Production Management

Take all production stages under control — plan a production order, manage inventory and supply, monitor your employees’ work, evaluate the unit cost of produced goods, and sell them to customers.

Run your manufacturing business in one browser-based app, there is no need to switch from Excel sheets to printed documents.

Handy for All Production Stages

Plan all production stages in advance from supplies to selling finished goods. Stay flexible and make amendments during the production process — change the amount of used raw materials and finished products, and assign a specific employee for a certain operation.

MRP in Kladana enables you to plan the resources need to complete a production order: provide necessary raw materials, and estimate operational & materials costs.

Keep track of what’s left in stock, including WIP. Purchase as many raw materials as you need to process production orders. Record receiving, and transfers of goods between warehouses, and do stocktaking.

Monitor all stages of the manufacturing process. Manage your employees’ work and assign them to certain tasks.

The unit cost of the produced goods is calculated automatically based on the cost of purchased raw materials and costs of production operations. Using Online Order App in Kladana, you can sell produced goods without having a website or an online shop.

Talk to our Expert

routine and answer your questions

Step-by-step Manufacturing

- Create routings with production operations, and change their sequence

- Make bills of materials for finished goods

- Create production orders based on sales orders

- Produce goods in one operation

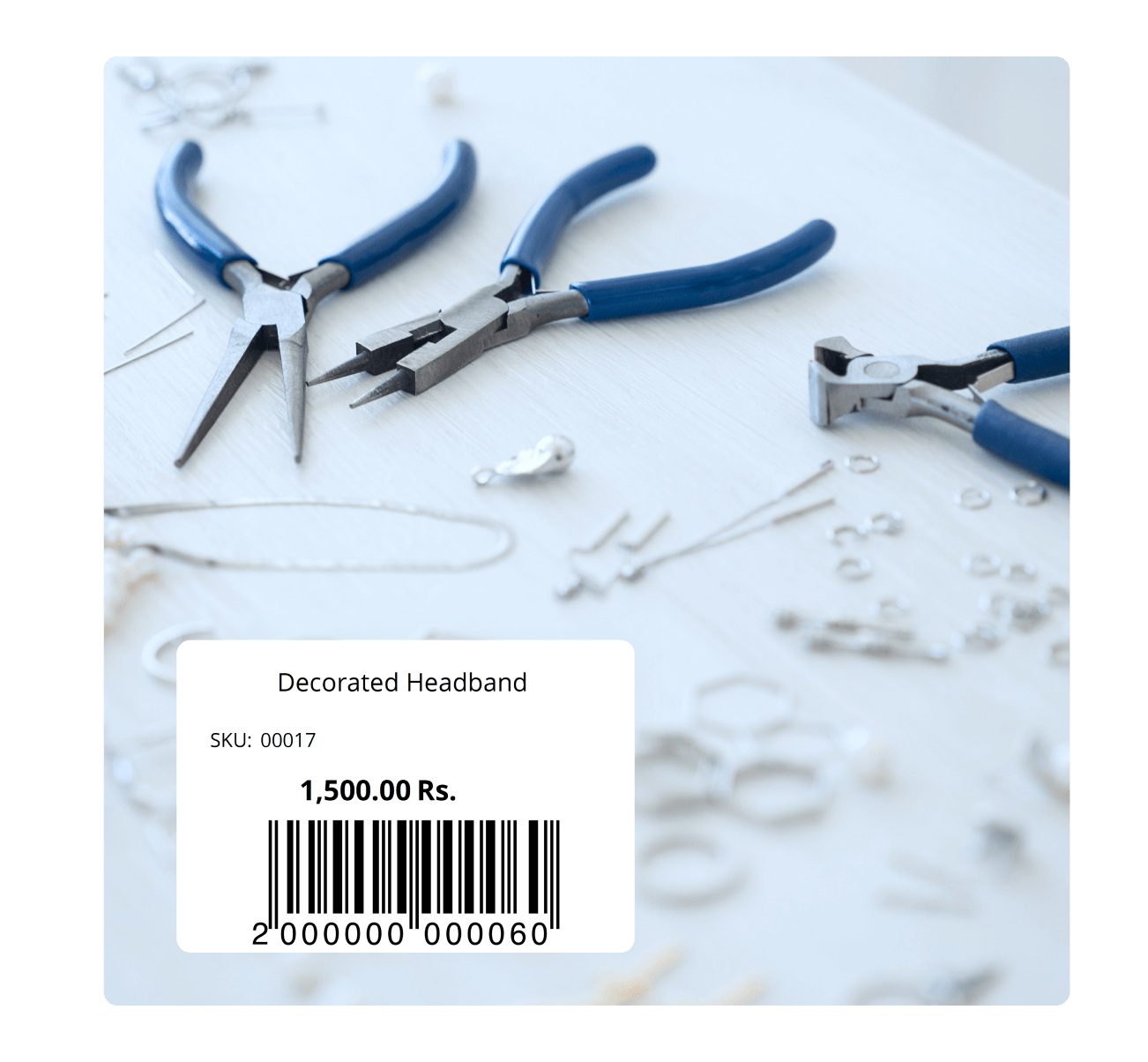

or stage-by-stage - Print labels with barcodes and price tags for finished goods, and papers related to the production process

Full Control & Customization

- Monitor all production stages — the number of ready-to-use goods, the number of completed operations, and the time they were completed

- Assign employees to certain operations

- Produce in batches

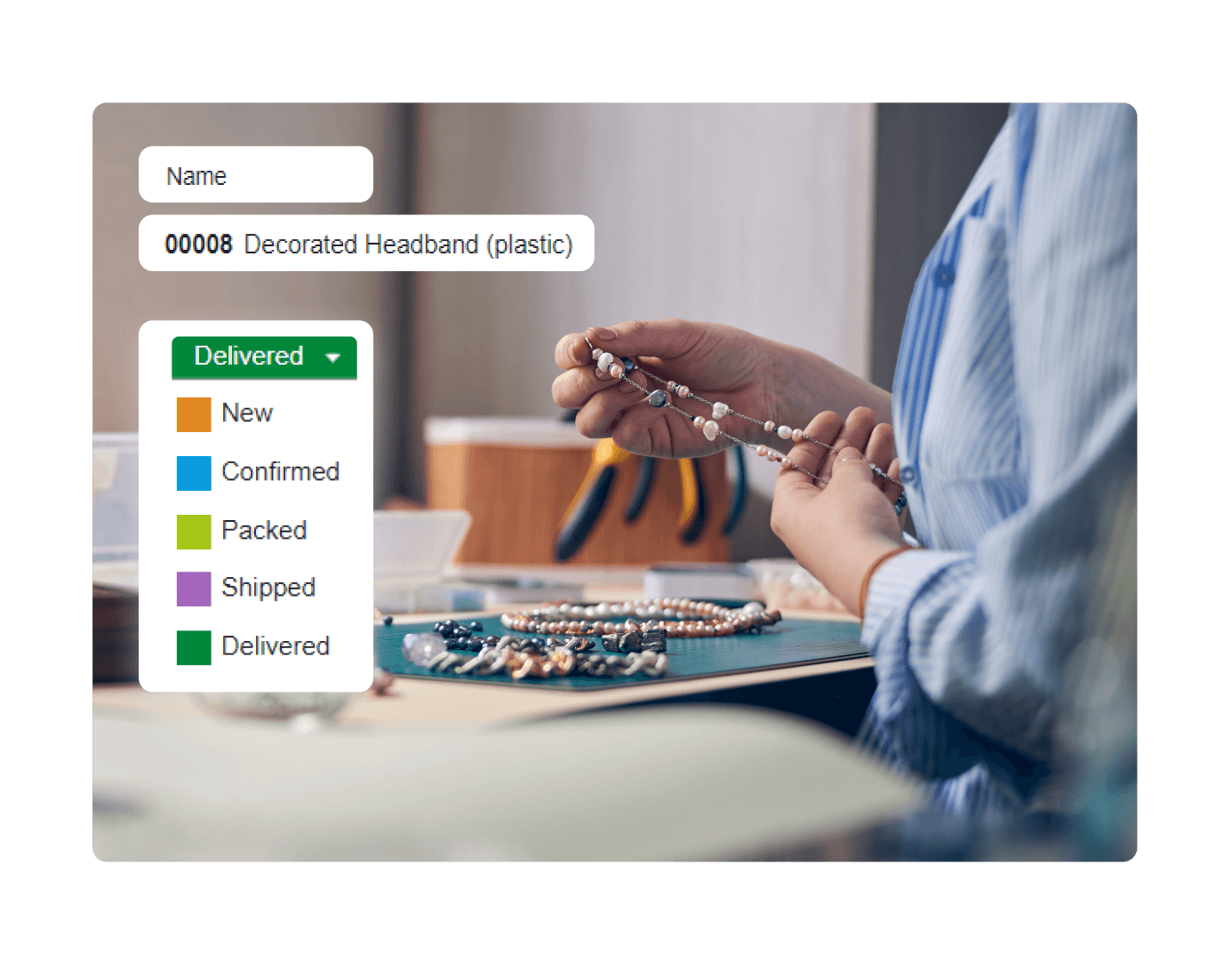

- Use your own statuses, custom fields, and individual print forms to customize your production process

- Use different warehouses for raw materials, semi-finished, and finished goods

- Make different BOMs for specific variants of your goods

Inventory & Supply

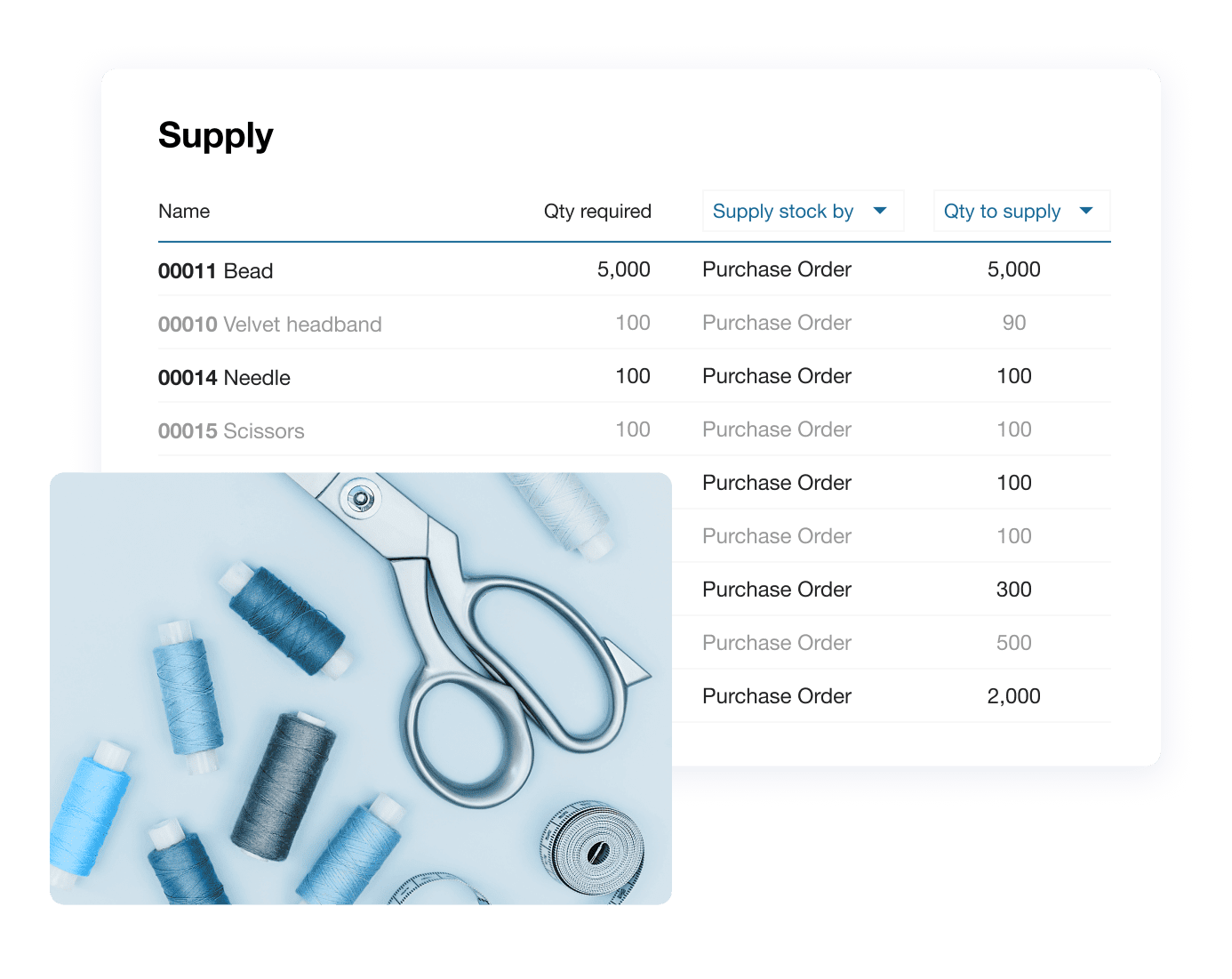

- Control stock of raw materials, and finished goods

- Purchase raw materials for a certain production order

- Order supplies of raw materials that aren’t sufficient for a production order

- You can make specific amendments regarding actually used raw materials or finished goods for any stage of manufacturing

Try Production Management in Kladana for Free

Give it a Go

Cost & Profit Evaluation

- Evaluate the unit cost of the goods produced

- Control money flow — monitor calculations made by products, materials, and operations costs

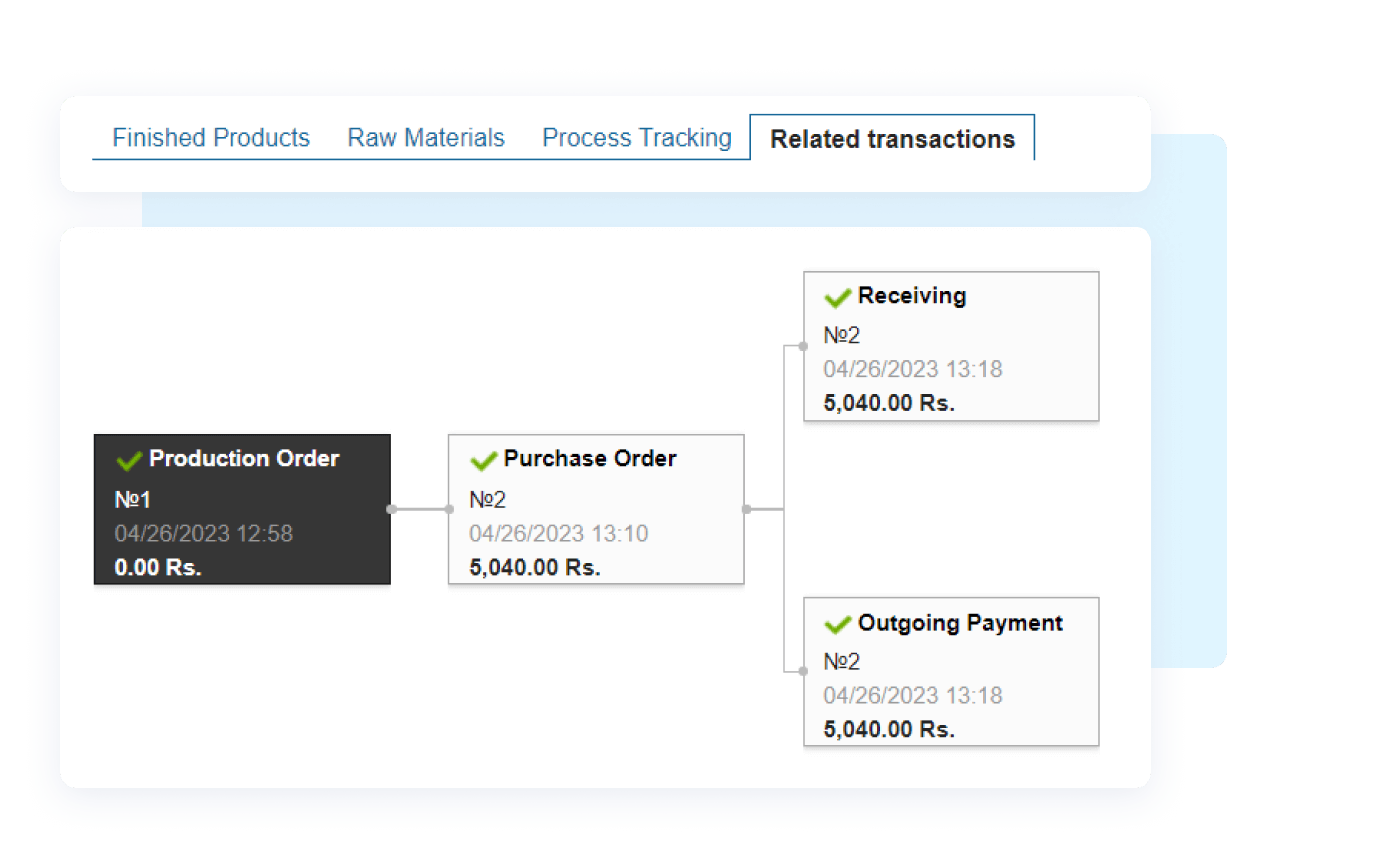

- Keep track of related transactions in a production order

- Sell produced goods using Online Order App. Generate catalogues with your products and send links to customers

No Complicated

and Overpriced Integration

Our Expert

Will onboard you, adjust all the important settings, and answer your questions

Support Team

Will help you fix a problem or explain an exact feature to you within 2–3 hours

FAQ

BOMs, Routing & Operations Reports

Production Orders

Get New Knowledge

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce