When defects recur, audits leave you scrambling for proof, and operators follow different versions of the process, you know something is missing. What ties all of this together is the production control plan.

Think of it as the backbone of your quality system. Every time a customer requests evidence of process control, or an auditor verifies whether risks from the PFMEA (Process Failure Mode and Effect Analysis) have been linked to shop-floor checks, the conversation inevitably circles back to the control plan in quality. Without it, compliance feels reactive. With it, you gain a structured way to show consistency, reduce variation, and stay prepared.

This isn’t just best practice, it’s enforced. In 2025, Ford updated its IATF requirements to mandate a pre-launch control plan, which requires four consecutive weeks of defect-free production before suppliers can transition into full production. That shows how preeminent manufacturers treat stability and evidence of control.

In this guide, you’ll learn how to build a practical plan that transitions from prototype to production, supported by clear templates, production control software, and a connected manufacturing control system that ensures accurate and up-to-date quality checks.

- What Is a Production Control Plan?

- Why It Matters: Benefits in Quality & Efficiency

- Control Plan vs PFMEA vs Process Flow Diagram

- Types & Levels of a Control Plan

- How to Develop a Control Plan

- Key Columns: Parameters, Characteristics, Sampling Reaction Plan

- Example of Control Plan

- Tools & Templates

- Common Pitfalls & Tips for Maintenance

- Example Case: Automotive Component

- Summary & Next Steps

- Frequently Asked Questions on Production Control Plan

- List of Resources

What Is a Production Control Plan?

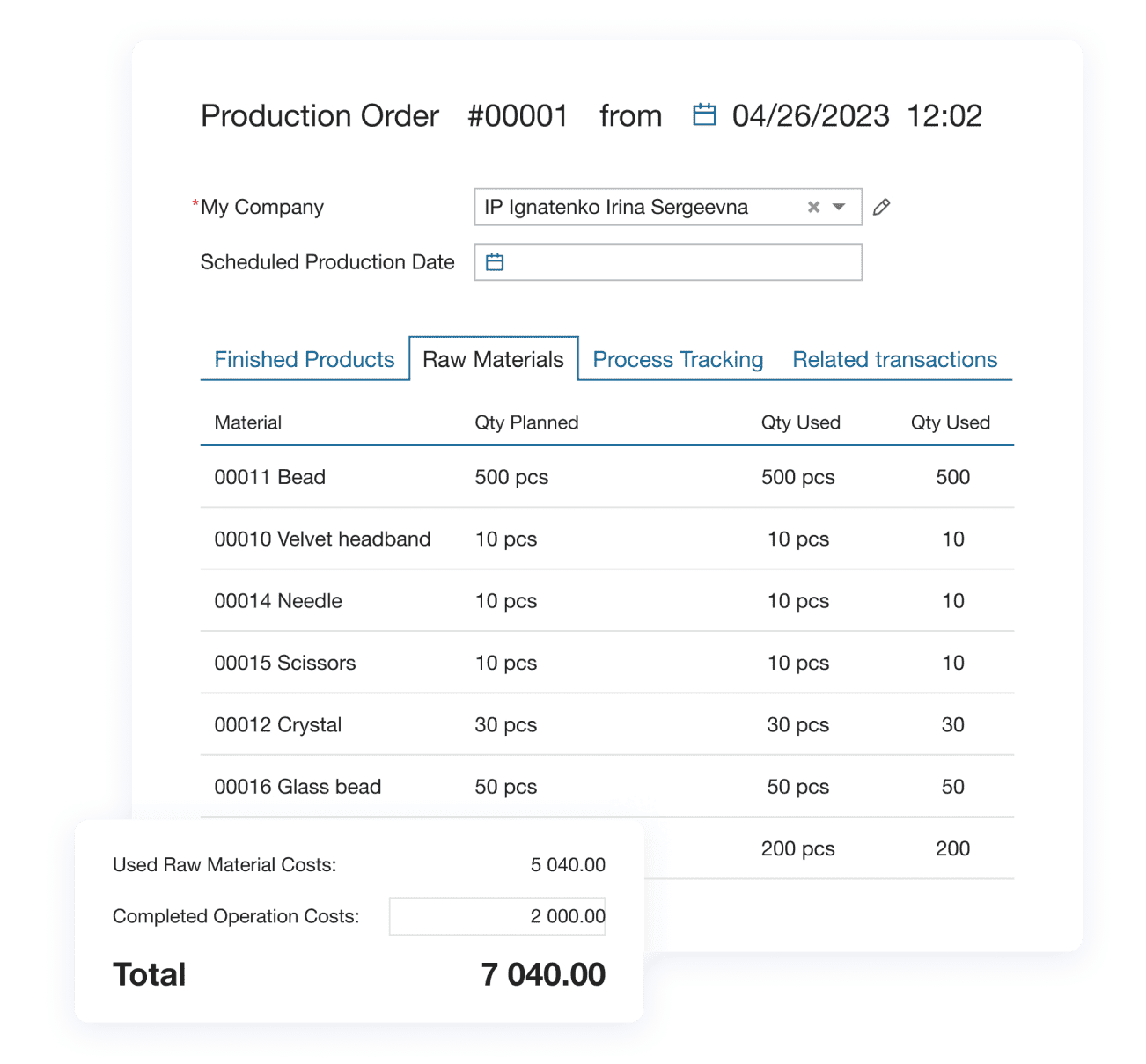

A production control plan is a core requirement in quality systems, such as (Advanced Product Quality Planning) and PAAP (Production Part Approval Process). Its purpose is to document how you will monitor and control product and process characteristics so that compliance, customer requirements, and efficiency targets are consistently met.

📍In practice, this becomes especially useful when you need to document and standardize quality checks

For example, a manufacturer preparing for an audit may decide to create a production control plan template. This way, the company ensures consistent quality, reduces risks of non-conformance, and passes compliance checks with confidence.

That’s exactly the role this plan plays. Beyond audits, it keeps your team aligned, reduces wasted effort, and makes it easier to spot problems early. For managers, it provides a single reference point to track performance. And for customers, it ensures they consistently get the same quality every time.

In Six Sigma’s DMAIC cycle (Define, Measure, Analyze, Improve, Control), the production plan is central to the control phase. After improvements are made, the plan helps you solidify them. It does this by standardizing checks, setting clear rules for monitoring stability, and defining what to do if things drift. This way, you don’t just solve the problem once; it also ensures that the fixes stay in place and your process remains predictable over time.

📖 Recommended Read: Managing Production in SMEs — A Practical Guide — Learn how small manufacturers organize production steps, track resources, and align them with quality requirements

Why It Matters: Benefits in Quality & Efficiency

Defects, scrap, and late corrections may seem insignificant in isolation, but collectively they erode profitability. This combined loss is what’s known as the Cost of Poor Quality (CoPQ).

Recurring defects or process variations are a common trigger for updating the production control plan. Instead of letting those issues pile up, manufacturers can adjust the plan dynamically — adding new checkpoints, refining tolerances, or tightening monitoring. As a result, they cut waste, improve consistency, and stay on track with KPI goals.

Instead of letting those issues pile up, a production control plan helps you get ahead of them. By standardizing checks, making quality predictable, and surfacing drift early, you can reduce CoPQ to a manageable level.

Statistical Process Control (SPC) makes this possible. When your control plan is tied to SPC charts, you can monitor variation in real time. Trends and alarms trigger the documented reaction plan, stopping problems before they multiply.

The benefits go far beyond compliance:

Waste reduction: Early SPC signals + reaction rules prevent large-scale scrap.

Efficiency gains: operators have clear sampling and stop rules, so time isn’t wasted on rework.

Audit readiness: Your updates and SPC evidence prove to auditors that risks are contained.

ROI Impact: First-pass yield improves, defect rates and cycle times stabilize.

