When production management, inventory, and costing run on separate systems, minor problems quickly become expensive delays. This leads to shrinking profits and production mismanagement.

According to a PwC South Africa Manufacturing Analysis, the manufacturing sector makes up 13% of South Africa’s total GDP. This highlights its crucial economic importance. The industry is projected to grow at a rate of 5.7% annually, presenting significant opportunities for manufacturing software in South Africa.

However, many South African manufacturing businesses, especially SMEs, still rely on manual tools or disconnected systems. This causes fragmentation and prevents them from reaching their full potential. They lack real-time manufacturing visibility, batch tracking, and integration between inventory and production.

Adopting an ERP for manufacturing is no longer just an option for South African manufacturers. It’s the new standard. A modern manufacturing ERP system combines all key production functions — like production scheduling, job costing, Bill of Materials (BOM), and shop floor control — into one unified, efficient workflow.

In this blog, you’ll explore why ERP adoption is accelerating, what challenges SMEs face locally, and which ERP manufacturing solutions best fit your business. Whether you’re looking for a production ERP software or inventory and manufacturing software built for small businesses in South Africa, you’ll find the top options here.

- Why Are Manufacturing Businesses in South Africa Adopting ERP?

- Why Legacy Tools No Longer Work?

- How Does ERP Solve These Pain Points?

- Local Considerations for South African SME Manufacturers

- Best ERP Options for Manufacturing in South Africa

- How to Choose the Right ERP for Your Factory in South Africa

- To Sum Up

- FAQS on ERP manufacturing Software in Africa

- List of Resources

Why Are Manufacturing Businesses in South Africa Adopting ERP?

South African manufacturing is driven by agile small and medium-sized enterprises (SMEs), each with complex, fast-moving workflows that quickly outgrow manual tools.

Massive industrial plants do not dominate South Africa’s manufacturing landscape. It mostly thrives on the agility and diversity of SMEs. From clothing manufacturing, food processing, packaging, to precision engineering, these businesses are the backbone of local production. However, with complexity comes fragmentation — many manufacturing SMEs operate manually without integrated systems for inventory, production, and costing.

Core Manufacturing Segments in South Africa

Understanding why ERP adoption in manufacturing is rising starts with the dominant industries and workflows that benefit from production visibility and automation.

1. Textiles & Apparel

Textile manufacturers manage high SKU variation, frequent style changes, and outsource heavily to vendors for dyeing, stitching, and finishing. A manufacturing ERP system brings structure to Bill of Materials (BOMs), raw material tracking, barcode labeling, and multichannel order fulfillment.

📍 Body Motion, a South African sportswear and scrubs manufacturer, replaced spreadsheets with Kladana ERP after struggling with inventory visibility and double buying. They now track hundreds of fabric and trim SKUs, manage subcontracted embroidery through BOMs, and plan weekly production — all from a single dashboard.

2. FMCG

In FMCG manufacturing, especially packaged food and beverages, producers require batch tracking, expiry date management, and accurate production scheduling with packaging-level BOMs. An ERP for FMCG automates and centralizes these processes to meet compliance and scale production.

3. Agricultural Processing

SMEs in agri-processing — milling, cold storage, fruit packing, or dairy — depend on seasonal yield cycles, traceability, and dispatch logistics. ERP software enables real-time manufacturing visibility, aligning raw material intake with batch production and route planning.

👉 We’ve explored key trends in agricultural production in another article.

4. Plastics & Chemicals

Plastic & chemical manufacturers face volatile raw material pricing, recycling processes, and regulatory compliance. ERP supports formula-based BOMs, quality control documentation, and inventory value forecasting — essential for production ERP software in this segment.

5. Engineering & Fabrication

In metalworking and fabrication, manufacturers handle complex routing, custom cost estimation, and outsourced operations like plating or welding. Here, ERP for manufacturing industry streamlines shop floor control, subcontracting, and scrap tracking — enhancing both throughput and job costing accuracy.

Why Legacy Tools No Longer Work?

When your manufacturing business scales, so does the complexity behind it. You need to manage more SKUs, raw material types, approvals, and production scheduling under tighter deadlines. But if your tools can’t scale with that complexity, they create problems instead of solving them — especially for SMEs in South Africa.

Here’s where outdated systems start to break down, making the shift to manufacturing ERP systems not just a choice, but a necessity.

➡️ Inventory confusion: Without real-time inventory visibility, you rely on manual checks. This leads to overpurchasing, missed production runs, and delays that ripple across the shop floor.

➡️ Duplicate data entry: Entering product data multiple times across Excel, billing software, and manual cost logs wastes time and increases the risk of errors. A centralized ERP for manufacturing eliminates this by syncing inventory, invoicing, and job costing in one system.

➡️ Delayed decision-making: Reports compiled after production are too late to help. ERP systems for production management offer live dashboards and alerts so you can act in the moment, not after the damage is done.

➡️ Disconnected workflows: A missed Bill of Materials (BOM) update, late approval, or raw material delay can halt production. Without a connected workflow, these bottlenecks continue. ERP software links all operations — from material requirement planning (MRP) to production approvals — in one real-time system.

➡️ No traceability or cost control: Without proper tracking, you don’t know how much material was used, what it costs per batch, or where wastage occurred. That makes it impossible to price accurately, improve margins, or trace faulty lots — all core features in a modern ERP manufacturing solution.

How Does ERP Solve These Pain Points?

Modern ERP for manufacturing isn’t bulky or enterprise-exclusive. Today’s systems are lightweight ERP manufacturing solutions, built for SMEs and designed to be cloud-based, easy to adopt, and cost-effective.

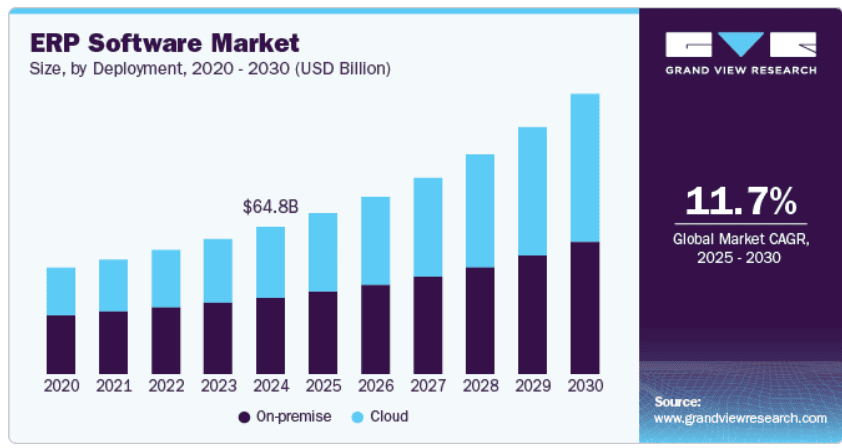

According to the report by Grandview Research, the global ERP software market is valued at $64.83 billion and projected to grow at a CAGR of 11.7% between 2025 and 2030. This growth shows how more businesses are replacing legacy tools with production ERP software to boost efficiency and gain real-time manufacturing visibility.

Here’s how a manufacturing ERP system fixes what outdated systems can’t.

1. Live Inventory Visibility

Forget manual checks or last-minute walks around the warehouse. A good inventory and manufacturing software platform gives you real-time updates on available, incoming, and reserved stock — across all warehouses or production sites. That reduces stockouts, improves material planning, and streamlines production scheduling.

2. BOM Automation

Managing variants or kits? ERP lets you configure multi-level Bills of Materials (BOMs) for products like textiles, food packs, or engineered parts. You can standardize components, reuse subassemblies, and avoid manual errors in pulling materials — critical for South African SMEs juggling complexity.

3. Accurate Costing

Manual costing is slow and error-prone. With ERP, job costing software automatically logs everything — material consumption, machine runtime, and labor. You know the cost per unit in real time, enabling margin analysis, better pricing, and profitability tracking across ERP systems for production management.

