Manufacturing ERP software is essential for businesses aiming to enhance efficiency and competitiveness. These systems integrate core operations — such as production planning, inventory management, procurement, and quality control — into a unified platform, providing real-time visibility and control across the manufacturing process.

According to Precedence Research, the global ERP software market is projected to grow from $59.42 billion in 2025 to approximately $110.15 billion by 2034, reflecting a compound annual growth rate (CAGR) of 7.1%. This growth is driven by the increasing adoption of cloud-based solutions and the need for streamlined operations.

AIMultiple states that manufacturers represent the largest segment of ERP adopters, accounting for 47% of companies seeking to implement ERP systems. This trend underscores the critical role of ERP in addressing the complex needs of the manufacturing sector.

Whether you’re an SME aiming to scale operations or a large manufacturer seeking to optimize complex workflows, selecting the right ERP for manufacturing is crucial. In this guide, we’ve curated the 15 best ERP software for manufacturing, highlighting their features, benefits, and suitability for various business sizes and industries.

- What Is Manufacturing ERP?

- Key Features of ERP for the Manufacturing Industry

- Benefits of Implementing ERP in Manufacturing

- Top 15 Manufacturing ERP Software

- How to Choose the Right ERP for Your Manufacturing Business

- Signs Your Manufacturing Company Needs an ERP System

- Standard ERP vs. Manufacturing ERP

- Types of ERP Systems for Manufacturing

- Why Manufacturers Choose Kladana ERP

- FAQs about Manufacturing ERP

- List of Resources

What Is Manufacturing ERP?

Manufacturing ERP (Enterprise Resource Planning) is a specialized software system designed to manage, automate, and integrate all core manufacturing processes within a single platform. It gives businesses real-time visibility and control over everything from procurement and production to inventory and delivery.

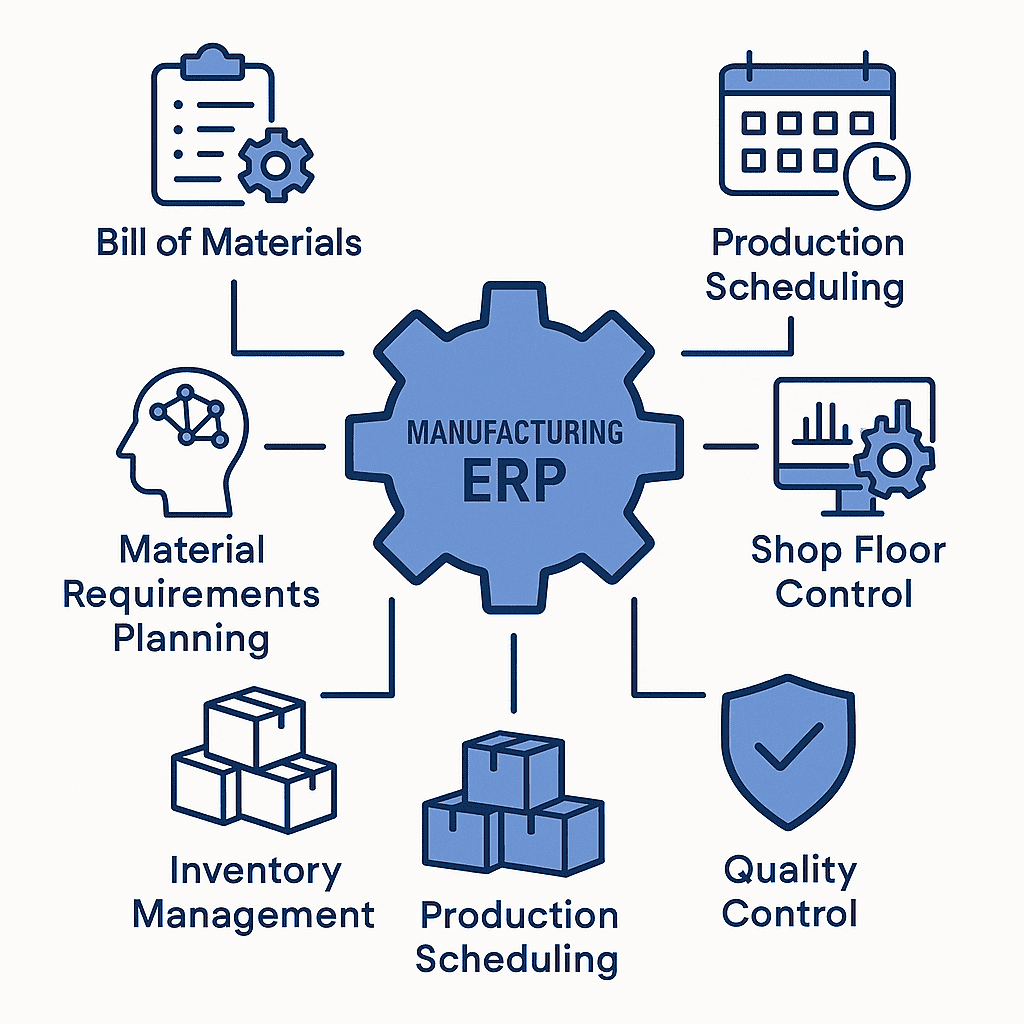

Unlike general-purpose ERP systems, manufacturing ERP software is tailored specifically for production environments. It typically includes critical components such as:

- Bill of Materials (BOM) — to define product structure and calculate cost

- Material Requirements Planning (MRP) — to ensure materials and components are available for production

- Inventory Management — to track raw materials, work-in-progress, and finished goods across locations

- Shop Floor Control — to monitor and manage production operations in real time

- Production Scheduling — to plan, prioritize, and assign tasks efficiently

- Quality Control and Compliance — to ensure standards are met throughout the production lifecycle

Modern ERP systems for manufacturing often integrate with other business tools like CRM, HRM, accounting, and warehouse management systems. This creates a unified ecosystem that enhances collaboration, reduces manual errors, and improves decision-making across departments.

Key Features of ERP for the Manufacturing Industry

A robust manufacturing ERP system goes beyond basic resource planning — it helps manufacturers control every step of the production lifecycle. Below are the essential features to look for when evaluating ERP solutions for manufacturing.

🏭 Production Planning & Control

Plan and schedule production runs efficiently to reduce downtime and meet delivery timelines. ERP software helps allocate resources, prioritize jobs, and track progress on the shop floor.

🧾 Bill of Materials (BOM) Management

Create and manage multi-level BOMs, including sub-assemblies and cost breakdowns. This is essential for accurately tracking materials and planning production workflows.

Example: Kladana’s BOM module allows easy setup, cost estimation, and tracking for every product component.

📦 Inventory & Raw Material Management

Maintain optimal inventory levels by tracking raw materials, WIP, and finished goods in real time. ERP systems automate reorder points, reduce stockouts, and prevent overstocking — saving both space and money.

📊 Material Requirements Planning (MRP)

Forecast material needs based on demand, BOM, and production schedules. MRP ensures that you procure the right materials at the right time, helping avoid delays and waste.

🛠️ Shop Floor Control

Monitor production orders, equipment status, and employee performance. Real-time shop floor tracking improves productivity and gives operations managers complete visibility.

✅ Quality Management

Track inspections, record non-conformance, and maintain compliance with industry regulations. ERP software for manufacturing often includes quality checkpoints across stages like procurement, assembly, and shipping.

🔗 Supply Chain Visibility

Gain end-to-end visibility across your supply chain — from procurement and inbound logistics to production and final delivery. ERP systems connect vendor data, lead times, and stock availability to improve planning and reduce disruptions.

📈 Reporting & Analytics

Generate real-time reports and dashboards on production efficiency, inventory turnover, material usage, and profitability. Analytics help identify bottlenecks and support better business decisions.

💵 Financial Integration

Link production and inventory data to your accounting system for real-time cost tracking, budgeting, and profitability analysis.

🔄 Workflow Automation

Automate repetitive tasks, set up approval workflows, and standardize processes. This ensures consistency and saves hours on manual operations.

🧰 Preventive Maintenance Scheduling

Schedule and manage routine maintenance to reduce machine downtime and extend asset life. ERP alerts can help avoid costly production halts due to unexpected failures.

Benefits of Implementing ERP in Manufacturing

Implementing a robust manufacturing ERP system offers far more than operational convenience — it brings measurable improvements in cost control, efficiency, and traceability. By integrating core functions such as production, inventory, and procurement into a unified platform, ERP software for manufacturing helps businesses run smarter and scale faster.

Here are the key benefits of ERP for the manufacturing industry:

- Cost Savings: ERP systems reduce manual tasks, eliminate duplicate data entry, and improve resource allocation. By automating procurement, inventory, and production workflows, manufacturers can significantly cut administrative and operational costs.

- Improved Efficiency: With real-time data and process automation, manufacturing ERP software streamlines operations across departments. From scheduling and inventory control to maintenance and dispatch, everything becomes faster, more coordinated, and easier to track.

- Reduced Waste and Downtime: Optimized production planning and material requirements planning (MRP) help minimize overproduction, stock obsolescence, and machine idle time. The result: less waste and more sustainable operations.

- Better Inventory & Supply Chain Control: Accurate demand forecasting and live inventory tracking prevent shortages and overstocking. ERP enhances collaboration with suppliers and ensures timely deliveries through automated order and stock management.

- Enhanced Traceability & Compliance: Track every raw material, batch, or serial number from procurement to finished goods. This traceability ensures regulatory compliance and enables fast, accurate recalls if needed.

- Real-Time Insights for Better Decisions: With centralized dashboards and advanced analytics, managers gain immediate visibility into performance metrics — from production efficiency to financial KPIs. This supports more confident, data-driven decision-making.

Top 15 Manufacturing ERP Software

Now that we’ve covered what manufacturing ERP software is and how it benefits production businesses, it’s time to explore the leading solutions available. Below is a quick comparison of the top 15 ERP systems for manufacturing, helping you evaluate the best fit based on features, scalability, pricing, and industry focus.

📅 Latest update: May 14, 2025 — All pricing, features, and platform details have been reviewed and refreshed to reflect the most current information.

| Software Name | Pricing (Year) | Score | MRP | Multi-Level BOMs | Progress Monitoring | Shop Floor Control | Quality Control | Subcontracts | Payrolls | CRM | OMS | Customization | Deployment | ||

| Cloud | Desktop | Mobile | |||||||||||||

| Kladana | $60–748 |

⭐⭐⭐⭐⭐ (5.0) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| SAP | Custom quotation |

⭐⭐⭐⭐ (4.8) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Oracle | Custom quotation |

⭐⭐⭐⭐ (4.7) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Microsoft Dynamics 365 | $840–1,200 per user |

⭐⭐⭐⭐ (4.7) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Acumatica | Custom quotation |

⭐⭐⭐⭐ (4.6) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Infor SyteLine | Custom quotation |

⭐⭐⭐⭐ (4.6) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Sage X3 | Custom quotation |

⭐⭐⭐⭐ (4.6) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| IFS | Custom quotation |

⭐⭐⭐⭐ (4.6) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Plex | Custom quotation |

⭐⭐⭐⭐ (4.5) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

❌ |

✅ |

| Odoo | $345–517+ per user |

⭐⭐⭐⭐ (4.5) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| QAD Adaptive ERP | Custom quotation |

⭐⭐⭐⭐ (4.4) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Eresource | $282+ |

⭐⭐⭐⭐ (4.3) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| VasyERP | Custom quotation |

⭐⭐⭐⭐ (4.2) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Absolute ERP | Custom quotation |

⭐⭐⭐⭐ (4.2) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Zoho | $108–337+ |

⭐⭐⭐ (3.8) |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

Kladana — Overview

A cloud‑based ERP solution where small and medium‑sized manufacturers can leverage its dedicated modules. It can be used to simplify operations with its inventory control, production management, and financial tracking features.

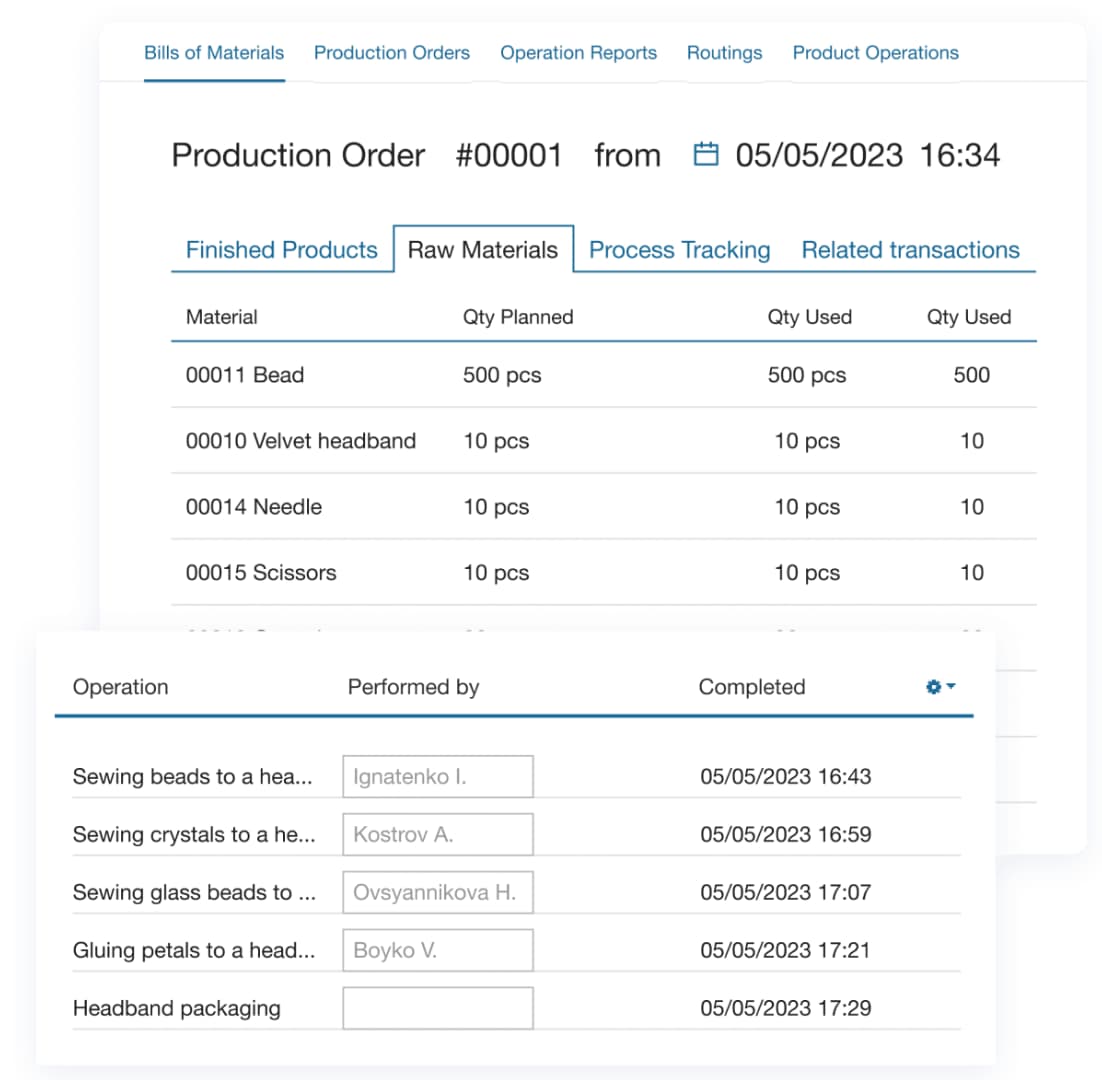

Key Features

- Production Management: Create and manage multi‑level Bills of Materials (BOMs) and track work‑in‑progress.

- Inventory Control: Real‑time stock tracking and automated reordering to prevent stockouts.

- Order Management: Simplifies order processing, tracking, and fulfillment.

- Workflow Automation: Automate routine tasks to save time and reduce manual errors.

- CRM for Manufacturing: Manage customer relationships, monitor buying patterns, and create personalized offers.

Pros & Cons

Here are some pros & cons of adopting Kladana as your manufacturing ERP:

Pros:

- Affordable, ideal for small & medium businesses and startups

- Includes Shop Floor App for real-time task tracking by production staff

- Rich set of production features: multi-level BOMs, progress tracking, subcontractor management, partial production, and multi-location support

- Cloud-based access with intuitive inventory and production management

- Integrates smoothly with tools like Shopify, Xero, etc.

Cons:

- Not designed for large-scale manufacturing operations or complex enterprise workflows

- No dedicated mobile app

Pricing

Starts at $60/year.

Get a feel of Kladana’s state of the art manufacturing ERP software. Take a free product tour and explore the features.

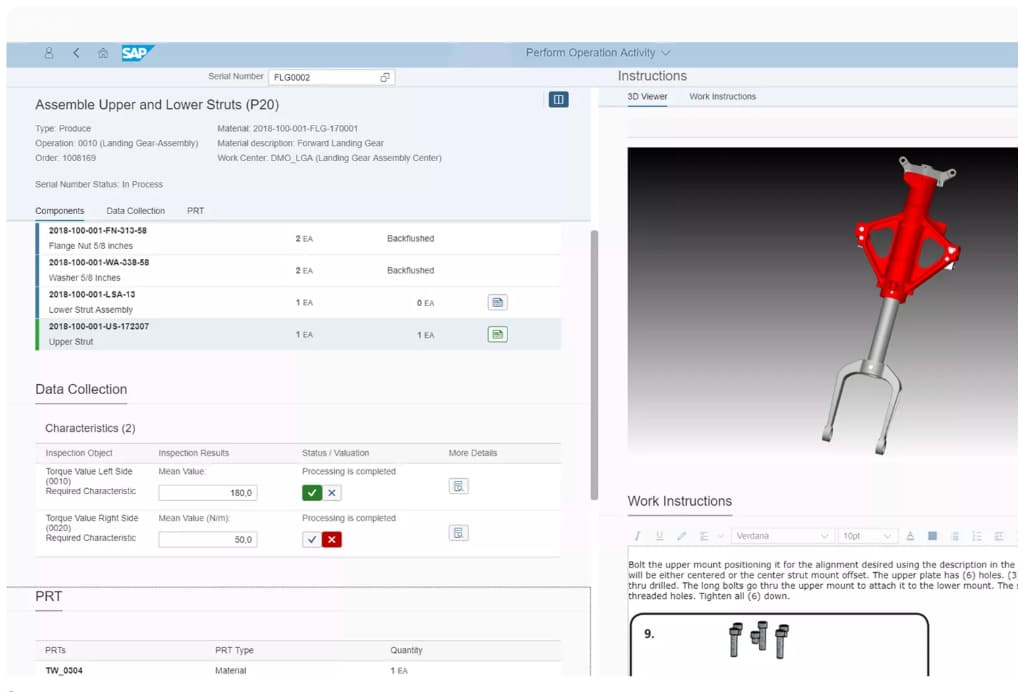

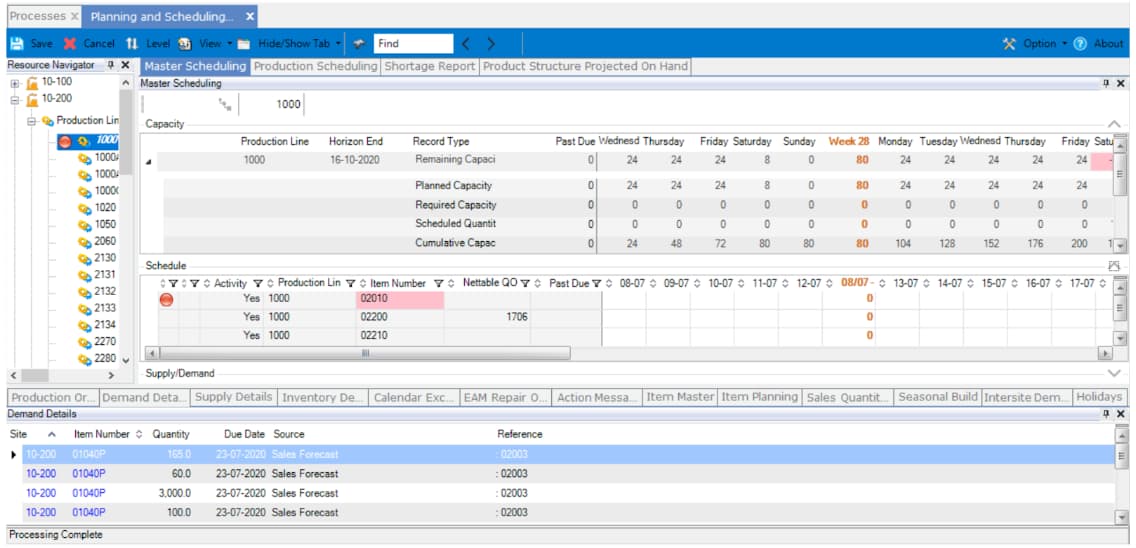

SAP — Overview

Suitable for large‑scale manufacturing environments needing robust production planning, scheduling, and operations management capabilities. Manufacturers can optimize every aspect of production by integrating planning, execution, and analytics within a unified platform.

Key Features

- Advanced Production Planning: Exception‑based planning and detailed scheduling that relies on real‑time capacity and resource constraints.

- Integrated Supply Chain Management: Connects demand forecasting, material procurement, and shop floor execution.

- Digital Manufacturing Collaboration: Ensures collaboration across design, engineering, and production teams.

Pros & Cons

Here are some pros and cons of using S/4HANA as a manufacturing ERP:

Pros:

- Ideal for complex production environments requiring multi‑site and global collaboration

- Built‑in analytics and automation features that support advanced manufacturing setups

- Provides real‑time visibility and control over the entire supply chain

- High degree of customization available, especially in on-premise deployments

Cons:

- High cost and complexity make it better suited for large enterprises

- Requires a skilled implementation team for deep customization and performance

- Can get too complex for smaller businesses and hence is ideal only for highly scalable manufacturers

Pricing

Custom quotation based on request

Oracle NetSuite for Manufacturing — Overview

This cloud‑based ERP solution is designed for manufacturers that need to manage complex production processes. It provides end‑to‑end visibility into production, inventory, and supply chain activities for improved decision‑making.

Key Features

- Order Management: Automates order‑to‑cash processes for accurate order tracking and fulfillment.

- Quality Management: Built‑in tools help define inspection plans and track quality metrics.

- Demand Planning: Forecasts customer demand and aligns production schedules to avoid overproduction and stockouts.

Pros & Cons

Let’s check the pros and cons:

Pros:

- Suitable for both small and large manufacturers

- Advanced features for global supply chain management and multi‑location support

- Cloud deployment reduces the need for heavy IT infrastructure

Cons:

- Higher costs may limit it to larger‑scale businesses

- A steep learning curve for first‑timers

- Complex implementation

Pricing

Custom pricing on request.

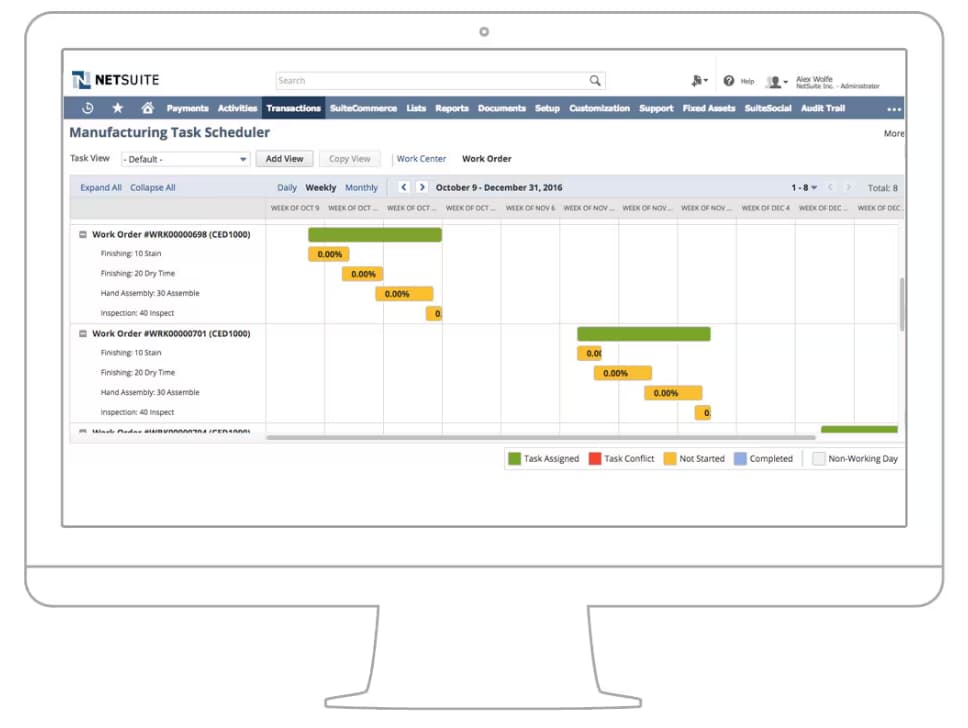

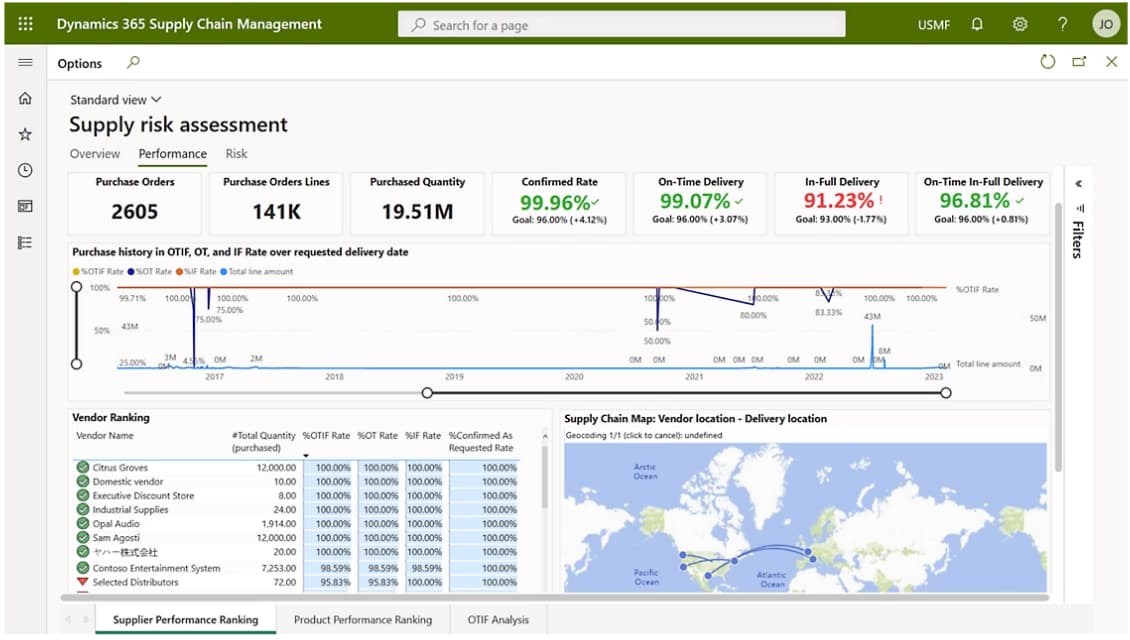

Microsoft Dynamics 365 — Overview

Microsoft Dynamics 365 Supply Chain Management (SCM) is a comprehensive ERP solution providing manufacturers with the tools to optimize production. It can improve supply chain efficiency and provide real‑time visibility into operations.

Key Features

- MES Integration: Connects with third‑party Manufacturing Execution Systems (MES) that eliminate data silos.

- IoT and AI‑Driven Operations: Leverages machine learning and IoT to predict maintenance needs.

- Advanced Analytics with Power BI: Delivers real‑time data and insights to identify trends and make informed decisions.

Pros & Cons

Let’s review some pros and cons of this software:

Pros:

- Rich set of features for end‑to‑end supply chain management

- AI and IoT integrations support intelligent decision‑making and predictive maintenance

- Powerful real‑time analytics to optimize production and logistics

Cons:

- Integrating with legacy systems or third‑party tools requires extensive configuration

- A high level of customization overhead needs a skilled technical team

Pricing

Starts at $210 user/month.

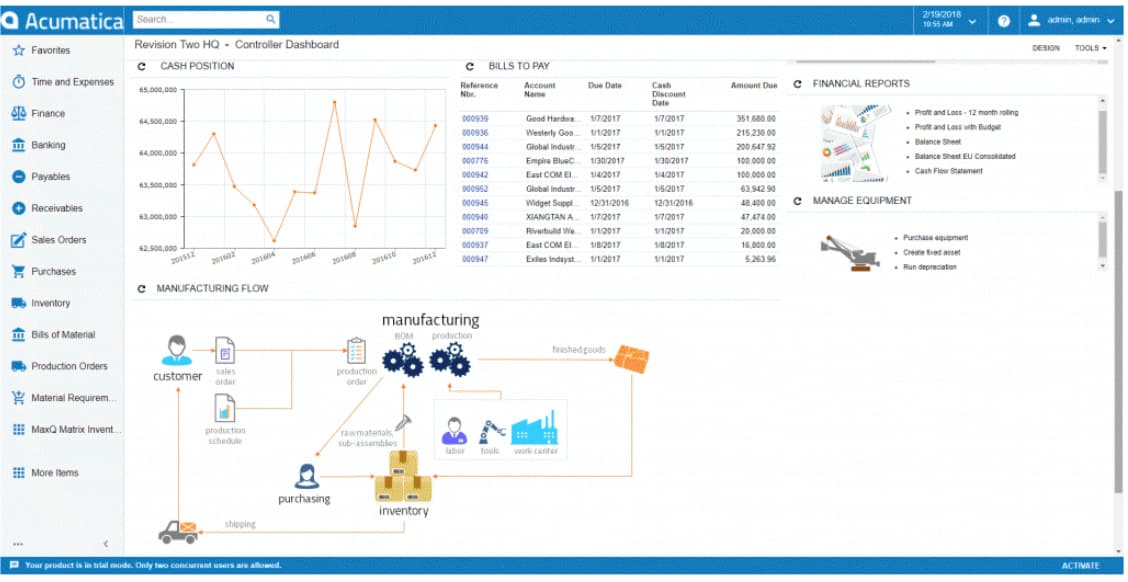

Acumatica — Overview

This one is a cloud‑based ERP solution designed to meet the unique needs of small and midsize manufacturers. It provides tools for different stages of production and has built‑in automation capabilities.

Key Features

- Supply Chain Visibility: Gives you transparency across the supply chain to optimize material flow and procurement.

- Inventory Tracking: Monitors inventory in real‑time, reducing the risk of stockouts and overproduction.

- Quality Control: Integrates quality checks into every production stage.

Pros & Cons

Let’s review some of its pros and cons:

Pros:

- Specifically tailored for small to mid‑sized manufacturers

- User‑friendly design makes adoption easy for teams with limited tech expertise

- Flexible integration with other business tools

Cons:

- Lacks advanced features required by larger enterprises

- High implementation costs that typically range from $25,000 to $200,000+, depending on complexity and customization

Pricing

On request.

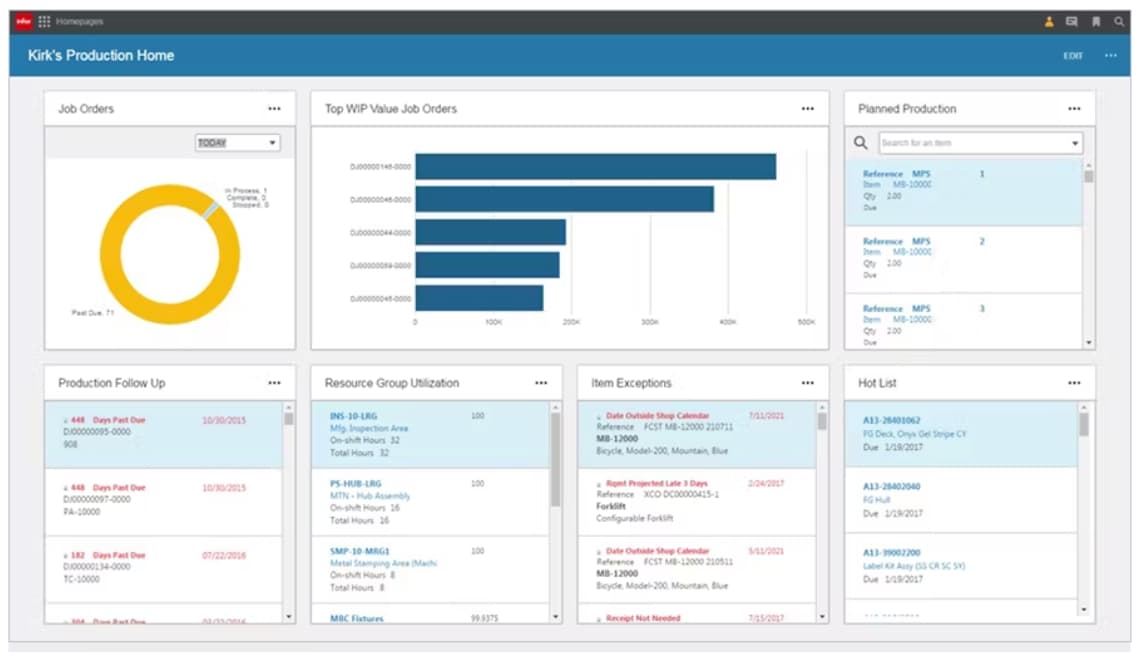

Infor SyteLine — Overview

Infor SyteLine (also known as CloudSuite Industrial) is an ERP solution built for manufacturing companies needing a range of production models. It’s a helpful tool with engineer‑to‑order, configure‑to‑order, and repetitive manufacturing features.

Key Features

- Material Requirements Planning (MRP): Converts materials requirements directly into purchase orders and jobs to ensure smooth production flows.

- Quality Management System (QMS): Tracks quality checks throughout the manufacturing cycle.

- Customizable Reporting with DataViews: Enables creating and saving personalized reports for easy analysis of material requirements.

Pros & Cons

Let’s review some of its pros and cons:

Pros:

- Extensive customization options to tailor the system for specific manufacturing needs

- Advanced features for production and material management

- Multi‑mode support for different manufacturing processes

Cons:

- Complex navigation between modules

- Limited advanced QMS functionality

Pricing

On‑request only.

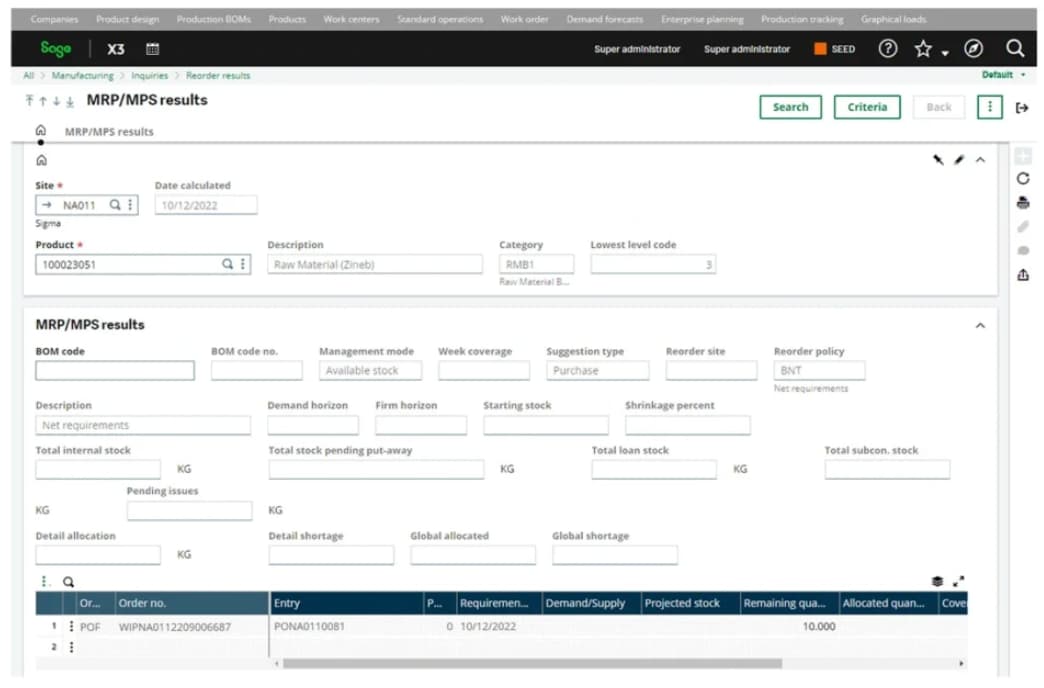

Sage X3 — Overview

A manufacturing ERP system designed for those needing more control over production, inventory, and supply chain operations. It offers an agile solution for industry‑specific requirements like process manufacturing, food and beverage, and chemicals.

Key Features

- Cost Management: Real‑time visibility into production costs to identify cost-saving opportunities.

- Quality Assurance: Tracks compliance requirements and automates quality inspections.

- Global Compliance: Supports multi‑language, multi‑currency, and multi‑legislation for international operations.

Pros & Cons

Here are some pros and cons to know:

Pros:

- Flexible configuration options

- Strong support for global manufacturing operations

- Integrated project management features

Cons:

- A complex implementation requires skilled resources to set up

- Higher learning curve for small teams

- Customization adds to implementation costs

Pricing

On request.

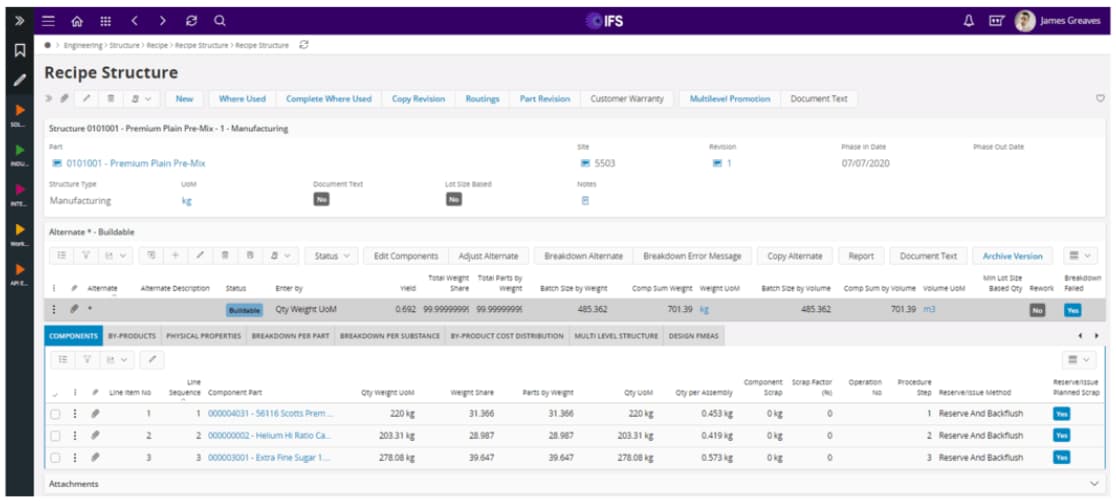

IFS — Overview

IFS Cloud has complex, global manufacturers seeking a unified solution for ERP, supply chain, and asset management.

It provides deep industry‑specific functionality and supports multiple modes of manufacturing, making it a strong fit for engineer-to-order and project‑based manufacturing environments.

Key Features

- Comprehensive Asset Management: Help manage asset lifecycle from procurement to retirement.

- Integrated Project Management: Combine project and production management to align resources and schedules.

- Advanced Manufacturing Module: Supports mixed‑mode manufacturing, such as discrete, process, and project‑based, for different production setups.

Pros & Cons

Let’s review some of the pros and cons of the IFS cloud.

Pros:

- Strong project management and asset management capabilities

- Supports multiple manufacturing modes within a single solution

- Scalable and adaptable, making it suitable for large enterprises

Cons:

- High initial implementation cost, though it provides a solid ROI for large‑scale operations

- Potential over‑engineering for small teams resulting in underutilization and wasted investment

Pricing

Available on request.

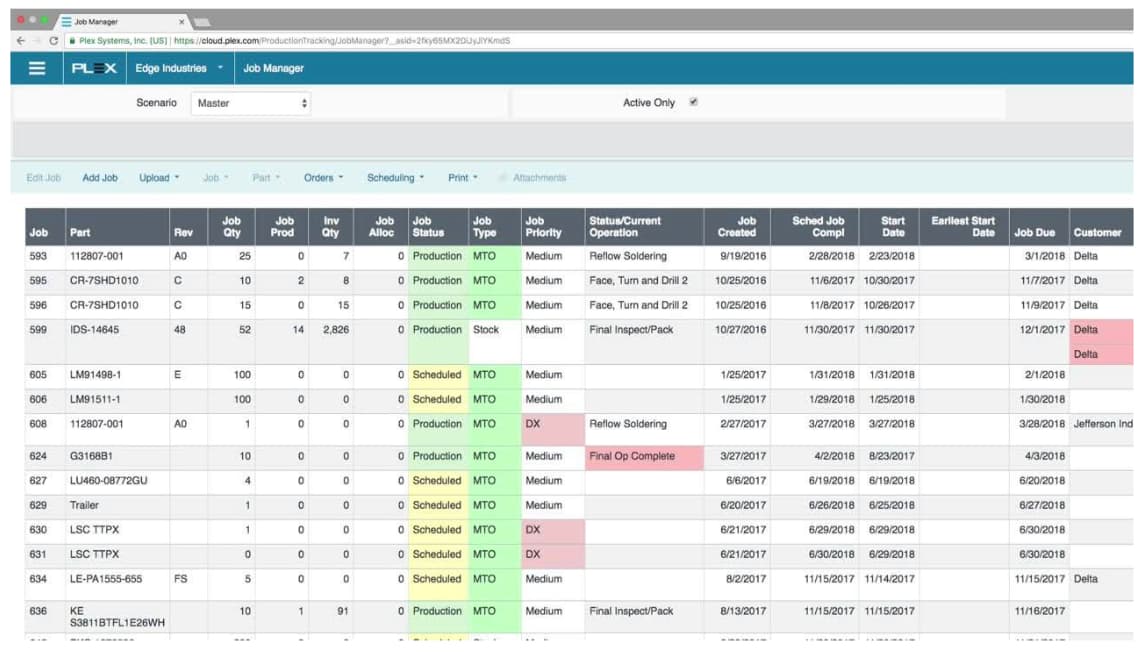

Plex — Overview

This is a cloud‑native ERP solution built specifically for manufacturing execution and operations management (MES/MOM) capabilities. It focuses on continuous improvement and lean manufacturing, so choose the same for its flexibility and scalability.

Key Features

- Real‑Time Production Monitoring: Instant insights into production metrics, quality checks, and machine performance.

- Shop Floor Control: Track work orders in real time to minimize production bottlenecks.

- ERP Integration: Combines MES capabilities with core ERP functions like finance and human resources.

Pros & Cons

Let’s find out the pros and cons of using Plex manufacturing ERP:

Pros:

- Cloud‑native design for faster deployment and easier upgrades

- Strong shop floor control features supporting lean manufacturing principles

- Real‑time data analytics to identify areas for improvement

Cons:

- Requires significant customization for complex manufacturing setups

- High cost for small manufacturers

- Requires more time in training

Pricing

Customized on request.

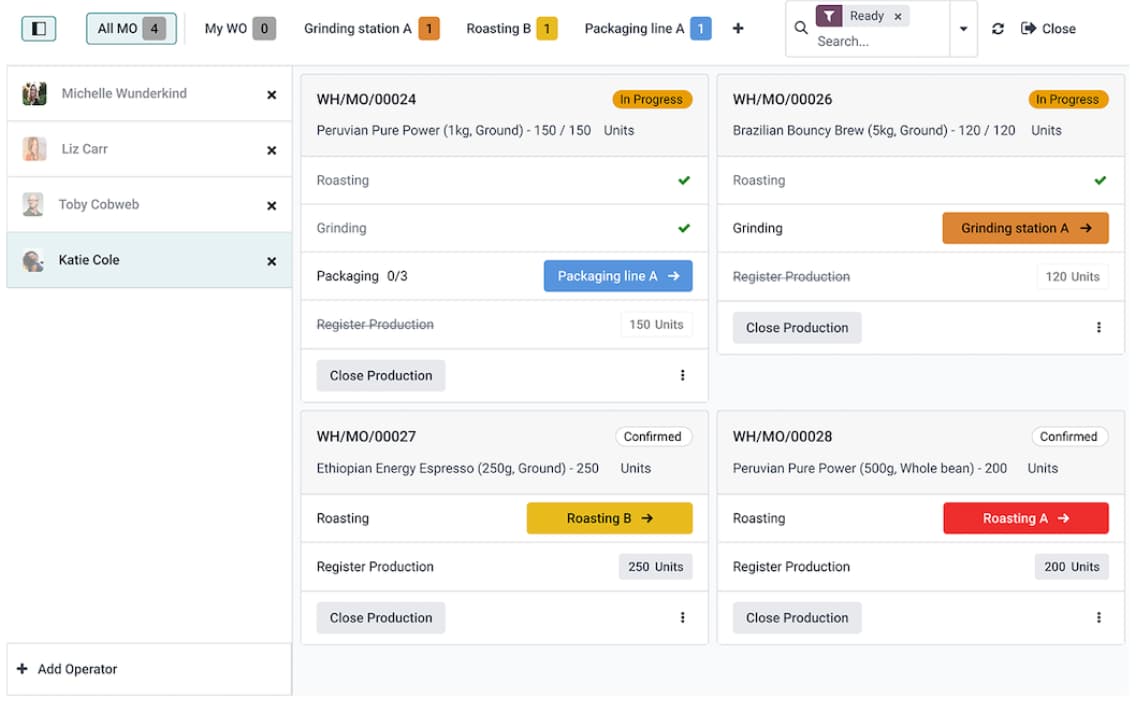

Odoo — Overview

Odoo manufacturing ERP is a highly adaptable tool for small‑to‑medium‑sized manufacturers. Its open‑source nature and modular structure allow businesses to start small and add more features as they grow.

Key Features

- MRP Integration: Combines Material Requirements Planning (MRP) with production scheduling to ensure smooth operations.

- Customization and Open Source: Offers extensive customization capabilities and a vibrant community for support.

- PLM (Product Lifecycle Management): Manage engineering changes, track versions, and collaborate with the design team.

Pros & Cons

Pros:

- Modular and flexible design that can be adapted to fit any business size or need

- Lower cost compared to many competitors, making it ideal for growing businesses

- Open‑source that allows deep customization

Cons:

- Lacks advanced features needed by large enterprises

- Customization demands more time and resources

Pricing

When paid yearly, it starts at around $6 per user/month to $24 per user/month, depending on your geographic location.

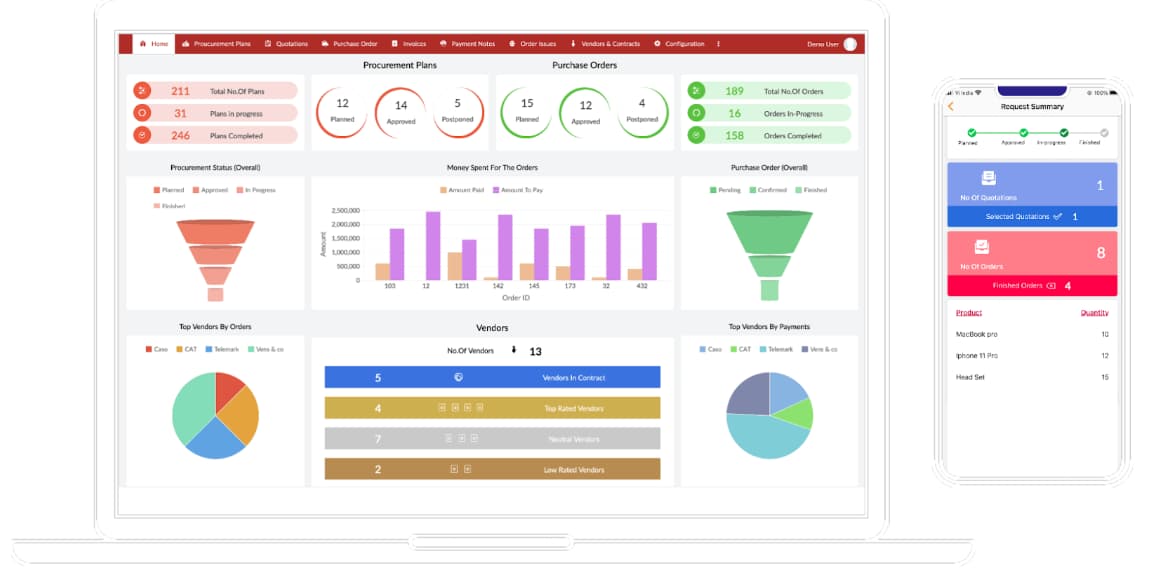

QAD Adaptive ERP — Overview

QAD Adaptive ERP is preferred by manufacturers operating in complex and fast‑changing environments like automotive, life sciences, and consumer goods.

This ERP supports global manufacturers with complex supply chains and regulatory requirements. You’ll have highly customizable tools for lean manufacturing, precision inventory management, and real‑time analytics for each industry sector.

Key Features

- Production and Supply Chain Management: Offers end‑to‑end visibility into production processes and supply chain activities for optimal efficiency.

- Process Manufacturing: Supports batch tracking, formula management, and process data collection to optimize operations for process manufacturers.

- IoT and Automation: Leverages IoT integrations for real‑time monitoring of equipment and production metrics to enhance efficiency and predictive maintenance.

Pros & Cons

Below are the major pros and cons of QAD Adaptive ERP:

Pros:

- Flexible and scalable ERP for mid‑to‑large‑sized manufacturing companies operating globally

- Comprehensive compliance and quality management features tailored for industries like automotive, life sciences, and food & beverage

- Cloud‑based architecture provides flexibility and ease of deployment

Cons:

- Implementation and customization can be time‑consuming and skill‑demanding

- The difficult learning curve as vast features may overwhelm smaller businesses or teams without dedicated ERP experts

Pricing

On request.

Eresource — Overview

This one is a complete solution for manufacturers of all sizes since it provides end‑to‑end modules for production planning, quality management, and supply chain optimization. You should choose it because of its easy implementation and strong focus on the Indian manufacturing sectors.

Key Features

- Production Planning: Optimizes production schedules and resource allocation for efficient manufacturing processes

- Supply Chain Management: Streamlines procurement, supplier management, and logistics for a cohesive supply chain

- Bill of Materials (BOM): Manages complex, multi-level BOMs for accurate production planning and costing

Pros & Cons

Below are the major pros and cons of Eresource:

Pros:

- Comprehensive Module Suite: Offers a wide range of modules covering all aspects of manufacturing operations

- Customization Flexibility: Highly configurable to meet specific business requirements

- Cost-Effective: Provides robust features at a competitive price point, offering value for money

Cons:

- Implementation Time: Some users have experienced lengthy implementation timelines

- Limited Financial Reporting: Specific departmental reports in finance may require further development

- Support Response Time: Some users have noted variability in the responsiveness of customer support

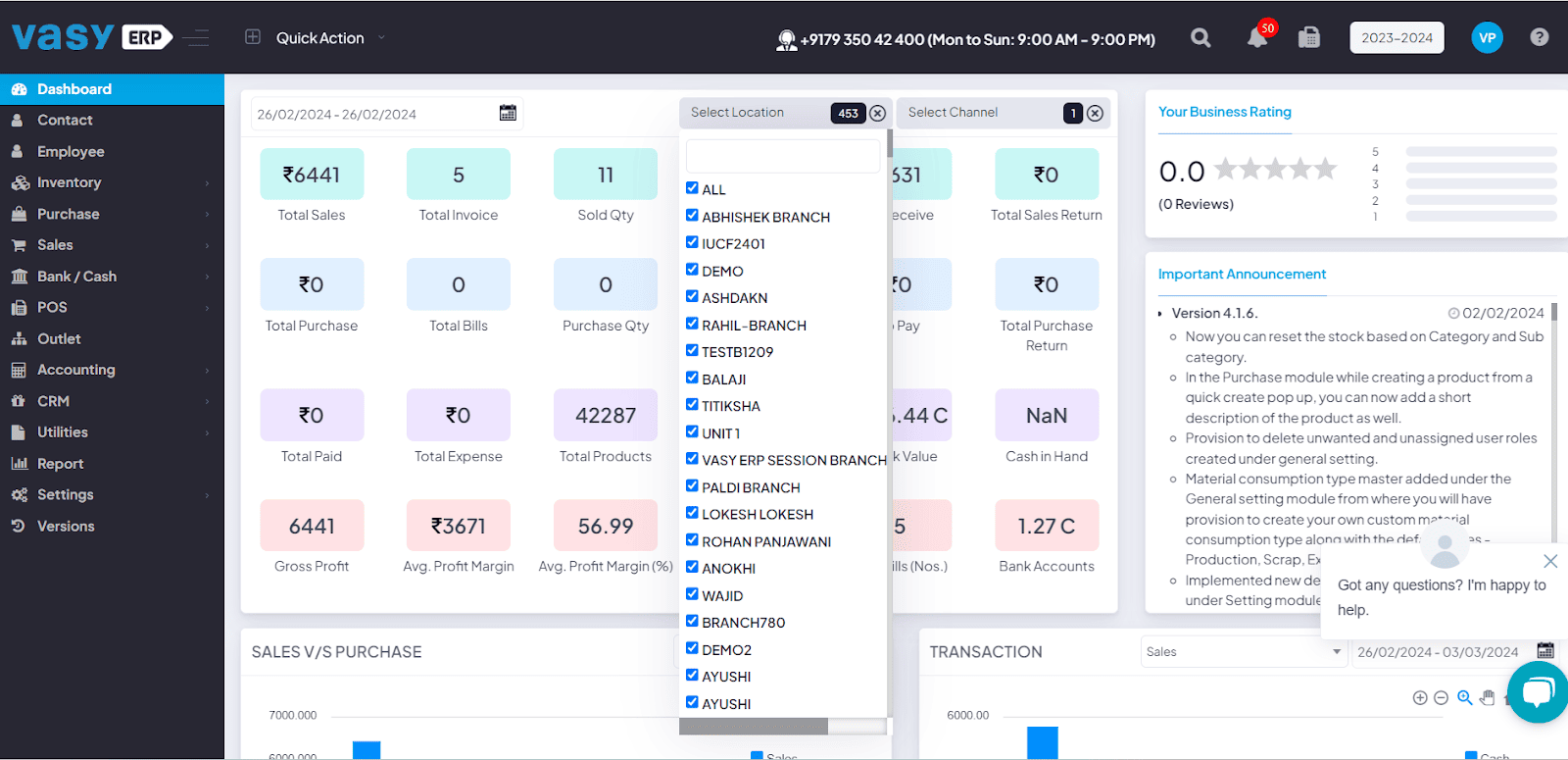

VasyERP — Overview

VasyERP provides a lightweight ERP solution that suits small — to mid‑sized manufacturers who want a more straightforward tool to manage their production, inventory, and finances. The user‑friendly interface and quick deployment are two factors that make it an ideal choice for manufacturers seeking affordability without sacrificing essential features.

Key Features

- Retail POS Integration: Facilitates seamless retail operations for manufacturers with retail outlets, enabling efficient billing and inventory management

- Smart Manufacturing Integration: Offers real-time monitoring and control of manufacturing processes, enhancing operational efficiency

- Integrated GST Accounting: Automates GST-compliant invoicing and accounting, including direct GSTR submissions from the ERP system

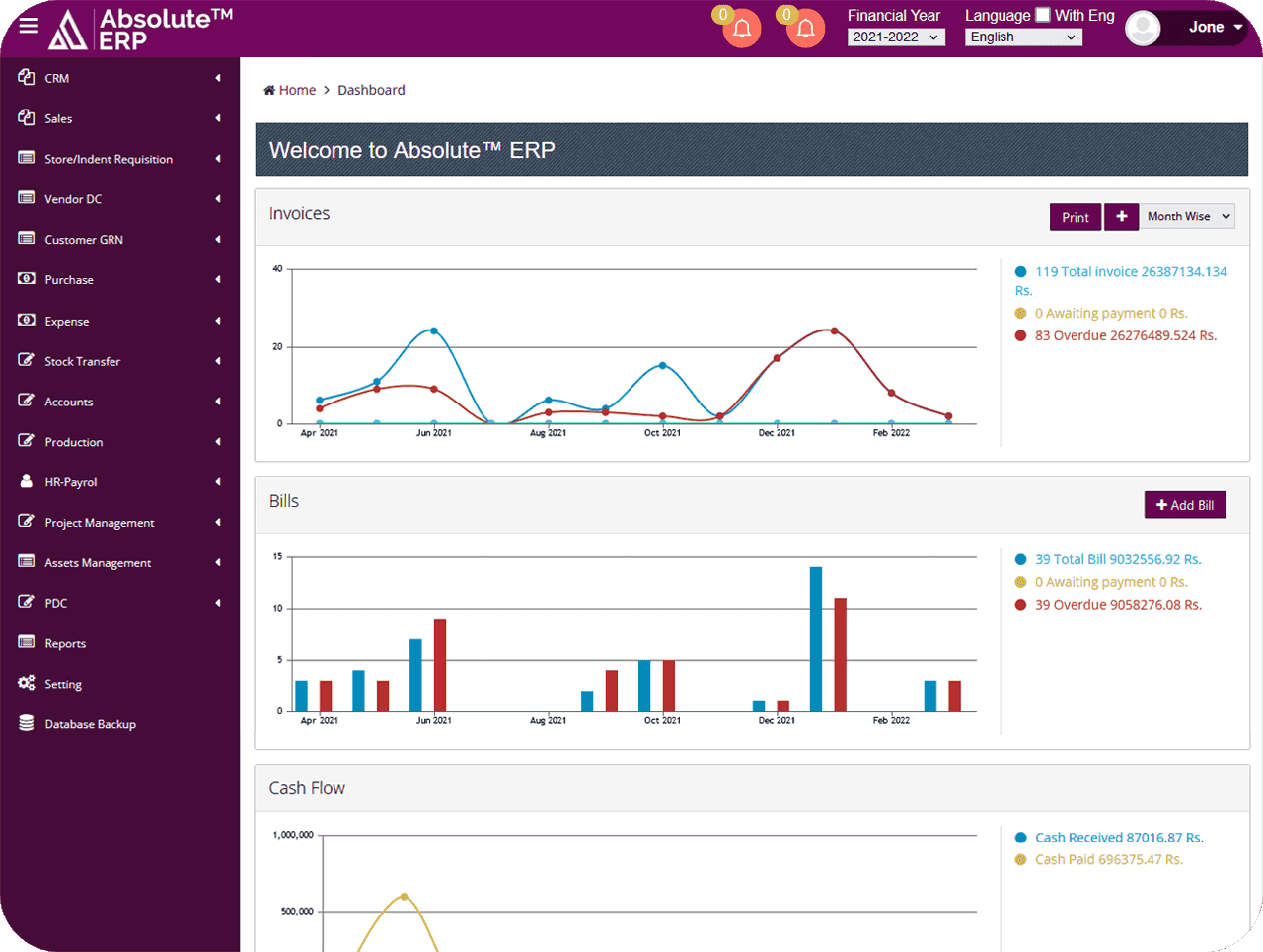

Absolute ERP — Overview

Cloud-based ERP solution tailored specifically for small and mid-sized manufacturing businesses. It combines modules for production, inventory, quality control, and MRP, all within a centralized platform that simplifies complex operations. Known for its flexibility and customization options, Absolute ERP is ideal for discrete and process manufacturers looking to streamline workflows without investing in bulky enterprise systems. With real-time monitoring and mobile access, it supports fast-growing manufacturers who value agility and visibility.

Key Features

- Machine/Workstation Efficiency Tracking: Monitors and optimizes the performance of machinery and workstations.

- Quality Control Integration: Ensures products meet quality standards through integrated quality management processes.

- Multi-Level BOM Management: Facilitates detailed tracking and management of complex Bills of Materials.

Zoho — Overview

Zoho’s manufacturing ERP is a low‑code solution that streamlines operations with customizable modules. The focus is on improving productivity by automating manual tasks and providing complete visibility into production and inventory management.

Key Features

- Inventory Management: Centralized control to track raw materials, finished goods, and MRO (maintenance, repair, operations) items.

- Material Procurement: Create purchase orders, invoices, and approvals optimized supply chain.

- Customizable Workflows: Drag‑and‑drop builder to create workflows for unique business requirements.

Pros & Cons

Major pros and cons of Zoho’s manufacturing ERP:

Pros:

- Quick customizations without extensive coding knowledge

- Strong integration capabilities with Zoho People, Payroll, Inventory, CRM, along with third‑party tools

Cons:

- Not designed for manufacturing, workarounds for production only

- High learning period for teams new to low‑code platforms

- Add‑ons & custom solutions required even for basic production features

- When billed annually, the price ranges between $6/user/month to $8/user/month, depending on your country/region.

Pricing

When billed annually, the price ranges between $6/user/month to $8/user/month, depending on your country/region.

How to Choose the Right ERP for Your Manufacturing Business

Choosing the best ERP for manufacturing involves more than picking a popular brand. You need a system that aligns with your size, industry needs, growth plans, and available resources. Follow these steps to make an informed decision.

Step 1: Define Your Business Size and Complexity

For small manufacturers, ease of use and quick setup matter most. Cloud-based ERP systems like Kladana are ideal — affordable, simple to implement, and scalable.

If you run a medium or large manufacturing business with complex workflows, consider robust platforms like SAP S/4HANA or Microsoft Dynamics 365, which offer extensive manufacturing modules and multi-location support.

Step 2: Look for Industry-Specific Features

Choose ERP software that supports your industry’s requirements:

- Food & Beverage: Look for batch tracking, traceability, and compliance tools

- Automotive or Electronics: Prioritize supply chain management, inventory control, and production scheduling

- Apparel & Textile: Go for systems with variant-based inventory (size, colour, fit) and subcontractor handling

Step 3: Cloud ERP vs On-Premise ERP

Cloud ERP: Best for businesses wanting flexibility, remote access, fast deployment, and lower upfront costs.

On-Premise ERP: Offers more control over data and customization but demands higher initial investment and in-house IT support.

Step 4: Evaluate Vendor Expertise and Support

Choose a vendor experienced in your industry. Ask about:

- Case studies with similar manufacturers

- Post-implementation support

- Training and onboarding quality

- Customization services

Step 5: Plan for Future Growth

Your ERP should grow with your business. Look for modular ERP solutions that allow you to start with essential features and add more over time — such as CRM, payroll, or advanced MRP. Scalability ensures your investment pays off long-term.

👉 Still wondering if manufacturing ERP is right for you or not? Check it out with our 14‑day free trial. No credit card required.

Signs Your Manufacturing Company Needs an ERP System

If your manufacturing business is struggling to keep up with growing orders, disconnected systems, and recurring inventory issues — it may be time to implement an ERP system. A manufacturing ERP helps centralize operations, automate processes, and provide real-time visibility.

Key indicators include:

- Operational inefficiencies: Frequent errors, delays, and wastage

- Lack of real-time data: Inability to make informed decisions quickly

- Scattered processes: Using separate tools for inventory, finance, and production

- Poor inventory management: Stockouts, overstocking, and manual tracking.

Standard ERP vs. Manufacturing ERP

While standard ERP software handles general business needs like accounting or HR, it often lacks production-specific features required by manufacturers. A manufacturing ERP system includes modules like MRP, shop floor control, and quality assurance, enabling full visibility across supply chain and production cycles.

| Feature | Standard ERP | Manufacturing ERP |

Purpose |

General business operations |

Production-focused operations |

Best for |

Service or retail businesses |

Manufacturers (SMEs to large enterprises) |

Production Planning |

Limited or missing |

MRP, BOM, scheduling, capacity planning |

Inventory Management |

Basic tracking |

Real-time stock control, material tracking |

Supply Chain Management |

Basic procurement |

Integrated SCM with order tracking, supplier performance |

Shop Floor Control |

Not included |

Real-time order and task visibility |

Cost Control |

Basic cost allocation and financials |

Tracks production costs, waste, and profitability |

Quality Management |

General quality checks |

Specific to manufacturing: compliance, QC, and audits |

Types of ERP Systems for Manufacturing

Choosing the right ERP for manufacturing depends on your size, IT resources, and compliance needs. Here’s a quick overview of options.

Cloud‑Based ERP

Hosted online, accessed via browser or mobile — ideal for SMEs.

Pros:

- Low upfront cost

- Remote access

- Easy to scale

Best for: SMEs and multi-site manufacturers.

Example: Kladana.

On‑Premise ERP

Installed on local servers — gives full control over data and systems.

Pros:

- High security

- Deep customization

Best for: Large enterprises or those with strict IT policies.

Example: Infor CloudSuite, Epicor.

Hybrid ERP

Combines on-premise and cloud benefits — flexible deployment.

Pros:

- Gradual migration

- Site-specific configurations

Best for: Companies transitioning to the cloud.

Example: SAP S/4HANA.

Why Manufacturers Choose Kladana ERP

Kladana is designed for small and medium manufacturers who need more than spreadsheets but don’t want the complexity of a large ERP. It includes tools like:

- Multi-level BOM & production planning

- Real-time stock control

- Cost tracking per production batch

- Barcode scanning and warehouse tracking

- Cloud access and mobile app for the shop floor

Customer Story — Jtronix Technologies

Jtronix migrated from Excel to Kladana and quickly streamlined production. According to founder Jay Senghani, the team cut down time on manual updates and improved visibility across orders and materials.

FAQs about Manufacturing ERP

Let’s answer some of the most common questions for deploying manufacturing ERP software.

What is manufacturing ERP software?

Manufacturing ERP software is a system that helps businesses manage core production, inventory, and supply chain activities in one platform. It includes modules like MRP, BOM, production scheduling, and quality control — all tailored for manufacturers.

Which ERP is best for manufacturing?

The best ERP for manufacturing depends on your business size and industry. For small to mid-sized manufacturers, cloud-based solutions like Kladana offer affordability and ease of use. Larger enterprises may prefer systems like SAP S/4HANA, Oracle NetSuite, or Microsoft Dynamics 365 for advanced capabilities.

Can ERP integrate with machinery or IoT devices?

Yes. Modern manufacturing ERP systems support integration with IoT sensors and shop floor machinery to enable real-time data collection, predictive maintenance, and automated production tracking.

What is the cost of ERP for a manufacturing company?

ERP pricing varies widely:

- Cloud ERP for SMEs: starts at $60–$150/month (e.g., Kladana)

- Enterprise-level ERP: from $1,000+/month with high implementation costs

- Costs depend on user count, modules, deployment type, and customization.

Can small manufacturers benefit from ERP?

Absolutely. A scalable ERP like Kladana helps small manufacturers automate manual tasks, reduce errors, and gain better control over inventory, production, and costs.

What is MRP in ERP systems?

MRP stands for Material Requirements Planning — a module that ensures raw materials are available when needed. It automates purchase planning, production scheduling, and stock replenishment.

Can ERP help with compliance and quality control?

Yes. Manufacturing ERP software includes quality management features like inspections, audits, documentation, and regulatory compliance tracking.

Why do ERP implementations fail?

Common reasons include:

- Poor project planning

- Lack of internal alignment or training

- Choosing software that doesn’t fit your business model

- No change management strategy

How long does ERP implementation take?

Implementation time can range from 3 to 12 months, depending on business complexity, team involvement, and whether the ERP is on-premise or cloud-based.

Why is Kladana ideal for small manufacturers?

Kladana is affordable, cloud-based, and tailored for Indian SMEs. It offers tools like production tracking, BOMs, barcode inventory, and vendor management — with a simple onboarding process and no coding required.

List of Resources

- Precedence Research — ERP Software Market Size, Share, and Trends 2025 to 2034

- AIMultiple — ERP market statistics