Effective inventory management plays a crucial role in the smooth operation of companies both big and small. However, even the most seasoned businesses can stumble upon common inventory management mistakes that severely affect their control. These inventory challenges often lead to significant inventory errors, resulting in financial losses, eroded customer trust from stockouts, and warehouses full of obsolete goods due to overstocking.

The consequences of poor decision-making in this sphere are far-reaching. In this article, we’ll delve into the typical inventory management mistakes and issues that plague businesses, from the financial impact of understocking to the logistical nightmares of poor visibility. Join us as we explore these inventory challenges and uncover practical inventory management solutions to enhance your strategies and build a more resilient operation.

What Is Effective Inventory Management in 2026

Good inventory management is crucial for the smooth operation of any business, serving as a primary defense against costly inventory management mistakes. It involves maintaining an optimal balance between supply and demand to ensure that products are readily available without excess stock. Effective inventory management prevents overstocking, which ties up valuable resources, and understocking, which can lead to missed sales opportunities.

Timely and accurate tracking of inventory levels helps businesses avoid unnecessary costs and navigate common inventory challenges, ensuring that products are in the right place at the right time. It also aids in identifying slow-moving items and preventing obsolescence, thereby minimizing costly inventory errors. In essence, good inventory management streamlines operations, reduces costs, and enhances overall efficiency, contributing to the success of a business.

How Inventory Mistakes Harm a Business

Inventory management mistakes can seriously harm your company’s bottom line. Failure to prioritize products based on demand often leads directly to stockouts of popular items, impacting sales and customer satisfaction, while simultaneously causing overstocking of slow-moving goods. Additionally, neglecting regular audits results in outdated items remaining in stock, further hindering profitability.

Neglecting a robust tracking system contributes to theft, shrinkage, and widespread inventory errors. This lack of organization leads to tedious manual work, decreasing employee motivation and productivity across the company.

Ultimately, these inventory management mistakes create a cascade of operational and financial problems. Let’s examine the most widespread errors and learn the practical inventory management solutions to overcome them.

Top 10 Inventory Management Mistakes and Solutions

Now, we’ll explore the ten most frequent inventory mistakes and provide actionable strategies to resolve them — helping you optimize stock levels, reduce costs, and improve overall supply chain performance.

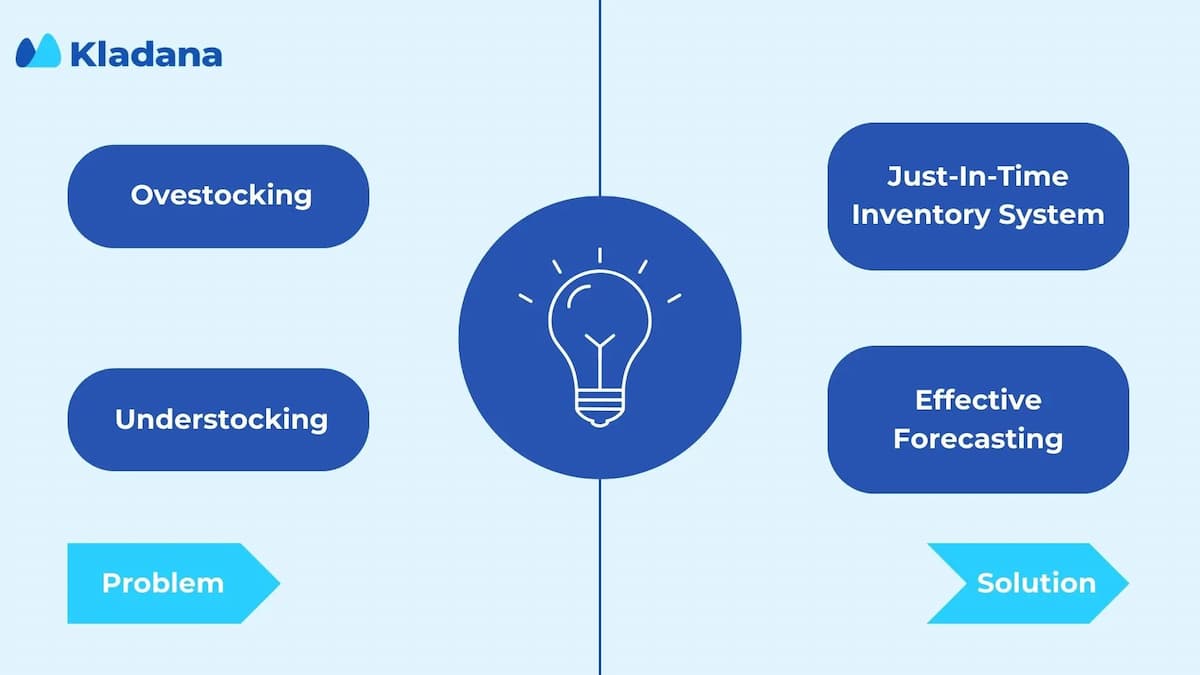

Mistake 1. Overstocking — How to Prevent It

Overstocking is a common inventory challenge that occurs when businesses hold excessive stock beyond demand. This classic inventory management mistake ties up capital, creates storage issues, and increases the risk of obsolescence, directly harming profitability.

Solution: To fix this inventory error, regularly analyze sales trends, set automated reorder points, and improve supplier communication. Implementing a just-in-time (JIT) system is one of the most effective inventory management solutions, as it ensures products are restocked only as needed. This approach helps maintain optimal stock levels, reduces carrying costs, and prevents the financial strain of overstocking, while also mitigating the opposite problem — understocking and potential stockouts.

🚀 How an Apparel Manufacturer Solved Overstocking

🧵 Problem: Lack of inventory visibility led to costly double purchases, cluttered shelves, and production delays.

🧵 Solution with Kladana:

- Uploaded all inventory data and organized storage bins — down to every single button

- Implemented daily tracking of every item — from fabric to zippers

- Eliminated double purchases through real-time inventory visibility

📘 Recommended Read:

🔹 How to Calculate Safety Stock and Prevent Shortages — a template for stock optimization

🔹 Dead Stock: How to Identify and Liquidate It — methods to handle obsolete inventory

🔹 Inventory Control: Complete Guide — comprehensive warehouse management manual

Mistake 2. Understocking — Forecasting to Avoid It

Understocking represents a critical inventory management mistake where insufficient stock levels lead directly to stockouts, lost sales, and customer dissatisfaction. These inventory errors damage brand reputation and revenue streams, making them a serious inventory challenge for growing businesses.

Solution: To prevent these costly inventory errors, implement robust demand forecasting and analyze sales trends consistently. By leveraging historical data and monitoring market patterns, businesses can anticipate demand accurately — a core inventory management solution. Maintaining strong supplier relationships and creating flexible replenishment strategies further ensures prompt restocking. Addressing understocking proactively not only prevents stockouts but also transforms inventory into a competitive advantage, maximizing both customer satisfaction and revenue potential.

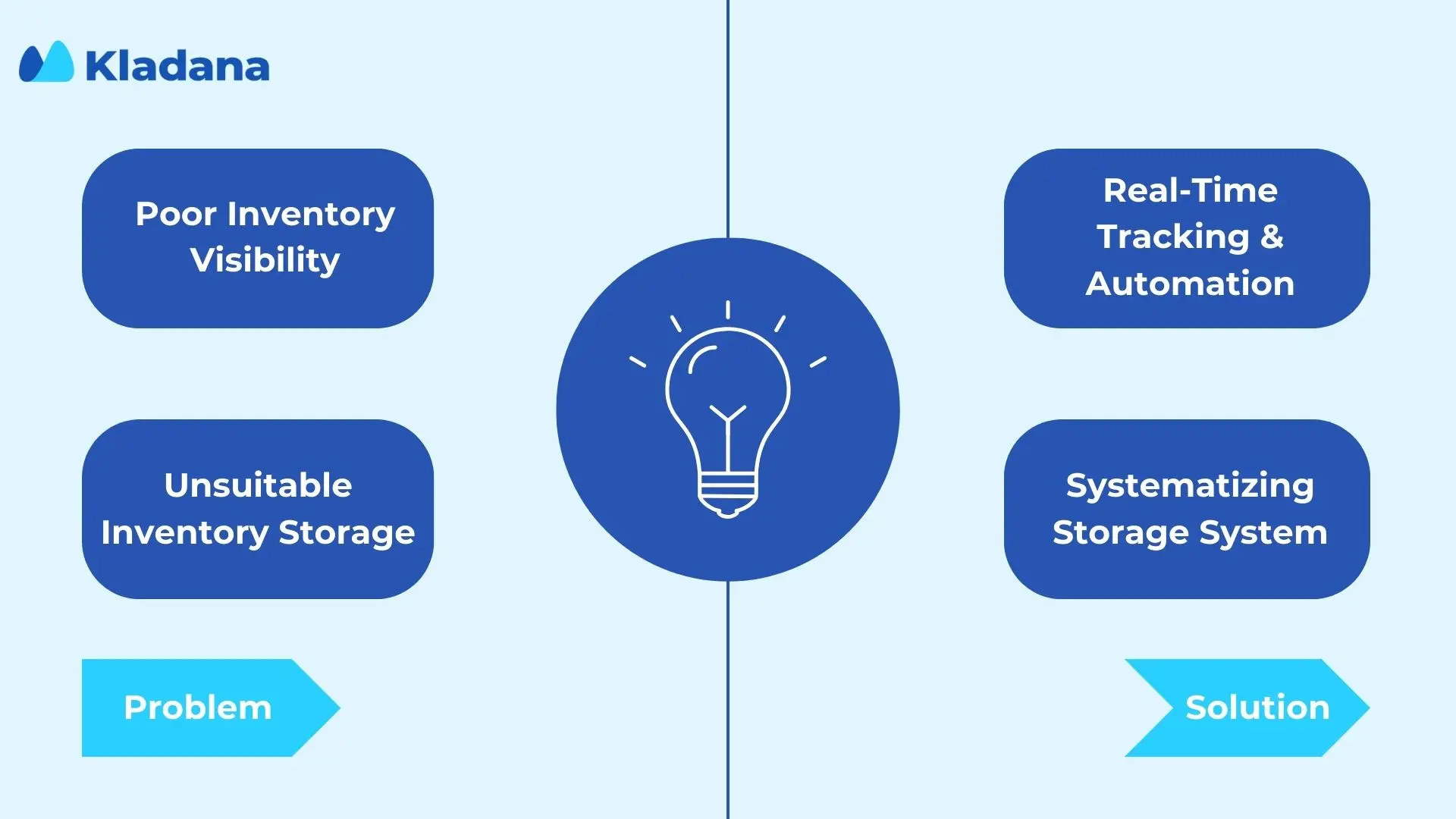

Mistake 3. Poor Inventory Visibility — Fix It with Barcoding Technology

Poor inventory visibility is a fundamental inventory management mistake that leaves businesses struggling to track stock accurately. This critical inventory challenge creates a chain reaction of inventory errors, leading directly to both overstocking and unexpected stockouts, resulting in financial losses and customer dissatisfaction.

Solution: Implementing modern inventory management solutions with real-time tracking is key to resolving this. Utilizing barcode scanners, RFID technology, or dedicated software provides a clear, instant view of stock levels. This automation eliminates manual inventory errors, enables informed decision-making to prevent excess stock, and ensures product availability. By fixing poor visibility, businesses not only enhance operational efficiency but also build a foundation for successful inventory control.

🚀 How an Rug Manufacturer Solved Inventory Visibility Issues with Barcoding

✂️ Problem: Discovery of 270 carpets shipped without any tracking — complete loss of inventory control.

✂️ Solution with Kladana:

- Implemented barcode system for all inventory items

- Generated unique barcodes for all 270 products within an hour

- Enabled real-time tracking with scanner technology

- Eliminated manual Excel updates and data discrepancies

📘 Recommended Read:

🔹 Barcode Inventory Software: How to Implement and Use — a complete guide to implementing barcode systems

🔹 Barcoding in Warehouse Management: Best Practices — how to optimize warehouse operations with barcode technology

Mistake 4. Unsuitable Inventory Storage — Optimize Layout for Faster Fulfillment

Unsuitable inventory storage represents a significant inventory challenge that many businesses overlook. This common inventory management mistake — storing items haphazardly without proper organization — leads to difficulties in locating products, causing delays, picking inventory errors, and ultimately financial losses.

Solution: Implementing a systematic storage system is a crucial inventory management solution. By categorizing products based on size, demand frequency, or expiry date, businesses can dramatically improve location accuracy and retrieval speed. Investing in proper shelving, clear labeling, and digital tracking systems further enhances organization, ensuring items are always accessible when needed.

Addressing unsuitable storage not only streamlines operations but also creates a foundation for resolving other inventory management mistakes like stockouts and overstocking, ultimately boosting fulfillment speed and customer satisfaction.

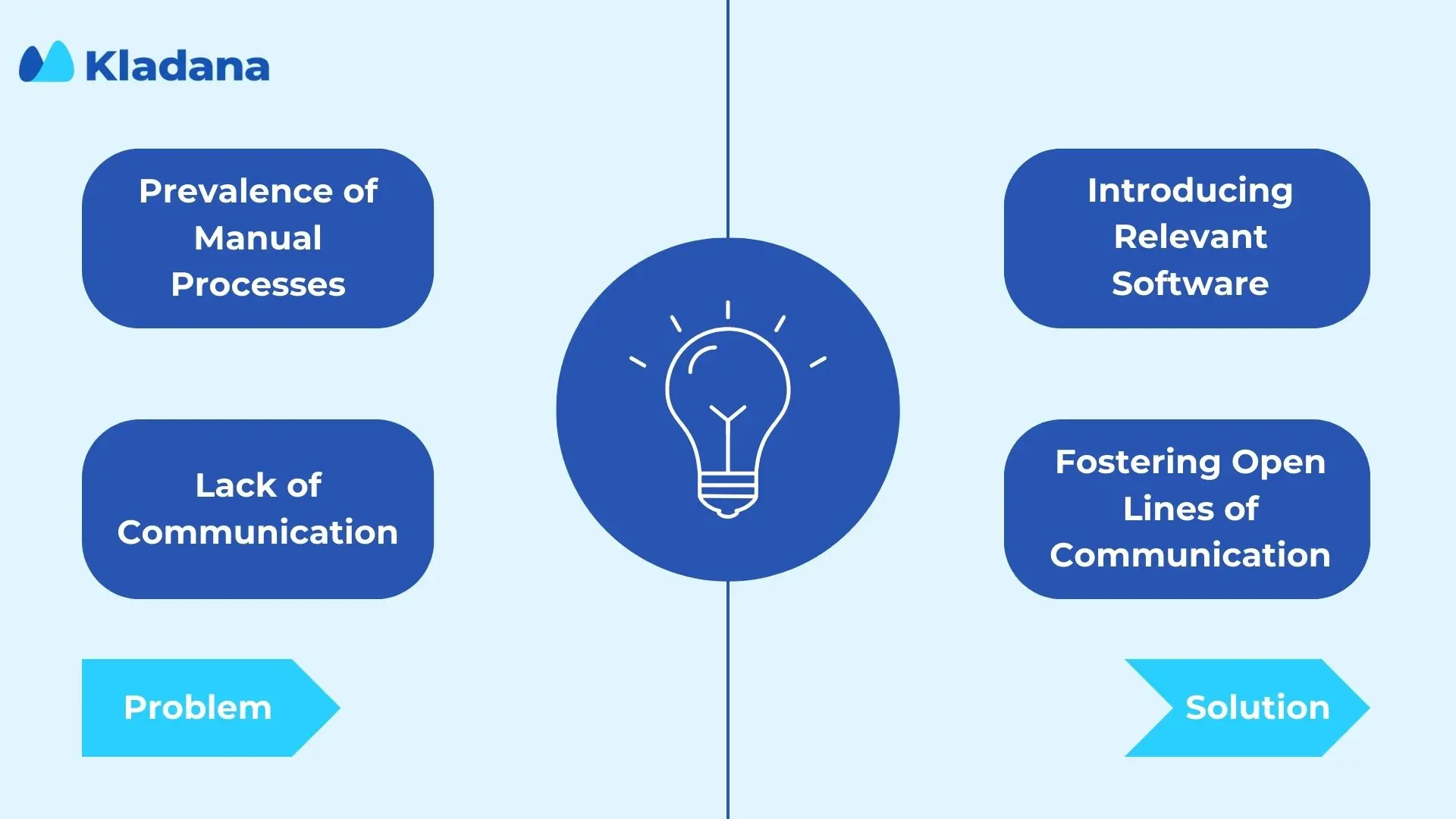

Mistake 5. Prevalence of Manual Processes — Switch to Automated Inventory Control

Relying on manual processes like spreadsheets and paper logs is one of the most costly inventory management mistakes. This approach creates significant inventory challenges, leading directly to data inventory errors, operational inefficiencies, and a higher risk of both stockouts and overstocking.

Solution: Transitioning to automated inventory management solutions is the most effective way to eliminate these issues. By implementing modern software that automates order processing, stock tracking, and reporting, businesses can drastically reduce human error and streamline operations. This digital transformation not only enhances data accuracy but also provides real-time insights for better decision-making.

Adopting automation is a fundamental inventory management solution that helps optimize stock levels, prevent costly inventory errors, and create a more efficient, responsive supply chain.

Automate Inventory Control — End Manual Tracking in One System

Kladana replaces spreadsheets and handwritten logs with real-time, accurate inventory management

✅ Eliminate human errors in stock level monitoring and reporting

✅ Gain real-time visibility across all warehouses and storage zones

✅ Automate replenishment to prevent stockouts and overstocking

✅ Sync inventory data seamlessly with sales and procurement

Mistake 6. Lack of Communication and Limited Skills — Bridge Gaps with Training and Tools

A lack of communication and limited employee skills are inventory challenges that often lead to costly inventory management mistakes. When information doesn’t flow seamlessly between departments, discrepancies in stock levels and delayed orders become common inventory errors. Furthermore, if staff lack the skills to use modern systems or understand supply chain principles, these problems are compounded, increasing the risk of stockouts and overstocking.

Solution: To resolve these issues, businesses should implement structured inventory management solutions. This includes fostering open communication through regular inter-departmental meetings and unified reporting platforms. Simultaneously, investing in continuous training ensures employees can effectively utilize inventory software and understand best practices.

By bridging these communication and skill gaps, companies can minimize inventory errors, optimize efficiency, and build a more resilient inventory system that prevents many common inventory management mistakes.

Mistake 7. Inadequate Integration with Other Systems — How to Create a Unified Business Ecosystem

Inadequate integration with other business systems is a critical inventory management mistake that creates significant inventory challenges. When your inventory system operates in isolation from sales, procurement, and accounting platforms, it leads to data silos and inconsistent information. This fragmentation causes widespread inventory errors, including inaccurate stock levels, which can result in both stockouts and overstocking.

Solution: Implementing seamless integrations is a powerful inventory management solution that creates a unified business ecosystem. By connecting your inventory software with other critical systems, you enable real-time data exchange across all departments. This integration ensures everyone works with accurate, up-to-date information, streamlining processes and minimizing inventory errors.

A well-integrated system not only prevents the inventory management mistakes associated with poor connectivity but also enhances overall operational efficiency, providing a solid foundation for sustainable business growth.

Mistake 8. Growing Competition — Leverage Technology to Stay Ahead

As growing competition intensifies, businesses face heightened inventory challenges where inefficiencies directly impact market position. Companies using outdated methods often struggle with inventory errors that lead to either stockouts (missing sales opportunities) or overstocking (tying up capital), putting them at a significant disadvantage.

Solution: Adopting advanced inventory management solutions provides the necessary competitive edge. Modern systems with automation and real-time analytics enable precise stock control, accurate demand forecasting, and streamlined procurement. This technological advantage helps prevent costly inventory management mistakes, ensures optimal stock levels, and improves customer satisfaction through reliable order fulfillment.

By leveraging technology, businesses can transform their inventory from a cost center into a strategic asset, effectively responding to market demands and maintaining competitiveness despite growing competition.

Mistake 9. Fluctuating Customer Demand — Master Forecasting for Stability

Fluctuating customer demand presents a significant inventory challenge that, if mismanaged, becomes a critical inventory management mistake. Unpredictable market shifts often lead to a damaging cycle of overstocking and stockouts — tying up capital in slow-moving goods while missing revenue opportunities from popular items.

Solution: Implementing robust demand forecasting is a fundamental inventory management solution. By analyzing historical sales data, market trends, and customer behavior patterns, businesses can create accurate predictions rather than relying on guesswork. Modern inventory systems enable regular forecast updates using real-time data, allowing for dynamic inventory adjustments.

This proactive approach to fluctuating customer demand helps maintain optimal stock levels, prevents costly inventory errors, and creates operational stability. Ultimately, mastering forecasting transforms inventory management from reactive to strategic, ensuring you meet market demands efficiently while minimizing costs and maximizing customer satisfaction.

Mistake 10. Supply Chain Complexity — Tame It with Digital Tools

Supply chain complexity represents one of the most demanding inventory challenges in modern business. An intricate network of suppliers, distributors, and partners often leads to communication breakdowns, delayed shipments, and misaligned production schedules. These complications frequently result in critical inventory management mistakes, including widespread inventory errors that manifest as both unexpected stockouts and costly overstocking.

Solution: Implementing digital tools provides powerful inventory management solutions to tame this complexity. Cloud-based inventory systems, advanced analytics, and automation technologies create visibility across the entire supply chain, enhancing communication and streamlining processes. These tools provide accurate demand forecasting and real-time inventory tracking, enabling businesses to optimize stock levels and respond proactively to disruptions.

By leveraging technology to simplify supply chain operations, companies can transform complexity from a liability into a competitive advantage, reducing costs and building a more resilient, efficient inventory management system that minimizes inventory errors and maximizes operational performance.

Tools and Systems That Eliminate Inventory Mistakes

To effectively tackle common inventory challenges, modern automated inventory management solutions have become essential for businesses seeking to eliminate costly inventory management mistakes. These systems directly address root causes of inventory errors and provide comprehensive protection against stockouts and overstocking.

Key solutions include:

1. Barcode & RFID Systems

Automated identification technology ensures accurate product tracking from receipt to sale, eliminating manual counting inventory errors and providing real-time visibility into stock movements.

2. Cloud-Based Inventory Platforms

Centralized systems maintain consistent data across all locations and departments, preventing discrepancies and enabling coordinated inventory control. These platforms offer real-time stock level updates accessible from anywhere.

3. Automated Replenishment Systems

Smart algorithms analyze sales patterns and automatically generate purchase orders when inventory reaches predetermined levels, effectively preventing both stockouts and overstocking while optimizing inventory turnover.

4. Integration Capabilities

Seamless connectivity with delivery, e-commerce, and accounting systems ensures data consistency across business functions, eliminating siloed information that often leads to inventory management mistakes.

These technological inventory management solutions not only streamline operations but also create a foundation for sustainable growth by minimizing manual errors and providing the analytical insights needed for strategic decision-making. By implementing these tools, businesses can transform their inventory management from a constant challenge into a competitive advantage.

📘 Recommended Read:

🔹 Best Free Inventory Management Software in 2026 — compare top free tools that provide real-time tracking and automated alerts without upfront costs

🔹 Stock Taking: Methods and Best Practices — learn how to conduct accurate inventory counts and reconcile discrepancies using barcode system

🔹 Why Inventory Management Matters for Business Growth — understand how proper inventory control impacts cash flow, customer satisfaction, and operational efficiency

Frequently Asked Questions on Typical Inventory Management Mistakes

Below you’ll find answers to common questions about inventory management mistakes, their causes, and how to implement effective inventory management solutions.

What is bad inventory management?

Bad inventory management refers to the inefficient control of stock, leading to common inventory errors such as overstocking, understocking, and inaccurate record-keeping. It represents a failure to align inventory levels with actual demand, resulting in financial losses, customer dissatisfaction, and operational inventory challenges.

How can automation reduce inventory mistakes?

Automation directly tackles common inventory management mistakes by replacing error-prone manual processes. It reduces inventory errors in several key ways:

- Eliminates manual data entry: automated data capture via barcode scanners prevents typos and miscalculations in stock counts, a primary cause of discrepancies.

- Prevents stockouts and overstocking: automated reorder points trigger purchase orders when inventory falls to a specific level, ensuring timely replenishment and avoiding both understocking and overstocking.

- Provides real-time visibility: cloud-based systems offer a single source of truth, giving a clear, real-time view of stock levels across all locations to prevent overselling and improve decision-making.

- Enhances forecasting accuracy: by analyzing sales data automatically, these systems provide more reliable demand forecasts, helping to optimize stock levels and mitigate inventory challenges related to fluctuating demand.

These inventory management solutions create a more resilient, accurate, and efficient system.

What are the main causes of inventory inefficiency?

The main causes of inventory inefficiency often stem from a combination of manual processes and poor visibility, leading to significant inventory challenges. Key causes include:

- Reliance on manual processes: using spreadsheets and handwritten logs is slow and highly prone to inventory errors, leading to incorrect stock data.

- Poor demand forecasting: without accurate data analysis, businesses struggle to predict customer demand, resulting in the twin problems of overstocking (tying up capital) and understocking (leading to stockouts and lost sales).

- Lack of real-time visibility: inability to track inventory accurately across multiple warehouses or sales channels causes fulfillment delays, overselling, and misguided purchasing decisions.

- Inadequate inventory management solutions: the use of disconnected systems that don’t integrate with sales, procurement, or accounting creates data silos and operational delays.

Addressing these root causes with integrated inventory management solutions is crucial for optimizing efficiency and profitability.

Why is inventory management so complicated?

Inventory management complexity stems from multiple inventory challenges, including fluctuating demand, supplier reliability issues, and evolving market trends. Balancing sufficient stock to prevent stockouts while avoiding excess inventory that ties up capital requires precise coordination and reliable inventory management solutions.

Why is inventory management a high‑risk endeavor?

Inventory management carries significant risk due to its direct impact on cash flow and customer relationships. Overstocking increases holding costs and obsolescence risks, while understocking leads to missed sales opportunities. Market volatility and supply chain disruptions further amplify these inventory management mistakes, making proactive management essential.

How does poor inventory management affect a company’s bottom line?

Poor practices directly reduce profitability through multiple channels: excess inventory increases storage costs, stockouts cause lost sales, and inventory errors require costly corrections. These inventory challenges strain resources, lower operational efficiency, and ultimately diminish revenue and customer trust.

What steps can businesses take to mitigate inventory management challenges?

Businesses can overcome these inventory challenges by:

- Implementing automated tracking systems

- Using data analytics for accurate forecasting

- Maintaining strong supplier relationships

- Conducting regular inventory audits

- Adopting cloud-based inventory management solutions

These strategies help prevent common inventory management mistakes, optimize stock levels, and create a more resilient supply chain.