👉 Read more about costing methods in our dedicated guide.

4. Production Scheduling and Monitoring

An ERP brings clarity to the shop floor. Assign tasks to machines, monitor job progress, and balance loads across shifts. You’ll eliminate guesswork, avoid bottlenecks, and meet dispatch deadlines more reliably with live production monitoring tools.

5. Subcontractor or Outsourced Job Management

Whether you’re outsourcing finishing, dyeing, welding, or other tasks, ERP lets you track it all. You’ll see what materials were sent out, when they return, and what it costs. This ensures better lead time visibility, prevents raw material losses, and supports smoother subcontractor management — a common need in South African manufacturing ERP use cases.

Local Considerations for South African SME Manufacturers

Choosing the best ERP for manufacturing in South Africa isn’t just about features or cost — it’s about operational fit for local SME challenges. Manufacturers here face specific realities that global ERP systems often fail to accommodate. These include load shedding, limited internet infrastructure, and SARS compliance. Addressing these factors ensures long-term usability and ROI from your manufacturing ERP system.

Here are the most critical considerations before adopting ERP manufacturing software in South Africa.

1. Load Shedding and Power Disruption

Modern ERP manufacturing solutions automate workflows and improve resilience — a crucial benefit in a country where power outages frequently halt operations.

A study by Mokgadi Ngoepe-Ntsoane confirms that load shedding disrupts production cycles and lowers business confidence. ERP tools with cloud-based redundancy and auto-syncing help maintain real-time manufacturing visibility even during unstable grid conditions.

What to prioritise:

- Systems that offer offline functionality or a mobile-first design

- Auto-save and background sync capabilities

- Hosting via secure cloud ERP with South African data centers or global providers with high uptime

2. Internet Reliability and Infrastructure Gaps

Many small manufacturing businesses operate in rural or semi-urban zones with spotty internet. Desktop-based, heavy-installation ERPs will struggle in these areas. Cloud ERP platforms with mobile and low-bandwidth support work far better for SME ERP users.

Look for ERP systems that:

- Work smoothly on mobile data or 3G/4G networks

- Do not require constant syncing for basic use

- Support remote manufacturing access without large software downloads

3. SARS Compliance and Financial Reporting

ERP software in South Africa must comply with local tax laws, VAT invoicing, and audit trails. Especially for SMEs undergoing B2B audits or working with government tenders, a SARS-compliant ERP ensures legitimacy and faster reconciliation.

Key features to ask for:

- Custom reporting formats for SARS submissions

- Integrated inventory + supplier reconciliation

- Built-in audit trail exports, VAT reports, and financial statements that meet South African accounting standards

4. Procurement Audits and B-BBEE Documentation (Broad-Based Black Economic Empowerment)

For manufacturers working with corporate buyers, municipalities, or tender boards, having audit-ready records is essential. Your ERP for manufacturing should support procurement traceability, track supplier B-BBEE certificates, and centralize invoice management.

Why it matters:

- Corporate buyers often require detailed procurement logs

- Missing B-BBEE documentation or proof of supply timelines can lead to lost opportunities

- Inventory and manufacturing software with built-in compliance tools eases the audit process and improves funding eligibility

5. Limit Internal IT Resources

Most small business ERP users in South Africa don’t have dedicated IT departments. An ideal ERP system for manufacturing SMEs must offer low-friction onboarding, not demand IT specialists or external consultants.

Choose systems that:

- Are cloud-native with plug-and-play onboarding

- Offer clear documentation and local language guides

- Provide responsive support within South African business hours

- Don’t require heavy user training or external consultants for basic use

This ensures your team stays focused on production, costing, and inventory control, not system maintenance.

6. Product Variants and Seasonal Production

Many South African ERP users work in seasonal or variant-heavy sectors like clothing, food, or cosmetics. You’ll need flexible BOM features and variant support to avoid SKU chaos or miscounts.

Make sure the system can handle:

- Product variants tied to a shared inventory (e.g., one fabric used across sizes)

- Configurable BOMs for small-batch or mixed production

- Automated product structure duplication for fast creation of new SKUs

By choosing a tool with this level of shop floor control and BOM automation, local manufacturers can scale operations smoothly — even during peak seasons.

Best ERP Options for Manufacturing in South Africa

1. Kladana — Overview

Who it’s for

Kladana is tailored for small manufacturing businesses looking for production ERP software that supports fast setup, real-time manufacturing visibility, and minimal training effort.

Why it stands out

This ERP system for SMEs focuses on the essentials: inventory and manufacturing software, costing, production, and shop floor task management. It’s not overloaded with unnecessary modules, making it ideal for South African SME manufacturers.

Kladana is especially suited for:

- Make-to-order operations (e.g., custom apparel, machinery)

- Subcontracted production workflows (e.g., metal coating, chemical blending)

Key strengths

- Shop Floor App for real-time task tracking by operators and supervisors

- Multi-level BOM support for managing assemblies and subassemblies

- MRP with accurate demand forecasting, reorder points, and procurement planning

- Batch-wise raw material tracking with support for expiration dates, serial numbers, and bin locations

- Detailed product costing based on material usage, labour input, and operational overheads

Pricing: Paid plans start at $47/month

Free trial: 14 days

Run Your Entire Production Process in One System With Kladana

If you’re running a manufacturing business in South Africa using Excel, job cards, or disconnected systems, it’s time to move forward.

Kladana’s cloud ERP for small manufacturers centralizes all your production workflows — from raw material management to finished goods dispatch.

2. QuickEasy BOS — Overview

Who it’s for

It’s designed for South African SMEs that require robust quoting and costing tools, particularly in sectors such as print, signage, fabrication, or packaging.

Why it stands out

Quick Easy BOS is a locally developed ERP that understands South African tax, reporting, and commercial needs. It includes built-in quoting, job cards, inventory control, procurement, and delivery modules.

What sets it apart is the tight integration between sales, costing, and production. It is ideal for jobbing manufacturers who need to quote accurately and deliver on time.

Key Strengths

- In-depth job costing

- VAT-ready invoicing and supplier reconciliation

- Visual production dashboards

- Built-in CRM and quote follow-ups

Pricing: On request

Free trial: Demo is available

3. Katana MRP — Overview

Who it’s for

It’s designed for SMEs that sell online or manage batch production, such as DTC food brands, cosmetics, or furniture producers.

Why it stands out

Katana is designed for visual thinkers. It is ideal for businesses that produce small batches and manage raw material planning in conjunction with online sales.

Key strengths

- Visual production calendar and order priority

- Integration with e-commerce and accounting tools

- Simple material planning and low inventory alerts

- Batch and expiry tracking

Pricing: Starts at $359/month for the essential plan

Free Trial: 14 days

4. Syspro ERP — Overview

Who it’s for

SMEs in industrial sectors such as electronics, metal fabrication, heavy engineering, plastics, etc. It requires extensive configuration and deep compliance.

Why it stands out

Syspro is a long-standing South African ERP solution designed for industrial-grade manufacturing. It supports advanced features, including engineering change control, quality inspection workflows, supply chain traceability, and highly detailed MRP logic.

It offers on-premise and hybrid cloud solutions, making it suitable for firms operating in secure environments or those subject to regulatory mandates.

Key strengths

- High customisability for complex manufacturing

- Regulatory compliance, like ISO, ITAR, and traceability

- Full suite: CRM, finance, HR, BI, and manufacturing

- Strong partner ecosystem for implementation

Pricing: Custom quote based on modules and seats

Free trial: Demo available via partner

5. ERP Next — Overview

Who it’s for

Digitally capable SMEs with IT resources or partners who want complete control and customization, including self-hosted deployments

Why it stands out

ERPNext is an open-source ERP that delivers robust manufacturing, accounting, HR, and CRM modules, all under one roof. It offers deep configuration, complete code transparency, and no user limit.

For SMEs with specific needs, such as custom job routing, unique inventory valuation rules, or local integrations, ERPNext enables them to build what they need without being locked into proprietary solutions.

Key strengths

- Full-featured open source ERP with localisable modules

- Built-in MRP, job costing, subcontracting, and asset management

- Rest API for integrations with e-commerce or POS

- Document-level permissions and workflow builders

Pricing: Free (self-hosted) and cloud starts from $50/user/month

Free Trial: Yes

6. Odoo Manufacturing — Overview

Who it’s for

It is designed for growth-stage companies seeking to consolidate sales, manufacturing, finance, and HR into a single, flexible ecosystem.

Why it stands out

It offers a modular platform that allows you to add functionality as your business grows. Its manufacturing module includes work orders, routing, scrap handling, maintenance, and product lifecycle tracking. It stands out because the manufacturing module seamlessly works with accounting, CRM, helpdesk, and even e-commerce apps.

Key strengths

- Workflow automation for approvals and routing

- Support for barcode scanners and IoT integration

- Multiple deployment options such as cloud, on-premise, and partner-hosted

Pricing: Free for one app and full suite starts at $24/user/month

Free trial: 15 days

7. MRPeasy — Overview

Who it’s for

It is designed for SMEs in the mechanical parts, electronics, or 3D-printed products sectors that require clean dashboards and a hassle-free setup.

Why it stands out

It is a streamlined ERP tool designed for small factories. It provides end-to-end visibility into inventory, job costing, production orders, and procurement, eliminating the need for complex configurations. It is specially built for speed and ease, making it ideal for South African SMEs that want beyond spreadsheets.

Key strengths

- Easy-to-use UI, suitable for lean teams

- Automatic rescheduling based on stock availability

- Visual BOMs and multi-level production flows

- Integrated CRM and purchasing

Pricing: From $49/user/month

Free Trial: 15 days

8. Embrace ERP — Overview

Who it’s for

South African manufacturers require a local team, rapid support, and a robust manufacturing strategy.

Why it stands out

Used by SA manufacturers for over 35 years, Embrace offers strong costing, localised financials, stock management, and workshop control. It is ideal for engineering and job-based production.

Key strengths

- Job costing and material variance analysis

- Project-based manufacturing and project accounting

- Regulatory reporting (SARS, Building Energy Efficiency tracking)

- Batch and expiry tracking

Pricing: Custom

Free trial: Demo on request

9. Epicor ERP — Overview

Who’s it for

Firms with international customers or compliance-heavy manufacturing.

Why it stands out

It helps deliver advanced planning, Manufacturing Execution System, Supply chain visibility, and Industry templates.

Key strengths

- Make-to-order and make-to-stock planning

- MES integration and IoT-ready

- Role-based dashboards

- Batch, IoT, and serial number controls

Pricing: On request

Free Trial: No

10. SAP Business One — Overview

Who it’s for

SMEs who want the brand reliability of SAP but in a simplified package. It is ideal for operations with expanding product lines or export requirements.

Why it stands out SAP Business One provides a comprehensive, integrated suite of tools for inventory management, production, accounting, and purchasing.

Key strengths

- BOM and routing, make-to-order and make-to-stock workflows

- Batch, expiry, and serial number management

- SAP Crystal Reports for custom dashboards

- Integration with e-commerce and warehouse automation tools

Pricing: Custom quote

Free Trial: Demo available

11. Acumatica — Overview

Who it’s for

SMEs aiming to scale 10-100 employees and needing pricing without user caps

Why it stands out

Acumatica will not charge per user. It is excellent for growing South African Manufacturers. It is a cloud-native solution, ensuring uptime even during infrastructure challenges.

It stands out because it facilitates seamless integration with warehouse transfers, job orders, bills of materials (BOMs), and customer pricing, all without requiring a switch to different platforms.

