You check your shelves and realize a top-selling item is out of stock. Orders are pending, customers are waiting, and your team scrambles to send out rush purchase requests. The worst part? This didn’t happen for the first time.

Running out of inventory at the wrong moment can stall the entire supply chain, hurt your reputation, and eat into profits. On the flip side, overstocking ties up capital and clutters storage with items that may not move fast enough. For small manufacturers, where every unit and every dollar counts, the margin for error is razor-thin.

That’s where stock replenishment comes in. A clear, repeatable replenishment strategy helps maintain ideal stock levels across products and locations. This guide will walk you through the key methods, calculations, and tools to help you restock smarter and avoid costly inventory mistakes.

- What is Stock Replenishment?

- How the Inventory Replenishment Process Works

- Manual vs Automated Replenishment Systems

- Key Replenishment Strategies for Small Businesses

- Reorder Point Calculation and Safety Stock

- Best Practices for Stock Replenishment

- Inventory Optimization for Small Manufacturers

- Replenishment in Supply Chain Operations

- FAQs on Inventory and Stock Replenishment

- List of Resources

What is Stock Replenishment?

Stock replenishment is the process of restocking inventory to maintain optimal stock levels and meet customer demand. It involves tracking stock usage, setting reorder points, and placing orders to avoid both shortages and excess inventory. The goal is to have the right products available at the right time, without tying up capital in overstock or facing lost sales due to stockouts.

This process is especially important for small manufacturers and retailers, where delays in production or fulfillment can directly affect revenue and customer satisfaction.

Let’s explore why stock replenishment matters so much in day-to-day operations.

Why Stock Replenishment Is Important

A good replenishment system does more than just fill shelves. It directly affects your bottom line, your customer relationships, and your ability to grow.

1. Prevents Stockouts and Lost Sales

Running out of raw materials or finished goods can halt production and delay customer orders. According to a study by ElectroIQ, 94% companies reported a negative impact due to supply chain disruption. Stock replenishment keeps essential items flowing to avoid such losses.

2. Reduces Overstock and Storage Waste

Overstocking ties up working capital and fills up valuable warehouse space. For small businesses with limited storage, this quickly becomes costly. Replenishment strategies help avoid buying too much of what you don’t need.

3. Improves Order Fulfillment Speed

Consistent restocking means fewer delays in shipping orders. This not only speeds up delivery but also improves your reputation with customers who expect reliability.

4. Enhances Cash Flow Management

Ordering just what you need, when you need it, helps free up funds for other areas of the business — whether that’s marketing, hiring, or expanding operations.

5. Supports Forecasting and Growth Planning

A stable replenishment process gives you historical data to forecast better. When you know what sells and how fast, you can plan seasonal campaigns and scale operations with less guesswork.

🚫 Never Run Out of Stock Again

Automate reorder points and streamline stock replenishment with Kladana.

Here’s what you get:

- Real-time inventory tracking across SKUs, warehouses, and raw materials

- Automated reorder point triggers with built-in lead time and safety stock settings

- Purchase order creation and supplier management in one place

- Visual inventory dashboard for faster restocking decisions

➡️ Explore our Inventory Management Module

Now that you know why replenishment matters, it’s worth clarifying how it differs from demand forecasting, a concept often confused with replenishment.

Replenishment vs Demand Forecasting

Replenishment and forecasting often work together but serve different purposes. Understanding the difference helps in choosing the right tools and strategies for each.

Replenishment is reactive. It’s triggered when the stock falls below a certain level. For example, if you manufacture wooden furniture and notice your stock of screws is down to 200 units (below your reorder point of 300), that prompts a replenishment order. It focuses on maintaining availability.

Forecasting, on the other hand, is proactive. It estimates future demand based on historical sales, market trends, and seasonality. If you know your chair sales increase by 40 percent in the winter, your forecast will prompt you to prepare higher stock levels before demand spikes.

You can replenish without forecasting (using static thresholds), but forecasting enhances the accuracy and timing of your replenishment actions.

| Aspect | Stock Replenishment | Demand Forecasting |

| Purpose | Maintain ideal stock levels | Predict future demand |

| Trigger | Stock falls below reorder point | Based on trends, sales data, seasonality |

| Nature | Reactive | Proactive |

| Data used | Current stock, lead time, safety stock | Sales history, promotions, market conditions |

| Tools | Inventory software, ERP systems | Forecasting tools, BI platforms |

| Outcome | Prevents stockouts and overstock | Helps in planning procurement and promotions |

Understanding the line between the two helps businesses act faster, restock smarter, and reduce waste. Next, we’ll explore what the replenishment process actually looks like and how to put it into action.

How the Inventory Replenishment Process Works

Stock replenishment isn’t a single task. It’s a cycle that starts with monitoring inventory and ends with goods being restocked and ready for sale or use. If one step breaks down, the entire chain slows down or collapses. Here’s how to make sure every part runs like clockwork.

Monitoring Stock Levels

The first step is visibility. You need to know exactly how much stock is on hand, how fast it’s moving, and where it’s stored.

For growing businesses, manual tracking through spreadsheets often becomes unreliable. Instead, inventory management systems like Kladana offer real-time tracking, multi-location visibility, and alerts when items fall below critical levels.

For example, if a small manufacturer produces hand-crafted candles and sells through both Shopify and retail outlets, monitoring stock across locations ensures one channel doesn’t oversell while the other sits on inventory.

📘 Recommended Read: You can use VED Analysis for Inventory Management to prioritize critical items, reduce the risk of production halts, and optimize stock levels based on operational importance and not just quantity.

Triggering Replenishment Through Thresholds or Time-Based Models

Once stock levels are visible, the next step is setting rules to trigger replenishment. These usually fall into two models:

Threshold-based (Reorder Point): You replenish when stock falls below a predefined quantity. This is ideal for fast-moving items or essential raw materials. For instance, a textile manufacturer might set the reorder point for cotton rolls at 500 units based on average daily usage and supplier lead times.

Time-based (Periodic Review): You check stock at regular intervals, say every two weeks or at the end of each month. This works better for lower-priority or seasonal items where demand is more predictable.

You can also combine both models. High-value items can be reviewed weekly, while essentials auto-trigger orders once they hit the threshold.

Sourcing, Purchasing, and Receiving Inventory

Once a trigger activates, the purchasing cycle begins.

Sourcing: Choose suppliers based on price, delivery speed, and reliability. For critical materials, always have a backup vendor to avoid bottlenecks.

Purchasing: Use inventory software to generate accurate purchase orders. Include item SKUs, quantities, required delivery dates, and any packaging instructions. Clear communication helps avoid delays or order errors.

Receiving: When goods arrive, inspect them before updating your system. Verify quantity and quality, and check for any damages. This step is key in maintaining accurate inventory records.

As soon as stock is received, it should be added to your storage or production area and logged in your system immediately to keep everything in sync. Delays here can lead to confusion, duplicate orders, or missed sales.

Done right, this process creates a rhythm that helps your business avoid emergency orders, streamline production, and stay ahead of customer demand.

📦 4 Free Inventory Checklists

Get step-by-step guides to manage stock, organize your warehouse, track barcodes, and create product cards, even without prior experience.

✅ Stock management

✅ Warehouse organization

✅ Barcode tracking

✅ Product cards for e-commerce

Next, we’ll look at how manual and automated systems affect each step of this cycle.

Manual vs Automated Replenishment Systems

Every business starts somewhere. Most small manufacturers begin by tracking inventory with spreadsheets and reorder logs. It works for a while, but as sales channels grow or orders become more frequent, these systems often fall short. That’s when automation steps in.

Let’s break down both approaches so you can see which one fits your business today and what might be worth upgrading to next.

Traditional Spreadsheets or Reorder Logs

Manual replenishment usually involves maintaining reorder logs or Excel sheets that track inventory counts, reorder points, and supplier details. While this method is accessible and low-cost, it depends heavily on accuracy, consistency, and manual input.

Consider a small furniture workshop with fewer than 50 SKUs that may use a spreadsheet to track the number of screws, wood planks, and packaging boxes. Once any item hits its reorder point, someone places a purchase order manually.

Pros and Cons of Manual Replenishment

Pros:

✔️ Low upfront cost

✔️ Easy to implement

✔️ Full control without software learning curve

Cons:

❌ High risk of human error

❌ No real-time updates

❌ Difficult to scale with growing SKUs

❌ Limited reporting or data analytics

❌ Time-consuming for daily operations

Manual systems may work in the short term, but they often become error-prone as product variety, sales channels, and order volumes increase. Missed entries or outdated stock counts can result in lost sales or over-ordering.

Inventory Software and ERP Automation

Automated replenishment systems are built to solve these problems by syncing inventory data across purchasing, production, and sales. ERP software like Kladana lets you set reorder points, track raw materials, and generate purchase orders automatically based on real-time stock movements.

Pros and Cons of Automated Replenishment

Pros:

✔️ Real-time stock visibility

✔️ Auto-generated purchase orders

✔️ Tracks raw materials across sales and production

✔️ Reduces manual errors

✔️ Provides estimated delivery timelines

Cons:

❌ Requires setup and learning time

❌ Higher upfront cost than spreadsheets

❌ May offer features not needed by very small businesses

How they both compare:

| Aspect | Manual Tracking | Automated System |

| Accuracy | Depends on manual entry | Based on real-time data |

| Speed | Slower | Faster, proactive |

| Scalability | Limited | Built for growth |

| Cost | Low | Medium (with higher ROI) |

| Inventory Visibility | Static | Dynamic and live |

| Workflow Integration | Minimal | Integrated with order management and, production workflows |

For small manufacturers, choosing between manual and automated systems depends on volume, complexity, and team size. But if inventory issues are starting to eat into profits or delay orders, automation is no longer optional, it’s a growth enabler.

📘 Recommended Read: Struggling with delayed orders or missed stock updates? Explore automated inventory management to see how real-time tracking, barcode automation, and smart reorder triggers can fix stock problems before they start.

Neytt Homes Automates Replenishment with Kladana

Neytthomes, a premium rug and carpet brand, replaced Excel with Kladana to gain full control over inventory, sales, and procurement. Within nine months, the team set automated reorder points, implemented barcode tracking, and began tracking sales and replenishment KPIs across 10 locations, all from a single dashboard. This helped them prevent stockouts, streamline vendor management, and make faster, data-backed decisions.

Rajni Mittal, head of Supply Chain Management & Production shares her experience:

“We explored multiple ERP solutions, but none offered the flexibility and support Kladana did. It’s fully adapted to our business and industry-specific needs. Before Kladana, every sale required a manual stock update in Excel, which led to frequent errors and confusion. Now, with automated tracking and barcodes, we have full confidence in our inventory data.”

“We finally have complete visibility into purchase orders, vendor timelines, and reorder points. Kladana has made replenishment predictable and efficient. We can also calculate profits accurately, track COGS, and evaluate supplier performance in real time. It has completely changed how we run our business.”

Read the complete case study here.

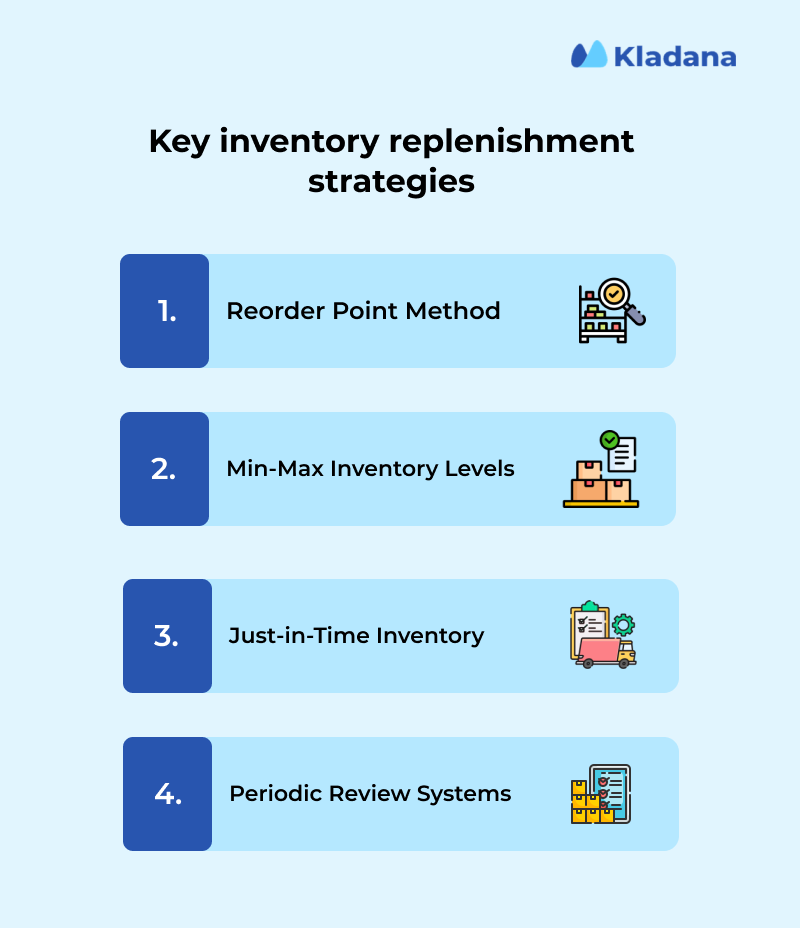

Key Replenishment Strategies for Small Businesses

There’s no one-size-fits-all when it comes to inventory restocking. Your replenishment strategy depends on how predictable your demand is, how fast your suppliers deliver, and how much stock you can afford to hold.

Let’s look at four reliable methods that small manufacturers and retailers use to keep their shelves full without overcommitting resources.

1. Reorder Point Method

The reorder point (ROP) method is the most widely used replenishment strategy for businesses with steady demand and known lead times. It triggers a new purchase when stock falls to a specific level.

Example:

You run a small bakery that uses 20kg of flour per day, and your supplier takes 4 days to deliver. You also want a safety buffer of 10kg in case of a delay.

Reorder Point = (20kg × 4 days) + 10kg = 90kg

When your flour stock hits 90kg, it’s time to reorder.

This method gives you just enough stock to cover your needs until the new order arrives, reducing both stockouts and excess inventory. But it relies on accurate lead time tracking and consistent usage data.

Pros and Cons of Reorder Point Method

Pros:

✔️ Helps prevent stockouts by triggering timely orders

✔️ Minimizes excess inventory and carrying costs

✔️ Easy to automate with inventory software

✔️ Works well for items with steady demand and predictable lead times

Cons:

❌ Requires accurate sales and usage data to set correct reorder points

❌ May lead to stockouts if demand spikes unexpectedly or suppliers delay

❌ Needs ongoing review as demand patterns or lead times change

❌ Not ideal for items with highly seasonal or erratic demand

2. Min-Max Inventory Levels

This strategy sets two inventory thresholds: a minimum level that triggers a reorder, and a maximum level that stock should never exceed. When stock hits the minimum, you order enough to reach the max.

Example:

A pet accessory brand sets a min level of 100 and a max of 400 for its dog harness inventory. When the stock hits 100, they reorder 300 units.

It’s useful when you want to maintain a buffer stock while reducing order frequency. However, setting the right min and max values requires historical sales data and frequent review.

Pros and Cons of Min-Max Inventory Method

Pros:

✔️ Reduces ordering frequency

✔️ Maintains buffer for demand surges

Cons:

❌ Can lead to overstock if demand drops

❌ Requires accurate demand history

3. Just-in-Time Inventory

Just-in-time (JIT) focuses on restocking goods only when needed. It reduces carrying costs but demands tight coordination with suppliers and minimal room for delays.

Example:

An electronics workshop builds products to order. Instead of stocking every part, they rely on JIT delivery of components like PCBs and connectors based on confirmed customer orders.

JIT is ideal for made-to-order businesses or high-cost inventory. But it can collapse quickly if suppliers are unreliable or demand spikes unexpectedly.

Just-in-Time Pros and Cons

Pros:

✔️ Low storage costs

✔️ Minimal excess stock

Cons:

❌ High risk of stockouts

❌ Requires dependable supplier timelines

4. Periodic Review Systems

Instead of constantly tracking stock, this method reviews inventory at fixed intervals — weekly, monthly, or quarterly — and places orders based on current stock levels.

Example:

A handmade soap manufacturer checks inventory on the first Monday of every month and restocks all SKUs based on projected needs for the month ahead.

This method is easy to schedule and manage but lacks responsiveness. If sales spike after a review period, you risk running out before the next order window.

Periodic Review Pros and Cons

Pros:

✔️ Simple to manage

✔️ Suitable for multi-item restocking

Cons:

❌ Less flexible for fast-moving products

❌ Higher chance of missed reorder timing

Each strategy has its strengths, but most small businesses benefit from a hybrid approach. Use reorder points for fast-moving SKUs, periodic review for slow sellers, and JIT for high-value or custom items. The next section explains how to calculate reorder points and set safety stock levels to make these strategies work in practice.

Reorder Point Calculation and Safety Stock

Knowing when to reorder stock is not a guessing game, it’s a calculated decision based on your sales velocity, supplier lead times, and how much buffer you need for unexpected delays or spikes in demand. This is where Reorder Point (ROP) and Safety Stock work together to help you avoid stockouts while keeping inventory costs in check.

Let’s break this down step by step and show you how to calculate it for your own operations.

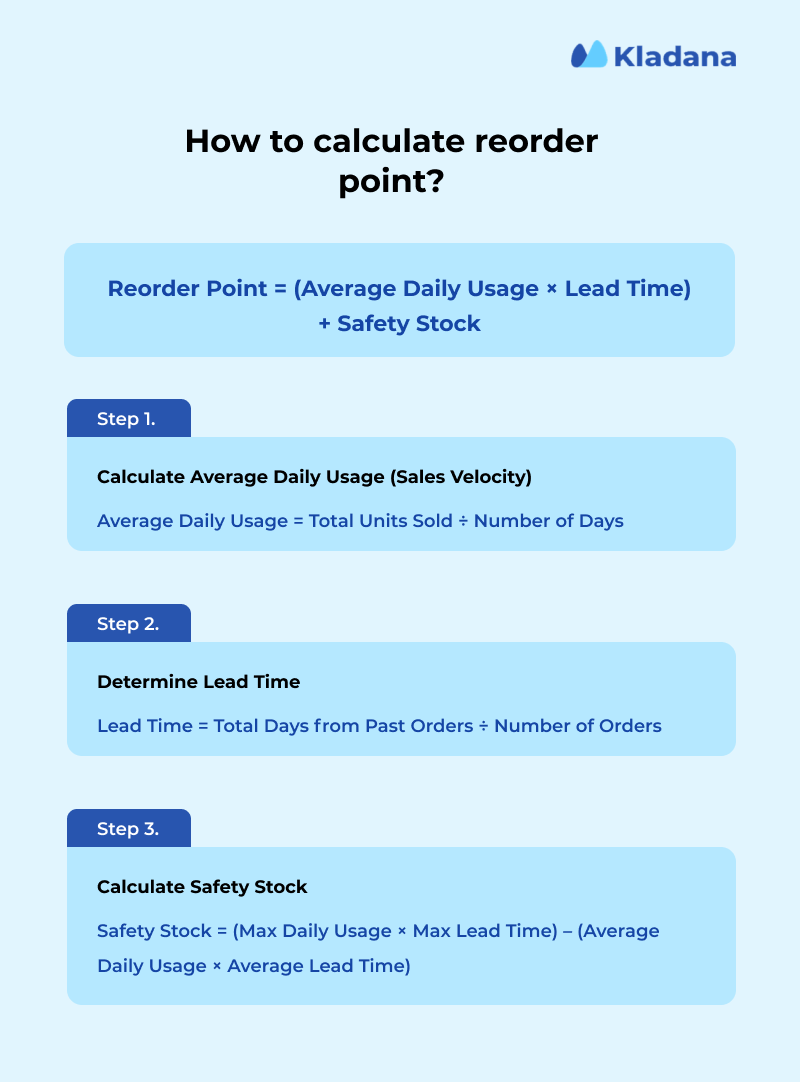

What is the Reorder Point Formula?

The reorder point is the exact stock level at which a new purchase order should be placed. The formula looks like this:

Reorder Point = (Average Daily Usage × Lead Time) + Safety Stock

Each variable in this formula plays a specific role. Let’s look at how to calculate them.

Step 1: Calculate Average Daily Usage (Sales Velocity)

This is how many units you sell (or use in production) each day.

Formula:

Average Daily Usage = Total Units Sold ÷ Number of Days

Example:

If you sell 600 units in a 30-day month,

Average Daily Usage = 600 ÷ 30 = 20 units

Step 2: Determine Lead Time

This is how many days it takes from placing a purchase order to receiving the stock.

Formula:

Lead Time = Total Days from Past Orders ÷ Number of Orders

Example:

If 5 shipments took 3 days and 5 shipments took 5 days,

Total = (5 × 3) + (5 × 5) = 15 + 25 = 40 days

Average Lead Time = 40 ÷ 10 = 4 days

Step 3: Calculate Safety Stock

Safety stock is the extra inventory you keep as a buffer. It protects you from supply chain delays or sudden demand spikes.

Formula:

Safety Stock = (Max Daily Usage × Max Lead Time) — (Average Daily Usage × Average Lead Time)

Example:

Max daily usage = 30 units

Max lead time = 7 days

Average usage = 20 units

Average lead time = 4 days

Safety Stock = (30 × 7) — (20 × 4) = 210 — 80 = 130 units

Now Plug It All In

If your average daily usage is 20 units, lead time is 4 days, and safety stock is 130 units:

Reorder Point = (20 × 4) + 130 = 80 + 130 = 210 units

This means when your stock drops to 210 units, it’s time to reorder.

Use Case: Small Manufacturer Example

A handcrafted soap business produces and sells 1,200 soap bars monthly. Their supplier takes 5 days to deliver raw ingredients. Average daily usage is 40 bars. They want to maintain a safety stock of 100 bars in case demand spikes during holidays or deliveries are delayed.

ROP = (40 × 5) + 100 = 200 + 100 = 300 bars

When the stock level reaches 300 bars, they automatically reorder supplies to avoid production delays.

Reorder points help streamline purchasing, reduce panic buying, and ensure production doesn’t stop. Safety stock, on the other hand, gives you breathing room during seasonal rushes, supplier delays, or sudden spikes in demand.

Both need regular review. As sales patterns shift or supplier lead times change, your reorder point and safety stock should be updated to reflect real inventory levels.

📘 Recommended Read: Want to fine-tune not just when you reorder, but how much? Learn how EOQ in Inventory Management helps you calculate the ideal order size to cut costs, avoid overstocking, and reduce purchase frequency without compromising supply.

Best Practices for Stock Replenishment

Even the best replenishment strategies fall short without disciplined execution. The difference between businesses that stay stocked and those that frequently scramble often comes down to consistency in these core practices.

Let’s walk through four habits that will keep your inventory operations running efficiently and help prevent stockouts or overstocking.

Maintain Accurate Stock Counts (Cycle Counting)

If your stock data is not accurate, every decision you make based on it will be inaccurate, too. That’s why regular stock counts matter.

Cycle counting is a technique where you count a subset of your inventory on a rotating schedule instead of doing a full count once a year. This saves time, avoids disruption, and keeps your numbers more accurate throughout the year.

For example, instead of halting business operations once a quarter to count 5,000 units, a small parts supplier might count 200 to 300 SKUs per week, rotating through the catalog over a month.

Frequent cycle counts help detect shrinkage, data mismatches, or mis-shelved items that can throw off your replenishment triggers.

Categorize SKUs (ABC Analysis)

Not all products deserve the same level of attention. Use ABC analysis to prioritize inventory management based on value and velocity.

- A items are high-value or high-turnover. Track these closely and replenish frequently.

- B items are moderate value. Review and replenish as needed.

- C items are low-value or slow-moving. Stock conservatively and review periodically.

A manufacturer of electronics accessories, for example, may treat power banks as A items (high sales), phone grips as B, and custom stickers as C.

ABC analysis helps focus replenishment efforts on what matters most, reducing wasted time and money on low-impact SKUs.

Track Supplier Lead Times

If you don’t know how long your suppliers take to deliver, your reorder points won’t work. Supplier lead times fluctuate due to holidays, raw material shortages, or shipping delays.

Keep a log of actual delivery times vs. promised lead times for each vendor. This lets you spot patterns or performance issues early.

If your supplier says they deliver in 5 days, but consistently take 7, you’ll need to adjust your reorder timing to reflect that.

Over time, this data builds a more realistic foundation for setting reorder points and safety stock levels.

Regularly Review and Adjust Reorder Levels

Reorder points are not set-and-forget. Sales trends, supplier behavior, and product lifecycles all change, and so your reorder levels should too.

Review your ROP settings every quarter or whenever there’s a shift in:

- Sales volume

- New product launches or discontinued SKUs

- Supply chain disruptions

- Seasonality (holiday spikes, monsoon delays, etc.)

Let’s take an example for a clothing brand, which sees winter gloves spike in demand from October to January. They increase safety stock and reorder points in September, then reduce them by February.

Good stock replenishment isn’t just about reacting when inventory runs low. It’s about staying ahead of the curve through routine checks, accurate data, and smarter planning. In the next section, we’ll explore how to tie these practices into broader inventory optimization strategies.

Inventory Optimization for Small Manufacturers

Optimizing inventory is all about aligning stock levels with demand, cash flow, and production capacity. When done right, it improves profitability without sacrificing service levels. You can do that with the following:

Inventory Turnover Ratios

The inventory turnover ratio measures how quickly stock is sold and replaced. A high turnover means products are moving fast, while a low turnover signals overstock or slow demand.

Formula:

Inventory Turnover = Cost of Goods Sold ÷ Average Inventory

Example:

If your COGS is $500,000 and the average inventory is $100,000, your turnover is 5. That means you’re cycling through your stock five times a year.

Tracking this ratio monthly helps identify dead stock and improve purchasing decisions.

Balancing Cash Flow and Stock Availability

Too much stock ties up cash. Too little risks of losing sales. Find a middle ground by prioritizing fast-moving items, consolidating purchase orders, and negotiating better payment terms with suppliers.

A craft tools maker may order in smaller batches but negotiate 45-day payment terms, giving them more room to manage cash flow while keeping essentials in stock.

Using Forecasting Tools to Improve Restocking Accuracy

Basic spreadsheets can’t capture sales trends, seasonality, or promo-driven spikes. That’s where demand forecasting tools come in. They help you make data-backed decisions by analyzing past sales, supplier performance, and customer behavior.

Kladana’s inventory management solution makes it easier by showing real-time stock levels, product movement, and reorder alerts all in one place. It tracks how your inventory flows through sales, purchases, and production, so you always know what to restock and when. You can also set dynamic reorder points based on lead times and demand patterns, reducing the guesswork in restocking.

Replenishment in Supply Chain Operations

Replenishment doesn’t happen in isolation. It’s part of a larger supply chain network that spans warehouses, suppliers, and logistics partners. To keep operations smooth and costs low, your replenishment process must align with how your supply chain is structured.

Centralized vs Decentralized Replenishment

In centralized replenishment, a single distribution center manages stock for all locations. It simplifies control, reduces duplicate orders, and often lowers inventory holding costs. But it may increase delivery time to distant sites.

Decentralized replenishment allows each location to manage its own stock. It improves speed and local responsiveness, but requires more coordination and inventory oversight.

Example:

A food packaging company may centralize replenishment for raw materials but decentralize finished goods across regional hubs to shorten delivery times.

Multi-Location Inventory Planning

If you store inventory across multiple warehouses or outlets, visibility is key. Use tools that show real-time stock by location, track inter-warehouse transfers, and optimize where items are stored based on regional demand.

Collaboration with Suppliers and 3PLs

Regular communication with suppliers and third-party logistics (3PL) providers improves lead time accuracy and replenishment efficiency. Share demand forecasts and planned order volumes in advance to reduce delays and stockouts.

Replenish Your Stock With Confidence Using Modern ERP

Kladana brings your sales, stock, and supplier data into one connected view, so you can automate reorders, respond to demand in real time, and streamline your inventory management and operations.

FAQs on Inventory and Stock Replenishment

Got questions about how replenishment actually works? Here are quick, straight answers to the most common ones.

What is stock replenishment in inventory management?

Stock replenishment is the process of restocking inventory to maintain ideal levels and avoid stockouts. It ensures products are available when needed without overstocking or tying up excess capital.

How do you calculate reorder point?

Use the formula: (Average Daily Usage × Lead Time) + Safety Stock. It tells you when to reorder based on demand, delivery time, and buffer stock.

What is safety stock and why is it important?

Safety stock is buffer inventory kept to cover unexpected demand or supplier delays. It helps avoid stockouts and ensures consistent order fulfillment.

What is the difference between manual and automated replenishment?

Manual replenishment relies on spreadsheets and manual tracking. Automated systems use software to monitor stock, trigger orders, and reduce errors.

Which replenishment strategy suits small manufacturers?

A mix of reorder point, just-in-time, and periodic review methods works best. Choose based on product demand, lead times, and storage capacity.

What is just-in-time replenishment?

Just-in-time means ordering inventory only when needed. It reduces storage costs but requires reliable suppliers to avoid stockouts.

How does ERP software automate stock replenishment?

ERP systems track inventory in real time, set reorder points, and auto-generate purchase orders to streamline and simplify restocking.

How often should inventory levels be reviewed?

Review inventory monthly, or more often for fast-moving items. Regular checks help adjust reorder points and prevent stock issues.

What’s the role of lead time in replenishment?

Lead time affects when you need to reorder. Longer or inconsistent lead times require higher safety stock to avoid delays.

How can poor replenishment lead to stockouts or overstocking?

Late or excessive ordering causes stockouts or overstock. Both impact cash flow, storage costs, and customer satisfaction.

List of Resources

ElectroIQ — Supply Chain Statistics and Facts (2025)