Fulfillment doesn’t fail at shipping. It fails before that, in the aisles of your warehouses. It occurs when orders accumulate faster than they can be processed, resulting in pickers spending more time locating SKUs than moving them, even when the right products are packed incorrectly.

These aren’t surface-level issues. They point to deeper inefficiencies in the picking and packing process within your warehouse, especially when your operations scale across e-commerce, wholesale, or multi-channel distribution.

A high-performing pick and pack warehouse doesn’t just move the goods. It moves with precision. It keeps inventory flowing, labor focused, and error rates low, whether you are fulfilling 200 orders or shipping in bulk through 3PL partners.

In supply chains, where speed and accuracy define customer retention, optimizing your warehouse picking and packing processes is no longer an option; it is a must.

In fact, according to Global Market Insights, the warehouse automation market was valued at $26.6 billion in 2024, with projections showing a 15.9% CAGR through 2032. This reflects a global shift toward automating core fulfillment functions, especially picking and packing, to improve speed, accuracy, and scalability.

This guide explains how the process works and what it takes to improve efficiency through layout, benefits, methods, and fulfillment tools.

- What Is Pick and Pack in Warehousing?

- Key Characteristics of a Pick and Pack Warehouse

- Picking and Packing Process Step-by-Step

- Popular Pick and Pack Methods

- Benefits of Optimizing Pick and Pack

- How to Improve Pick and Pack Efficiency

- What Kind of ROI Can You Expect from Improving Pick and Pack?

- To Sum Up

- Frequently Asked Questions on Pick and Pack Warehousing

- List of Resources

What Is Pick and Pack in Warehousing?

A pick and pack warehouse is a fulfillment facility designed to process individual, item-level orders with speed and accuracy. Unlike traditional distribution centers that ship pallets or bulk cartons, a pick and pack warehouse is specifically tailored to handle orders with precision.

Pick and pack operations specialize in breaking down larger inventory volumes into smaller, customized shipments often destined for end customers, retailers, or multi-channel partners.

These warehouses serve as the operational backbone for e-commerce brands, B2B wholesalers, 3PLs, and even scaling SMBs that require agility. When a customer places an order, the warehouse executes a structured sequence: locating the SKUs (picking), preparing them safely for transport (packing), and staging the final parcels for delivery.

What makes this model complex and critical is the variability. One order may include three SKUs from different zones. Another might be urgent, fragile, or require branded packaging. As a result, warehouse picking and packing must be precise, repeatable, and digitally traceable.

Key Characteristics of a Pick and Pack Warehouse

| Feature | Description |

Order-Level Fulfillment |

Processes mixed-item orders individually rather than shipping full cases of pallets |

High SKU Variety |

Handles a large number of SKUs across categories, especially common in ecommerce and D2C fulfillment |

Live Inventory Sync |

Requires real-time visibility into stock levels, bin locations, and D2C fulfillment |

Integrated Packing Workflows |

Packing isn’t just about boxes; it may involve inserts, labeling, protective materials, and carrier compliance |

Built for Flexibility |

Must adapt quickly to volume spikes and changing order types |

Scalable Systems |

Whether fulfilling 100 or 10,000 orders per day, the workflow must stay accurate |

How It Differs from Bulk Shipping

| Feature | Bulk Shipping | Pick and Pack Warehousing |

Order type |

Full pallets or cartons |

Mixed -SKU individual orders |

Destination |

B2B retailers or retailers |

D2C or channel-specific |

Handling requirement |

Minimal item sorting |

Item-level picking, packaging, and labeling |

Inventory complexity |

Low (single SKU per batch) |

High (many SKUs per zone/order) |

Operational priority |

Volume efficiency |

Accuracy and flexibility |

Where It Fits in the Fulfillment Chain

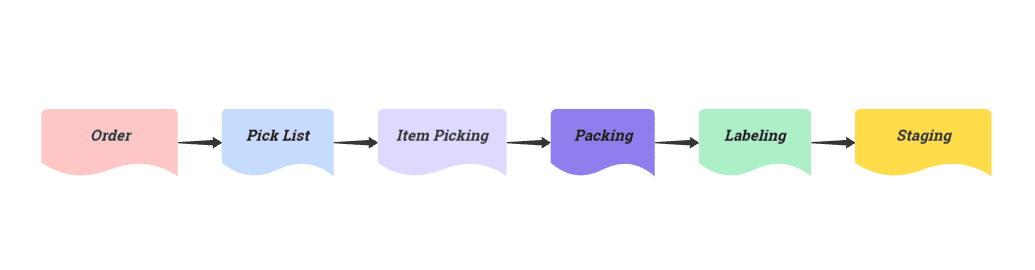

The pick-to-pack process begins after order confirmation and continues until items are handed off to the shipping carrier.

Fulfillment flow:

- As soon as your customer places an order, it enters your system and gets queued for fulfillment inside your pick and pack warehouse.

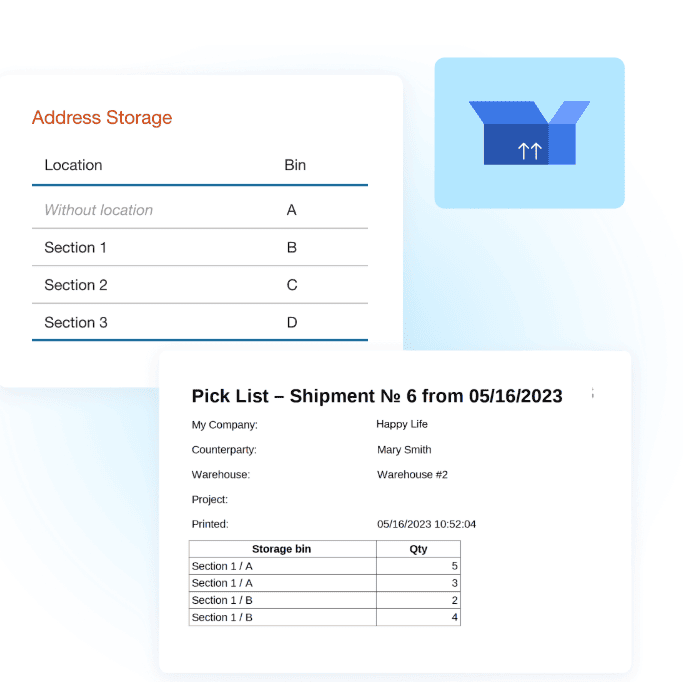

- Your WMS generates a digital pick list, assigning the task to a picker based on zone, priority, or SKU availability, kicking off the warehouse picking process.

- The picker collects items from storage, scanning each one to confirm accuracy and update your inventory in real time, ensuring a smooth picking and packing process in the warehouse.

- Next, the order moves to your packing station, where it’s verified, securely packed, and labeled according to carrier and customer requirements, the core of your pick-to-pack workflow.

- Finally, the parcel is staged for shipment, sorted by courier, delivery zone, or dispatch window, and marked ready for handoff.

📚 Recommended Read: Curious how inventory visibility impacts picking speed and accuracy? Dive into Warehouse Inventory Management to explore how stock tracking, bin mapping, and reorder accuracy can set the foundation

Picking and Packing Process Step-by-Step

The efficiency of a pick-and-pack warehouse depends heavily on how well each stage of the order fulfillment process is designed and executed.

Here’s a detailed breakdown of the key steps.

🟫 Step 1: Order Receipt & Picking Slips

- Once an order is confirmed through your sales channel or ecommerce platform, it’s pushed to the warehouse system, either through direct integration or manual upload.

- A digital pickling slip gets generated instantly. It assigns the task to a picker based on location, priority, or cut-off time

- The task is assigned to a picker and pushed to their mobile scanner or handheld

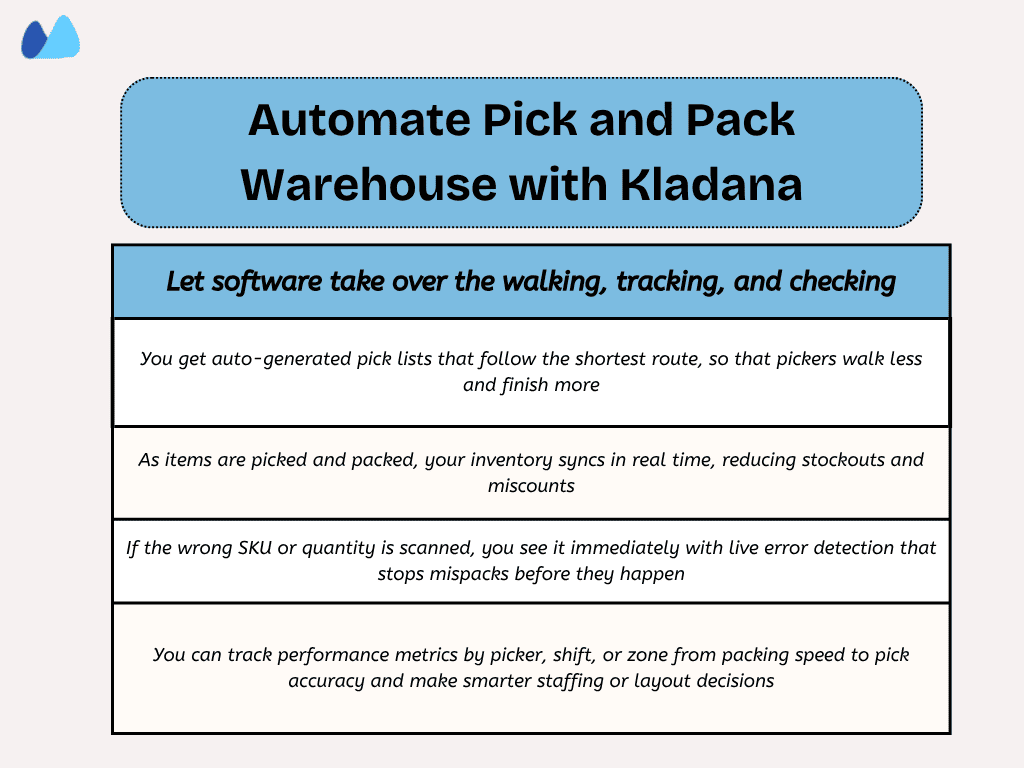

- With tools like Kladana, your system can also auto-generate the most efficient pick path and update inventory the moment the task begins

🟫 Step 2: Item Picking

With the task assigned, your picker gets straight to work by retrieving items from storage based on the pick list.

- You use a picking method suited to your volume, whether it’s piece batch, zone, or wave.

- Your picker follows the optimized route, scanning each SKU to confirm accuracy and trigger inventory updates.

- Scanned data is instantly logged in your WMS, reducing the risk of mispicks or stock discrepancies.

- Using software like Kladana, the picker receives a sequenced task list that minimizes walking time and flags mismatches before they leave the aisle.

- Once all items are picked, the order is moved to packing for verification.

🟫 Step 3: Quality Check and Packing

- You verify the SKUs against the order to catch any orders before packing begins.

- Items are boxed using appropriate materials, with inserts, void fill, or product-specific order or destination.

- Packing slips, compliance labels, and invoices are added where required by the order or destination.

- Barcode validation ensures the right items are packed before sealing the box.

- By implementing WMS software like Kladana, packing errors are flagged in real time, and completed orders are instantly marked for staging.

🟫 Step 4: Labeling and Staging for Shipment

- You apply shipping labels that meet carrier standards, including tracking details and return instructions.

- Orders are sorted based on delivery zone, shipping method, or carrier pickup schedule.

- The packed cartons are staged in your outbound area, organized for speed and easy access.

- One final scan marks the shipment as complete and triggers inventory updates.

- With a connected system like Kladana, this handoff syncs across your WMS and sales channels automatically.

Popular Pick and Pack Methods

Not all pick-and-pack warehouses operate in the same way. The right picking method depends on factors like order volume, SKU variety, warehouse layout, and workforce size.

Here are the four most common picking strategies used in warehouses.

Method 1: Piece Picking

This is the most basic form of picking used by many smaller or entry-level operations.

| Aspect | Details |

How it works |

✓ A picker completes one order at a time. They collect all the SKUs before moving to the next |

Best for |

✓Low order volumes |

Strengths |

✓ Easy to implement |

Limitations |

➙ High travel time per order |

Scalability |

Suitable for early-stage operations, but not ideal as order volume grows |

Method 2: Batch Picking

Batch picking is designed to reduce travel time by consolidating multiple orders into a single trip.

| Aspect | Details |

How it works |

✓ A picker collects items for multiple orders in one trip, typically grouped by SKU or location |

Best for |

✓ Medium to high order volume |

Strengths |

✓ Reduces walking time |

Limitations |

➙ Requires accurate post-pick sorting |

Scalability |

✓ Very effective when paired with barcode validation |

📚 Recommended Read: Wondering how to reduce picker walk time? Explore Warehouse Bin Storage to see how organized shelving, clear labeling, and logical slotting speed up order fulfillment

Method 3: Zone Picking

Zone picking works well in large or segmented warehouses.

| Aspect | Details |

How it works |

✓ Picker retrieves SKUs only from their assigned zone. They complete the orders by combining picks from each zone |

Best for |

✓ Large pick and pack warehouses |

Strengths |

✓ Reduces congestion |

Limitations |

➙ Slower if zones become a bottleneck |

Scalability |

✓ Works best with an integrated WMS that can coordinate multizones and merge orders for packing |

Method 4: Wave Picking

Wave picking syncs picking activity with the outbound schedules.

| Aspect | Details |

How it works |

✓ Orders are grouped into timed waves based on carrier and delivery time. Picking is synchronized to match shipping details |

Best for |

✓ High volume ecommerce |

Strengths |

✓ Aligns picking with outbound schedules |

Limitations |

➙ Requires precise planning |

Scalability |

✓ Ideal for large warehouses using advanced WMS tools to automate wave scheduling and carrier mapping |

Benefits of Optimizing Pick and Pack

A disorganized pick-and-pack process slows down fulfillment, increases costs, and erodes customer trust. But when optimized strategically, this single function becomes one of the most powerful levers for operational efficiency in any warehouse.

Here’s how optimizing your picking and packing process in the warehouse pays off across time, cost, and accuracy.

1. Faster Order Cycle Times

When picking is slow or packing lines are backed up, your fulfillment times spiral, and so do your costs. Optimization targets every point of delay.

What changes:

- Slotting fast-moving SKUs closer to packing stations cuts walk time

- Batch and zone picking enable multiple orders to move in parallel

- Pick to a light or barcode-driven workflows reduce friction at each step

Why it matters:

- Meeting same-day or next-day delivery

- Reducing your order cycle time unlocks higher throughput without adding headcount

According to Grand View Research, the warehouse order picking market was valued at $10.12 billion in 2024, following steady growth from $9.19 billion in 2023. With a projected CAGR of 10.18% through 2030, this reflects continued investment in faster, more accurate picking systems, from barcode workflows to route-optimized tasking

2. Fewer Returns Due to Packing Errors

Incorrect items, missing SKUs, or damaged goods are fulfillment killers. Many of these errors originate from the picking or packing stage, rather than shipping.

What changes:

- Barcode validation during both picking and packing phases ensures the correct SKU is matched to the order

- Visual quality checks can be integrated into packing workflows

- With proper packing standards, breakage and repacking costs are minimized

Why it matters:

- When you mispack an order, you’re not just fixing a mistake. You’re doubling your effort and cost

- Incorrect or damaged items make customers lose confidence in your brand

- Fewer packing errors mean fewer returns, lower overhead, and more repeat buyers

3. Lower Operational Costs

Inefficient pack and pack workflows quietly bleed money from your warehouse every day.

What changes:

- You reduce idle time and overstaffing by assigning tasks more efficiently

- Your warehouse layout gets smarter, so space is used more productively

- Packing becomes more cost-effective with better box logic and less filler waste

Why it matters:

- Small inefficiencies stack up fast when your volume scales

- You’re spending more than you need without even realizing it

- Fixing your pick and pack process can cut costs by up to 25%, without adding space or staff

📚 Recommended Read: Thinking of upgrading your warehouse Ops without blowing your budget? Check out Free WMS Software for tools that automate picking, packing, and inventory.

How to Improve Pick and Pack Efficiency

To improve the pick and pack process in your warehouse, work smarter. Below are three high-impact strategies to improve picking and packing efficiency:

📦 Layout and Slotting Optimization

Your warehouse layout directly affects how far and how often your pickers move. Inefficient floor plans lead to excessive walking, congestion, and order delays.

Key layout strategies:

- Slot fast-moving SKUs near packing zones to reduce retrieval time

- Use ABC analysis to group products by movement frequency

- Minimize travel path with U-shaped or serpentine picking routes

- Establish marked zones to prevent picker overlap and confusion

- Standardize shelf heights and labeling to reduce search

📱 Barcode Scanning & Validation Tech

Manual picking and visual checks leave too much room for human error. Introducing barcode scanning systems brings precision and accountability to every step of the process.

How barcode systems help:

- Scan-to-pick confirms each SKU in real time before adding it to the cart

- Packing station validation ensures the correct quantity and items per order

- Reducing picking errors, mispacks, and customer returns

- Tracks picker productivity, dwell time, and location performance

💻 Using Software Like Kladana

Manual systems slow you down, especially as orders scale. A WMS software like Kladana helps you streamline every step of your pick and pack process, enabling your team to move faster with fewer errors.

Why it matters:

- You don’t waste time reacting to errors or chasing missing stock

- Your team knows precisely what to do, where to go, and when to flag issues

- The entire process becomes predictable, efficient, and ready to scale

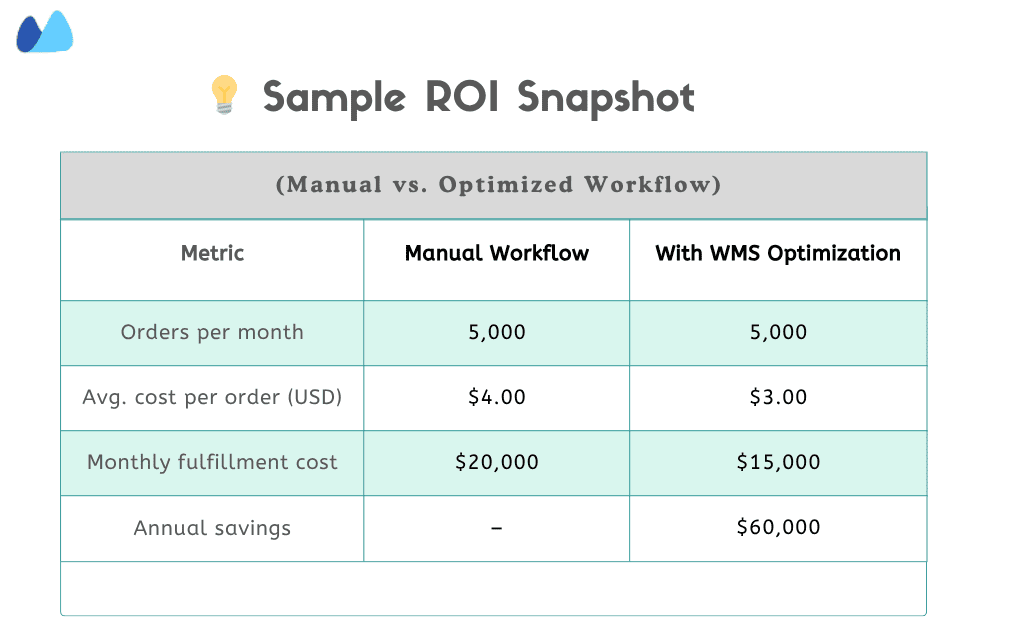

What Kind of ROI Can You Expect from Improving Pick and Pack?

Improving your pick and pack process directly affects your labor costs, order accuracy, and customer retention.

And when you’re processing thousands of orders a month, those improvements scale fast.

Whether you’re running a fast-moving ecommerce store, managing B2B orders, or handling multi-brand fulfillment as a 3PL, the right method and tool can improve throughput and reduce errors.

ROI By Business Type

Different industries face different bottlenecks. Here’s where the ROI tends to show up fastest

| Business Type | Your Challenge | How You Benefit |

|

|

|

|

|

|

3PL |

|

|

SMB Scaling |

|

|

💡 Lower Costs, Fewer Errors — Optimize Pick & Pack with Kladana

Smart barcode validation, automated task flow, and live inventory updates built for modern warehouses

To Sum Up

The pick and pack process is where speed, accuracy, and operational clarity either come together or fall apart. It’s a performance lever that impacts your margins, customer experience, and ability to scale.

With the right combination of layout strategy, barcode validation, and warehouse software like Kladana, you can transform fulfillment from a cost center into a competitive advantage.

Frequently Asked Questions on Pick and Pack Warehousing

What does pick and pack mean?

Pick and pack refers to the warehouse process where specific items are picked from inventory and packed for shipment, typically for individual customer orders. It’s a key area of pure commerce and D2C fulfillment, where speed, accuracy, and SKU-level tracking are essential.

What is the difference between pick, pack, and ship?

There are three steps in the fulfillment workflow:

- Pick: Locating and retrieving the correct items from inventory

- Pack: Verifying, protecting, and packaging those items for shipment

- Ship: Labeling, staging, and transferring parcels to a carrier for delivery

How does batch picking work?

Batch picking groups multiple orders together, so that a picker can collect items for all of them in a single trip. It’s beneficial when multiple orders standardize standard SKUs, as this helps reduce travel time and increase efficiency. Post-pick sorting happens at the packing station.

Why is pick and pack important?

E-commerce orders are often small, fast-moving, and SKU-rich. A strong pick and pack fulfillment system enables:

- Quick turnaround from order to shipment

- High order accuracy

- Flexible packaging for varied SKUs

- Smooth multi-channel fulfillment

Can small warehouses use pick and pack?

Yes. Even a small warehouse can implement a structured pick-and-pack process using simple tools, such as printed pick lists, barcode scanners, and optimized layouts. As volume grows, these processes can be scaled using WMS platforms, such as Kladana.

What tools improve pick and pack accuracy?

- Barcode scanners for pick and pack validation

- Mobile devices for task management

- The pack checklist is to verify SKUs and quantities

- WMS software like Kladana to track performance and detect errors in real time

How do WMS systems help?

Warehouse management systems automate and optimize key pick and pack tasks:

- Generate efficient pick lists.

- Reduce picker travel

- Enable real-time inventory updates

- Prevent SKU mismatches

- Monitor KPIs like picker speed, packing time, and error rate

How can pick and pack errors be reduced?

- Introduce scan-based verification during both picking and packing

- Use color-coded totes or packing zones to avoid mix-ups

- Build in quality checks at every handoff

What is the cost structure for pick and pack?

Cost typically includes:

- Labor (pickers, packers, supervisors)

- Packing materials (boxes, fillers, labels)

- Software and automation tools

- Space and storage optimization

How does pick and pack integrate with shipping carriers?

Once orders are packed:

- Carrier-compliant labels are printed

- Packages are sorted by delivery zone or courier

- Handoffs are recorded in the WMS

- Real-time tracking info is sent to customers

List of Resources

- Global Market Insight: Warehouse Automation Market Size and Growth

- Grand View Research: Warehouse Order Picking Market Trends