Key strengths

- Job shop and batch production workflows

- Embedded CRM and financials

- Mobile barcode scanning, device-agnostic UI

- Role-based dashboards with live analytics

Pricing: Resource-based pricing

Free Trial: Yes

12. BatchMaster ERP — Overview

Who it’s for

SMEs in food, cosmetics, chemical, and pharmaceutical sectors requiring formula management and regulatory compliance

Why it stands out

It stands out because it can handle compliance, allergens, expiry dates, and test logs without needing bolt-on apps.

Key strengths

- Formula and recipe BOMs

- Allergen control and Safety Data Sheet (SDS) management

- Cost stimulation based on ingredient fluctuation

- FDA, ISO, and SAPC Compliance options

Pricing: Custom quote

Free Trial: Available on request

13. QAD adaptive ERP — Overview

Who’s it for

For SMEs, Advanced, export-focused manufacturers in sectors like automotive components, regulated chemicals, or medical devices.

Why it stands out

QAD Adaptive ERP is engineered for global compliance and supply chain resilience. It also offers a comprehensive cloud-based ERP for SMEs that are growing or have complex manufacturing needs.

Key strengths

- It has supplier collaboration portals

- It controls serialization, labeling, and shipment control

- It has compliant tracking and quality events

- It helps in adaptive supply chain forecasting

Pricing: Tiered enterprise-level

Free Trial: No

How to Choose the Right ERP for Your Factory in South Africa

Selecting the best manufacturing ERP is not just about ticking off features. It’s about choosing an ERP system that matches your production process, team size, and South Africa’s unique business environment. Many SME manufacturers rush into ERP adoption without assessing operational maturity or aligning tools with real factory needs — leading to expensive failures.

Here’s how to make a smart, future-proof choice.

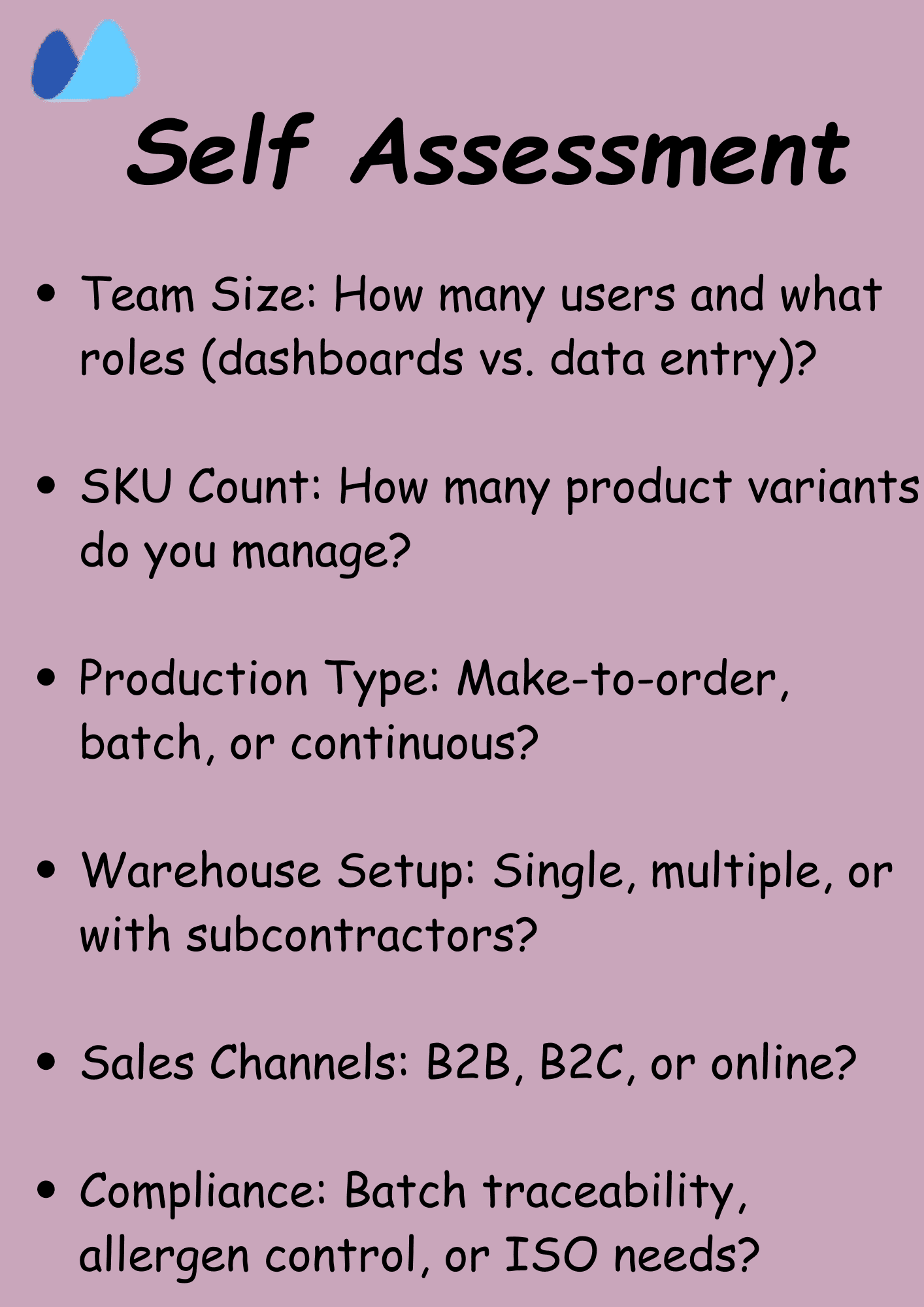

1. Start with a Self-Assessment

Before speaking to ERP vendors, clarify your workflows and business needs.

📌 Tip: Don’t rely on generic checklists. Ask for live demos showing how the ERP system handles your real-world manufacturing use cases.

2. Asses Ease of Use and Learning Curve

Even the best system will fail if your production team can’t use it. South African SMEs often operate with lean teams that cannot afford a 6-month training curve.

So, before that, you need to evaluate:

- Is the interface intuitive and visual enough for shop floor operators?

- Can users easily start jobs, issue raw materials, and monitor output?

- Are there in-app guides, training videos, or documentation in plain language?

Look for real-time manufacturing visibility without requiring a degree in IT.

3. Clarify Total Cost of Ownership (TCO)

The actual cost of an ERP manufacturing solution goes beyond monthly fees.

Evaluate:

- One-time setup or implementation charges

- Customization and workflow adaptation costs

- Training and support plans

- Data migration costs

- Third-party plugins or integrations, for example, accounting, payroll, e-commerce

📌 Tip: Ask vendors if pricing is per user, per module, or based on transaction volumes. For growing SMEs, unexpected costs are a common trap. Request a full cost breakdown before onboarding.

4. Match the ERP’s Scalability to Your Growth Plan

A common mistake is choosing an ERP that fits your current state but becomes limiting within six months.

Check for:

- Can you add more users, warehouses, or sales channels without modifying the existing systems?

- Does it support advanced modules like CRM, HRM, and accounting (even if you don’t need them now)?

- Is there a free or lite version you can start with, then upgrade later?

📌 Tip: Avoid rigid systems that force full upgrades once you outgrow entry plans. Prioritize modular ERP systems for production management with scalable pricing.

5. Review Onboarding Timeframes and Support Models

For SME ERP solutions in South Africa, fast and simple onboarding is essential.

Questions to ask vendors:

- What’s the average go-live time for a business like mine?

- Is the Implementation self-service or partner-led?

- Is training included?

- What support channels are available?

Ideally, the ERP vendor should offer support within South African business hours and understand local implementation hurdles, like load shedding.

6. Common Mistakes to Avoid During ERP Selection

Watch out for these traps:

- Rushing implementation without mapping your workflows

- Buying more features than your team can use

- Ignoring power outage contingencies (e.g., no offline access)

- Underestimating total cost of ownership or post-onboarding support

To Sum Up

Outdated systems might keep things running, but they can’t keep up with a growing manufacturing business. Whether you are managing high-SKU apparel lines, food batches with expiry dates, or complex outsourced jobs, the risk of fragmented operations adds up fast.

The right ERP manufacturing solution brings structure and real-time visibility across all operations — from inventory to production and costing. For South African SMEs, the choice isn’t about the most complex system; it’s about the best ERP for manufacturing industry fit.

Before you adopt a system:

- Map your workflows

- Measure your current level of visibility and control

- Assess your production and inventory complexity

The right ERP is the one that supports growth — not just operations. Especially for SMEs in South Africa, a well-fitted, affordable ERP is the path to smarter decisions and sustainable margins.

FAQs on ERP manufacturing Software in Africa

Here are answers to the most common questions South African manufacturers ask when evaluating ERP systems for production management.

What is ERP software in manufacturing?

ERP (Enterprise Resource Planning) software integrates core manufacturing operations, including inventory, production, procurement, and costing, into a single, unified system. It helps you streamline workflows, reduce manual errors, and track real-time data across your factory.

How is manufacturing ERP different from generic ERP systems?

Manufacturing ERP systems include production-specific features such as Bill of Materials (BOM), job costing, batch tracking, and shop floor control. Whereas generic ERP tools may only cover accounting or inventory, but not the actual production process.

Why are South African Manufacturers moving to ERP now?

Because spreadsheets and entry-level software fall apart as soon as things scale, many local factories are facing tighter margins, stricter audits, and more complex product lines. SME ERP solutions give them the visibility and control they need.

What kind of challenges does ERP help solve in South African manufacturing?

It helps manage inventory across multiple sites, track subcontracted work, plan production even during load shedding, and stay compliant with VAT or audit requirements. If you have ever had to stop a batch because materials weren’t ready or realized you undercharged a job, ERP solves those problems before they happen.

How does ERP help manufacturing companies in South Africa?

It integrates inventory, production, and costing into a single system. It helps factories manage multi-location stock, track outsourced jobs, stay compliant with SARS, and reduce delays caused by manual processes or power cuts. For SMEs, it’s a scalable way to manage growing complexity without hiring additional staff.

How much does ERP software cost for small manufacturers in South Africa?

Most cloud ERP systems for SMEs start around R300 to R1,000/month per user, depending on features and support. Some vendors offer pricing in USD with local support options.

Is there a free ERP system for manufacturers?

Yes, some cloud-based ERPs, such as Kladana, offer a free tier with basic production, inventory, and Bill of Materials (BOM) features. These are ideal for small teams.

Which ERP modules are most important for manufacturers?

- Inventory management

- Production planning & Scheduling

- BOM and product structure

- Shop floor control

- Costing tools

- MRP

- Sales order management

- Batch tracking and compliance

How long does ERP implementation take for a small factory?

Cloud-first systems like Kladana can go live in 2–6 weeks. Larger systems may take 2–4 months depending on complexity and customisation needs.

What should I consider before choosing an ERP system?

Look at how complex your production is, such as:

- Number of SKUs and BOM complexity

- Whether you outsource any production

- Whether you can handle ERP without customization

- Check if it supports local tax rules like VAT

- Whether it works well during load shedding and offers local support training

List of Resources

- PWC — PwC South Africa Manufacturing Analysis

- Case Study — Case Study on Load Shedding South Africa

- Grand View Research — Global ERP Software Report

Read‑alikes

Top ERP Software in South Africa for 2026: Comprehensive Guide, Solutions, Pricing & Business Impact

ERP Software in Malaysia: 2026 Buyer’s Guide for SMEs

How To Create a Quotation Format In Excel, That’s GST Ready, Error-Free, and Built for Scale

Quotation Format In Word: Free Templates for Freelancers, SMEs & MSMEs, Step-By-Step Guide

20 Best ERP Software in India and Worldwide for SMEs: 2026 Update