Control Plan vs PFMEA vs Process Flow Diagram

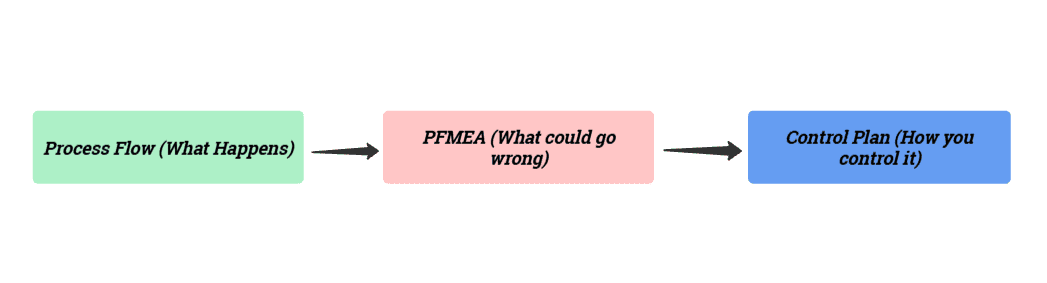

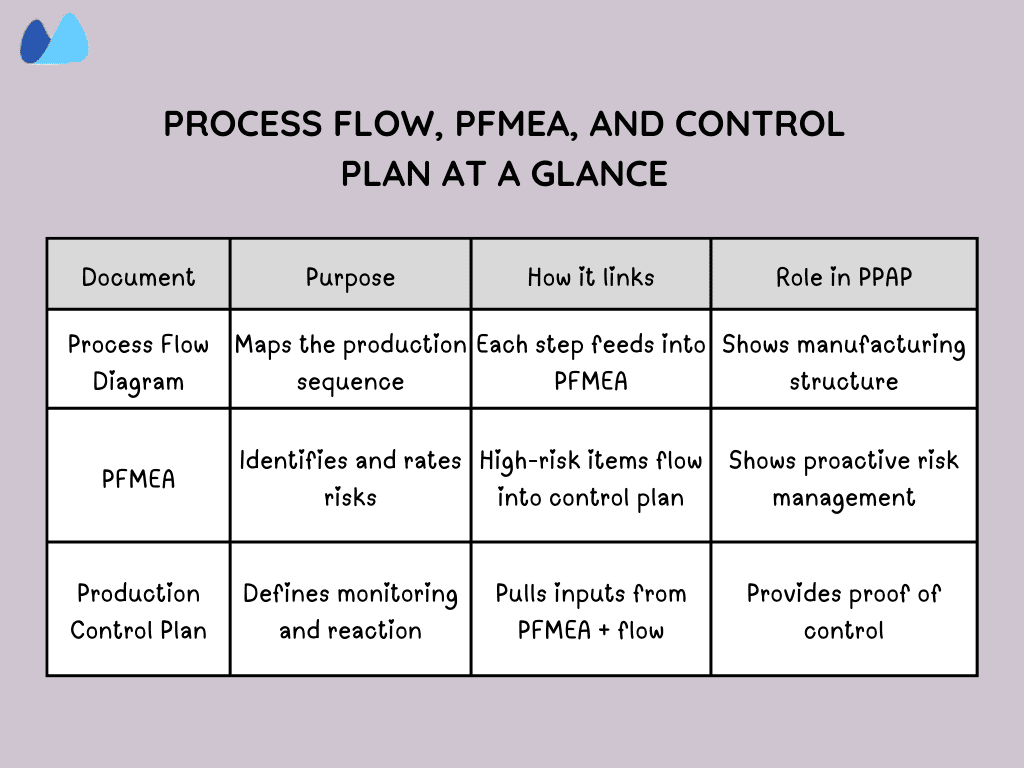

One of the biggest challenges in manufacturing documentation is keeping three tools straight — the control plan, PFMEA, and Process Flow Diagram. They often look similar on paper, but each serves a different purpose. Unless you align them, auditors will find gaps in traceability.

This alignment is very important. In the Production Part Approval Process (PPAP), auditors specifically check whether your process flow, PFMEA, and control plan link together. If they don’t, gaps in traceability become apparent during reviews.

To see how these tools connect in PPAP, here’s the high-level flow:

Step 1: Control Plan

The control plan is your action sheet. It explains how you’ll check quality, how often, and what to do if something goes wrong.

Purpose: It turns risks into daily checks and creates proof that quality is under control.

Step 2: PFMEA

The PFMEA digs deeper into the process and asks: what could go wrong at each step?

Purpose: It identifies risks, and the most serious ones must be addressed in the control plan so they don’t slip through.

Step 3: PFD (Process Flow Diagram)

The PFD is your process map. It shows the order of steps like cutting ➞ drilling ➞ inspection.

Purpose: It lays out the whole sequence of operations so that each step can later be checked for risks in the PFMEA.

Why Integration Matters in PPAP?

If a step in the process isn’t included in the PFMEA, or if a PFMEA risk isn’t carried over into the control plan, auditors view it as a traceability gap. These gaps raise red flags in PPAP reviews and can lead to rework, delays, or outright rejection of your submission.

By starting with a well-structured manufacturing control that links directly to the process flow and PFMEA, you eliminate duplication, close gaps, and make your PPAP package audit-ready.

If a step or risk isn’t connected across all three, it raises red flags in PPAP. By starting with a well-structured manufacturing control plan, you can make sure there’s no duplication or missing links.

📖 Recommended Read: Quality Management System: Key Elements for SMEs — Learn how to structure a QMS, document processes, and connect it with everyday manufacturing tasks

Types & Levels of a Control Plan

A single production control plan doesn’t fit all project stages. As a product matures, the level of detail and frequency of checks must evolve. That’s why APQP defines three levels: prototype, pre-launch, and production — each with its own distinct role.

| Level | Purpose | Characteristics | Checks & Frequency | Role in PPAP |

| Prototype Control plan | Verify design intent | Few stable processes, high uncertainty | Frequent checks, experimental methods, variable sampling | Early learning and evidence of feasibility |

| Pre-launch control plan | Stabilize the process before mass production | More consistent methods, capability targets set | Increased sampling, interim SPC, confirm corrective actions | Provides data for PPAP submission |

| Production control plan | Lock process controls for routine runs | Stable methods, defined operators & equipment | SPC rules, standard frequencies, and a documented reaction plan | Becomes the auditable baseline in PPAP |

In practice, some manufacturers extend these stages further. In 2025, Nexteer required suppliers to maintain a 90-day launch containment phase, with every Control Plan tied directly to the PFMEA and process flow diagram for PPAP. It highlights how extended checks and traceability are used to secure stability before full production.

How to Develop a Control Plan

Building a production control plan is not about filling a template; It’s about translating risks and requirements into actionable, auditable checkpoints. The process works best when it’s systematic and team-driven.

Step 1: Build Your Team and Gather Inputs

A strong plan is cross-functional. It includes quality engineers, process/industrial engineers, production supervisors, and maintenance. For PPAP projects, involve the customer quality representative early.

Inputs to bring into the session:

- Process flow diagram — maps each operation step

- PFMEA — Identifies where failures could occur

- Drawing/specifications — highlights critical to quality characteristics (CTQs) and special characteristics

- MSA (Measurement System Analysis) studies — ensure gauges and tools are reliable

- Historical defect and SPC data — show where controls are most critical

Step 2: Structure the Control Plan

Once inputs are ready, set up your plan and consistent columns:

- Operations/step (from the process flow)

- Product/process characteristics (CTQs, special symbols)

- Specification/tolerance or control limits

- Measurement method/instrument (must be MSA-approved)

- Sampling plan/frequency

- Reaction plan (what to do if out of spec)

- Responsibility (who owns it)

- Evidence/record where results are logged)

📍 At this stage, many manufacturers choose to create a production control plan template. A structured template makes quality checks easy to document and standardize, ensures consistent output, and helps the business demonstrate compliance during audits.

Step 3: Define Clear Reaction Plans

Each line must clearly state what happens if the limits are breached. For example, stop the machine, inspect the lot, recheck the last 200 parts, and escalate the issue to quality engineering. This makes the plan a control system, not just a checklist.

Step 4: Link Responsibilities and Evidence

Assign ownership for each control, operator, line lead, or quality engineer and specify how evidence is captured, such as SPC charts, e-signature, or electronic QC logs. This builds accountability and provides proof during audits.

Key Columns: Parameters, Characteristics, Sampling Reaction Plan

When you build a control plan, these four columns are very important. It helps your team to know precisely what matters, how to keep it in check, and what to do if things go wrong.

1. Parameters

These are the process settings you must hold steady always (like oven temperature, machine speed, torque, etc). If parameters drift, quality drifts too.

2. Characteristics

The product features that are critical to quality, such as dimensions, strength, or safety requirements. These are the main points you shouldn’t neglect.

3. Sampling

This explains how often you check. It could mean checking a few per batch or just once a shift. A Clear sampling avoids both over-checking and missed problems.

4. Reaction Plan

The defined response when results fall outside limits. This gives operators step-by-step instructions, such as stopping the process, isolating affected parts, notifying the supervisor, and recording the non-conformance.

➡️ Together, these four columns make the control plan practical. Your team knows what to control, how often to check, and how to respond when something goes wrong.

Example of Control Plan

Here are a few examples of production control plans. They show how different steps can be documented with their characteristics, standards, checks, responsibilities, and reaction plans.

| Process Step | Characteristics | Standard | Method | Frequency | Reaction Plan | Owner | Record |

| Labelling | Sticker applied | The sticker must be aligned | Visual check | 1 in every 10 boxes | If crooked ➞ stop line, correct stickers, check last 10 boxes | Operator | Label check sheet |

| Drilling | Hole | Within tolerance | Gauge check | Sampled regularly | Stop the machine, fix the tool, and recheck the batch | Operator | Quality Control log |

| Assembly | Bolt torque | Meets specification | Manual torque check | Each unit | Re-torque and check recent items | Line lead | Torque Log |

| Packaging | Barcode label | Must scan | Scan test | Each carton | Replace label re-scan | Operator | Packing log |

Tools & Templates

Excel may work for quick setups, but it struggles as teams grow. This comparison demonstrates how dedicated control plan software addresses the gaps and ensures processes are audit-ready.

That’s why many manufacturers move to production control software or a manufacturing control system once the process scales. Software automates version control, links PFMEA directly to the control plan, and integrates SPC dashboards so checks aren’t just documented but monitored in real time.

📍 For example, when teams are under pressure to launch quickly, software can auto-fill control plan fields from PFMEA data. This reduces manual entry, speeds up PPAP submission, and helps avoid costly errors.

| Without Automation | With Manufacturing Control Software |

| Manually editing Excel control plans each time PFMEA changes | Auto-sync PFMEA changes to control plans instantly |

| Missing signatures | Digital sign-off with audit trail in seconds |

| Templates stored locally are prone to version confusion | Centralized, cloud-based version control |

These improvements solve a common pain point: when processes are revised, teams want control plans to update automatically. With automation, updates happen instantly, compliance is maintained, and there’s no need for repetitive rework.

📖 Recommended Read: How To Build a Production Schedule That Works — Check how to design production schedules and automate them with Kladana ERP

Common Pitfalls & Tips for Maintenance

A control plan only works if it is kept up to date. If it becomes a static file that no one touches, it quickly loses value and may even cause mistakes. Here are the most common pitfalls and how you can avoid them.

Pitfall 1: Vague Checks

A common mistake is writing things like “visual inspection” without explaining what that means. Operators are left in a state of uncertainty, and auditors remain confused.

☑️ Tip: Always describe what to look for and how often. For example, the sticker must be straight and aligned with the mark. Check one in every 10 boxes.

Pitfall 2: No Reaction Plan

Some plans list what to measure but not what to do if the result is out of range. In that case, bad parts may keep moving down the line until someone notices, which leads to rework and waste.

☑️ Tip: Write a simple action plan. For example, stop production, separate the bad parts, call the supervisor, and recheck the last batch.

Pitfall 3: Outdated after Changes

Processes don’t stay the same. It constantly changes, with new machines and methods being introduced all the time. If the control plan isn’t updated, it quickly becomes outdated and doesn’t match the way work is actually done.

☑️ Tip: Update the plan whenever the processes change. Keep track of revisions so that everyone knows which version is current.

👉 Kladana enables seamless integration, version control, and compliance.

Pitfall 4: Records not Available

Even if checks are done, if records can’t be found quickly, it looks like they were never done. Paper logs are often misplaced, and unsigned sheets don’t count as proof.

☑️ Tip: Store records in an organized way so you can show them instantly if asked during an audit.

Pitfall 5: No Clear Ownership

Sometimes checks are written down, but nobody is sure who should perform them. Operators think quality engineers are responsible, while quality engineers assume operators are doing it. This creates gaps in control.

☑️ Tip: Assign a clear owner for each check, such as operator, line lead, or quality engineer. When responsibility is clear, checks are done consistently.

Example Case: Automotive Component

A supplier was making a small metal bracket. The job looked simple, but two things were critical:

- The hole had to be the correct size

- The press had to use the right amount of force

How they controlled it:

- For the hole size, workers measured one out of every 20 parts using a gauge. For example, if 100 parts were made, they checked 5 of them. If a hole was wrong, they stopped the line, fixed the tool, and rechecked the recent parts.

- For the press-fit, a sensor measured the force on every single part. If the force was wrong, the machine stopped automatically, the faulty part was removed, and maintenance was called.

How they tracked it:

- Operators entered results in an electronic log

- Supervisors reviewed and signed off at the end of each shift

Results:

- Scrap was reduced by more than one-third

- Production became steady

- Customer approval was achieved without issues

💡 From Blank Sheets to Templates: Kladana Standardizes Control Plans

Standardize your quality checks with Kladana in minutes

Summary & Next Steps

A production control should never be a static file. It works best when it guides daily work, adapts to changes, and provides clear proof of quality for both teams and customers.

Next steps:

- Review your current control plan and update it to reflect today’s process.

- Add clear reaction plans so operators know exactly what to do when problems occur.

- Keep records in a format that can be retrieved quickly during audits.

- Shift your manual spreadsheets if you manage multiple lines or frequent changes to software integration, which will save your time and reduce errors.

- Treat the plan as a living document: revise it whenever tools, methods, or risks change.

By following these steps, your control plan will become more than a compliance form. It will be a tool for stability, waste reduction, and long-term customer retention.

Frequently Asked Questions on Production Control Plan

What is a control plan in manufacturing?

A control plan documents what to check, how to check it, when to check it, and what to do if something’s off. It helps ensure consistent quality in production.

How does a control plan relate to PPAP?

In PPAP, the control plan shows how you’re monitoring risks identified in error analysis and production flow, demonstrating your system ensures quality.

Who should help create the control plan?

Build it with a team such as quality, production, engineering, and maintenance. So, risks, tools, and controls are aligned across departments.

How often should a control plan be updated?

Update it whenever processes change, tools are modified, or risks evolve. Even during stable production, a quarterly review ensures it stays current.

Is a control plan required for ISO or IATF certification?

Yes. ISO 9001 and IATF 16949 require documented and updated control methods. A signed and live control plan offers clear proof of compliance.

How does a control plan help reduce waste in production?

It forces focused monitoring of critical steps. When out-of-spec parts are caught early, waste is reduced. It helps you prevent defect trends from escalating.

What’s the link between control plans and SPC?

The control plan defines what to measure and when to measure it. Whereas SPC notes that monitoring trends over time helps detect drift before defects appear.

Can I automate my control plan inputs from PFMEA?

Absolutely. It can auto-populate the control plan directly from PFMEA, keeping everything linked and error-free.

What are the benefits of treating the control plan as a living document?

It adapts to your process, remaining audit-ready, minimizing errors, and keeping teams aligned on how quality is managed.

What’s the quickest way to build a control plan for a new line?

Start with your top 3 risks — document checkpoints, backups, and who owns each step. The MVP plans keep you running and audit-ready while you build in more coverage.

List of Resources

- Ford: Pre-Launch Control Plan

- Nexteer: Case study on Control Plan

Read‑alikes

Production Scheduling in Manufacturing: Methods, Tools, and Best Practices

Free Production Schedule Templates (Excel + Google Sheets)

Managing Production in a Small Manufacturing Company: Planning, Control, and Profit Calculation

QMS for Manufacturing: How a Quality Management System Improves Efficiency