Inventory decisions shape everything: from what gets sold to what sits untouched on a shelf. It affects cash, order delays, and how much time your team spends fixing things that shouldn’t have gone wrong in the first place.

There’s no single way to track inventory. Some brands use perpetual systems, which update in real time through scanners, POS tools, and purchase records. You always know what’s happening and when.

Others rely on periodic systems, where stock levels are checked weekly or monthly. It’s simpler, but that delay means you’re reacting to problems after they’ve already happened.

Both models work. It depends on your pace. If you sell fast-moving items or run multiple locations, real-time visibility might be non-negotiable. If your catalog is manageable and you prefer fewer moving parts, periodic tracking could be enough.

Next, we’ll look at how both systems operate, where they fit, and how to make the right call for your business.

We’ll now explore how each system fits and how to choose with confidence.

Perpetual Systems and Periodic Systems

These are the two major systems: perpetual and periodic.

Perpetual Inventory System

With a perpetual system, inventory updates, like sales or product returns, happen automatically in real time as things move. Point-of-sale systems, barcode scanners, and warehouse software are in complete sync, so your numbers stay up to date without manual checks.

This setup works best when accuracy is critical. If you’re running a retail chain, it helps prevent overselling by keeping store shelves and online listings in sync. In manufacturing, it tracks raw materials and finished goods as they move through production, helping you avoid costly line stoppages. For e-commerce, it protects delivery promises by making sure stock availability is always current.

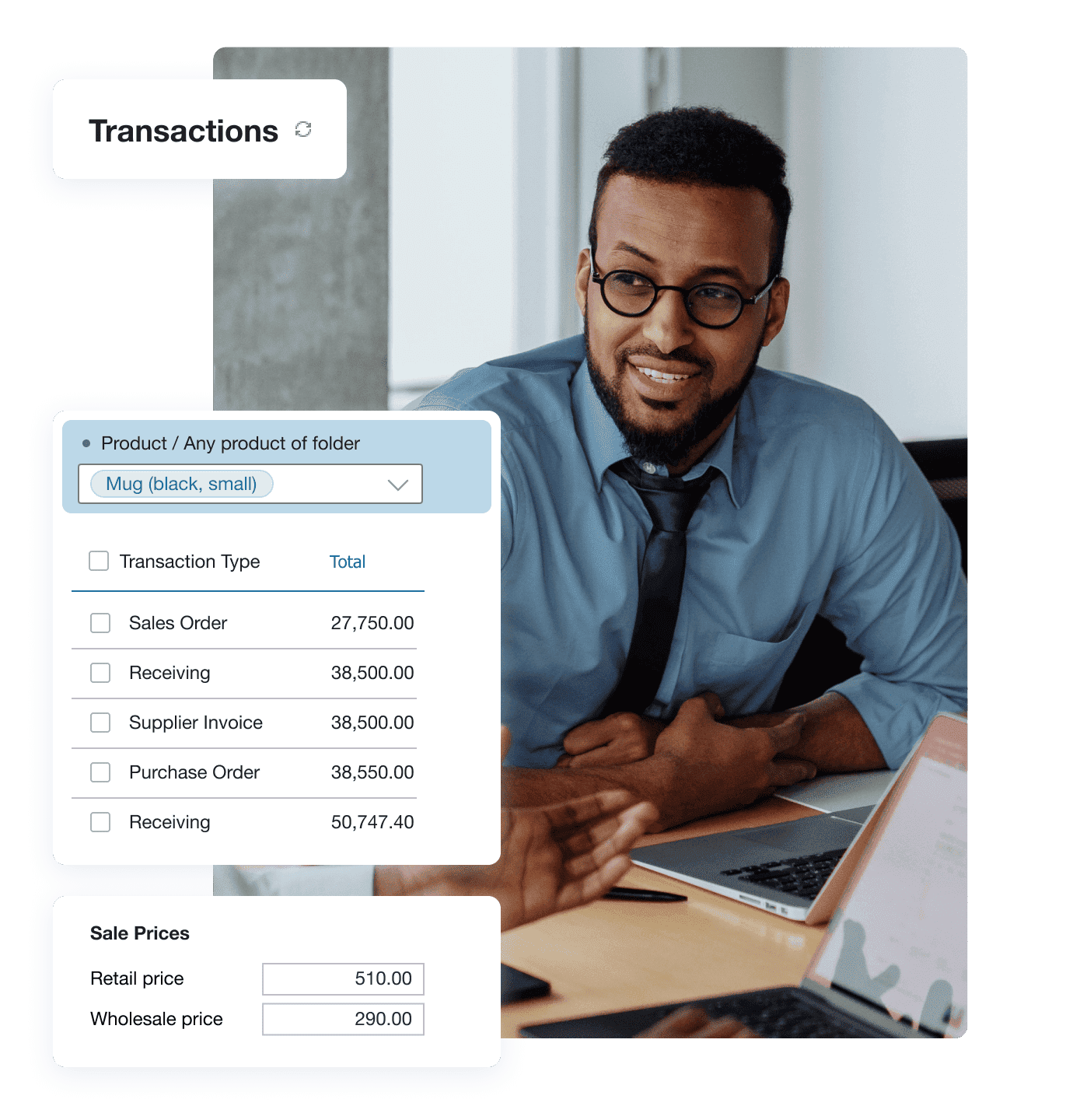

Why Kladana Makes Perpetual Inventory Simple

✅ ERP-Integrated Stock Control — Sync every sale, purchase, return, and transfer with your financial records in real time. No end-of-month reconciliations, no manual catch-up.

✅ Live Inventory Updates — See your exact stock levels the moment something moves. Whether it’s sold at the counter, picked in the warehouse, or received at the dock.

✅ Barcode Ready — Speed up scans, reduce manual input, and track items down to batches for better traceability and faster audits.

✅ Multi-Location Visibility — Keep counts accurate across stores, warehouses, and online channels so you can prevent overselling and improve fulfillment speed.

✅ Automatic Cost Adjustments — Link every inventory change to its financial impact, from COGS updates to accounts payable entries, without double work.

✅ Customizable Reports & Alerts — Monitor fast-moving items, low-stock alerts, and shrinkage risks with reports you can filter and schedule your way.

✅ Scales With Growth — From one store to a multi-location operation, Kladana keeps your inventory, sales, and accounting in sync without adding complexity.

Periodic Inventory System

A periodic inventory system takes a slower, batch-based approach. Inventory is counted at scheduled intervals that could be every week, month, or quarter. The records are adjusted afterward to match what’s physically on the shelf.

This method is simpler, with fewer tech dependencies. But it comes with a lag. You won’t know about shrinkage, mispicks, or misplaced stock until the next count. That makes it better suited for smaller operations with predictable sales cycles and tighter control over what moves in and out.

This setup works well for retailers with a small product range and steady, predictable demand. For example, independent boutiques or specialty shops may find that periodic counts keep things simple without adding extra overhead.

Cafés and small food vendors are another good fit. With limited menus and daily prep routines, inventory tracking stays manageable and doesn’t require real-time updates.

Pop-up stores and seasonal sellers often benefit too. When you’re working with a narrow assortment and a short selling window, simplicity wins. A periodic system reduces complexity and helps the team stay focused.

It’s also a good match for low-turnover businesses, where products sit longer on the shelf and the urgency to update inventory daily just isn’t there. The table below captures the key differences between the two:

| Feature | Perpetual Inventory System | Periodic Inventory System |

Update Frequency |

Real-time updates with every transaction |

Updates occur at scheduled intervals |

Data Accuracy |

Continuously reflects current stock levels |

May lag behind actual stock due to infrequent counts |

Technology Requirement |

Requires POS systems, scanners, and software |

Can be managed manually or with basic tools |

Operational Complexity |

Higher, needs system integration |

Lower, simpler to implement |

Ideal For |

Large retailers, e-commerce, manufacturers |

Small shops, cafés, seasonal pop-ups |

Visibility |

High visibility into daily movements |

Limited visibility between counts |

Cost to Maintain |

Higher due to tech and integration |

Lower due to minimal system needs |

Discrepancy Detection |

Instant identification of issues |

Errors may go unnoticed until the next count |

Scalability |

Better suited for growing or high-volume operations |

Works well for smaller or low-turnover businesses |

When Should You Move to a Perpetual Inventory System

A perpetual inventory system makes sense when speed, scale, and accuracy are non-negotiable. If your products move quickly, you sell through multiple channels, or you need inventory accuracy down to the minute, this system can keep up.

It’s especially useful when your team needs real-time visibility into what’s available, where stock is located, and when it needs to be replenished. It also helps maintain audit-ready records and reduces the guesswork that can cost you sales or slow down fulfillment.

Best for: High-volume Businesses, E-Commerce, Retail Chains

If your business handles thousands of daily transactions across stores and online platforms, a perpetual system helps maintain accurate product availability, reduce overselling, and support faster restocks.

Real-time Stock Tracking Benefits

With live updates, you always know your on-hand, allocated, and available stock. This helps you catch stock issues early, set accurate reorder points, and respond faster when something runs low or goes missing.

Integration with POS, WMS, and ERP

Perpetual inventory relies on connected systems. When your POS, scanners, warehouse software, and ERP all speak to each other, every transaction. Sales, returns, transfers, and receipts are all automatically updated in the inventory records. This keeps teams aligned, reduces manual data entry, and eliminates timing gaps that cause delays.

Perpetual systems bring speed and accuracy, but they also come with higher costs and setup requirements. If your business doesn’t need real-time visibility or if your product movement is slower and more predictable, a periodic system might be a better fit.

This approach works best when your product range is small, your stock movement is steady, and you have the discipline to run counts regularly.

Cost Comparison: Periodic vs Perpetual Systems

Inventory systems come with visible costs and hidden ones. You’ll pay for software, training, and tools, but you’ll also deal with indirect costs like delays, rush shipping, or lost sales from stock errors. Choosing between periodic and perpetual systems means looking beyond the initial setup and understanding how each model impacts cost over time.

Licensing, Hardware, and Software

This includes everything from inventory modules and barcode scanners to POS, ERP, and warehouse software.

Perpetual

Requires a higher upfront investment in scanners, software licenses, and system integrations. The payoff comes from automation, as it reduces manual entry, errors, and time spent fixing mismatches. Over time, that stability adds up.

Periodic

Spending is low at the start. You might only need spreadsheets or basic tools. But as operations grow, the cost shifts toward manual labor for counts, corrections, and last-minute fixes when stock levels are off.

Staff Training and Operational Discipline

You also need to factor in the people who run the system. They will require training, guidance, and supervision to run things smoothly.

Perpetual

Teams must follow clear procedures: scan each transaction, update in real time, and follow defined workflows. The learning curve is higher upfront, but once adopted, it creates consistency across locations and staff.

Periodic

Everyday work stays simple, but physical counts take more effort. Teams often scramble during count periods, and any data drift between counts leads to bigger corrections. The lack of early training can cause more work down the line.

Return on Investment Over Time

Think long-term. The best system isn’t the cheapest, but it saves you time, improves accuracy, and supports growth.

Perpetual

Higher accuracy means fewer stockouts, better reorder planning, and fewer rush shipments. In high-volume environments, the benefits scale quickly and reduce margin loss from reactive fixes.

Periodic

Initial savings are real. But as orders increase, so do the hidden costs. Inaccurate counts, lost sales, and emergency logistics can slowly erode the value. The system can hold up at a small scale but often breaks under pressure.

Tech Stack for Perpetual Inventory

A perpetual inventory system works only when every stock movement is captured and shared across systems in real time. That’s why the tech stack matters.

WMS, barcodes, RFID, and ERP integration form the foundation of a working perpetual system. Scanners capture events, warehouse software records them, and the ERP syncs those movements with financials. Together, they create a shared source of truth: keeping counts accurate, operations smooth, and decisions faster. Let’s look at each one of them.

WMS (Warehouse Management System)

WMS directs daily warehouse tasks like receiving, storing, picking, and shipping. Every step is time-stamped and automatically posted to inventory. The result is faster fulfillment, better tracking, and fewer missed orders.

Barcodes

Standard printed labels are scanned during each movement. Barcodes reduce manual data entry, link stock actions to specific users, and improve traceability. This means fewer input errors and smoother audits.

RFID

RFID tags transmit data wirelessly, without needing a direct scan. Especially useful for high-value items, pallets, or doorway reads. RFID speeds up counts, improves visibility, and flags issues like shrinkage early.

ERP Integration

The ERP (Enterprise Resource Planning) system connects inventory with your financials. It records how every stock movement affects things like sales, purchasing, and accounting.

In a perpetual system, the ERP plays a key role. When stock moves in your warehouse, it’s not just the quantity that changes. The cost, value, and related financial records also need to stay in sync. That’s where ERP comes in.

How it works:

- When you receive goods, the ERP updates the inventory and logs the cost under accounts payable

- When you ship an order, it reduces stock and records the cost of goods sold

- If a customer returns an item, the ERP adjusts both the stock and the sales figures

- When you transfer stock between locations, the ERP keeps values aligned for both sites

This helps finance and operations stay on the same page. It also avoids manual reconciliations, errors, and delays at the end of each month.

For growing businesses, managing this level of coordination manually becomes harder with scale. Kladana’s inventory system helps automate these updates, so your stock, sales, and financial records always match. Whether you’re receiving goods, shipping orders, or processing returns, Kladana ensures every movement is recorded accurately, without any spreadsheet hassles.

Which Inventory System Scales Better with Growth?

As your business grows, so do the challenges. More products, more warehouses, and more sales channels make it harder to track stock accurately. That’s when your inventory system starts to show cracks.

The right setup helps you keep pace without constant patchwork.

Why Perpetual Systems Scale Better

A perpetual system grows with you. Whether you’re adding new stores, expanding online, or entering new markets, the same rules apply. Every movement is tracked in real time.

Scanners log receipts and shipments, the WMS guides warehouse tasks, and the ERP keeps your inventory and financials in sync.

As volume increases, automation handles most of the load. You don’t need to shut down for full stock counts. You connect new platforms through APIs instead of creating workarounds.

Good signs you’re ready:

- You’re planning to expand locations or sell internationally

- You publish stock availability online and need it to stay accurate

- You want traceability and clean financials at any point in time

When Periodic Still Fits

Periodic systems can handle early growth, especially if your operations are simple. You can add a second location and more SKUs while still doing monthly counts.

You might tighten your routines, add barcode labels to reduce errors, and even start scanning during receiving and shipping. That builds a path toward real-time tracking without switching all at once.

When the time comes, you can move the ledger to a perpetual setup and keep the tools your team already knows.

It still works if:

- You have a small product range with slow movement

- You can pause to count without hurting service

- Finance is okay reconciling cost of goods sold at the end of the month

Here’s a decision matrix to help you compare perpetual and periodic inventory systems across key business criteria. This should make it easier to decide which system fits your current needs and growth plans.

| Criteria | Perpetual Inventory System | Periodic Inventory System |

Business Size |

Mid to large businesses with growing complexity |

Small businesses with limited SKUs and simple operations |

Sales Channels |

Multichannel (online, offline, marketplaces) |

Single or limited sales channels |

Order Volume |

High volume, frequent transactions |

Low to moderate, stable volume |

Inventory Accuracy Requirement |

Must stay accurate at all times (e.g. eCommerce, retail) |

Can afford delays or small discrepancies |

Data & Reporting Needs |

Real-time stock, audit trails, accurate COGS |

End-of-period reports and manual reconciliation |

Operational Complexity |

Multiple warehouses, drop shipping, BOPIS, returns |

One or two locations with basic receiving and shipping |

Tech Readiness |

Has WMS, POS, or plans to integrate ERP systems |

Comfortable using spreadsheets or simple tools |

Staffing & Training Capacity |

Teams trained in scanning, SOPs, and automated systems |

Minimal training, manual processes with occasional counts |

Budget Considerations |

Higher upfront investment, long-term ROI |

Low upfront cost, but higher manual effort and risk over time |

Scalability |

Easily adapts to new locations, SKUs, and platforms |

Becomes harder to manage as business complexity grows |

Inventory Movement Speed |

Fast-moving stock that needs constant updates |

Slow-moving or predictable inventory |

Financial Syncing Needs |

Requires real-time financial alignment |

Can wait until the end of the period for reconciliation |

Ready to switch from periodic to real-time inventory tracking?

Kladana connects your inventory, sales, and financials in real time so you always know what’s in stock, where it is, and what it’s worth.

FAQs on Periodic vs Perpetual Inventory Systems

These quick answers help clarify common questions around perpetual and periodic inventory systems.

What’s the main difference between perpetual and periodic inventory?

Perpetual systems update inventory continuously after every transaction. Periodic systems only update after scheduled counts. The difference comes down to how often stock levels are refreshed.

Which system gives more accurate inventory data?

Perpetual is more accurate. It tracks sales, returns, receipts, and transfers in real time. That means fewer blind spots and faster detection of errors or shrinkage.

Is a perpetual inventory system worth the investment?

Yes, especially for fast-moving or multi-channel businesses. It reduces stockouts, write-offs, and last-minute shipping costs, which helps protect margins over time.

How often should you run counts in a perpetual system?

Use cycle counts weekly or monthly. Focus on high-value or fast-moving items, so you catch errors early without disrupting daily work.

Can you move from periodic to perpetual without major disruptions?

Yes. Start by cleaning item records and labeling key locations. Test the system on your top-selling items, then expand gradually. Set a clear cutoff to switch methods and reconcile once.