If you’ve ever faced a stockout risk during peak sales or tied up capital in buffer stock, the issue may not lie in your demand forecast. The real culprit could be your lead time in inventory management.

So, what is lead time? In inventory terms, it’s more than just the number of days between placing and receiving a purchase order. It’s a critical metric that impacts inventory replenishment, reorder point calculation, supplier performance, and overall stock visibility.

Long or inconsistent supply lead times increase the risk of overstocking or stockouts, affecting cash flow and customer satisfaction. That’s why businesses are increasingly adopting automation to optimize order cycle time, reduce delays, and improve forecasting accuracy.

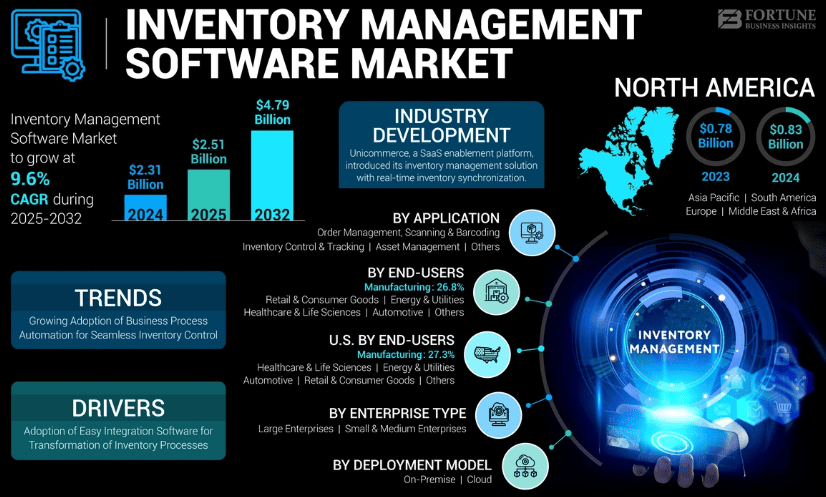

According to Fortune Business Insights, the inventory management software market will grow from $2.51 billion in 2025 to $4.97 billion by 2032 — driven by the need to reduce logistics lead time, improve vendor management, and streamline procurement lead time.

In this guide, you will explore what lead time in inventory management means, how to calculate it, and how to reduce it using practical strategies and examples.

- What Is Lead Time in Inventory Management?

- Why Lead Time Is Important in Inventory Management?

- How to Calculate Lead Time

- How Lead Time Impacts EOQ (Economic Order Quantity) and Safety Stock

- How to Reduce Lead Time in Inventory Management?

- Conclusion

- Frequently Asked Questions about Lead Time in Inventory Management

- List of Resources

What Is Lead Time in Inventory Management?

Lead time in inventory management refers to the total number of days between placing a purchase order and having the goods available for sale, use in production, or restocking. It is a critical metric that directly impacts your reorder point, inventory replenishment, and overall supply chain efficiency.

An inaccurate or inconsistent lead time can lead to stockouts, excess buffer stock, and poor vendor management decisions.

📍 We’ve explored methods & systems of stock control in another article.

Key Components of Lead Time

Each stage of lead time adds to the total delivery timeline. Understanding these stages helps businesses reduce delays and plan more accurate inventory turnover and order cycle times.

| Component | Description |

Order processing time |

Time needed to create, approve, and send the purchase order internally |

Supplier fulfillment time |

Time the supplier requires to produce, pick, or pack the order |

Shipping/transit time |

Time taken for goods to be transported — impacts logistics lead time |

Receiving/inspection time |

Time to receive, inspect, and record items in your inventory system |

✅ Including these stages helps businesses plan stock replenishment, optimize EOQ, and avoid disruptions caused by long supplier lead times.

Lead Time Formula

Let’s break it down. In inventory management, lead time is calculated by summing up the time taken at each stage from order to stock availability.

Lead Time = Order Processing Time + Supplier Fulfillment Time + Shipping Time + Receiving Time

📑 Example: Let’s say you run a boutique candle manufacturing business in Durban and import custom glass jars from India. Here’s how your procurement lead time might break down:

- PO creation and approval: 2 days

- Supplier production time: 6 days

- International shipping (logistics lead time): 10 days

- Receiving and quality check: 2 days

Total Lead Time = 2 + 6 + 10 + 2 = 20 days

Now, if your typical order cycle time is 18 days, you’re at high stockout risk if you wait too long to reorder.

Why It Matters

Understanding your lead time in inventory management helps you:

- Reorder on time using accurate delivery timelines

- Maintain the right level of buffer stock to handle delays

- Optimize inventory replenishment and warehouse space

- Improve vendor management by identifying the true source of delays

- Avoid costly errors caused by assumed or outdated lead times

📍Tip: Don’t rely on estimates. Measuring supplier lead time and internal delays accurately is essential to prevent stockouts or excess inventory.

Why Lead Time Is Important in Inventory Management?

Managing lead time in inventory is critical for reducing waste, improving accuracy, and minimizing stockout risk. Whether you run a warehouse, a retail outlet, or a production floor, your ability to forecast, plan, and replenish stock depends heavily on reliable supplier lead time and purchase order processing.

1. Prevent Stockouts

Running out of inventory doesn’t just lead to lost sales — it damages trust, disrupts delivery timelines, and halts production. With accurate lead time tracking, you can reorder at the right moment, especially when dealing with high-volume SKUs or fast-moving goods.

✅ Predictable lead time = smarter reorder point decisions

2. Reduce Buffer Inventory

To compensate for long or unreliable logistics lead times, businesses often carry excessive buffer stock, locking up cash and warehouse space. The longer the lead time, the more “just-in-case” stock you’re forced to hold.

Example:

A Swedish SME discovered their long lead time was caused by a combination of offshore suppliers and slow internal approvals. After switching to localized procurement and streamlining vendor management, they cut total lead time by 40% and significantly reduced inventory holding costs.

✅ Reliable lead time supports lean inventory replenishment

3. Improve Planning and Cash Flow

Fluctuating lead times complicate inventory planning, strain cash flow, and increase the risk of over-ordering. Shorter and more consistent lead times enable better inventory turnover, reduce holding costs, and improve working capital efficiency.

✅ Accurate lead time = better order cycle time and healthier cash flow

4. Support Production and Customer Experience

In manufacturing, delayed delivery of raw materials can halt an entire production cycle. In retail or ecommerce, it leads to late customer deliveries or out-of-stock items.

Whether you’re managing procurement lead time or tracking batches across warehouses, strong lead time control improves operational flow and customer satisfaction.

📍 Recommended Read: How to Maintain Daily Stock in Excel — Download Free Template

Tired of Inventory Delays? Let Kladana Fix Your Lead Time

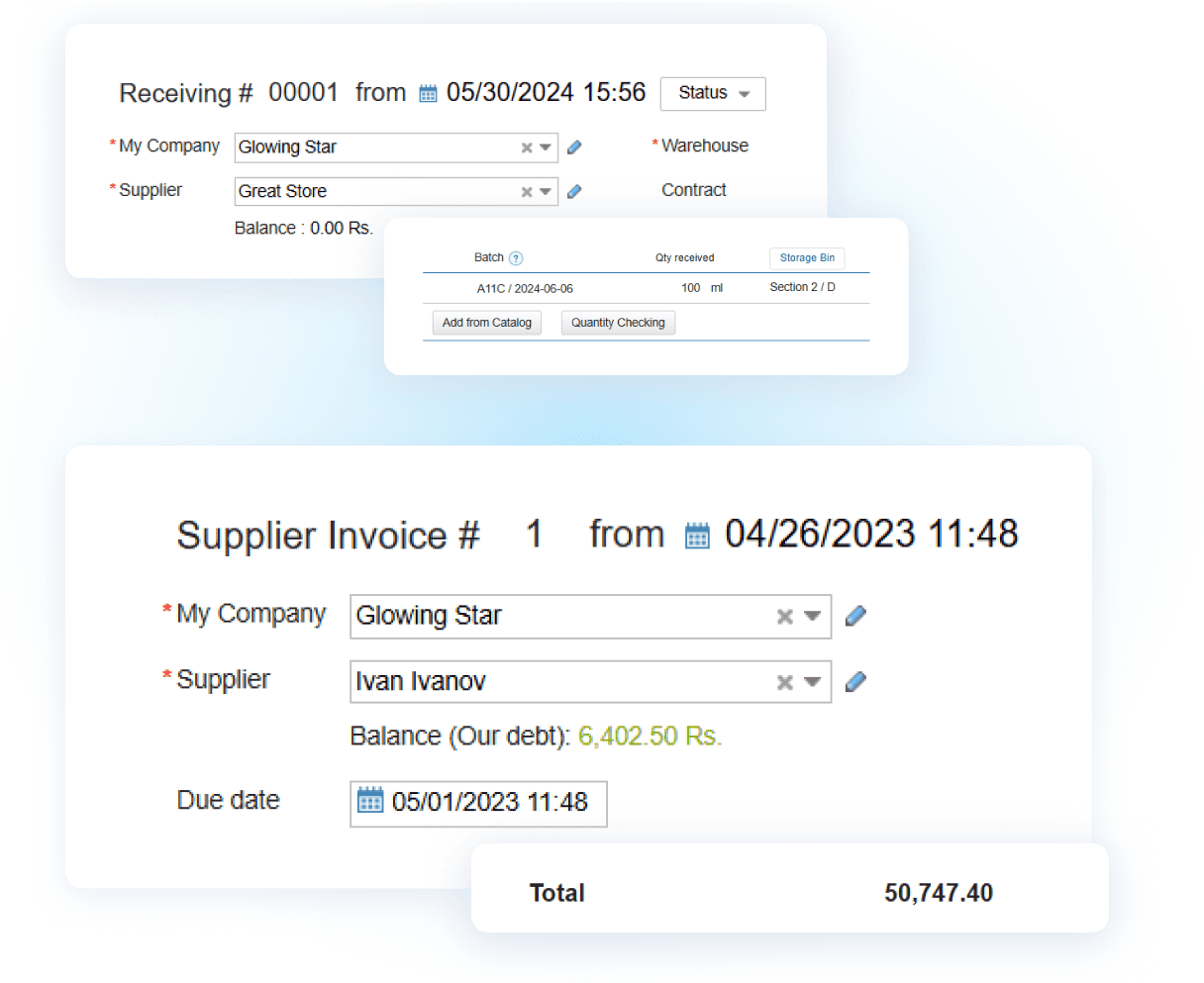

📦 Track purchase orders in real time — spot delays, approvals, and bottlenecks instantly

🔁 Automate reordering with actual lead time data — no more guesswork

📊 Compare supplier performance by delivery timelines and reliability

⏲️ Monitor production lead time — from raw material issue to finished goods

How to Calculate Lead Time

Once you understand what lead time is, the next step is to calculate it accurately. The goal is to know exactly how long it takes for stock to move from purchase order creation to being available for use or sale — enabling you to set the correct reorder point and avoid stockouts.

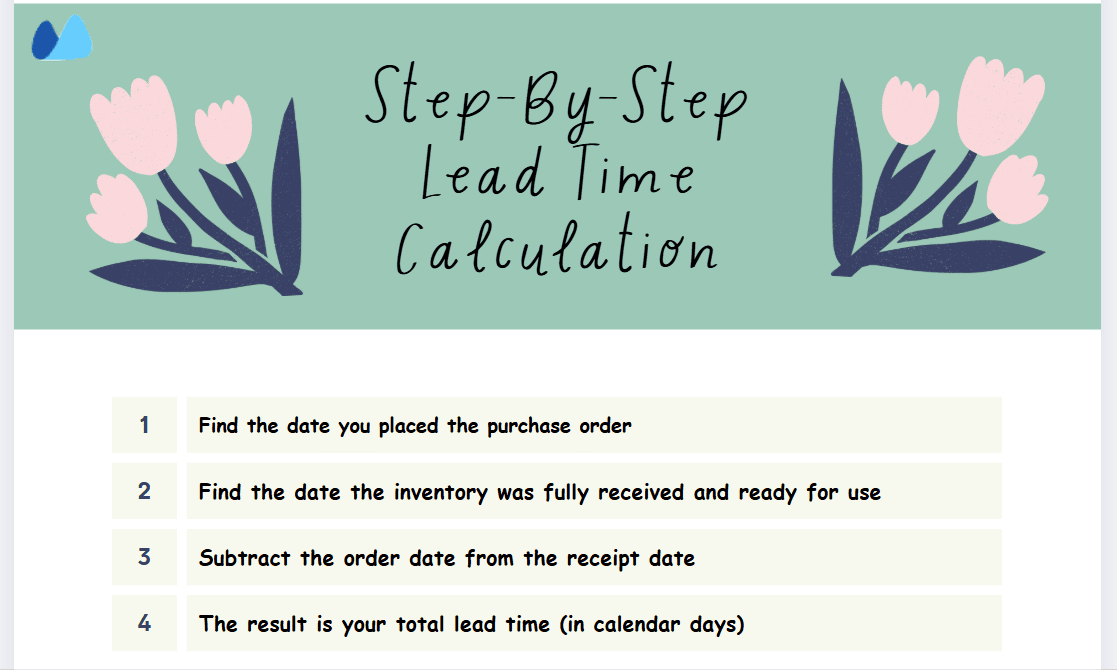

Step-by-Step Lead Time Calculation

To calculate lead time in inventory management, follow this process:

| Step | Action |

1. Order Placement |

Record the PO creation date |

2. Inventory Availability |

Record when goods are fully received, inspected, and stored |

3. Subtract the dates |

Final figure = Lead Time in days |

For example:

PO created: August 1

Inventory available: August 12

Lead Time = 11 days

📍 Recommended Read: 4 Free Purchase Order Templates

Lead Time Calculation Tips

- Track it by item or supplier

Not all supplier lead times are equal — track separately to improve vendor management and forecasting.

- Use rolling averages

If your procurement lead time ranges from 8–12 days, use a 10-day average but adjust buffer stock planning accordingly.

- Fix internal delays separately

Warehouse bottlenecks or approval delays shouldn’t inflate supplier lead time — address them independently.

- Automate with inventory software

Use your ERP system or inventory app to log order cycle times. Manual logs often miss micro-delays that add up.

Integrate Lead Time into Reorder Point

Once you have reliable lead time data, feed it into your reorder point (ROP) calculation to automate inventory replenishment.

Reorder Point Formula

ROP = Daily Usage × Lead Time + Safety Stock

Example:

- If average daily sales = 20 units

- Lead Time = 10 days

- ROP = 20 × 10 + Safety Stock

This ensures you reorder before hitting critical stock levels, minimizing stockout risk.

What If You Don’t Have Lead Time Data Yet?

- Use the supplier’s estimated delivery timeline as a starting point

- Track actual times from PO to receipt for every order

- Recalculate quarterly for accuracy

- Add conservative safety stock until patterns stabilize

📍Tip: Your inventory system is only as reliable as the lead time data you put into it. Don’t rely on assumptions. Start tracking lead time now to reduce delays, improve purchase order processing, and make informed reorder decisions based on real-world timelines — not guesswork.

How Lead Time Impacts EOQ (Economic Order Quantity) and Safety Stock

Your lead time in inventory management directly influences two key metrics:

- Economic Order Quantity (EOQ)

- Safety stock levels

When lead time is long or inconsistent, you need to carry more buffer stock to reduce stockout risk. Conversely, if your supplier lead time is short and reliable, you can operate with a leaner inventory and free up working capital.

Safety Stock Formula

To protect against variability in both demand and lead time, use the following:

Safety Stock = (Max Daily Usage × Max Lead Time) − (Avg Daily Usage × Avg Lead Time)

This formula ensures you have enough safety stock to handle supplier delays, customs issues, or unexpected sales spikes.

Example calculation

Let’s say you run a retail store selling phone chargers:

- Max daily sales = 20 units

- Max lead time = 15 days

- Average daily sales = 15 units

- Average lead time = 12 days

Apply the formula:

- Safety Stock = (20 × 15) − (15 × 12)

- Safety Stock = 300 − 180 = 120 units

You should maintain at least 120 extra units as buffer inventory to handle order surges or delayed shipments.

Why lead time in inventory management matters?

If your logistics lead time unexpectedly increases due to customs delays or supplier backlog, this safety stock protects you from stockouts and lost sales. But holding too much stock comes with high carrying costs.

That’s why tracking and updating your lead time is critical for:

- Smarter reorder point decisions

- Better EOQ accuracy

- Balanced inventory and cash flow

- Minimizing both stockout risk and overstocking

📍Tip: Recalculate your safety stock every quarter or whenever lead time or sales velocity changes.

How to Reduce Lead Time in Inventory Management?

Once you’ve measured your lead time, the next goal is to reduce it. Shorter lead times mean faster inventory replenishment, lower safety stock requirements, improved cash flow, and greater agility in responding to demand changes.

Here are four practical strategies to help you reduce lead time in inventory management.

1. Build Better Supplier Relationships

Your suppliers aren’t just vendors — they’re strategic partners. Stronger relationships help reduce supplier lead time and make your supply chain more responsive.

Benefits include:

- Faster production prioritization

- Improved coordination on urgent orders

- Proactive communication during disruptions

Example: A toy wholesaler began sharing monthly demand forecasts with their supplier. As a result, the supplier started pre-scheduling production, cutting fulfillment time from 10 days to just 5.

2. Use Local Suppliers or Multiple Vendors

One of the most effective ways to reduce logistics lead time is to source locally or diversify your vendor base. This decreases your dependence on a single supplier and reduces risks caused by customs, border delays, or production backlogs.

✅ Diversification is a key principle in vendor management.

3. Automate Reordering and Approvals

Manual reordering can create internal delays even before the supplier receives the purchase order. Automating these steps helps reduce procurement lead time and order cycle time.

Inventory automation tools to implement:

| Tool / Feature | Why It Helps |

Reorder point triggers |

Ensures timely order placement |

Purchase order automation workflows |

Eliminates email/Excel delays |

Pre-approved vendor spending limits |

Speeds up internal approvals |

📍 Recommended Read: Automated Inventory Management: Guide + Real-World Examples

4. Use Inventory Management Software for Real-time Tracking

Digital tools like Kladana enable businesses to track inventory, supplier performance, and reordering cycles in real time. This leads to proactive planning and fewer delays.

Key Software Features to Reduce Lead Time:

| Feature | Why It Helps |

Real-time stock tracking |

Prevents reordering too late |

Vendor lead time reporting |

Highlights slow or inconsistent suppliers |

Low stock alerts |

Triggers action before a stockout |

Order history |

Identifies recurring delays or bottlenecks |

📍 For example, Neytt Homes, a luxury interior brand, reduced production delays by switching from Excel to Kladana. With real-time visibility into raw material stock, the team cut coordination delays and improved on-time production.

Conclusion

Managing lead time in inventory management isn’t just about counting days — it’s about gaining control over your entire supply chain. When you clearly understand how long it takes for stock to move from order placement to inventory availability, you can:

- Reorder at the right time

- Maintain optimal buffer stock

- Respond faster to supplier delays or changes in demand

Accurate lead time tracking helps you reduce stockout risk, improve cash flow, and make informed, data-driven decisions that keep your operations running smoothly.

Frequently Asked Questions about Lead Time in Inventory Management

What is lead time in inventory management?

Lead time is the total time between placing a purchase order and having goods available in inventory. It includes internal approval, supplier processing, shipping, and receiving stages. Managing this time helps avoid stockouts and supports efficient inventory replenishment.

How do I calculate lead time for inventory?

Use the formula:

Lead Time = Delivery Date − Order Date

Track actual delivery timelines based on past orders — not just what suppliers estimate. Use your inventory system or ERP software to automate this process.

Why does lead time vary between suppliers?

Lead time can vary based on:

- Supplier production schedules

- Geographic distance

- Shipping method and carrier reliability

- Customs clearance and import delays

- Your internal approval or PO processing time

What is a good lead time for Inventory?

It depends on the business type:

- Retail / FMCG (local): 2–7 days

- Manufacturing / Imports: 10–30 days

Shorter and more consistent lead times reduce the need for safety stock.

Can I reduce lead time in inventory management?

Yes. Strategies include:

- Working with local suppliers

- Using multiple vendors

- Automating reordering and approval workflows

- Improving internal purchase workflows

- Tracking actual vs expected lead times to catch delays early

What is the difference between lead time and delivery time?

- Lead time = full timeline from order approval to inventory availability

- Delivery time = just the shipping portion

Lead time includes order processing, supplier prep, shipping, and receiving.

How can ERP software help with lead time tracking?

ERP or inventory management software can:

- Tracking order-to-receipt durations automatically

- Highlight supplier delays

- Recalculate reorder points automatically

- Generate alerts when lead time increases

What causes long lead times?

Common causes include:

- Supplier backlog or capacity limits

- Logistics and shipping delays

- Customs clearance issues

- Poor demand forecasting

- Internal approval bottlenecks

How often should I review lead time data?

Review supplier lead time quarterly at a minimum. For seasonal businesses or those with volatile suppliers, monthly reviews are recommended.

What happens if you miscalculate lead time?

Miscalculating lead time can lead to:

- Missed sales due to stockouts

- Production stoppages

- Over-ordering and excess holding costs

Always use real-world data, not assumptions.

List of Resources

- Case Study: Reducing Process Lead Time

- Fortune Business Insights: Inventory Management Market

Read‑alikes

Best 20 Inventory Management Software: 2026 Update

Inventory Management in Excel: Free Template and a Step‑by‑Step Guide

Barcode Inventory Systems 2026: 12 Best Software for Small Businesses

Smart Food Inventory Management: Slash Waste and Maximize Profits

Costing Methods and Approaches: A complete guide for Manufacturing & Inventory