Every business aims to cut costs without hurting efficiency. One approach that became famous worldwide is just-in-time inventory management (JIT). Instead of storing large amounts of stock, JIT focuses on receiving goods exactly when they are needed. This reduces storage expenses, improves cash flow, and limits waste from unsold or obsolete items.

In this article, we’ll explain how the JIT inventory system works, its advantages and disadvantages, and examples from Toyota & Dell to SMEs. We’ll also compare JIT with traditional inventory methods and discuss whether it is the right choice for your business.

- What Is Just-in-Time (JIT) Inventory Management?

- How the JIT Inventory System Works

- Key Advantages of Just-in-Time Inventory

- Disadvantages and Risks of JIT Inventory

- Just-in-Time Inventory Management Examples

- Technology and Tools for JIT

- JIT vs Traditional Inventory Systems

- Is JIT Right for Your Business?

- Conclusion

- Frequently Asked Questions on JIT

- List of Resources

What Is Just-in-Time (JIT) Inventory Management?

Just-in-time inventory management is a strategy where businesses keep stock levels as low as possible and receive goods only when they are needed for production or sales. Instead of filling warehouses with extra materials or products, companies align deliveries closely with demand.

The concept was first developed in the 1970s by Toyota. The company’s production system focused on efficiency, reducing waste, and improving cash flow. This approach later became a key part of lean manufacturing principles, where every step in the process aims to add value and cut unnecessary costs.

How the JIT Inventory System Works

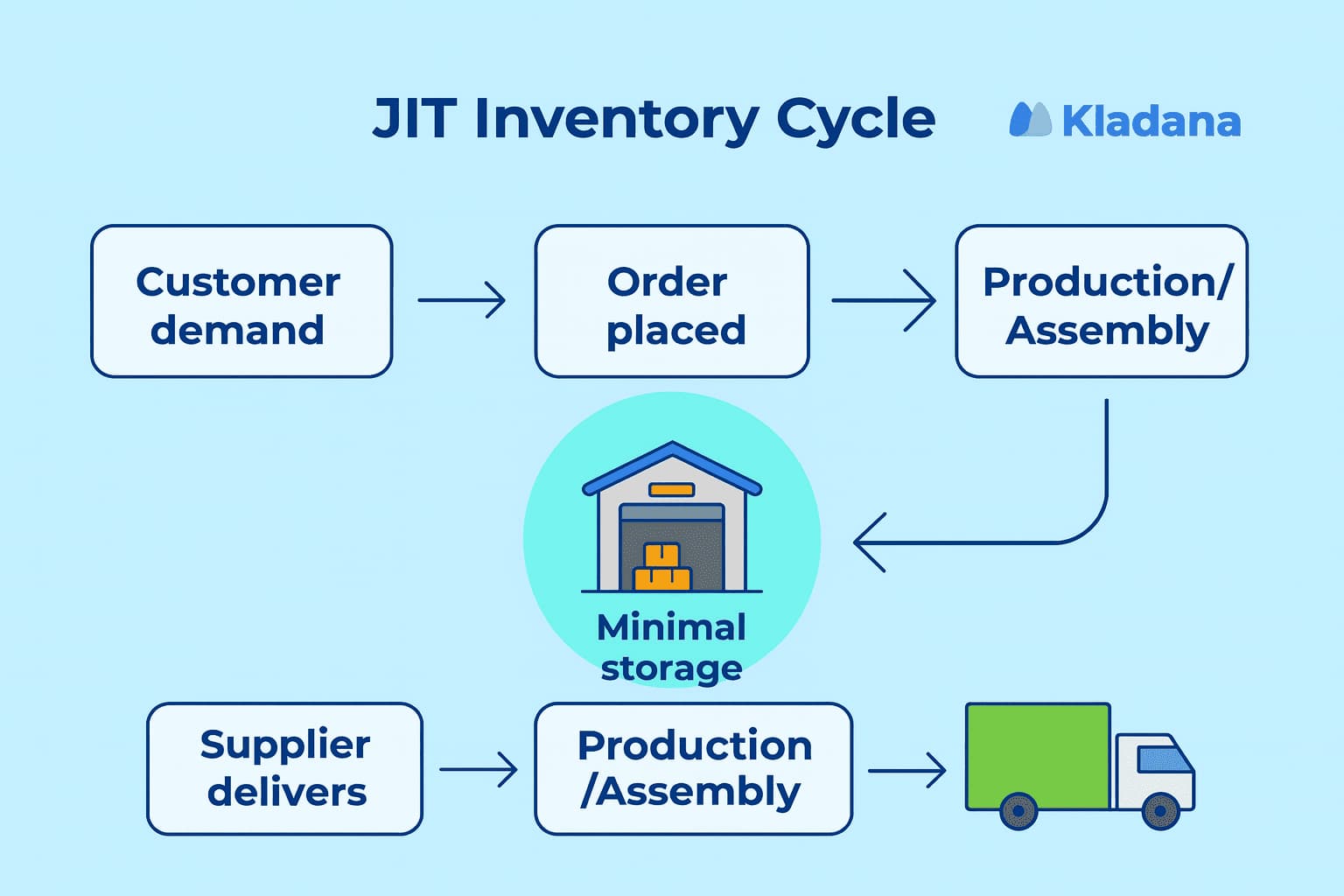

The JIT inventory system works by producing or ordering goods only when they are needed. Instead of storing large volumes of stock, businesses plan supply to match real customer demand. This means raw materials, parts, or finished products arrive “just in time” for use.

To make this possible, companies need tight coordination with suppliers. Deliveries must be reliable and frequent, often scheduled daily or even hourly. Any delay in transport or communication can affect production. Many manufacturers build strong local supplier networks to reduce the risk of disruptions.

The best-known example is the Toyota Production System. Toyota created JIT to reduce waste and lower costs. For instance, instead of storing thousands of car parts, the company worked with suppliers to deliver smaller batches directly to the assembly line. This practice helped Toyota cut inventory expenses and improve flexibility.

Today, the same principle applies across industries. Retailers order goods based on real-time sales data, while electronics makers like Dell use JIT to build computers only after customers place orders. The system focuses on precision, efficiency, and speed, but it demands reliable partners and accurate forecasting.

📚 Recommended Read: Going to master the essentials of inventory management? Check out our guide.

Key Advantages of Just-in-Time Inventory

Adopting just-in-time inventory management offers several benefits that help businesses stay lean and competitive.

Lower inventory holding costs.

Since stock levels are kept to a minimum, businesses spend less on warehousing, insurance, and handling. Money that would otherwise be tied up in excess goods can be redirected to growth.

Reduced Waste and Obsolescence

JIT prevents stock from sitting idle or becoming outdated. For manufacturers, this means fewer raw materials going unused. For retailers, it reduces the risk of unsold seasonal items.

Increased Cash Flow and Working Capital Efficiency

With less money tied up in inventory, businesses gain financial flexibility. This helps them invest in marketing, new products, or technology without waiting for old stock to sell.

Better Quality Control and Responsiveness

Smaller, frequent deliveries allow for closer inspection of materials. Any defect can be spotted early, reducing large-scale errors. At the same time, businesses can react faster to shifts in customer demand.

Companies that apply JIT often see faster order fulfillment, leaner operations, and improved profitability. For SMEs, even partial adoption — such as reducing safety stock — can bring noticeable cost savings.

Run Lean with JIT Inventory

Kladana helps reduce carrying costs by syncing supply with demand. Start your free trial today. No credit card needed. Quick to set up — you can start working on your inventory in just 15 minutes.

Disadvantages and Risks of JIT Inventory

While the JIT inventory system offers cost savings and efficiency, it also carries significant risks. Businesses considering it should weigh these carefully.

Vulnerability to Supply Chain Disruptions

Any delay — from transport strikes to natural disasters — can stop production or delay deliveries. Without buffer stock, even a short disruption can hurt sales.

Stockouts During Demand Spikes

JIT works best with stable demand. When customer orders rise suddenly, businesses may not have enough stock on hand to meet them, leading to lost revenue and dissatisfied customers.

High Dependency on Reliable Suppliers

JIT requires strong partnerships with vendors who can deliver on time, every time. If a supplier fails to meet expectations, the entire system is at risk.

Requires Advanced Forecasting and Planning

Accurate demand forecasting is critical. Mistakes in predicting sales or material needs can create shortages, production halts, or expensive emergency purchases.

JIT can be powerful, but it is not risk-free. Many companies use a hybrid model, combining JIT with small safety stocks to balance efficiency with stability.

Just-in-Time Inventory Management Examples

Examples of just-in-time inventory management show how both global corporations and small businesses use the system to save costs and stay flexible.

Toyota: Origin of JIT in auto manufacturing

The origin of JIT lies in the Toyota Production System. The company arranged for suppliers to deliver parts in small, frequent batches directly to assembly lines. This reduced storage needs and improved efficiency. Toyota’s success made JIT a global benchmark for manufacturing.

Dell: Build-to-order computers

In the 1990s, Dell Computers adopted a build-to-order model. Instead of keeping warehouses full of pre-built machines, Dell produced each computer only after receiving a customer order. This reduced inventory costs and allowed customization, which became a competitive advantage.

Small business example: Retailer reducing warehouse space

A clothing store with limited space uses JIT by restocking only after sales are recorded. Instead of keeping large volumes of seasonal clothing, it relies on real-time sales data and quick supplier deliveries. This cuts down on unsold items and frees up cash.

Technology and Tools for JIT

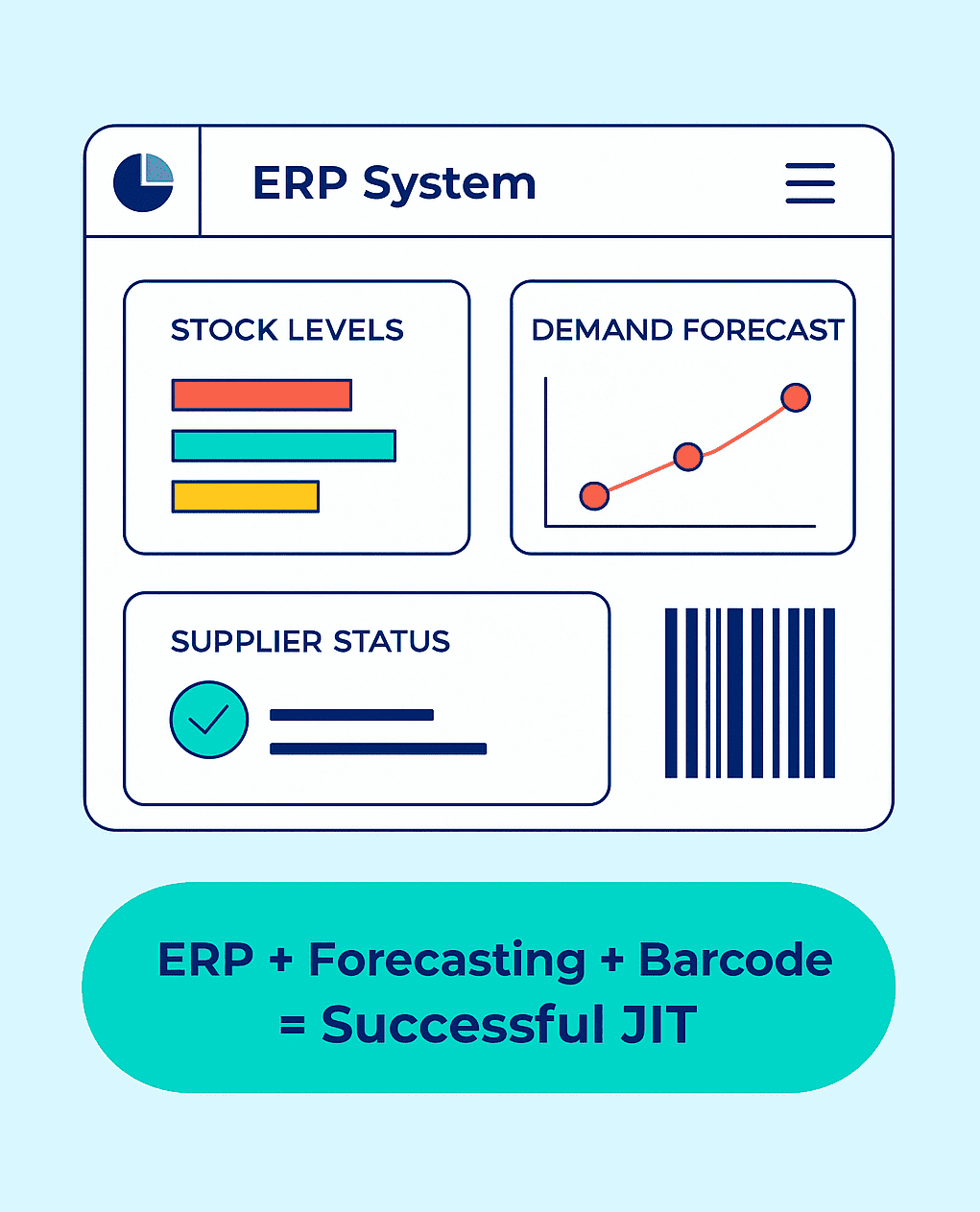

The success of just-in-time inventory management depends on real-time data and smooth coordination across the supply chain. Modern tools make this possible even for small and mid-sized businesses.

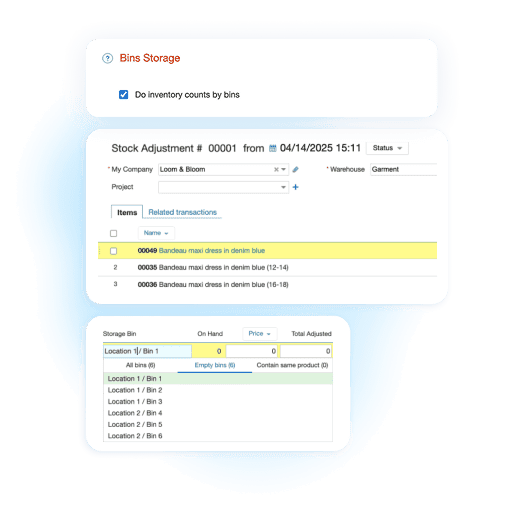

ERP systems with real-time inventory tracking Cloud-based

Cloud-based ERP software helps monitor stock across multiple locations. Managers can see what’s available, what’s in transit, and what needs to be ordered — all in one place. This reduces the risk of stockouts.

📚 Recommended Read: Select and introduce the ideal ERP system for inventory management, tailored to your business’s specific needs, with our comprehensive guide.

Supplier management and demand forecasting tools

Accurate forecasts are critical for JIT. Software powered by sales history and market trends predicts what stock will be needed and when. Supplier management modules track lead times and vendor reliability, ensuring that only dependable partners are part of the system.

Barcode/RFID integration

Scanners and RFID tags automate data entry, cutting errors in receiving, storing, and shipping goods. They keep inventory records up to date and support faster decision-making.

By combining these technologies, businesses can apply JIT without losing control. Even SMEs can start with simple digital tools before moving to advanced ERP systems that integrate purchasing, production, and sales.

JIT vs Traditional Inventory Systems

Both JIT and traditional methods aim to ensure goods are available when needed, but they take very different approaches.

| Criteria | JIT Inventory | Traditional Inventory |

| Stock Levels | Minimal, only what is needed | Higher buffer stock kept in storage |

| Cost | Lower holding and storage costs | Higher carrying and warehousing costs |

| Risk | High if supply is disrupted | Safer, as extra stock acts as a cushion |

| Flexibility | Quick response to demand changes | Slower to adapt due to large stockpiles |

| Best For | Stable, predictable demand with reliable suppliers | Markets with fluctuating or uncertain demand |

Traditional systems focus on security and stability, while JIT inventory management focuses on efficiency and cash flow. Many businesses today use hybrid approaches, combining lean stock levels with small safety buffers to balance cost and risk.

Is JIT Right for Your Business?

Just-in-time inventory management is not a one-size-fits-all solution. Whether it suits your business depends on your industry, demand patterns, and supplier network.

Best Suited Industries and Scenarios

JIT works well in sectors with predictable demand and reliable supply chains. Automotive, electronics, and food processing often benefit from lean operations and frequent deliveries. Retailers with access to quick local suppliers can also gain from reduced stock levels.

When JIT May not Be Ideal

If your business operates in a volatile market or relies on overseas suppliers with long lead times, JIT can be risky. Unstable logistics, customs delays, or sudden demand spikes can quickly lead to shortages.

Hybrid Approaches (Safety Stock + JIT)

Many companies now blend JIT with a “just-in-case” strategy. This means keeping small safety stocks of critical items while applying JIT to less risky parts of the supply chain. It reduces vulnerability without losing the financial benefits of lean inventory.

Before adopting JIT, evaluate your supplier reliability, demand stability, and ability to forecast accurately. Even partial implementation — such as applying JIT to fast-moving items only — can deliver savings while limiting exposure to risk.

Manage JIT Inventory with Kladana ERP

Cut down on storage costs and keep your stock lean with real-time tracking. Kladana ERP helps SMEs integrate purchasing, inventory, and sales into one system. Forecast demand, manage suppliers, and prevent stockouts with ease.

Conclusion

Just-in-time inventory management can help businesses cut costs, improve cash flow, and stay flexible. By ordering or producing goods only when needed, companies reduce storage expenses, limit waste, and respond faster to demand.

At the same time, JIT carries risks. Supply chain disruptions, unreliable vendors, or sudden demand changes can lead to shortages and lost sales. That’s why many businesses adopt hybrid models, mixing JIT with small safety stocks for balance.

Before choosing JIT, assess your industry, suppliers, and forecasting ability. For stable markets and dependable supply chains, JIT can bring strong efficiency gains. For volatile conditions, it may be better to combine lean methods with protective buffers.

If applied with the right tools and planning, JIT remains a proven way to run operations more efficiently for businesses of all sizes: from global manufacturers like Toyota to small retailers aiming to save space and improve cash flow.

Frequently Asked Question on JIT

Businesses often have common questions before deciding whether to use just-in-time inventory management. Here are the answers to the most frequent ones:

What does JIT mean in inventory management?

JIT, or just-in-time inventory management, means keeping stock levels very low and receiving goods only when they are needed for production or sales. It reduces storage costs and waste but requires strong supplier coordination.

What are the key benefits of JIT inventory?

The main benefits are lower holding costs, reduced waste, better cash flow, and improved quality control. Businesses also gain flexibility to respond quickly to changes in customer demand.

What are the risks of just in time inventory?

The biggest risks are supply chain disruptions, sudden demand spikes, and dependency on suppliers. Without buffer stock, even a small delay can halt production or cause lost sales.

How does JIT differ from traditional inventory management?

Traditional systems keep higher buffer stock to prevent shortages, while JIT minimizes stock to cut costs. JIT is leaner but riskier if supply is disrupted. Traditional methods are safer but more expensive to maintain.

What is an example of JIT in manufacturing?

Toyota is the best-known example. It developed the Toyota Production System, where parts are delivered directly to assembly lines in small batches, reducing the need for storage.

Can small businesses use JIT inventory?

Yes. A retailer with limited space can reorder stock based on real-time sales instead of storing large amounts. SMEs often adopt JIT partially, applying it to fast-moving goods while keeping safety stock for essentials.

How does JIT affect supply chain relationships?

JIT makes suppliers critical partners. Businesses must work closely with them to ensure timely, frequent deliveries and consistent quality. Strong trust and communication are essential.

What industries benefit most from JIT?

Automotive, electronics, and food processing industries benefit most due to predictable demand and established supplier networks. Retailers with quick supplier access also gain.

What role does technology play in JIT?

ERP systems, forecasting tools, and barcode/RFID tracking make JIT possible. They provide real-time data, reduce errors, and help align purchasing with demand.

Is JIT still relevant after COVID-19 supply chain disruptions?

Yes, but many companies now use a hybrid model. They apply JIT to most items while keeping small safety stocks of critical goods to handle unexpected disruptions.

List of Resources

- Yahoo! Finance — Toyota Company Profile

- Yahoo! Finance — Dell Company Profile