout, and product types. Most WMS platforms allow custom workflows.

What tools are used in warehouse automation?

Barcoding, RFID, mobile scanners, conveyor systems, and integrated WMS-ERP platforms are common tools.

How is inventory tracked in a WMS?

Each item is tagged and scanned at every stage, and your WMS logs quantity, location, and movement in real time.

What’s the difference between inbound and outbound processes?

Inbound handles receiving and putaway; outbound covers picking, packing, and dispatching customer orders.

Do I need a WMS for a small warehouse?

Yes. Even small warehouses benefit from reduced errors, faster processing, and easier scaling with WMS.

Can I monitor warehouse performance using WMS?

Yes. Dashboards display real-time KPIs like order accuracy, pick speed, and inventory turnover.

Is barcode scanning enough for full automation?

Not always. Barcode scanning is essential, but it works best when combined with real-time data sync and alerts.

How long does it take to implement a WMS process flow?

It depends on warehouse size and complexity, but most mid-sized operations can go live in 6–12 weeks.

List of Resources

Statista — Size of the warehouse automation market worldwide from 2023 to 2027