When you’re managing hundreds or even thousands of SKUs, every mistake adds up. A missing item here, an overstocked product there, or a delayed reorder can directly affect your cash flow, customer satisfaction, and fulfillment speed.

That’s exactly why you’re seeing a significant shift across the industry. In fact, according to Fortune Business Insights, the Global Inventory Management software market is projected to grow from $2.19 billion in 2024 to $4.12 billion by 2032. This proves that real-time control and automation are now mission“critical”.

This is where inventory management software features make a real difference. From real-time inventory tracking to automated reorder triggers, the right system gives you complete control over stock, orders, and warehouses without manual “guesswork”.

But not all platforms offer the same capabilities. You need to know which features of an inventory management system truly impact efficiency and which ones are just surface-level “add-ons”.

In this guide, you’ll explore:

- The essential features of inventory management software that power day-to-day operations

- Advanced tools that solve complex problems like stockouts, returns, or multi-channel sync

- Examples of how these inventory software features improve speed, accuracy and profitability

- Decisions checklists and ROI insights to help you choose the best fit system

What Is Inventory Management Software?

Inventory management software is a digital system designed to help you control stock movement across your supply chain. Whether you’re tracking raw materials, finished goods, or returns, it provides you with complete visibility into what’s available, where it’s located, and what actions need to be taken, such as replenishing fast-moving SKUs or halting expired stock.

A modern inventory management system connects your warehouse, purchase, and sales operations. Every transaction, whether it’s an inward shipment, a stock transfer, or a customer return, updates the system in real time. This eliminates the guesswork from your inventory processes.

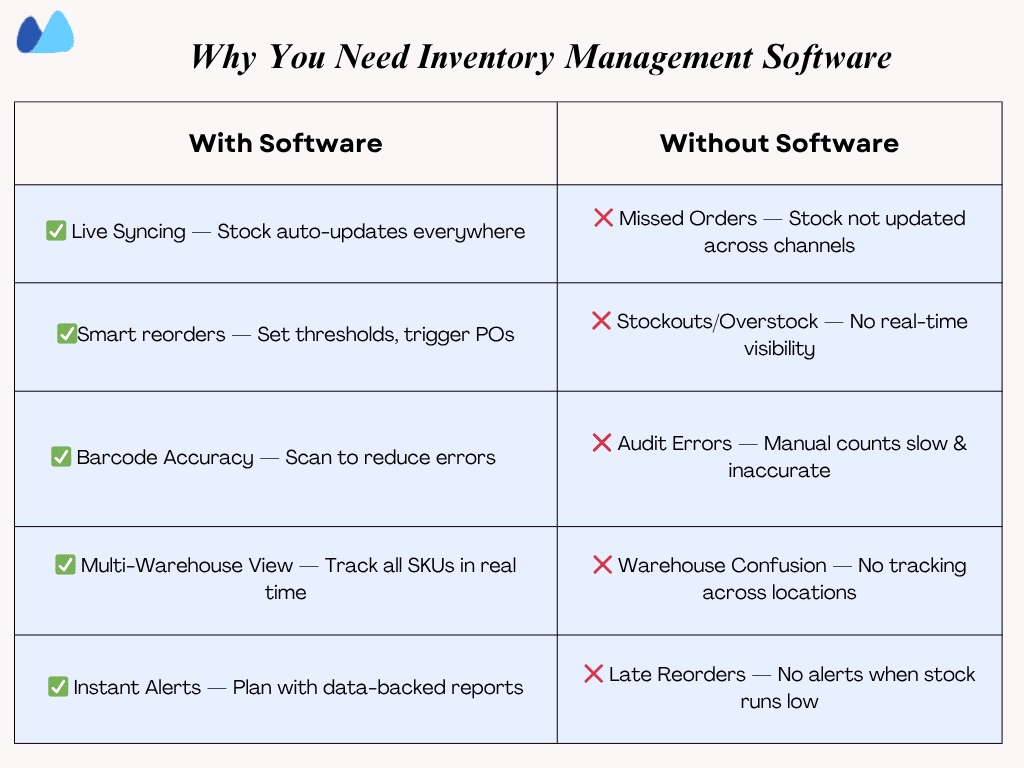

Why It’s Critical for Growing Businesses

Growth brings complexity. As your order volume rises or your catalog expands, small mistakes can snowball into big losses. You’ll suffer from missed orders, wrong shipments, overselling, or tying up capital in dead stock.

And that’s the reason why you should understand the features of an inventory management system.

You will need tools that will help you to:

- Avoid stockouts by setting reorder points and receiving alerts

- Prevent overstock through data-driven purchasing

- Eliminate dispatch errors using barcode scans and pick lists

- Coordinate multiple warehouses without duplication

- Track inventory movement at every stage, from supplier to customer

📔 Recommended Read: Want a deeper look at how inventory impacts every part of your operations? Explore the importance of Inventory management

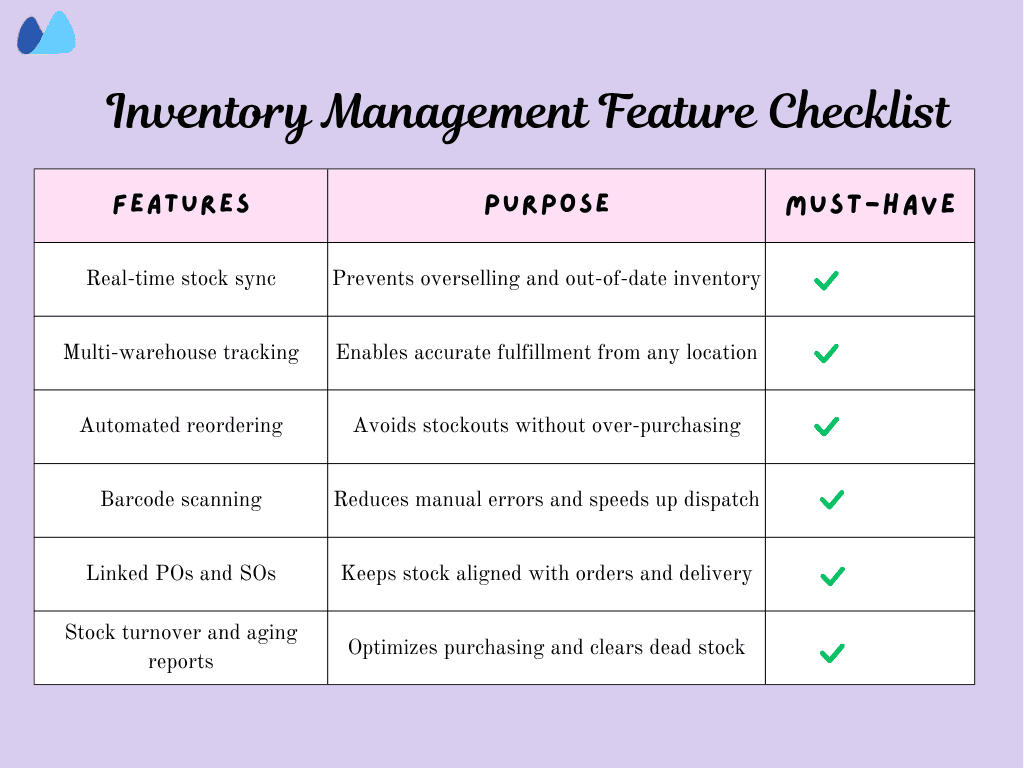

Must-Have Features OF Inventory Management Software

When evaluating solutions, it’s not enough for software to support inventory. You will need to know which features directly improve speed, accuracy, and control.

Below are the six essential features of Inventory management software for scaling your business without chaos.

1. Real-Time Inventory Tracking

If your inventory isn’t updated the moment something moves, you risk making decisions based on outdated or incorrect data.

Real-time inventory tracking ensures that every stock movement, whether it’s a purchase, sale, return, or internal transfer, should be reflected immediately across your team. It is very important if you’re selling on multiple platforms or managing more than one warehouse.

It allows you to:

- Prevent overselling by syncing available quantities across all channels

- Instantly reflect goods received or dispatched in your inventory

- Give every item, such as sales, warehouse, and procurement, access to accurate data

- Make purchasing and stocking decisions based on real-life numbers

➡️ With Kladana, this tracking happens automatically in the background. Your stock gets updated across sales channels and warehouses the moment goods are received, sold, or returned. This level of visibility helps you avoid last-minute order cancellations and customer dissatisfaction.

2. Multi-Locations & Multi-Warehouse Support

Once your business operates across regions, branches, or warehouses, managing inventory becomes complex. Without a system that supports multi-location inventory, stock discrepancies multiply quickly.

A robust inventory management system gives you:

- The ability to define each warehouse or location separately

- Stock tracking at the warehouse, zone, or bin level

- Warehouse-specific reorder rules, pricing, and supplier mapping

- Real-time stock transfer tracking with approval workflows

📌 For example: You might dispatch online orders from one warehouse while reserving bulk inventory at another. This feature makes that possible, without mixing up stock levels.

3. Automated Reorder Points

Manual reorder processes fail when order volumes increase or the number of SKUs diversifies. If you rely on memory or periodic checks to reorder stock, you’re bound to miss something.

With automated reorder points, you can:

- Set minimum and maximum inventory thresholds per SKU

- Add buffer stock based on vendor lead time or sales trends

- Auto-generate purchase orders when levels dip below safe thresholds

- Prioritize high-velocity SKUs without overstocking slow movers

➡️ With Kladana, you can configure smart reorder rules for every item. This system monitors inventory and automatically raises a PO the moment stock drops below your defined threshold. In this way, it protects your revenue while minimizing excess inventory that drains cash.

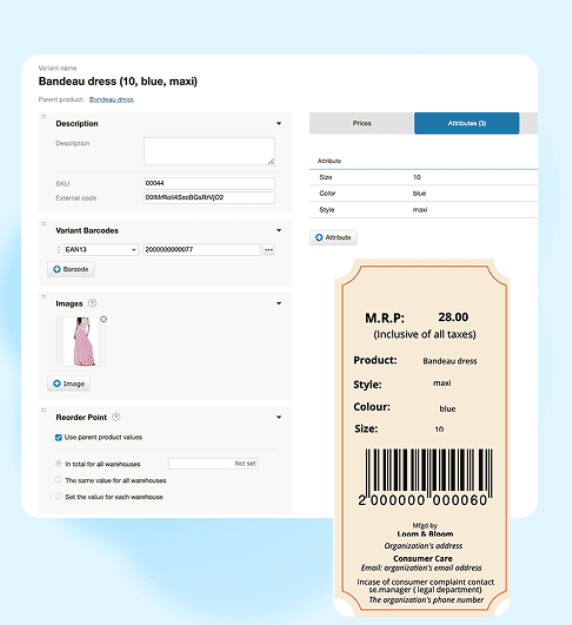

4. Barcode & RFID Integration

Accuracy and speed are everything in a growing warehouse. Barcode and RFID tools reduce dependency on manual entry, speed up operations, and improve stock accuracy.

The features of inventory management systems with barcode/RFID support allow you to:

- Scan SKUs during receiving, picking, packing, and returns

- Validate order accuracy with real-time error checks

- Run rolling stocks without halting operations

- Maintain traceability for serialized, batch, or expiry-bound products

📌 For Example: If a picker scans the wrong item, the system immediately flags it, avoiding mistakes. During audits, scanning shelves instead of counting manually can cut audit time by 60-70%

☑️ Note: These tools are especially helpful in high-SKU environments like ecommerce, pharma, or electronics, where minor errors have big costs.

5. Purchase & Sales Order Management

Inventory lives in between two flows. One is what you buy, and the other is what you sell. Your system should connect both ends seamlessly, so that stock always matches transactional reality.

A good inventory management system should let you:

- Link each incoming PO to specific vendors, SKUs, and expected delivery dates

- Auto-reserve available stock for incoming sales orders

- “Track order status”, such as pending, in progress, partially received, or fulfilled

- Prevent double-allocation or dispatching stock that’s already committed

📌 For Example: If 20 units are in stock but 15 are already committed to a B2B customer, your ecommerce site should show only five available. Without PO/SO integration, such allocations are not possible and, in the end, lead to short-ships and canceled orders.

6. Reporting & Analytics

You can’t improve what you can’t measure. That’s why inventory reporting is critical. It is not just for audits but for growth planning and working capital optimization.

Your system should give you:

- Inventory turnover ratios to identify fast-and slow-moving items

- Stock aging reports that show how long items sit unsold

- Dead stock alerts to clear non-performing SKUs

- Forecasting reports to plan purchases based on sales history

- Warehouse efficiency metrics to improve pick/pack performance

Advanced Features To Look For

Once your business has outgrown basic stock control, the next challenge is scale. These advanced inventory management software features help you streamline complex workflows, forecast better, and reduce errors in high-volume environments.

📈 Demand Forecasting

If you’re still guessing how much to reorder based on instinct or last month’s sales, then you are already behind. Demand forecasting is one of the most valuable yet underutilized features of an inventory management system.

This feature uses sales trends, lead times, and seasonality to predict future stock requirements.

With this, you can:

- Project SKU-level demand over weeks or months

- Adjust purchasing based on promotions, launches, or events

- Reduce overstock by aligning orders with actual trends

- Prevent last-minute orders or panic buys

📌 Accenture’s case study shows how businesses like yours can achieve 6-8 percentage point improvements in forecast accuracy just by unifying demand data across channels. That translates into over $100-130 million in inventory and operational benefits. It proves that advanced forecasting isn’t just an option, but it’s a direct lever for growth.

➡️ Note: Advanced features combine inventory data with historical sales and even external factors like lead time fluctuations to generate accurate forecasts. This helps your team transition from reactive to proactive. It directly improves cash flow by cutting excess stock

🔢 Batch & Serial Number Tracking

Batch and serial number tracking is a key inventory management feature that enables you to monitor the movement, sale, and expiry of individual units or lots.

With batch tracking, you can:

- Identify and isolate defective batches during a recall

- Comply with food, pharma, or cosmetic regulations

- Track expiry and avoid dispatching expired products

📖 Recommended Read: If you manage perishables or run a food business, this guide on Food Inventory Management breaks it all down for you

📌 For Example: If you’re a supplement seller, and one batch fails lab tests, batch tracking lets you instantly see which customers received products from that lot so that you can notify them and pull the inventory.

Serial number tracking, on the other hand, is ideal for individual product traceability. For instance, if you sell laptops or industrial tools, assigning a unique serial number to each unit helps with warranty tracking, support, and ownership verification.

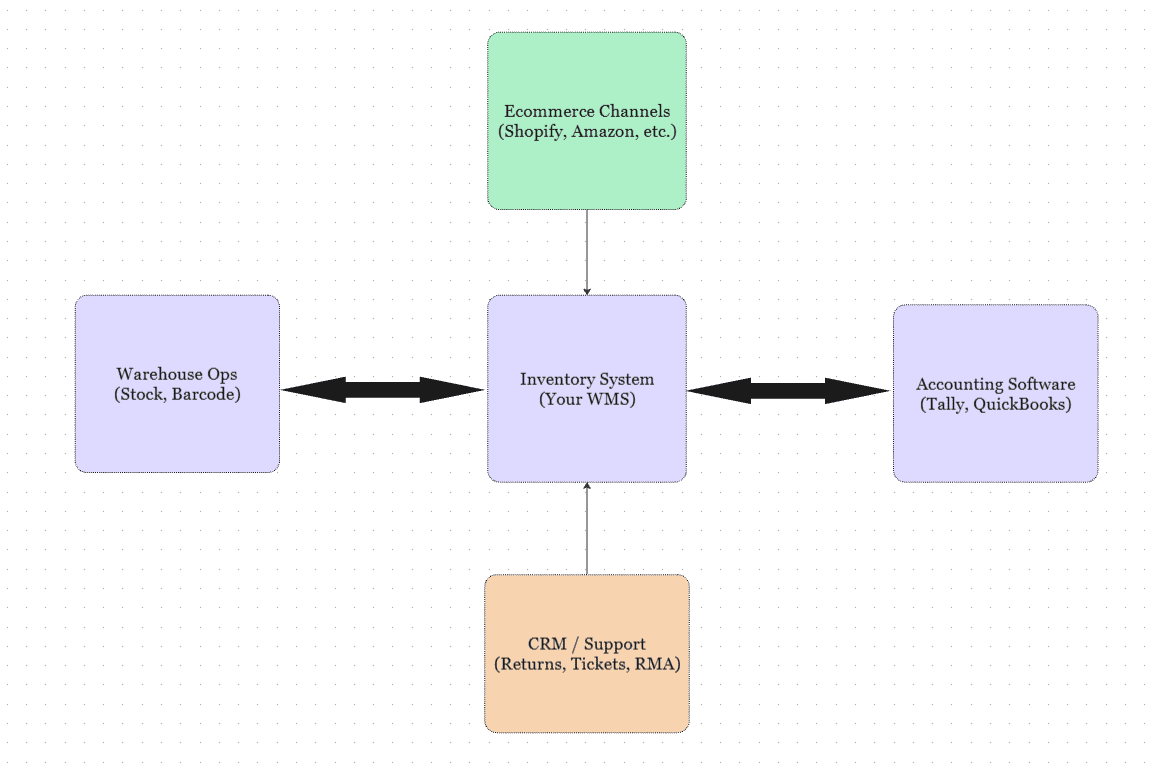

🔗 Integration with E-Commerce Platforms & Accounting Systems

The inventory system shouldn’t operate in silos. To avoid duplication, delays, and data mismatches, your software must integrate with both sales and financial platforms.

Look for inventory software features that support:

- Sync inventory with your e-commerce storefronts like Shopify, Amazon, or WooCommerce

- Send sales and purchase data to accounting software like Tally or QuickBooks

- Reflect order status changes in real time across channels

📌 For Example: If you’re an online furniture seller and someone places an order via your Shopify site, your inventory should reduce instantly, the PO should reflect the dispatch, and your accounting system should update the COGS (Cost OF Goods Sold) without you lifting a finger.

♻️ Returns & RMA (Return Merchandise Authorization) Workflows

Returns are a reality in e-commerce and wholesale, especially with higher volumes. But without structured handling, they create stock mismatches and shrinkage.

Therefore, an advanced feature of inventory management should include dedicated return workflows. These allow you to:

- Create and approve returns linked to the original order or invoice

- Record the condition of returned goods

- Move approved returns back into inventory or segregate them in a quarantine zone

- Automatically adjust stock levels and issue refunds or credit notes

📌 For Example: If you run a D2C electronics brand and a customer returns a Bluetooth speaker, the system should log in under that serial number, assign it a status, and mark the status whether it is “tested good or damaged. In this way, it either moves it to restock or initiates a supplier return, so manual updates are needed here.

☑️ Tip: If you are planning to scale across multiple channels or expand into new markets, these advanced inventory management software features will give you the edge. They allow you to reduce risk, improve forecasting, and stay lean even as complexity grows.

How These Features Solve Common Problems

The right inventory management software doesn’t just improve workflow; it also enhances overall business operations. They also eliminate recurring pain points that stall growth, waste time, and drain profits.

Here’s how they solve:

1. Stockouts and Overstocking

Running out of high-demand SKUs leads to missed sales, while overstocking locks up cash and space.

Fixed by: Real-time inventory tracking + Automated Reorder Points

- Prevent you from last-minute reorders by monitoring stock levels

- Keeps your sales channels updated instantly to avoid overselling

- Maintains your healthy stock with rules based on thresholds and lead times

- Removes guesswork from purchasing with demand-driven reordering

📌 For Example: You run a D2C supplement brand and set a reorder level for its top-selling vitamin. Your system auto-generates a PO as stock drops and syncs live quantities across your Shopify and Amazon sites, preventing you from overselling and understocking

2. Manual Entry and Order Errors

Manual processes lead to shipment mistakes, double entries, and costly customer returns.

Fixed by: Barcode & RFID Integration + Order Management Features

- Speeds up receiving, picking, and packing with scan-based workflows

- Reduces your pick-list errors through real-time validation

- Ensures that each order pulls from actual stock with automatic allocation

- Integrates your inventory with purchase and sales orders for full traceability

📌 For Example: A picker selects the wrong product. Barcode scanning detects the mismatch and stops dispatch. The correct item is scanned and packed, preventing a return and refund.

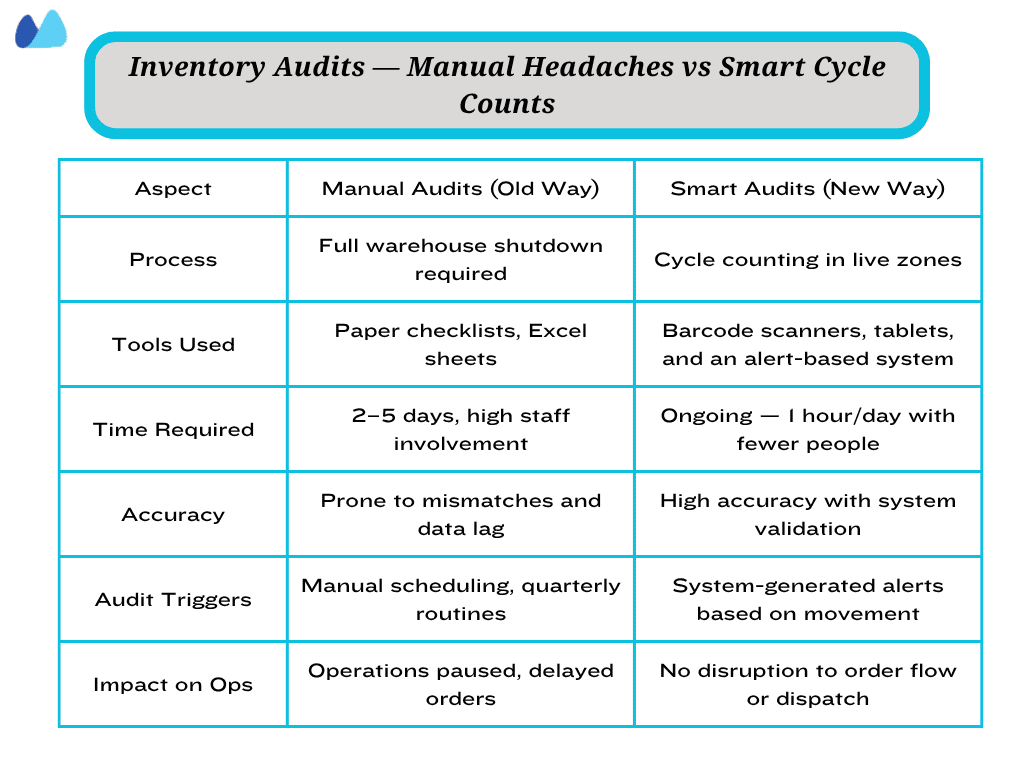

3. Long and Disruptive Stock Audits

Traditional audits stall operations, drain labor hours, and often miss underlying issues.

Fixed by: Cycle Count Workflows + Inventory Reporting

- It enables rolling counts without halting warehouse activity

- Flags discrepancies and mismatches before they escalate

- Prioritizes high-risk zones based on turnover or alerts

- Reduces audit time by focusing only on what needs attention

📌 For Example: Instead of shutting down for a full audit, your system highlights five SKUs in a single aisle. Staff count only that segment, fix variances, and continue operations with zero downtime.

Calculate The ROI Of Inventory Management Software

Understanding the return on investment isn’t just about the price of software. It’s about the cost you eliminate by using the right features. Whether you’re losing money to stockouts, fulfillment errors, or excess inventory, powerful inventory management software features directly impact your bottom line.

Simple ROI Formula (Previously, monthly cost − Cost after implementation) x 12 = Savings

📊 Sample ROI Table

| Operational area | Before software | After software | Monthly savings | Annual impact |

Fulfillment errors |

$4,000 |

$1,500 |

$2,500 |

$30,000 |

Lost sales from stockouts |

$6,000 |

$2,000 |

$4,000 |

$48,000 |

Overstock holding costs |

$3,500 |

$1,500 |

$2,000 |

$24,000 |

Manual audit & rework |

$2,000 |

$500 |

$1,500 |

$18,000 |

Total estimated |

$120,000/year |

|||

📌 Tip: Use your actual figures for error rates, order volumes, and labor hours to customize this table. Even small changes in accuracy or speed can create significant long-term savings.

🚀 Cut Errors, Boost Cash Flow — Upgrade To Kladana

Fewer mistakes, faster audits, and better Inventory ROI

To Sum Up

When inventory becomes harder to control, it’s often a symptom, not the cause. Disconnected tools, delayed reordering, and guesswork-heavy audits don’t just slow you down; they limit how far you can scale

By investing in the right inventory management software features, you gain more than operational efficiency. You unlock faster order cycles, better cash flow, cleaner audits, and fewer customer complaints.

FAQs On Inventory Management Features

What are the key features of Inventory management software?

The most important features include:

- Real-time stock tracking

- Automated reorder points

- Multi-warehouse support

- Barcode integration

- Purchase and sales order syncing

- Analytics dashboards

How does automated reordering work?

You can set reorder rules for each SKU based on:

- Minimum stock levels

- Vendor lead time

- Safety stock

So, when the system detects that inventory has dropped below the threshold, it automatically generates a purchase order.

Can Inventory Software handle multiple warehouses?

Yes. Most modern systems include multi-location and multi-warehouse support. It allows you to define separate warehouses, racks, or zones. You can transfer stock between locations, set reorder rules per warehouse, and monitor stock performance across your network.

What is the benefit of barcode scanning?

Barcode and RFID integration speeds up receiving, picking, and dispatch. It eliminates manual data entry, reduces picking errors, and ensures that your team scans exactly what was ordered.

Does It Integrate with e-commerce stores?

Yes. Leading systems integrate with platforms like Shopify, WooCommerce, and Amazon, among others. These e-commerce integrations sync orders, update stock levels in real-time, and prevent overselling.

Can it track batches or expiration dates?

Yes. With batch and serial number tracking. You can trace products on the production lot or individual unit. This is critical for industries such as food, pharmaceuticals, or electronics, where managing expiration dates, recalls, and warranties is essential.

How does inventory software reduce errors?

It eliminates manual processes such as spreadsheet entry or handwritten picklists. Features like barcode scanning, real-time updates, and linked order workflows prevent duplicate data, mispicks, and incorrect inventory allocations, dramatically reducing fulfillment errors.

What reports should it generate?

Your system should provide:

- Inventory turnover reports

- Stock aging

- Dead stock analysis

- Forecasting reports

- Warehouse-level performance

These help you optimize purchase decisions, avoid overstock, and track what’s driving your margins.

Is cloud better than on-premise for inventory systems?

Yes. Cloud-based inventory systems provide remote access, facilitate easier updates, offer lower upfront costs, and enable automatic backups. On-premises may make sense if you have strict offline requirements or custom infrastructure, but it is harder to scale and maintain

How do I choose the right feature set for my business?

Start by mapping your current pain points. If you face overselling, prioritize real-time tracking and ecommerce sync. If you manage perishable goods, look for batch tracking and expiration alerts. Select software that aligns with your order volume, warehouse setup, and integration requirements.

List of Resources

- Fortune Business Insights: Inventory Management Software Market

- Accenture: Case studies on supply chain using demand forecasting