Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

Pick and ship orders 3x faster. Count 300+ items in 1 hour. Move 1,500+ goods between warehouses in clicks. These aren’t promises — they’re real numbers from our clients. Use Kladana’s multi‑location WMS for small businesses

Track inbound and outbound warehouse operations

Run fast cycle counts to keep stock accurate

Fix errors, losses, or damaged goods instantly

Move products across locations in seconds

Kladana WMS is just the job if you’re never sure where products are stored, picking and shipping orders drags on, warehouses stay cluttered, barcodes don’t match specific variants, and you keep dreading those inventory counts.

With Kladana, your warehouse operations stay under control — from receiving and put‑away to picking, packing, shipping, and returns — all managed in one place.

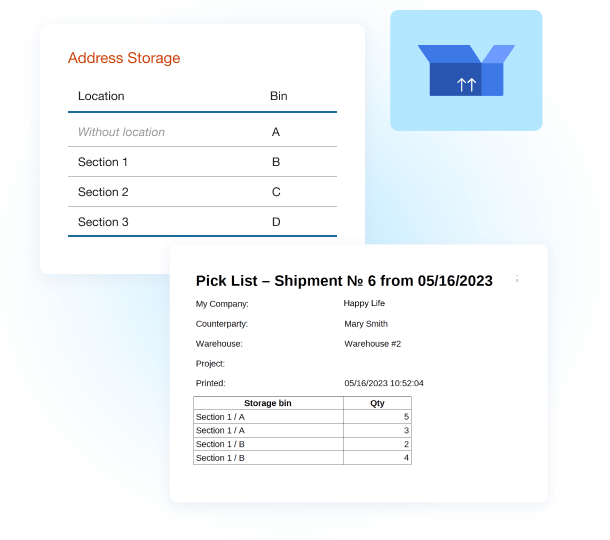

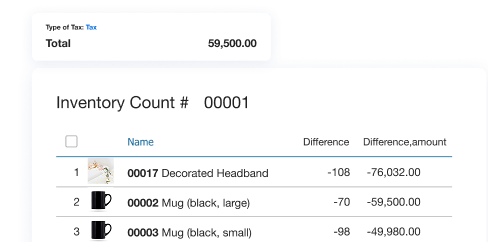

Run full or partial counts by warehouse and set statuses like to do, completed, or postponed to track progress

Generate and print lists to spot stock discrepancies within a time frame

Create adjustments for discrepancies and write‑offs for damaged or expired goods

Speed up receivings, shipments, transfers, and inventory counts across all warehouse operations

Improve quality control, cut costs, and reduce legal or reputational risks

Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

Customization + Responsive Support

We tried other ERP tools, but only Kladana let us customize formats and interfaces to fit our workflows. And when we had questions, support was right there — quick replies over messenger, no delays.

Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

In Kladana, we found the functionality we were looking for. In combination with affordability, it worked as a decisive factor. Another important area is tracking the amount of yield our company is getting. In this respect Kladana is suitable to our requirements, and we are going to start using the Financials module of the solution.

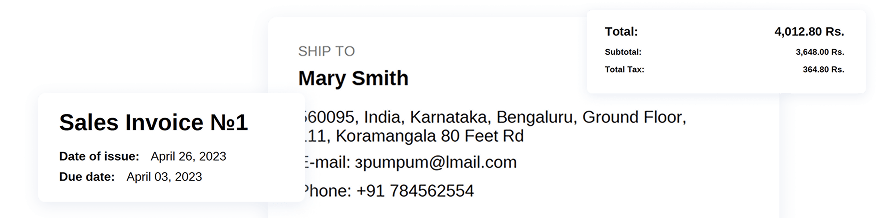

In Kladana we process sales orders, make sales invoices in pdf, and manage shipments. All bills of materials are stored in the software. All production stages are reflected in Kladana.

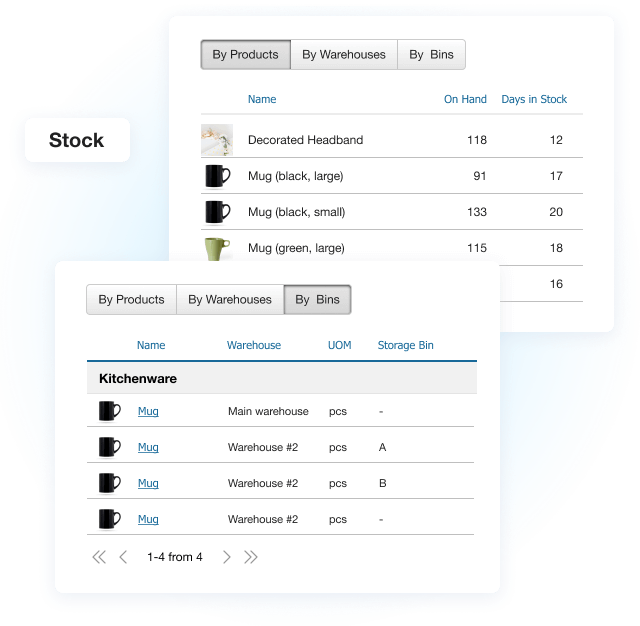

We have three warehouses: one for raw materials, one for production, and one for finished goods. We add the purchased materials to Inventory in Kladana, and the raw materials are transferred to production. In production, they are processed in a production order. Then the finished goods appear in another warehouse. Thus, 1,500 bottles are moved from one warehouse to another in a couple of clicks.

Manage and track operations across multiple warehouses, covering raw materials, WIP, finished goods, and products at branches or retail stores

Create pick lists, price tags, thermal labels, and supplier invoices with personalized fields and designs, then print them on demand

Set approval flows and employee access roles to protect sensitive data and track every action in your WMS

Use workflow templates to trigger routine processes automatically, streamlining operations across your team

The WMS module is included at no extra cost for all paid Kladana plans. Start with a 14‑day trial, use the free plan, or get essential features for just $60/year

Connect with platforms like WooCommerce, Borzo, and Zoho Books. Use Kladana Online Order App to sell directly, even without a website. An API is available for custom integrations

Get 1–3 onboarding sessions depending on your plan, plus fast free support via chat, email, or form — typically within 5–15 minutes

Manage your warehouses, inventory, sales, purchases, and production seamlessly, without juggling multiple tools

We have been using the service for a year. Previously we used an Excel to track products and stock. The interface is clear and simple. Customized templates and reports for printing — guys from Support can help you make them for free. Profit and loss reports, contacts cards, flexible access rights for employees, safe database — everything is great!

We’re a saree manufacturing factory, responsible for managing production, purchasing raw materials, storing and tracking them, and overseeing manufacturing and sales processes. Previously, we relied on spreadsheets, but constant errors made us exhausted. Kladana helps us to solve all these tasks now. And saves a whole bunch of time and effort.

It’s affordable, easy to set up, and doesn’t require a big IT team. A good WMS helps small businesses keep track of inventory, avoid stockouts, speed up picking and shipping, and reduce costly mistakes. Many systems come with simple dashboards, barcode scanning, and reorder alerts to make warehouse operations smooth — even if you’re managing just one warehouse or a small team.

The best warehouse management software (WMS) depends on your business size, budget, and needs. For small businesses, look for a WMS that is:

For examples of leading WMS options for small businesses — including free and cloud‑based tools — check out our complete guide to warehouse management software.

Prices for small business WMS vary. Many cloud‑based systems start at around $50—$100 per month. Some offer yearly plans from $60—$500 depending on features, user count, and warehouses. Basic versions might be free, which is great for small teams just starting out. Costs usually rise with more advanced functions like detailed analytics, integrations, or multi‑location tracking.

The four main types of WMS are:

SCM (Supply Chain Management) handles the whole flow of goods — from suppliers to manufacturing to delivery. It covers planning, sourcing, production, logistics, and even returns. A WMS (Warehouse Management System) is focused just on what happens inside your warehouse — managing stock locations, order picking, packing, and shipments. Think of WMS as one part of the bigger SCM picture.

An ERP (Enterprise Resource Planning) system manages your entire business in one platform — including sales, purchasing, production, accounting, and inventory. A WMS specializes in warehouse operations only — it tracks inventory, manages picking and packing, and organizes shipments. Many ERPs (like Kladana) have built‑in WMS modules, so you can handle everything from production to warehouse to invoicing in one app.

Kladana is a cloud‑based system designed for small businesses. It gives you real‑time inventory tracking, automated reorder alerts, barcode scanning, and simple dashboards so you can see everything at a glance. This means you’re not relying on someone’s manual Excel or chasing paper notebooks. Automated workflows prevent stockouts and expired items. Even small teams can pick and ship orders faster, keep accurate costs, and plan purchases with more confidence.

Yes. By automating barcode scans, stock updates, and picking lists, Kladana cuts manual data entry mistakes. You can track every movement and know exactly where products are stored, which reduces costly errors and saves hours on checks.

Yes. It runs on secure cloud infrastructure with encrypted connections, daily backups, and strict access controls to keep your data safe. More details are on our security page.

For small businesses with a few dozen SKUs and simple operations, you can get going in just a few weeks. Larger setups with thousands of SKUs, multiple warehouses, and more users usually take around three months. Kladana offers dedicated onboarding sessions to help you set up products, locations, users, and documents.

All paid plans include 1–3 onboarding sessions, plus free support by live chat, email, or phone — even during your trial. Most questions get a reply within 5–15 minutes. The team can even customize reports or documents to fit your needs.

You also get quick how‑to videos and Help Center guides, so you can start using the warehouse management system in just 15 minutes.

Yes. Kladana connects with accounting platforms like Zoho Books, e‑commerce sites like WooCommerce, and many other services. It also has an API for custom integrations. See more on our integrations page.

Key features include real‑time inventory tracking, barcode scanning, multi‑location support, automated reorder points, order management (picking, packing, shipping), and clear reports or dashboards to spot slow or fast‑moving stock.

The six key operations in warehouse management include:

Look at order accuracy rates, average inventory turnover, picking and shipping times, days goods stay in stock, and the frequency of stockouts or excess stock. These help you see how efficient and cost‑effective your warehouse is.

Yes. Whether you have one small warehouse or several locations for raw materials, production, finished goods, or retail, Kladana lets you track stock separately in each place. You can also manage subcontractor or third‑party locations.

Use bin storage and zoning to keep things organized, barcode scans to track every move, automated reorder points to prevent shortages, and clear reports to plan space and cash flow. A WMS like Kladana ties all of this together so even a big warehouse runs smoothly.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce