Choosing the right production management software is crucial for Indian manufacturers. ERP systems play a vital role by integrating and automating key processes, enhancing efficiency and competitiveness.

2025 Update: We’ve recalculated prices, updated plans, modules, and features. Go directly to our top 23 solutions. Use our detailed comparison table — featuring feature breakdowns, pricing, and free trials — to find the best fit for your needs. To learn more about implementation pitfalls, hidden costs, and other vital data, read this article.

- What Is Manufacturing ERP?

- What Are the 6 Main Types of Manufacturing Software?

- What Are the 6 Benefits of Manufacturing Software?

- Why Indian Manufacturers Need ERP Systems in 2026

- What 6 Industries Use Manufacturing Software Mainly?

- How to Choose the Best ERP for Manufacturing

- How Much Does Manufacturing Software Cost?

- Top 23 Manufacturing Management Software 2026 — Find the Best Fit For You

- Which Software is Right For You?

- Frequently Asked Questions on Manufacturing Software

💻 Free Webinar Recording Available!

Recently, we hosted the webinar Automation for Manufacturing Companies: Where to Begin, featuring Aleksandra Brovchuk, Kladana’s Director in India, and Uday Sharma, Senior Customer Support Executive.

They shared the insights on efficiently managing inventory, warehousing, sales, and production — all within a single app, without requiring expensive implementations or specialized skills.

Key topics covered included:

- 6 common production management challenges and solutions

- 5 steps to seamlessly implement manufacturing software

- How Kladana ERP can benefit manufacturing companies

Receive webinar recording, presentation slides, a promo code for an extended 30‑day trial, and additional content via email for free.

What Is Manufacturing ERP?

Manufacturing ERP, or Enterprise Resource Planning, is software that helps manufacturing businesses manage and integrate their core processes into a single system. Think of it as a central hub that keeps everything running smoothly!

Key functions of a Manufacturing ERP include:

- Production Management: Planning, scheduling, and tracking the entire manufacturing process, from raw materials to finished goods.

- Inventory Management: Keeping tabs on stock levels, locations, and movements to avoid shortages or overstocking.

- Procurement: Handling purchasing, supplier relationships, and ensuring you have the materials you need, when you need them.

- Sales: Managing customer orders, tracking sales, and ensuring timely deliveries.

Essentially, a good Manufacturing ERP helps you streamline operations, reduce errors, improve efficiency, and make better decisions based on real-time data. It brings all the pieces of your business together, so you have a clear picture of what’s happening and can stay ahead of the game.

What Are the 6 Main Types of Manufacturing Software?

MRP, MES, PLM, CAD, and EAM — let’s explore what these abbreviations stand for.

ERP Software with a Production Module

It’s the most sought-after type of software with inventory, CRM & sales modules at hand.

MRP

MRP (Material Requirements Planning) is focused on procurement, supplies, and forecasts. MRP systems usually have automated solutions for raw materials purchase, finished goods shipment, etc.

MES

MES (Manufacturing Execution Systems) is focused on management and real-time monitoring of all production stages.

PLM

PLM (Product Lifecycle Management) is about item parts, production papers, quality check routines, etc.

CAD

CAD (Computer-Aided Design) is utilized to create technical item designs and to transfer them into BOMs.

EAM

EAM (Enterprise Asset Management) is used for equipment maintenance & tooling.

What Are the 6 Benefits of Manufacturing Software?

Implementing manufacturing software brings a host of advantages, but it’s also important to be aware of potential challenges. Here’s a balanced look.

| Benefits | Considerations |

✅ Total Visibility: Track every step of your process. From raw materials to final delivery, and every action by your team, everything is recorded and visible. 📍 Hey Baby, a women’s business attire manufacturer, manage their production using Kladana: create BOMs & production orders, handle sales, and keep track of inventory. All their data — from a single thread to individual customer records — is maintained in Kladana. |

❌ Initial Costs: Most manufacturing software requires an investment. Be prepared for pricing considerations. |

✅ Increased Productivity & Speed: Streamlined processes and less manual paperwork mean your team can focus on production. |

❌ Implementation Efforts: Setting up new software requires process adjustments and training. Ensure your team is ready for the change. |

✅ Improved Profitability: Easily calculate unit costs and sales prices. Use dashboards to analyze real profits and forecast. 📍 Neytt, a carpet manufacturer, measures productivity in Kladana, using KPIs for production, purchasing, and sales. With these insights, they easily calculate project-wise profits and assess logistics cost ratios per dispatch or invoice. |

❌ Data Migration Risks: Switching software might involve database migration challenges. Take steps to avoid data loss. |

✅ Scalability: Upgrade plans as your company grows to add more users, modules, and integrations. |

|

✅ Simplified Decision-Making: Use reports to make informed choices about cost-cutting, product expansion, and more. |

|

✅ Reduced Risks: Minimize errors like raw material shortages, payroll mistakes, and incorrect pricing with better tracking and automation. 📍 Body Motion, a South African medical and sportswear brand, reduced double buying and stockouts by switching from spreadsheets to Kladana. They now plan production weekly, track in-house and subcontracted orders, and maintain full inventory visibility — all with real-time support. |

Why Indian Manufacturers Need ERP Systems in 2026

In 2026, Indian manufacturers really need to use ERP software. Here’s why.

1. To Compete Better Everywhere

- Indian businesses are selling products all over the world, not just locally. To do well, they need to be organized and work efficiently. ERP helps them do this by giving them the right information and tools to run smoothly.

- ERP makes sure they deliver on time and the quality is good, which is super important for selling to other countries.

2. To Use Government Help

- Programs like “Make in India” want factories to grow and get modern. ERP helps them manage bigger orders, make better products, and keep track of their work. This helps them meet the goals of these programs.

- ERP also helps businesses follow rules and get support from the government because it keeps all their records clear and easy to see.

3. To Go Digital

- Everything is becoming digital, and manufacturing is no different. Indian factories need to use computers and online tools to keep up. ERP helps them do this with online systems and mobile phone access.

- Going digital with ERP means less paperwork, fewer mistakes, and better information to make smart decisions.

4. To Avoid Problems

- Many small factories start with paper or simple spreadsheets. But as they grow, this gets messy. Things get lost, information is wrong, and it’s hard to know what’s happening.

- ERP fixes this by doing calculations automatically, tracking everything carefully, and giving accurate information about products and costs.

5. To Grow Easily

- Factories can only use paper for so long. To get bigger, they need to use computers and software. ERP lets them add more users and features as they grow.

- By having everything in one system and not doing everything by hand, ERP helps them avoid mistakes and grow steadily.

Basically, if Indian manufacturers want to do well in 2025, ERP is not just a nice thing to have — it’s a must-have. It helps them work better, get government help, and keep up with the modern world.

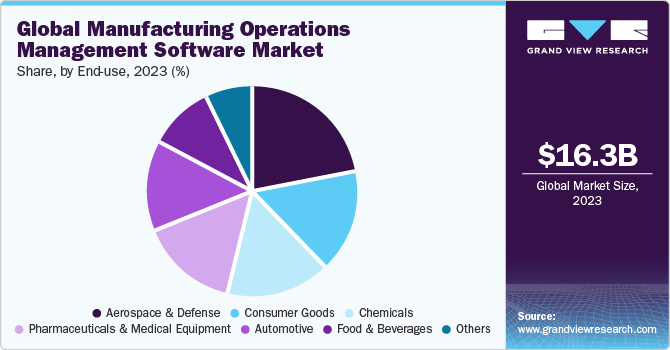

What 6 Industries Use Manufacturing Software Mainly?

According to Grand View Research, the most common are the following:

- Aerospace & defense

- Consumer goods

- Chemicals

- Pharmaceuticals & medical equipment

- Automotive

- Food & beverage

These industries’ production processes are the most complicated. Any mistake can lead to bad outcomes connected with security & health. That’s why advanced manufacturing software is required by these industries.

How to Choose the Best ERP for Manufacturing

Picking the right ERP system for your manufacturing business is a big decision, but it doesn’t have to be overwhelming. Here’s a simple guide to help you make the best choice.

Key Features to Consider

When you’re looking at different ERP systems, keep these essential features in mind:

- MRP (Material Requirements Planning): This feature helps you plan and manage your inventory. It tells you what materials you need, when you need them, and helps avoid running out or overstocking.

- BOM (Bill of Materials) Management: You need a system that can easily create and manage your BOMs, including multiple levels and versions. This helps track all the parts needed for your products.

- Execution: The system should handle all the details of production execution, including scheduling production orders, managing operations and routings, generating reports, tracking Work in Progress (WIP), scrap & finished goods.

- Shop Floor Control: This gives you real-time visibility into what’s happening on your factory floor. It helps you track production progress, manage work orders, and see any issues as they arise.

- Analytics: You’ll want an ERP that provides strong analytics. Look for features that track operational costs, labour costs, unit costs, profitability, payrolls, and employee performance. This data helps you make informed decisions.

- Quality Check: Ensuring quality is key. Your ERP should have tools for engineers to control the quality of produced items.

Cloud vs. On-Premise ERP for Manufacturing

- Cloud ERP: This means the software and your data are stored online.

- Pros: Easier to set up, often cheaper upfront, accessible from anywhere, automatic updates.

- Cons: Relies on internet connection, might have concerns about data security (though most providers have strong security measures).

- On-Premise ERP: This means the software is installed on your own computers and servers.

- Pros: More control over your data, less dependent on the internet.

- Cons: Higher upfront costs, you’re responsible for updates and maintenance, harder to access remotely.

Which one is right for you?

Consider your business size, budget, and IT capabilities. Cloud ERP is often a good choice for smaller businesses that want to get started quickly and don’t have a dedicated IT team. On-Premise ERP might be better for larger companies with complex needs and the resources to manage their own IT infrastructure.

By thinking about these key features and considering the pros and cons of cloud vs. on-premise ERP, you’ll be well on your way to choosing the best system for your manufacturing business.

How Much Does Manufacturing Software Cost?

The cost of manufacturing software can vary a lot. Here’s a quick breakdown to give you an idea:

- Basic — Cheaper Options: These might start around $500–700 per year. Good for very small businesses with simple needs.

- Mid-Range — Common Options: Many systems cost $1,000–6,000 per year. This usually gets you more features and good support, suitable for most small and medium-sized businesses.

- Advanced — More Expensive Options: Some big, complex systems can cost $40,000 per year or more. These are for large companies with very specific needs.

Things That Affect the Price:

- How many people will use it: more users = more money.

- What features you need: more features = more money.

- If it’s online (cloud) or on your computers: online is often cheaper to start.

- Extra costs: sometimes there are extra costs for setting it up, onboarding, support, or special add-ons.

Important:

- Prices are not always public: you might have to ask for a quote.

- Think about the total cost: don’t just look at the initial price. Think about all the other costs too.

Simply put: You can find affordable options for basic needs, but more complex software with lots of features will cost more. Always ask about all costs before you decide.

Top 23 Manufacturing Management Software 2026 — Find the Best Fit For You

We’ve done the homework for you! We looked at 23 great production management software options and compared them across key features. Our main goal was to find the best options for budget-conscious businesses, so price was a major factor.

The information below is based on data we collected from company websites, help centers, social media, and by talking to support teams. Everything is up-to-date as of April 24, 2025.

| Software Name | Price (Yearly) | Overall Score | Best for | Free Trial | Production Planning | MRP | Expenses & Advanced Features | Deployment | |||||||||||||

| BOMs | Orders | Reports | Operation Costs | Labour Costs | Unit Cost | WIP | Partial Production | Batches | Assignees | Ecommerce | Subcontractors | By-Products & Scrap | Cloud | Desktop | Mobile | ||||||

| Kladana | $563–1,109 |

⭐⭐⭐⭐⭐ (5.0) |

Small Manufacturers & D2C Brands |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| ERP Next | $60–2,400+ |

⭐⭐⭐⭐ (4.9) |

SMEs, Vertical-Specific (Customizable) |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| ERPAG | $588–2,388 |

⭐⭐⭐⭐ (4.9) |

SMEs |

15 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Tranzact | $705–4,227 |

⭐⭐⭐⭐ (4.9) |

Indian SMEs |

7 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

❌ |

❌ |

| MRPeasy | $488–1,564 per user |

⭐⭐⭐⭐ (4.9) |

SMEs, Light Manufacturing |

15 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Odoo | $345–517+ per user |

⭐⭐⭐⭐ (4.8) |

SMEs, Vertical-Specific (Flexible Modules) |

15 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Katana | $2,148–21,588+ |

⭐⭐⭐⭐ (4.8) |

SMEs |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| Cin7 | $4,188–11,988+ |

⭐⭐⭐⭐ (4.8) |

SMEs, Wholesale & Ecommerce |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Acumatica | No data |

⭐⭐⭐⭐ (4.7) |

Medium to Large, Manufacturing, Distribution |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Fulcrum | No data |

⭐⭐⭐⭐ (4.7) |

Construction, Field Service |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| Oracle NetSuite | No data |

⭐⭐⭐⭐ (4.7) |

Large Enterprises, Multi-Industry |

Live Demo Only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Deskera | $4,188–5,388+ per user |

⭐⭐⭐⭐ (4.7) |

Medium to Large, APAC Businesses |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Fishbowl | No data |

⭐⭐⭐⭐ (4.7) |

SMEs, Manufacturing, Warehousing |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

| Cetec ERP | $300–600 per user+ |

⭐⭐⭐⭐ (4.5) |

Manufacturing, Field Service |

30 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

✅ |

| Unleashed | $4,560–12,960 |

⭐⭐⭐⭐ (4.4) |

SMEs, Inventory-Centric Businesses |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

❌ |

✅ |

✅ |

❌ |

❌ |

| Global Shop Solutions | No data |

⭐⭐⭐⭐ (4.4) |

Large Manufacturers (Aerospace, Automotive) |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

❌ |

❌ |

| Statii | No data |

⭐⭐⭐⭐ (4.3) |

SMEs, Project-Based Industries |

14 Days |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

❌ |

✅ |

❌ |

❌ |

| PACT ERP | No data |

⭐⭐⭐⭐ (4.2) |

Food & Beverage, Process Manufacturing |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

✅ |

❌ |

❌ |

❌ |

✅ |

✅ |

✅ |

✅ |

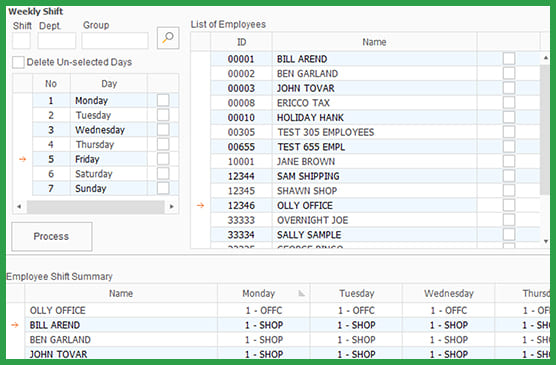

| Plex | No data |

⭐⭐⭐⭐ (4.2) |

Large Manufacturers (Automotive, Industrial) |

Demo only |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

❌ |

✅ |

❌ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

❌ |

✅ |

| Epicor | No data |

⭐⭐⭐⭐ (4.2) |

Large Enterprises, Manufacturing |

Demo only |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

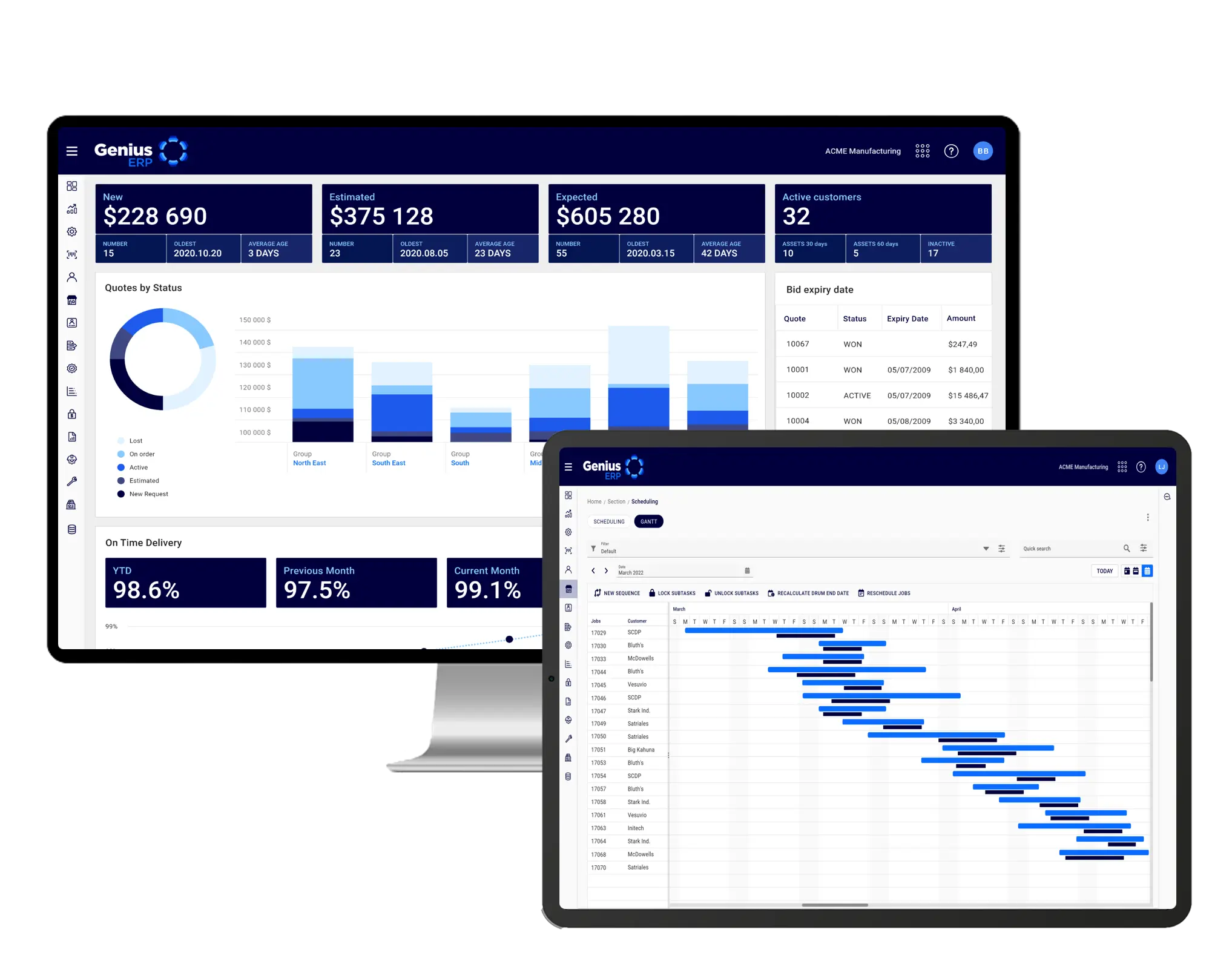

| Genius ERP | No data |

⭐⭐⭐⭐ (4.1) |

Made-to-Order & Industrial Manufacturing |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

✅ |

❌ |

❌ |

❌ |

✅ |

❌ |

❌ |

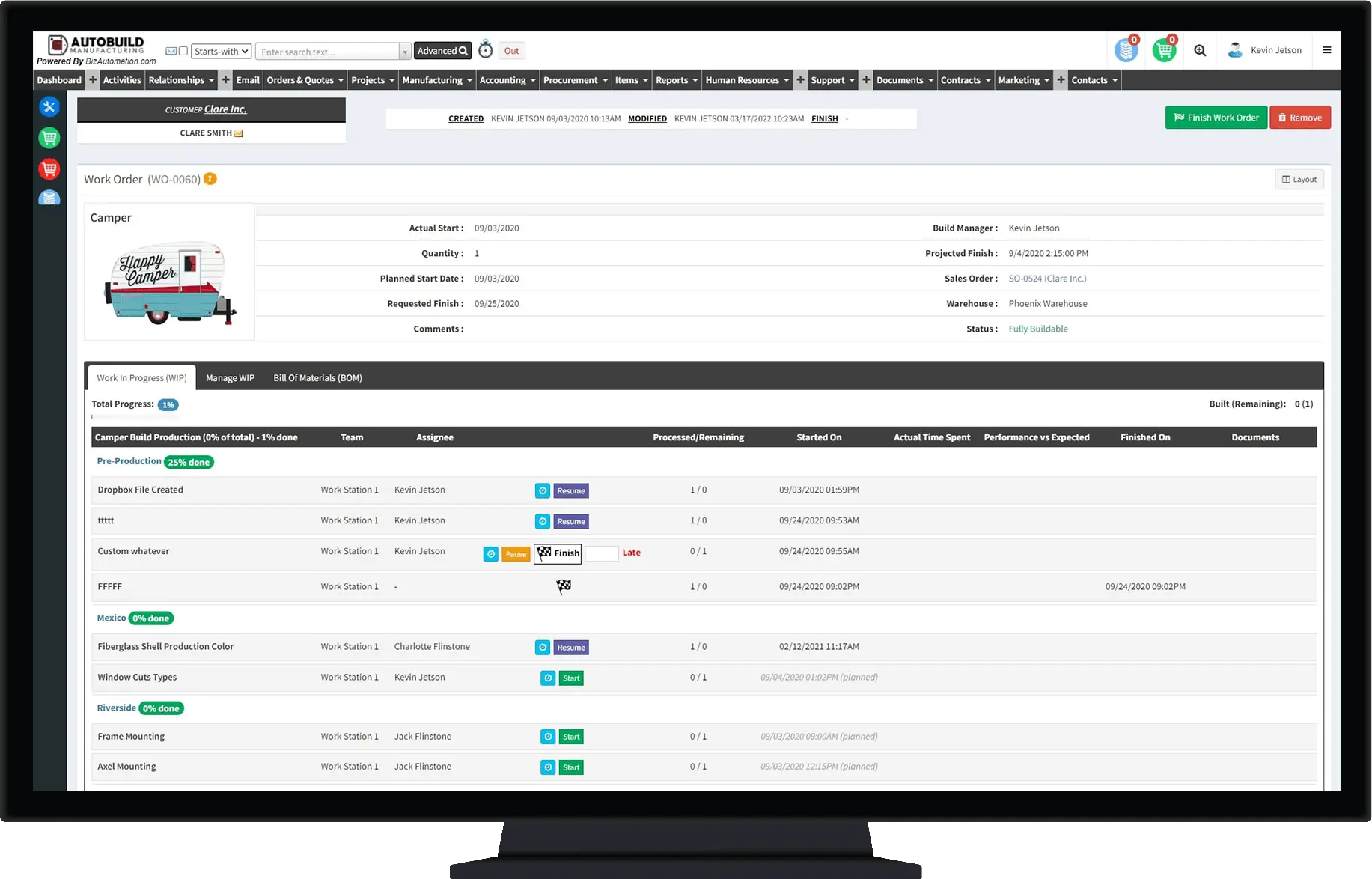

| BizAutomation | $11,988+ |

⭐⭐⭐⭐ (4.0) |

SMEs, Light Manufacturing |

Demo only |

✅ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

❌ |

✅ |

❌ |

❌ |

✅ |

✅ |

✅ |

✅ |

❌ |

❌ |

| inFlow | $2,388–11,988 |

⭐⭐⭐ (3.6) |

SMEs, Wholesale & Distribution |

14 Days |

✅ |

✅ |

✅ |

❌ |

✅ |

✅ |

✅ |

❌ |

❌ |

❌ |

❌ |

✅ |

❌ |

❌ |

✅ |

✅ |

✅ |

Which Software is Right For You?

Here’s a quick guide to help you narrow down your choices.

Most Affordable Options

If you’re looking for the best value for your money, check out:

- Kladana

- Odoo

- ERP Next

- MRPeasy

- Tranzact

- ERPAG

These offer strong features at reasonable prices.

Best for Dedicated Manufacturers

If your main focus is on core manufacturing processes, these are worth exploring:

- Kladana

- Tranzact

- Katana

- MRPeasy

- ERPAG

- Fulcrum

- Epicor

- Global Shop Solutions

- Genius ERP

These software options are built with manufacturers in mind.

Software with Mobile Apps

Want to manage your operations on the go? These options offer mobile apps:

- Deskera

- Fishbowl

- MRPeasy

- inFlow

- ERPAG

- Odoo

- Cin7

- Cetec ERP

Keep in mind that the mobile app features might differ between each system.

Kladana — Overview

![]()

Cloud composite manufacturing software with an MRP module suitable for D2C businesses, and small & medium-sized manufacturers. Kladana helps one to control all the production stages starting from a single cog to ready-to-use machinery.

Using Kladana, one can boost their manufacturing startup or develop an existing business: plan & purchase supplies, calculate costs & profit, create BOMs, complete production orders, and sell finished goods online. All these can be done in one app due to its multiple features, API, and integration with Shopify & WooCommerce.

Kladana is not a newcomer in the industry. Its story began 18 years ago, and now, the software is expanding to different markets, and working on new features. In case of any second thoughts & doubts, one can try a free 14-day trial, and then choose a proper plan. The production module is an option that can be purchased for $47+ a month or $563+ a year in the Growth, Business, and Business Plus plans.

The first steps of onboarding can be completed within 15 minutes. All features can be mastered in just 1–3 onboarding sessions, supported by a dedicated team, email assistance, video guides, and tutorials available in the Help Center.

There are a lot of manufacturers among Kladana clients. Read case stories to learn more:

- Neytthomes’ Journey: Managing Stock Across 10 Locations and Setting Up Store Inventory in 30 Minutes

- Jtronix: How Kladana Became a Game‑Changer for a Manufacturing Company

- Unicorn Natural Products Manufacturing: a Journey from Spreadsheets to ERP

- Artisanté: How to Streamline Chocolate & Coffee Manufacturing Management in Half a Year

- Cura Pharmaceuticals Manufacturing: Increased Data Accuracy & Business Workflows in 6 Months

| Pros | Cons |

✅ Affordable — starts at $47/month, with up to 30% off on annual plans |

❌ No desktop or mobile versions |

✅ Free 14-day trial — no credit card required |

|

✅ Complete production planning — multi-level BoMs for finished goods and components, routings, production orders, scheduling, and progress tracking |

|

✅ Built-in MRP — auto-generated reorder alerts, raw material demand forecasting, and purchase order management |

|

✅ Accurate cost calculations — includes raw materials, operations, and labor in unit cost |

|

✅ Web-based Shop Floor App — assign tasks, display instructions, and track piece-work payouts for operators and managers |

|

✅ Payroll management — calculate salaries with filters by employee, period, and payment status |

|

✅ Advanced features — partial manufacturing, WIP, subcontracting, barcoding, batch tracking, expiry dates, and serial numbers |

|

✅ Quality control tools — log rejected items, rework status, and non-conformance records |

|

✅ Sales & other third-party platform integrations — Online Order App, Shopify, WooCommerce, plus CRM, accounting, and delivery service integrations |

Available Plans with the Production Module

-

Growth

$67/monthly

$563/annually

Good for a start: 2+ users, 2 companies, 0.5+ GB of data storage. Unlimited warehouses, items, counterparties, and transactions. All production management features, including production orders, multi-level BOMs, expenses calculation, MTO, work orders, subcontractor management, WIP, etc. All manufacturing features can be found on the pricing page.

Barcoding, CRM, custom fields, custom print templates, and Online Order App are also included. Automation via workflows is an available option.

-

Business

$92/monthly

$773/annually

The most popular plan: 5+ users, 5 companies, 2+ GB of data storage. All features of the Growth plan plus user access rights, and unlimited support and onboarding.

-

Business Plus

$132/monthly

$1,109/annually

Suitable for a big company: 10+ users, unlimited companies, 10+ GB of data storage. All features of the Business plan are included plus workflows.

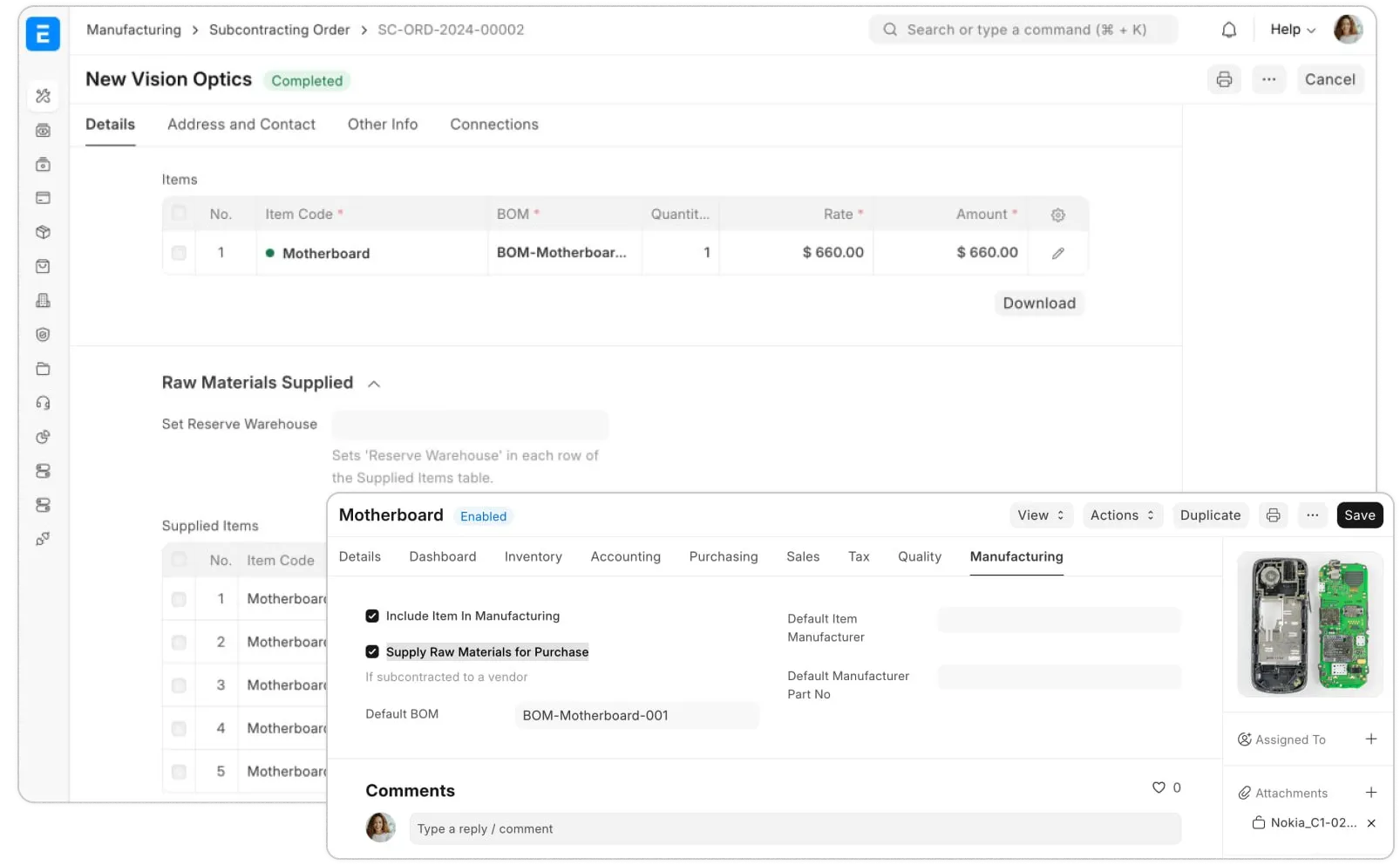

ERPNext — Overview

![]()

Smart cloud-based production ERP software.

| Pros | Cons |

✅ Affordable — from $5 a month |

❌ While ERPNext allows extensive personalization, the platform out of the box is very inflexible, and at the time of testing, many touted features simply were not present or did not behave as advertised |

✅ Manufacturing scheduling |

❌ Limited reporting capabilities |

✅ Production analytics |

|

✅ Workstations, shop floor management connected to the manufacturing |

|

✅ Integrations with Amazon, Shopify, Stripe, PayPal, etc. |

|

✅ Modern user-friendly interface |

|

✅ Comprehensive reports enable one to make data-driven decisions |

Available Plans

-

For Small Business

From $5/monthly

0.5 hrs CPU time

0.2GB database

2GB storage

-

For Mid to Large Enterprises

From $200/monthly

2 vCPUs

4GB memory

25GB expandable storage

Some features are extra-chargeable:

- Sites on private benches — from $25/monthly

- Standard support — from $50/monthly

- Premium dedicated hosting — from $400/monthly

- Hybrid hosting — from $1,000/monthly

ERPAG — Overview

![]()

Cloud-based MRP solution & end-to-end production software.

| Pros | Cons |

✅ Affordable — from $49 a month |

❌ Interface can feel dated compared to modern tools |

✅ Parts (subassemblies) manufacturing is available |

❌ The mobile version lacks full functionality compared to the web interface (e.g., detailed reporting, workflow setup) |

✅ Time-tracking is available |

❌ While support is responsive, some users mention a lack of depth in tutorials and help docs |

✅ Machines tracking & management |

|

✅ Solutions for various industries: food, medical devices, oil & gas manufacturing, etc. |

|

✅ Integrations with Woo, Shopify, Xero, etc. |

|

✅ 15-day free trial |

|

✅ Mobile app for Android |

Available Plans

-

Basic

$49/monthly

$588/annually

5 users

All modules, including manufacturing

-

Professional

$99/monthly

$1,188/annually

5 users

Live support

Customization

-

Advanced

$199/monthly

$2,388/annually

5 users

Customer portal

Automation

Smart API

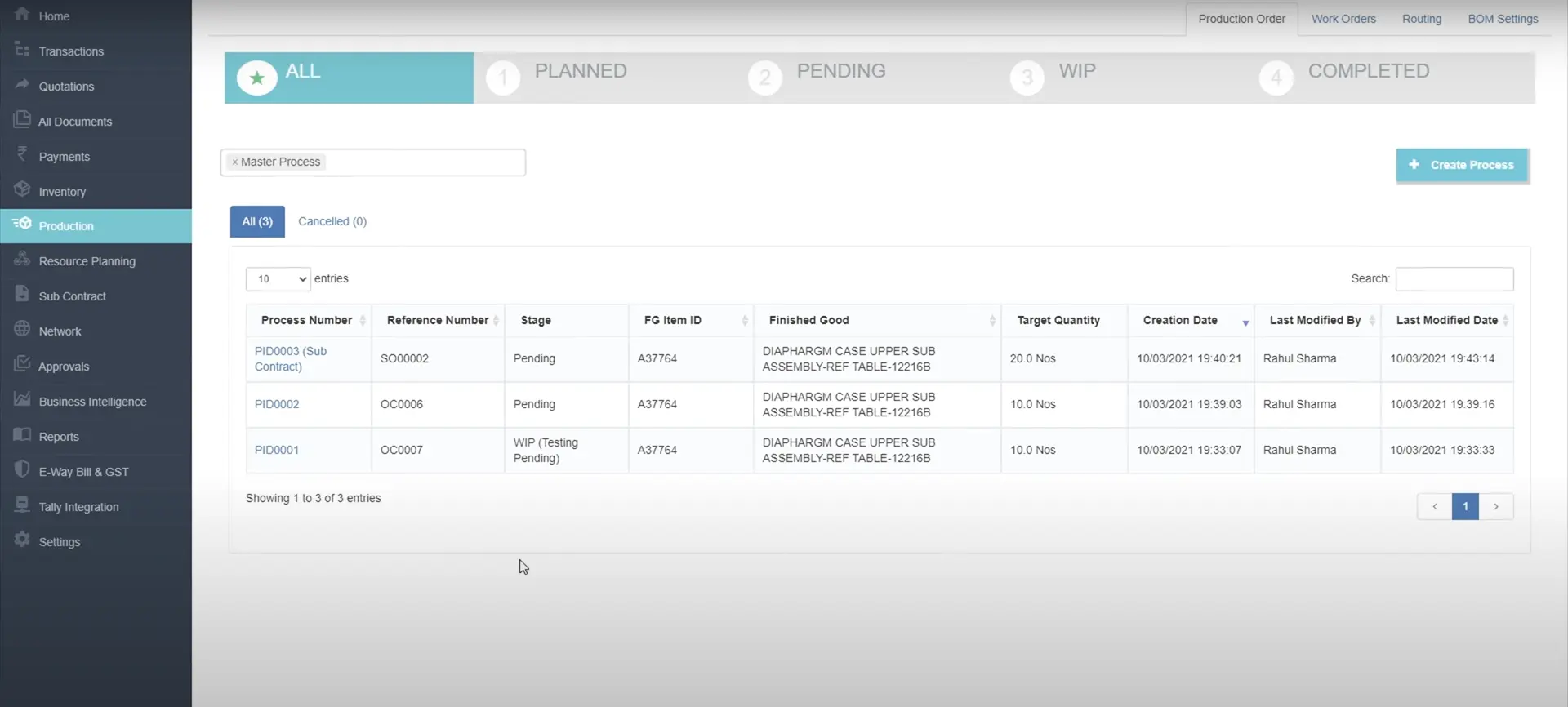

Tranzact — Overview

![]()

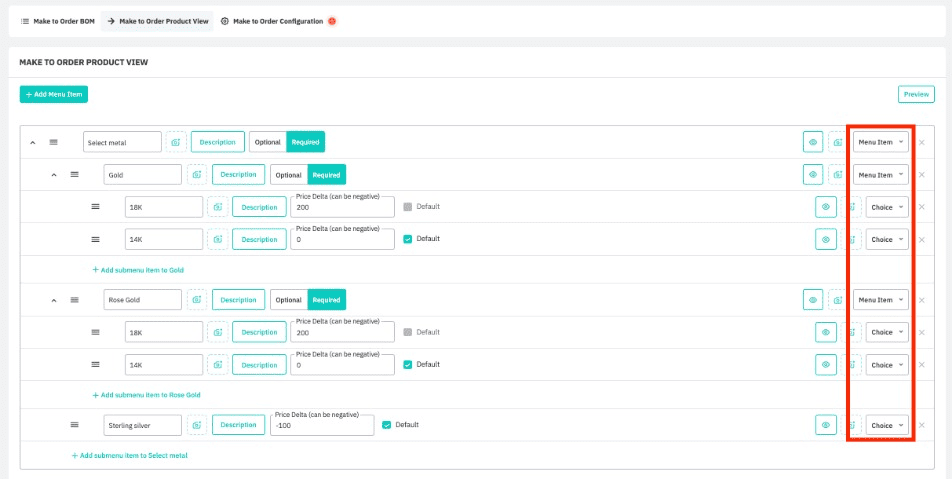

Tranzact sets itself up as MRP, ERP & production management software for Indian manufacturers. Tranzact enables a make-to-order production process: one can plan the resources, execute production stages, and test ready-made goods.

| Pros | Cons |

✅ Affordable — from $59 a month |

❌ Only quarterly or annual payments, no monthly payment is available |

✅ An evident choice for those who produce items |

❌ Add-ons are extrachargeable: barcoding, accounting, customizations, etc. |

✅ Finished goods testing is available after which items can pass the test, be rejected, or need repair |

❌ Isn’t suitable for D2C companies as there are no integrations with ecommerce platforms for product sales |

✅ Has an extensive set of production features |

|

✅ Forecasting & reporting, including real-time MRP reports (capacity planning and component availability checks) |

|

✅ Support is available even for the free plan |

|

✅ 7-day implementation is promised |

Available Plans

-

Micro Plan

Free

Up to 5 users

30 transactions/month

10+ reports

Advanced lead management

-

Small Plan

₹5,000/$59 per month

Up to 5 users

Unlimited transactions

15+ automatic alerts

Single-level BOMs

Single-step production

Business Intelligence

-

Medium Plan

₹15,000/$176 per month

Up to 10 users

65+ reports

E‑Invoicing

MRP

Multi-step BOM

Production Costing

Routing and Sub-Contracting

Advanced Access Management and Approvals

-

Enterprise Plan

₹30,000/$352 per month

15+ users

Batch tracking

Ecommerce Integration

Custom API Integrations

IP Whitelisting

Quarterly business review via dedicated CSM

MRPeasy — Overview

![]()

AI-powered MRP software for SMEs. MRPeasy is a company with a 23-year history. It started with web app development and later started making easy-to-handle solutions for small manufacturers.

| Pros | Cons |

✅ Relatively affordable — from $44 (per user) a month |

❌ Support is primarily available through a ticketing system; there is no phone or live chat support. Some users find the email-based support process slow and less responsive |

✅ Production statistics |

❌ Managing complex subcontracting workflows, such as multi-step vendor operations, can be cumbersome |

✅ Material requirements forecast |

❌ Built-in reporting tools are basic; advanced analytics and customizable dashboards are lacking |

✅ Production scheduling with a calendar & Gantt chart views |

|

✅ Free 30-day trial |

|

✅ Workstations, equipment utilization, multi-site production & matrix and co-product multi-level BOMs |

|

✅ Suitable for multiple industries: marine, biotechnology, textile, paper, etc. |

|

✅ Integrations with Amazon, HubSpot, Salesforce, etc. |

Available Plans

-

Starter

$44 (per user)/monthly

$488 (per user)/annually

Main functions & integrations

-

Professional

$67 (per user)/monthly

$737 (per user)/annually

Professional functions

-

Enterprise

$90 (per user)/monthly

$988 (per user)/annually

Enterprise functions

-

Unlimited

$142 (per user)/monthly

$1,564 (per user)/annually

Full package with no limits

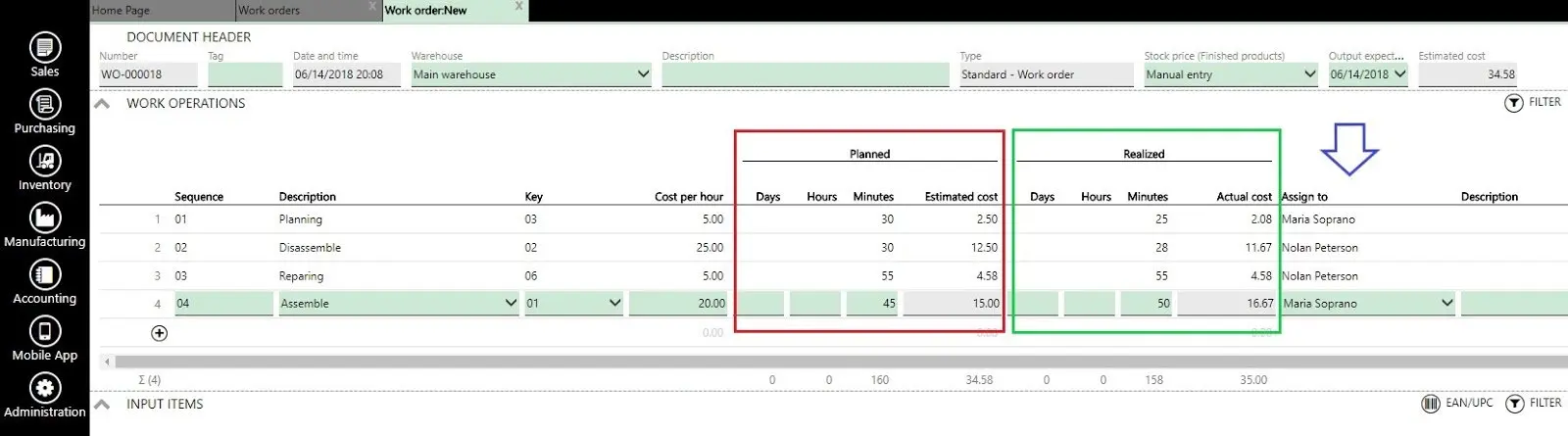

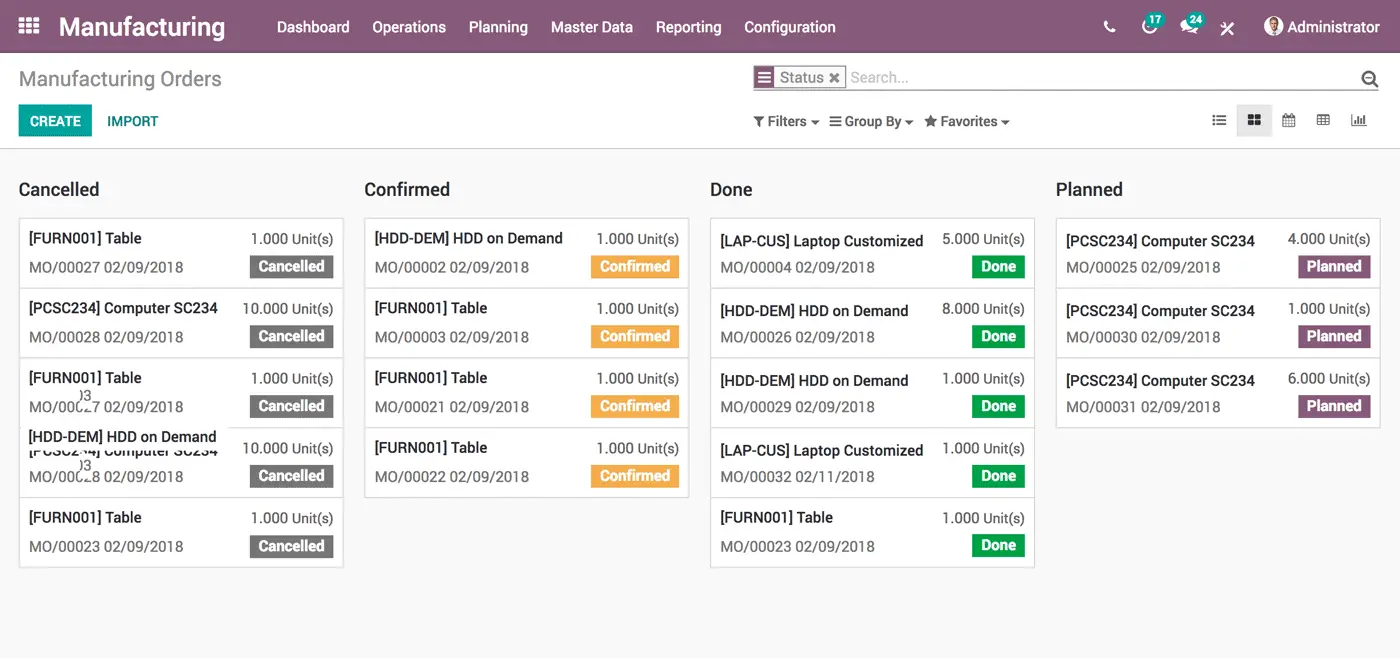

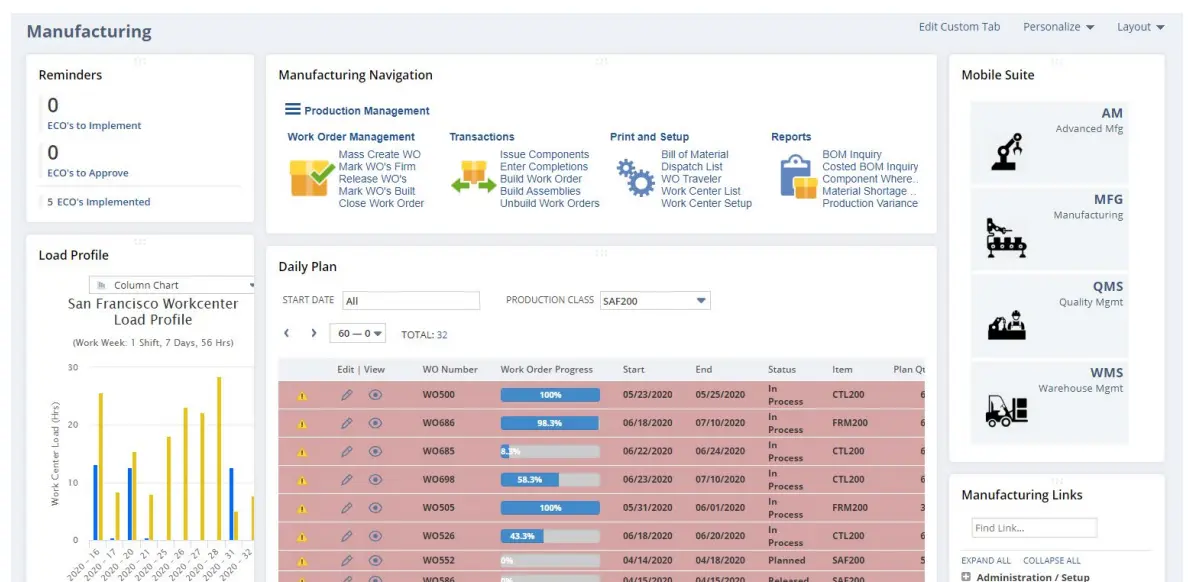

Odoo — Overview

![]()

Out-of-the-box manufacturing software that meets the needs of businesses of various sizes and from different industries. Odoo Manufacturing module is a part of a large Odoo ecosystem with 30+ applications helping entrepreneurs run their businesses.

| Pros | Cons |

✅ Relatively affordable — from $35 per user a month. One free app available |

❌ You can use only one app for free. Say, you choose Manufacturing. Then Marketing, Sales, HR, and Finance will be unavailable |

✅ Supports multi-level BOMs, including version control and optional routing |

❌ Non-technical users may find the interface and navigation overwhelming, especially when managing routings, work centers, or multi-company setups |

✅ Master production scheduling, demand forecast |

❌ Some users report slow performance when handling large BoMs or high transaction volumes unless hosted on a high-performance server |

✅ Product Lifecycle Management (PLM), maintenance, worksheets |

❌ No dedicated mobile-first Shop Floor App out-of-the-box; real-time floor control features require custom dashboards or third-party tools |

✅ Quality control: fail tests & photos |

|

✅ Printers, barcode scanners & other devices connection |

|

✅ Automatic time-tracking |

Available Plans

-

One App Free

Free

Includes: Access to one Odoo app of your choice (e.g., Manufacturing, Inventory, Purchase, etc.)

Note: Requires upgrade to access additional apps

-

Standard Plan

$35/user monthly

$345/user annually

Includes: Full access to all Odoo apps (Sales, CRM, Accounting, HR, etc.)

Extras: Optional implementation services and integrations

-

Custom

$54/user monthly

$517/user annually

Includes: All modules + advanced configurations

Extras: Custom development, flexible hosting, premium support

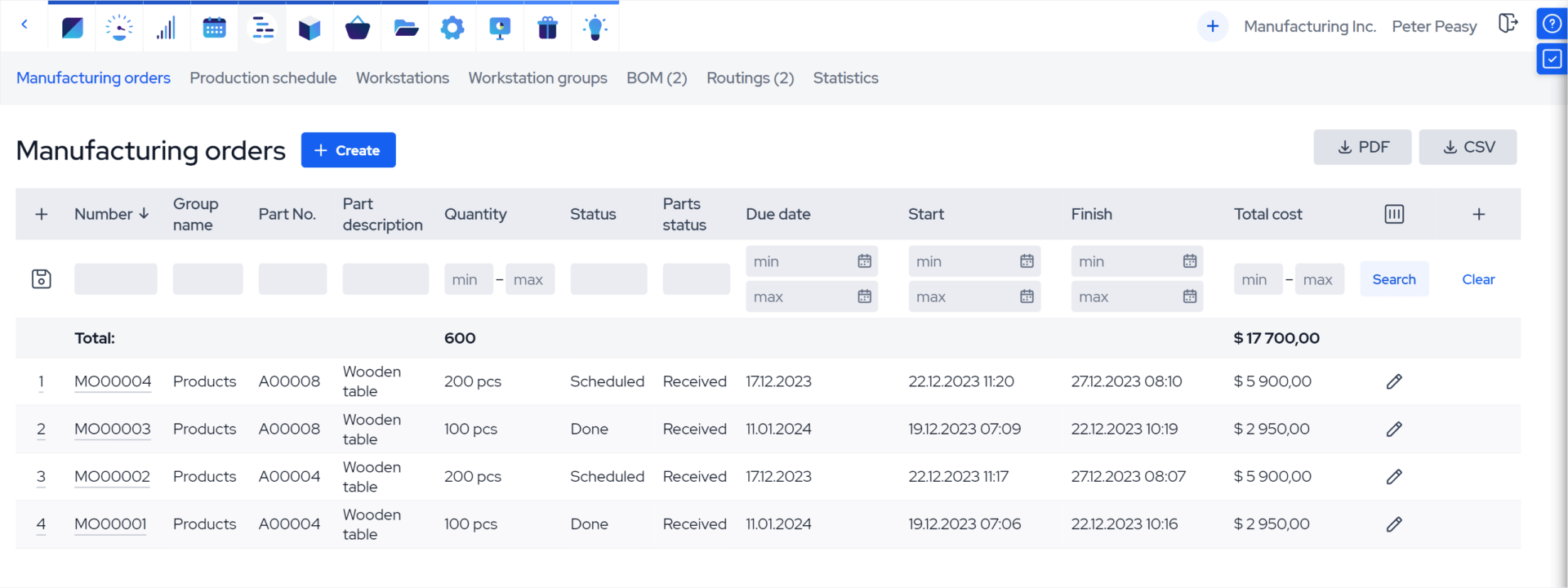

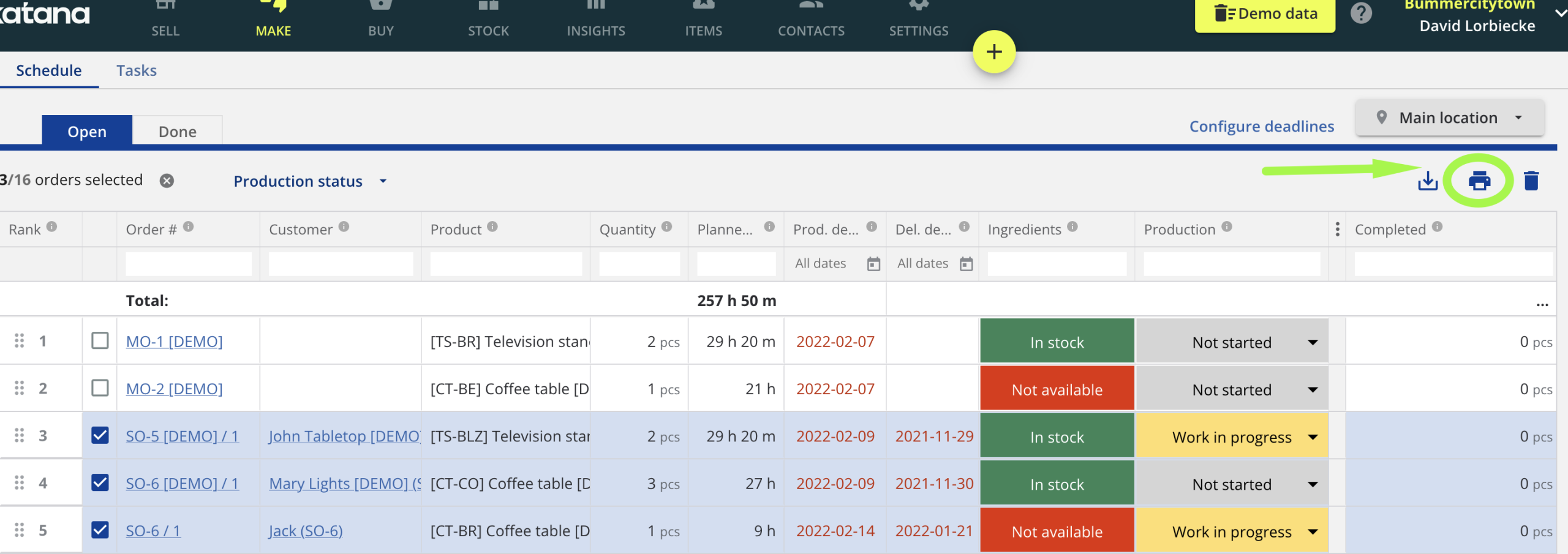

Katana — Overview

![]()

Katana MRP is designed for SMEs who want to optimize their production routines seamlessly — the user-friendly interface enables that. The software was founded in 2017.

| Pros | Cons |

✅ Make-to-order & make-to-stock workflows |

❌ Expensive — from $179 a month |

✅ BOMs with subassemblies, enabling accurate costing and inventory tracking |

❌ Not ideal for manufacturers with highly engineered or multi-stage production processes |

✅ Resource planning allows to avoid bottlenecks in the procurement process |

❌ Supports outsourcing via purchase orders, but lacks detailed subcontractor workflows (e.g. tracking external operations in routing) |

✅ Production deadlines |

|

✅ Integrations with Shopify, Amazon, eBay, HubSpot, Zapier, etc. |

|

✅ Free templates, spreadsheet, guides & SKU generator |

|

✅ Free 14-day trial |

Available Plans

-

Starter

$199/monthly

$2,148/annually

Basic manufacturing

1 inventory location

Unlimited users

Unlimited SKUs

Unlimited integrations

-

Standard

$399/monthly

$4,308/annually

3 inventory locations

Kits and bundles

Barcode scanning

Multicurrency support

Advanced insights

Custom templates

Custom fields

-

Professional

$899/monthly

$9,588/annually

10 inventory locations

Planning and forecasting

WMS

Katana’s API

Price lists

-

Professional Plus

$1,799+/monthly

$21,588+/annually

Unlimited inventory locations

Dedicated account manager

Cin7 — Overview

Cin7 Core is a cloud-based inventory and manufacturing management solution designed for small to mid-sized businesses — best for product-focused businesses. It offers comprehensive tools for production planning, inventory control, and sales integration, making it suitable for manufacturers seeking to streamline operations.

| Pros | Cons |

✅ 14-day free trial |

❌ Expensive — from $349/month |

✅ Full production workflow: supports multi-level BOMs, production orders, and assembly/disassembly |

❌ Complex setup: initial configuration can be time-consuming for some users |

✅ MRP: automatically calculates raw material needs based on demand and stock levels |

❌ Learning curve: some users report a steep learning curve due to the system’s depth |

✅ Production cost tracking: tracks labour, materials, and overhead costs per batch or unit |

❌ Customer support variability: mixed reviews on the responsiveness and helpfulness of support |

✅ Backflushing & batch production: automates stock deductions and supports batch manufacturing with expiry tracking |

Available Plans

-

Standard

$349 per month

$4,188 per year

5 users

Unlimited inventory locations

2 integrations

6,000 sales orders/year

BOM tracking

Batch & expiration tracking

Kits & bundles

-

Pro

$599 per month

$7,188 per year

10 users

4 integrations

24,000 sales orders/year

MRP

-

Advanced

$999 per month

$11,988 per year

15 users

6 integrations

120,000 sales orders/year

Advanced warehouse management

-

Omni

Custom pricing for enterprises

Fully customizable

Flexible sale order volume

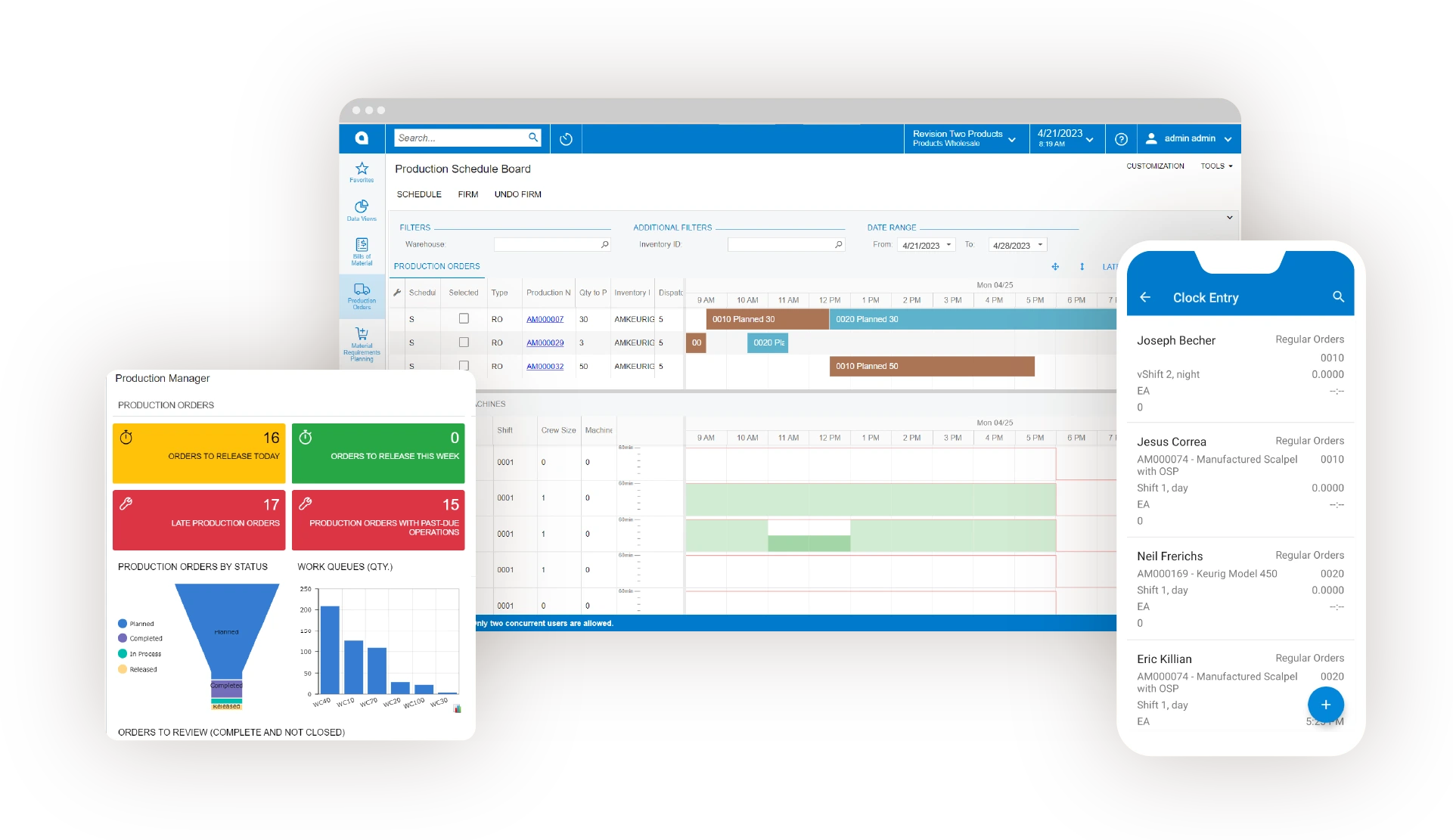

Acumatica — Overview

![]()

Multi-site cloud-based production software that provides all popular manufacturing methodologies: engineer-to-order, make-to-order, make-to-stock, etc. Acumatica has a 15-year history.

| Pros | Cons |

✅ Discrete and batch process production |

❌ Prices are not disclosed publicly |

✅ Multi-level BOMs with revision control, effectivity dates, phantom items, and cost rollups |

❌ Acumatica is a general-purpose ERP software and may not offer industry-specific features required by some businesses |

✅ Production scheduling, engineering change control |

❌ Some users have reported issues with customer support, which can be frustrating when issues arise |

✅ Machine maintenance & tooling |

|

✅ Integrations with Shopify, ShipStation, PayPal, etc. |

|

✅ An entrepreneur can choose where to store their data — on a public cloud or a private one |

|

✅ MRP: time-phased planning with forecasting, multi-warehouse support, and exception management |

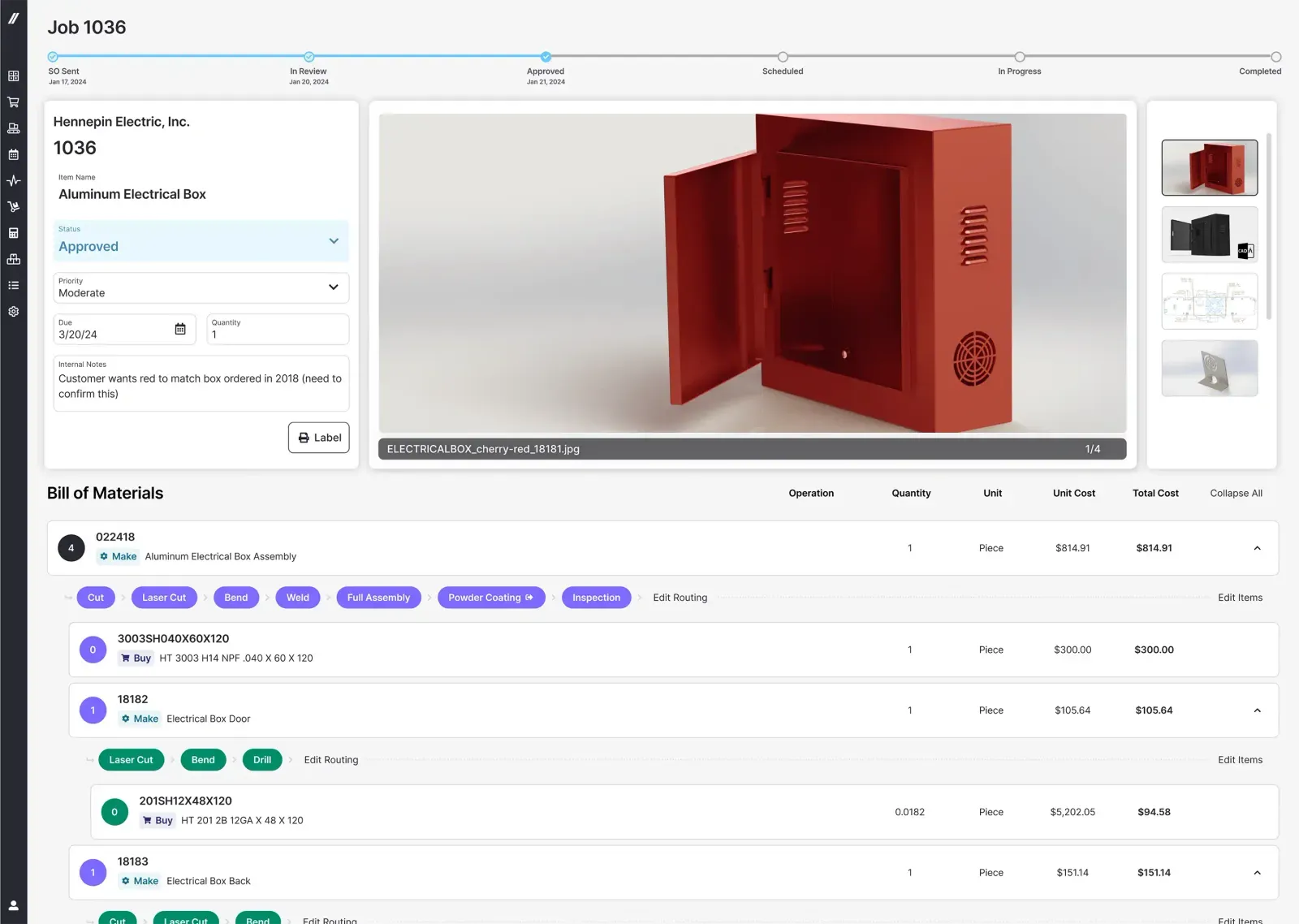

Fulcrum — Overview

![]()

The main idea of Falcrum is to connect one’s shop with production management for better decision-making. Also, the easy-to-handle software pays attention to the visual data: blueprints, 3D models, assembly instructions, etc.

| Pros | Cons |

✅ Contemporary user-friendly interface |

❌ Price plans are not publicly disclosed |

✅ Visual BOM and routing builder with AI-assisted uploading, enabling quick creation and management of multi-level BOMs |

❌ The built-in reporting tools lack advanced filtering and customization options, potentially necessitating external tools or custom development for complex reporting needs |

✅ Production operations progress tracking |

❌ The implementation timeline can be extended, especially when migrating complex or large datasets, leading to delays in full system utilization |

✅ Quality checks |

|

✅ Interactive education |

|

✅ Integrations with ShipStation, Salesforce, HubSpot, etc. |

Oracle NetSuite — Overview

![]()

NetSuite for Manufacturing is a module in the large Oracle NetSuite ecosystem.

| Pros | Cons |

✅ Multi-location planning & DRP (distribution requirement planning) |

❌ Pricing is not disclosed publicly |

✅ Shop floor control |

❌ The standard support package offers minimal assistance, with 24/7 support and comprehensive training available only through premium packages at additional costs |

✅ Quality management |

❌ Creating tailored reports may require technical expertise, as the system’s reporting tools have limitations in flexibility |

✅ MES |

|

✅ All basic features are available |

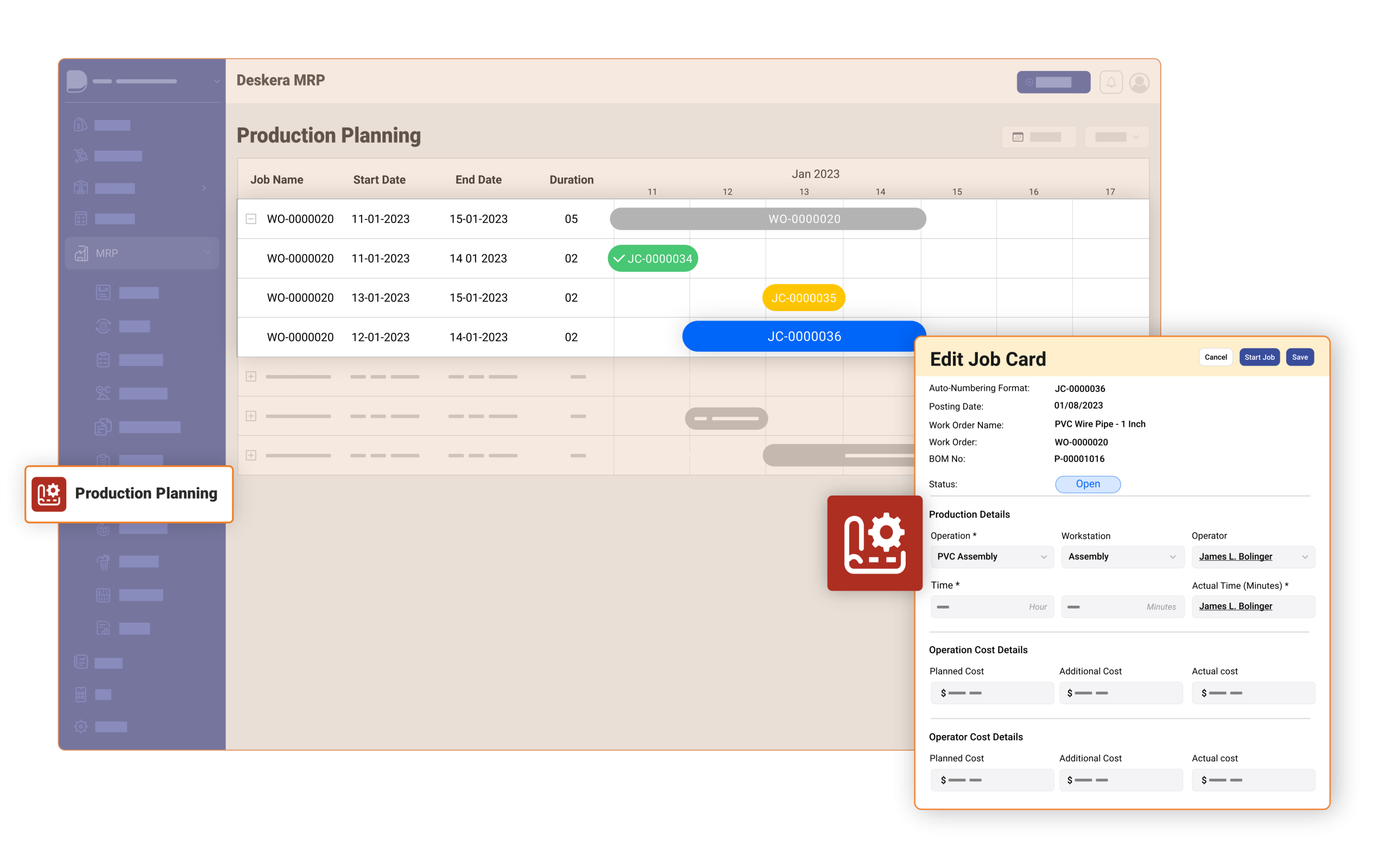

Deskera — Overview

![]()

The engineer-to-order MRP software that enhances productivity & visibility. Despite its high cost, Deskera is considered to be an industry-leading company that has been on the market for 15 years already. Deskera’s positioning is a growth business partner rather than simply a software provider.

| Pros | Cons |

✅ Demand forecasting helps reduce waste |

❌ Extremely expensive — from $349 per user per month |

✅ Machine management & maintenance |

❌ Users have reported restrictions in tailoring reports and workflows to specific business needs, which can hinder flexibility in operations |

✅ Solutions for various industries: apparel, beauty, healthcare, etc. |

❌ The system’s ability to export reports to Excel is limited, which may affect data analysis and sharing |

✅ Integrations with Amazon, Shopify, FedEx, Woo, etc. |

|

✅ A free mobile app with limited features can be used |

|

✅ Onboarding & training take a few hours, as promised |

Available Plans

-

Growth

From $349 per user/monthly

From $4,188 per user/annually

5 users minimum

Work orders

Multi-level BOMs

Manufacturing reports

Yield calculations

-

Mid Market

From $449 per user/monthly

From $5,388 per user/annually

5 users minimum

Demand forecasting

Contract production

Manufacturing scheduling

Quality checks

-

Enterprise

Custom pricing

Custom workflows

Custom routings

Custom automations

Custom reports & dashboards

Fishbowl — Overview

![]()

Complex all-in-one manufacturing management platform.

| Pros | Cons |

✅ Complete MRP suite — multi-level BoMs, automated packing, and custom product tracking |

❌ Pricing is not publicly disclosed. The production module is only available in the Fishbowl Advanced Manufacturing plan, which includes premium features — indicating a higher price point |

✅ Advanced traceability — supports lot, serial number, and expiration date tracking, including barcode printing and partial picking |

❌ Outdated interface: navigation can be clunky, with multiple clicks required for common tasks, leading to a steep learning curve for new users |

✅ Smart insights — demand forecasting powered by AI, with real-time dashboards and reporting |

❌ The system’s rigidity can make it difficult to adapt to unique business processes, limiting its flexibility for companies with specialized requirements |

✅ API access — for custom integrations and workflow automation |

❌ While some users praise Fishbowl’s customer service, others have found it to be unresponsive or ineffective, particularly when dealing with complex issues |

✅ Mobile-enabled — barcode & QR scanning |

|

✅ Product flexibility — supports kits, bundles, and unlimited SKUs |

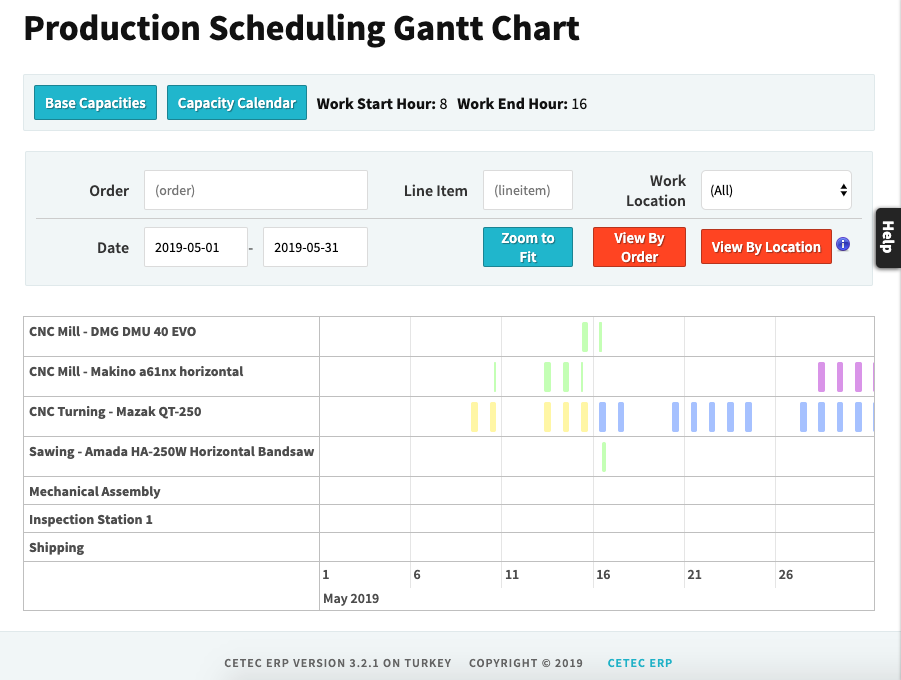

Cetec ERP — Overview

![]()

Cloud-native manufacturing ERP tailored for small to mid-sized manufacturers, especially those in regulated industries like aerospace, medical devices, and electronics. It offers a comprehensive suite of tools encompassing MRP, CRM, QMS, and accounting, all within a single platform. Designed with lean manufacturing principles, Cetec ERP provides real-time visibility and control over production processes, ensuring compliance and efficiency.

| Pros | Cons |

✅ Relatively affordable — from $50 per user per month. Special rate of $25/user per month available for «Production Only» users |

❌ Learning curve: initial setup and navigation may require training |

✅ 30-day free trial |

❌ Interface: user interface may seem dated compared to newer platforms |

✅ Comprehensive feature set: All-in-one platform covering MRP, CRM, QMS, and accounting |

❌ Customization: advanced customizations might need developer assistance |

✅ Regulatory compliance: built-in tools for ISO, AS9100, and ITAR compliance |

❌ Limited third-party integrations: fewer integrations compared to some competitors |

✅ Real-time shop floor control: live tracking of production processes and work orders |

Available Plans

-

Lite

$50/user per month

5 users minimum

No company fee

2GB storage/user

Weekly backups

-

Standard

$50/user per month

5 users minimum

$650/company per month

4GB storage/user

Daily backups

Priority support

-

Enterprise

$50/user per month

5 users minimum

$3,200/company per month

8 GB storage/user

Advanced support

BI tools

Sandbox environment

Unleashed — Overview

![]()

BOM software that streamlines one’s production, and increases efficiency in day-to-day manufacturing operations. Flexible & cohesive solution focused on MRP & BOMs. Unleashed is software with a 10-year history suitable as for startups, as for large-scale enterprises.

| Pros | Cons |

✅ Auto-assembled products, disassembly, kitsets, bundles & batches |

❌ Expensive — from $380 a month |

✅ Multi-level BOMS |

❌ While Unleashed captures some labour costs, it may require integration with other systems for comprehensive labour cost tracking |

✅ Precise profit margins |

❌ While tasks and production orders can be managed, assigning specific users or teams may require additional configuration or integration |

✅ Subassemblies |

❌ The system offers some support for subcontractor management, but comprehensive tracking may require additional customization |

✅ Integrations with Amazon, Shopify, Woo, Lightspeed, etc. |

|

✅ Free 14-day trial |

|

✅ Unleashes Academy educates existing & to-be customers |

Available Plans

-

Medium

$380/monthly

$4,560/annually

3 users

-

Large

$710/monthly

$8,520/annually

8 users

-

Large Plus

$1,080/monthly

$12,960/annually

20 users

Mind that add-ons are extra-chargeable:

- ecommerce integration — $30/monthly

- B2B ecommerce store — $129/monthly

- support — $79–239/monthly

- onboarding — $449–5,549 (one-off fee)

- advanced inventory manager — $100/monthly

- business intelligence — $39/monthly

Global Shop Solutions — Overview

![]()

ERP software with a production module that helps simplify one’s manufacturing routines. Suitable for businesses with $10M‑1B in revenue and 20‑1,000 employees. Global Shop Solutions is a family business that is nearly 50 years old.

| Pros | Cons |

✅ Scheduling, Shop floor data collection, quality check, tooling |

❌ Prices are not publicly disclosed, however, according to the target audience portrait, pricing is presumably high |

✅ Machines & equipment maintenance, engineering revisions |

❌ The user interface is considered dated and can be challenging to navigate, requiring multiple clicks to complete tasks |

✅ Workcenters, workgroups |

❌ Due to its comprehensive feature set, employees often need significant training to utilize the system effectively |

✅ Offers solutions for different industries: rubber, truck, concrete, electric vehicles, etc. |

|

✅ Integrations with FedEx, Magento, Woo, HubSpot, etc. |

|

✅ Additional resources: ERP training, manufacturing health test, Learning management system |

Statii — Overview

![]()

Cloud-based ERP/MRP solution designed specifically for small to medium-sized, make-to-order manufacturers. It offers a comprehensive suite of tools to manage and streamline production processes, from quoting and sales orders to inventory control and shop floor data capture. With real-time insights and a user-friendly interface, Statii empowers manufacturers to enhance efficiency and profitability.

| Pros | Cons |

✅ Month-to-month payment, no long-term contracts |

❌ Prices are not disclosed |

✅ 14-day free trial |

❌ Limited third-party integrations: fewer integrations compared to some competitors |

✅ Comprehensive feature set: all-in-one platform covering CRM, MRP, inventory, and scheduling |

❌ Customization: advanced customizations might need developer assistance. |

✅ Real-time shop floor control: live tracking of production processes and work orders |

|

✅ No extra support fees |

PACT ERP — Overview

![]()

End-to-end ERP software with a manufacturing module. PACT ERP has been developing solutions for SMEs for the last 25 years.

| Pros | Cons |

✅ Focus on accurate profit margin calculations, and all direct & indirect expenses connected to the production process |

❌ Prices are not publicly disclosed |

✅ Equipment tracking |

❌ While PACT ERP offers some integration capabilities with e-commerce platforms, the extent of this integration may be limited compared to specialized e-commerce solutions |

✅ Seasonal demands forecast |

❌ While PACT ERP is feature-rich, adding new functionalities often requires user requests and support intervention, potentially leading to delays in implementation |

✅ Multi-level BOMs |

|

✅ Shortfall Reports |

|

✅ Batch-wise consumption analysis |

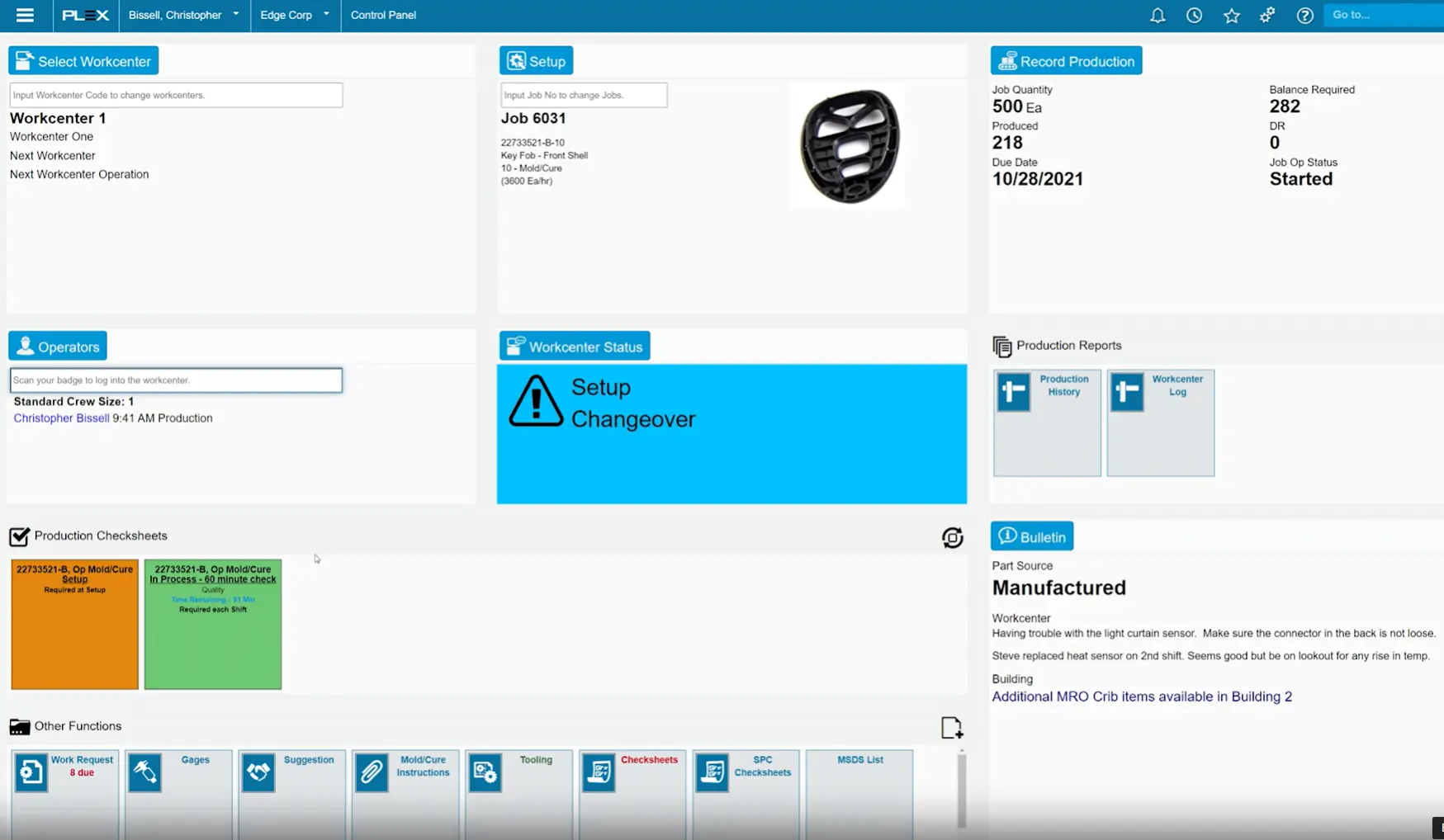

Plex — Overview

![]()

The manufacturing execution system enables visibility and helps control the entire production cycle. 30 years of experience, 20 of which are in the cloud format make Plex one of the leaders in the market.

| Pros | Cons |

✅ Control Panel for running production, maintenance, analytics, etc. |

❌ Prices are not disclosed publicly |

✅ Digital Kanban production scheduling |

❌ The abundance of interfaces and options can make the system challenging to navigate, potentially impacting user efficiency |

✅ Tools purchase & control |

|

✅ Quality Management System |

|

✅ Smart Manufacturing Platform |

|

✅ Chesksheet |

Epicor — Overview

![]()

Manufacturing execution software (MES) with a focus on a smart factory transformation. Epicor is one of the market dinosaurs (in a positive way) with a 50-year history. The software focuses on industry-based solutions.

| Pros | Cons |

✅ Energy consumption monitoring, machine capacity planning |

❌ Plans are not publicly disclosed |

✅ Kanban scheduling |

❌ Users have reported that the interface is not very intuitive, often containing numerous fields that may not be relevant to all users, leading to a steep learning curve |

✅ Quality control |

❌ Epicor ERP’s cloud offerings have been described as lacking a robust cloud story, which may impact businesses seeking advanced cloud-based solutions |

✅ Real-time shop floor visibility |

Genius ERP — Overview

![]()

A company from Quebec with 33 years of experience in manufacturing. The vast majority of Genius ERP customers are small & mid-sized companies. The software is said to be created and developed by manufacturing experts, mechanical engineers, and accountants.

| Pros | Cons |

✅ Planning, execution & engineering |

❌ Pricing isn’t publicly disclosed |

✅ CAD designs can be transferred into BOMs |

❌ While Genius ERP offers some integration capabilities with e-commerce platforms, the extent of this integration may be limited compared to specialized e-commerce solutions |

✅ Integrations with Autodesk, Microsoft, Avalara, FedEx, etc. |

❌ The system offers some support for subcontractor management, but comprehensive tracking may require additional customization |

BizAutomation — Overview

![]()

MRP focused on growing SMBs. BizAutomation calls itself a “customer advocate” because they claim that they don’t have hidden features, all the processes are transparent, and even the price plan is the only one.

| Pros | Cons |

✅ Production demand planning is included |

❌ Expensive — $999 a month |

✅ Production scheduling |

❌ BizAutomation lacks native payroll capabilities, requiring businesses to manage payroll through external systems or manual processes |

✅ WIP progress bar is available |

❌ While the platform allows for some customization, it may not offer the depth of customization required for highly specialized manufacturing processes |

✅ Quality check |

|

✅ A finished good can be disassembled |

One Plan

$999/monthly

$11,988/annually

10 users

inFlow — Overview

![]()

All-in-one production management software that helps one reduce manual labour on day-to-day operations. inFlow has been in business for 12 years. The mission is to support solo businesspeople & SMEs from various industries. Also, they build a community of entrepreneurs.

| Pros | Cons |

✅ Production orders prioritization & scheduling due to deadlines |

❌ Expensive — from $149 a month |

✅ Subassemblies & auto-assembly |

❌ inFlow does not offer dedicated MRP functionalities |

✅ Cloud, desktop & mobile apps |

❌ inFlow does not provide features to manage and track WIP inventory during the production cycle |

✅ Free 14-day trial |

❌ Limited partial production, batches, and assignees |

✅ B2B portal for online sales which works as a showroom |

❌ The platform does not support subcontractor management within the manufacturing module |

✅ Integrations with Amazon, Etsy, Xero, Walmart, etc. |

❌ inFlow does not offer features to track and manage by-products and scrap materials |

✅ Contemporary user-friendly interface |

Available Plans

-

Start-up

$249/monthly

$2,388/annually

2 users

1,200 sales orders per year

1 integration

-

Growth

$561/monthly

$5,388/annually

5 users

12,000 sales orders per year

2 integrations

-

Scale

$1,249/monthly

$11,988/annually

10 users

60,000 sales orders per year

3 integrations

-

Enterprise

Custom pricing

Mind that add-ons are extra-chargeable:

- Serial numbers — $29–69/monthly

- Advanced access rights — $99/monthly

- inFlow Stockroom — $49/monthly

- Showroom Pro — $99/monthly

- API access — $49–69/monthly

Frequently Asked Questions on Manufacturing Software

Thinking of implementing manufacturing software? Below are the most common questions businesses ask when exploring tools like ERP, MRP, MES, and production management software.

How does manufacturing software work?

Manufacturing software automates and streamlines production operations by integrating core functions — inventory management, production planning, order management, and quality control — into a single platform.

It enables real-time tracking of materials, work orders, labour, and machine performance, helping manufacturers reduce waste, increase throughput, and meet delivery deadlines.

What are the 5 types of software used in manufacturing?

Manufacturers often use a combination of these five core software types:

- ERP (Enterprise Resource Planning) — End-to-end business management, including finance, HR, and production.

- MES (Manufacturing Execution System) — Shop floor control, real-time data collection, and performance monitoring.

- PLM (Product Lifecycle Management) — Manages product design, revisions, and engineering change control.

- SCM (Supply Chain Management) — Coordinates logistics, procurement, and supplier interactions.

- CAD/CAM (Computer-Aided Design/Manufacturing) — Supports product design and CNC programming.

How do I choose the best manufacturing software for my business?

To select the right system:

- Define your needs (e.g., batch vs. make-to-order, traceability, machine shop workflows)

- Evaluate scalability for future growth

- Check for integration with accounting, CRM, eCommerce, and CAD tools

- Ensure cloud vs. on-premise deployment options match your IT preferences

- Compare training, implementation time, and support quality

What are the key features of manufacturing software?

Common features include:

- Multi-level Bills of Materials (BoMs)

- Production scheduling & work order management

- Inventory tracking with batch/serial control

- Shop floor data capture

- MRP (Material Requirements Planning)

- Quality control & non-conformance reporting

- Integration with accounting and CRM systems

What is the best ERP for manufacturing companies?

The “best” ERP depends on the specific needs of your manufacturing company. Factors like size, industry, complexity of production, and budget all play a role. Generally, look for an ERP that offers strong production planning, inventory management, and cost tracking. Some popular options include Kladana, Odoo, and ERP Next, each with its own strengths. See the software comparison table above for more detailed information.

What is the best ERP for small manufacturing businesses?

For small manufacturing businesses, affordability and ease of use are key. Cloud-based solutions like Kladana, MRPeasy, and ERPAG are often great options. These systems are generally easier to set up, less expensive upfront, and offer features tailored for smaller operations. Look for a solution with good support and clear onboarding to get started quickly.

How much does ERP for manufacturing cost?

ERP costs vary widely. You might find basic systems for a few hundred dollars per year, while large enterprise solutions can cost tens of thousands. Mid-range solutions typically range from $1,000 to $6,000 annually. Consider per-user pricing, module-based pricing, and potential hidden costs like implementation and training. See the “How Much Does Manufacturing Software Cost?” section for more details.

What to Choose: Cloud ERP vs. On-Premise ERP for manufacturers?

- Cloud ERP: Hosted online, easier setup, lower upfront costs, accessible from anywhere, automatic updates. But, you need a reliable internet connection and trust the provider’s security.

- On-Premise ERP: Installed on your servers, more control over data, less reliant on the internet. But, higher upfront costs, you’re responsible for maintenance and updates, harder to access remotely.

The best choice depends on your IT capabilities, security concerns, and budget. Cloud ERP is often ideal for smaller businesses, while larger companies with complex needs might prefer on-premise.

What is production management in ERP?

Production management in an ERP system coordinates the entire manufacturing cycle:

- Tracks raw materials and WIP (Work In Progress)

- Manages labour, machines, and routing

- Automates procurement and restocking

- Aligns production planning with customer orders and delivery dates

- Integrates cost tracking and performance reporting

This helps manufacturers reduce delays, optimize resources, and stay profitable.

What is MTO software and who needs it?

MTO (Make-to-Order) software supports businesses that manufacture only after receiving specific customer orders. It’s ideal for:

- Custom manufacturers

- Low-volume, high-variety production

- Engineering-to-order (ETO) environments

Key capabilities include:

- Custom order tracking

- Configurable BoMs

- Dynamic scheduling

- Demand-driven procurement

Read‑alikes

Full Guide to MRP Solutions: Core Features, Advantages and Pitfalls

Manufacturing Execution System (MES): The Smart Transformation Your Factory Needs

Bill Of Materials (BOM): Definition, Examples, Format and Free Template

Managing Production in a Small Manufacturing Company: Planning, Control, and Profit Calculation