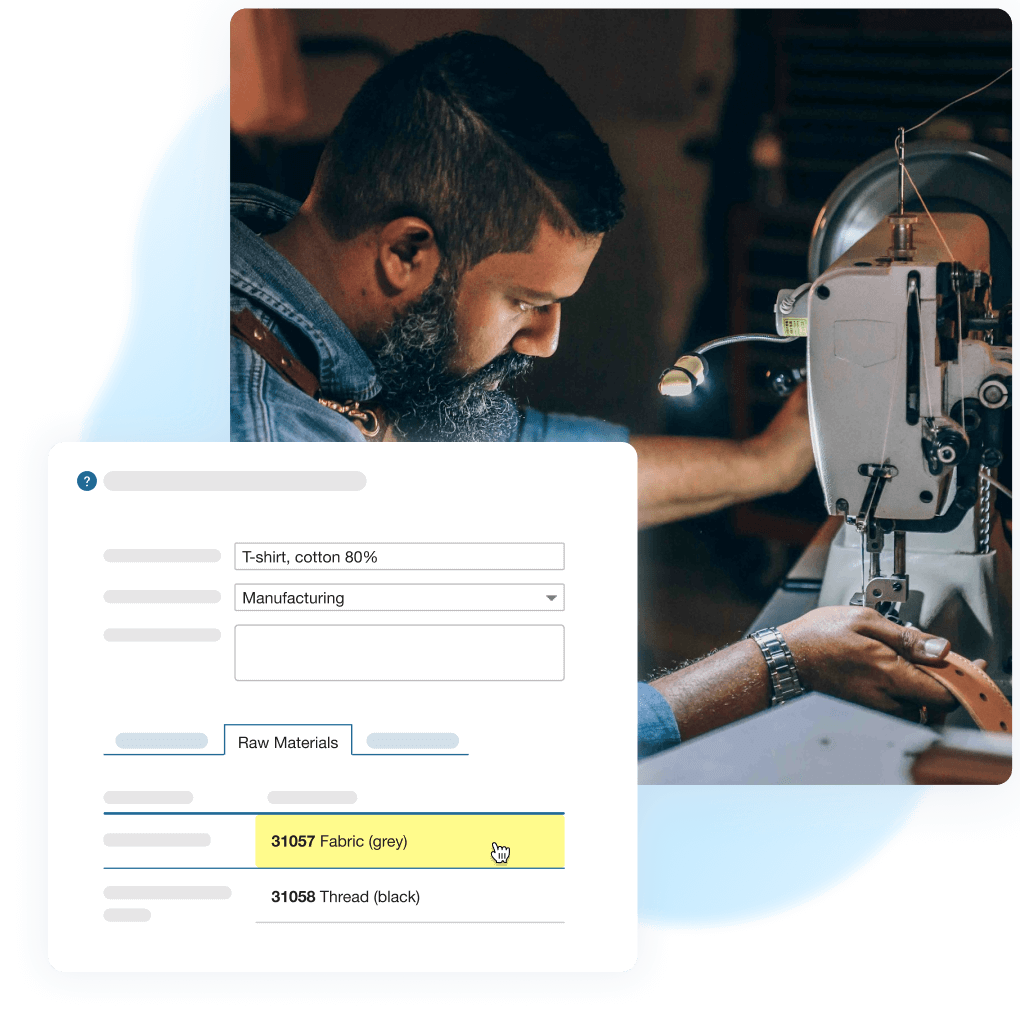

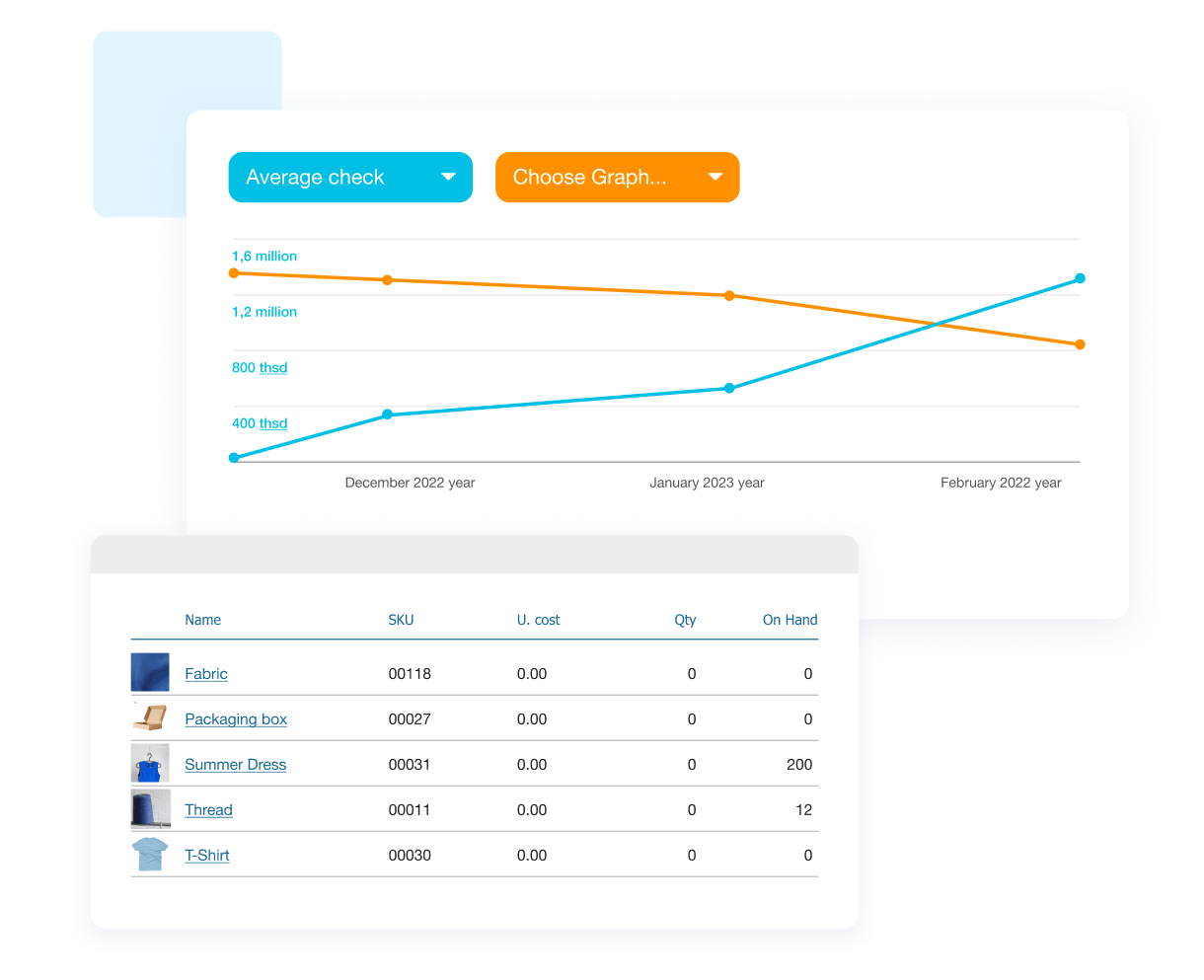

Before Kladana, I managed production on spreadsheets — and kept buying materials I already had. Now everything is tracked, from fabric rolls to finished goods.

The biggest game-changer? Real-time, helpful support. The team respond within seconds — that’s what made me choose Kladana out of 40+ systems I tested.

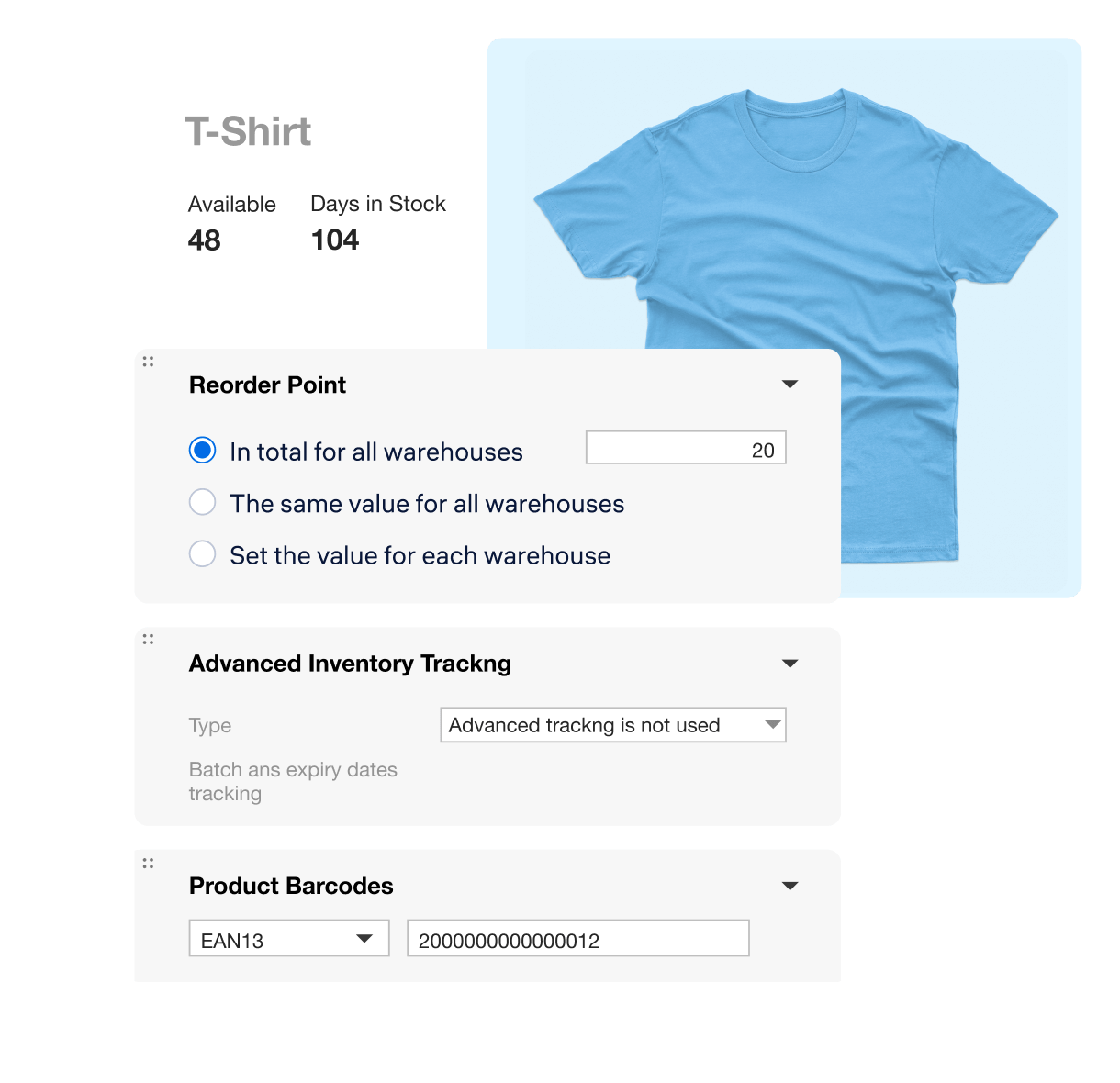

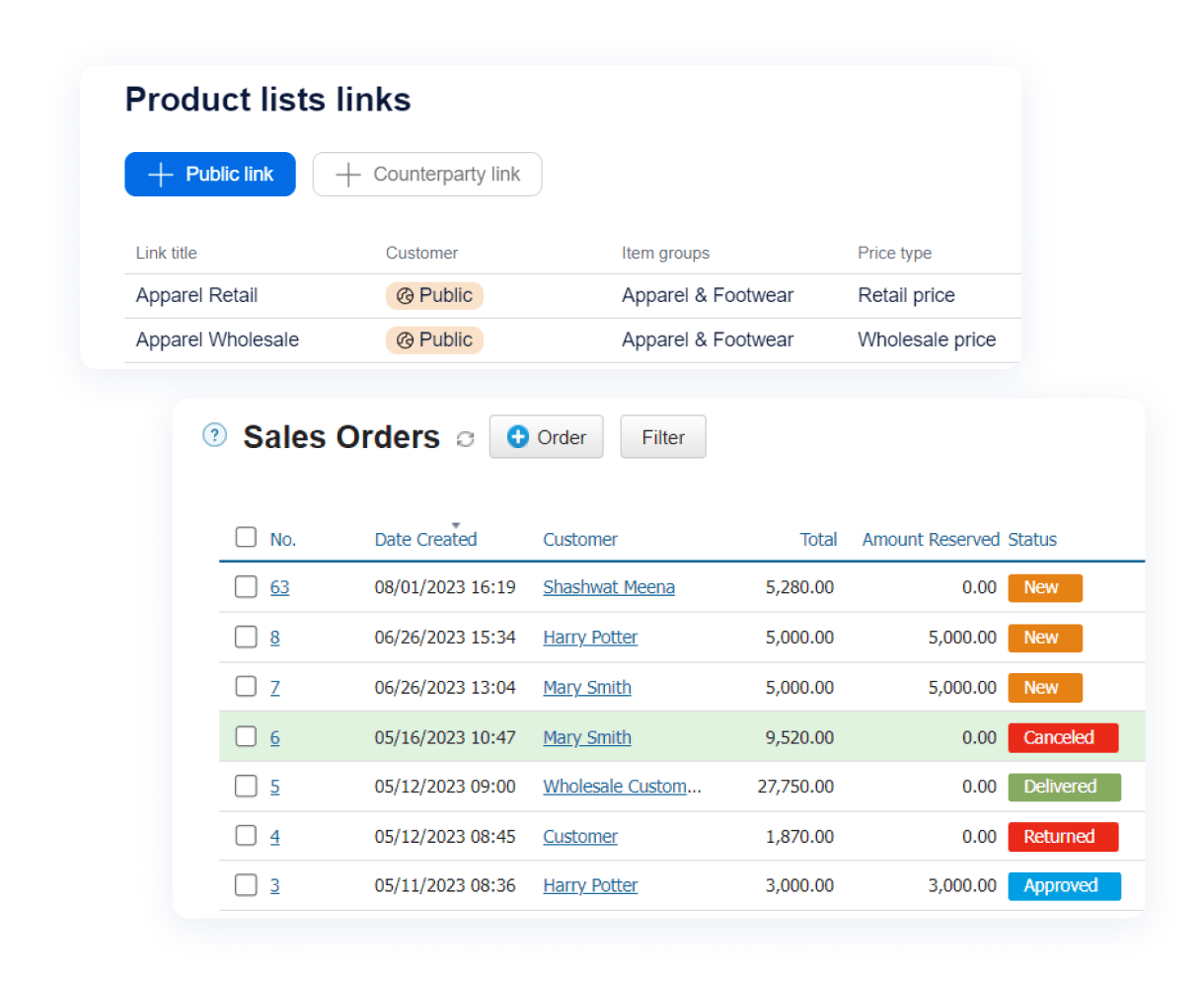

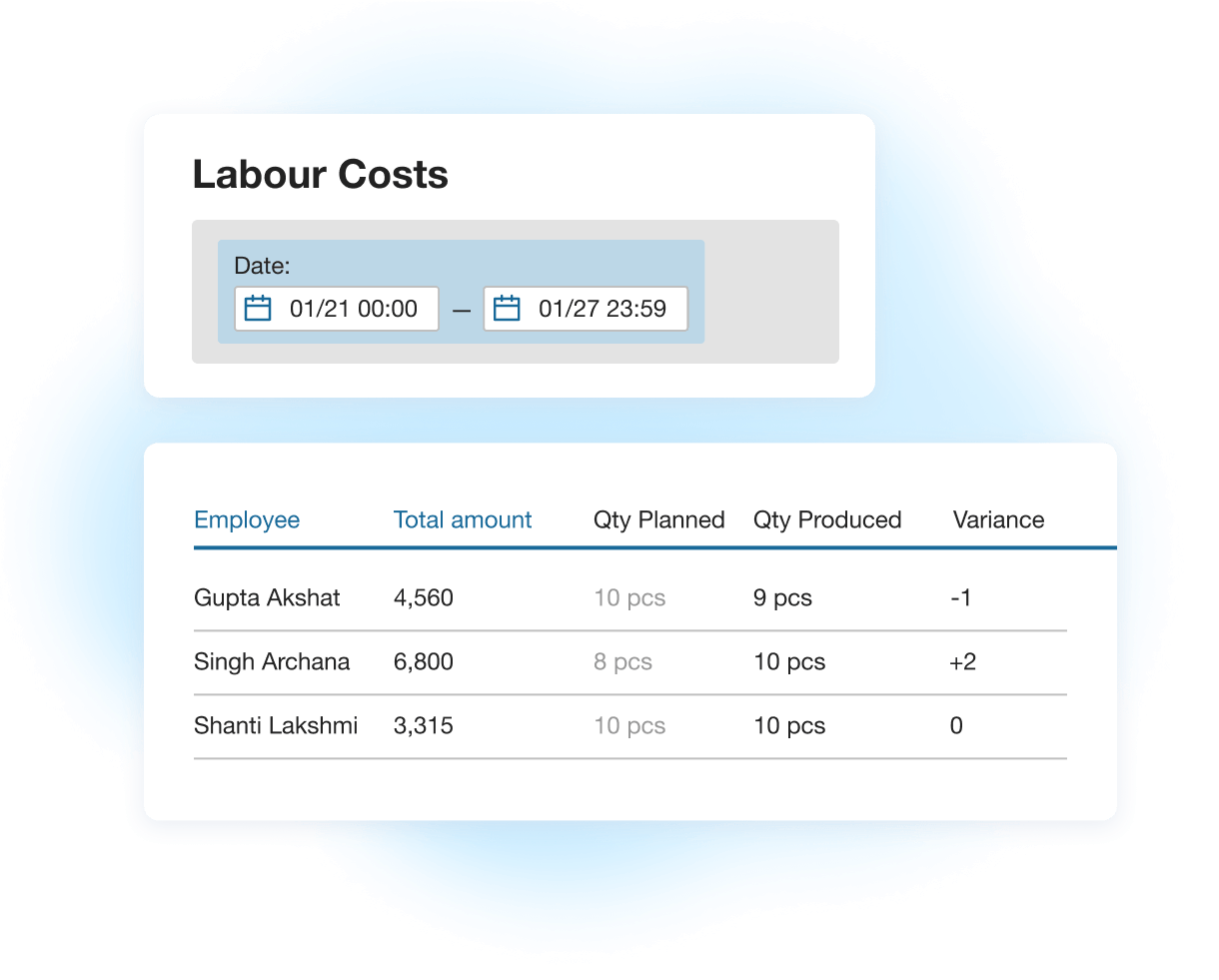

Today, I run weekly production planning instead of daily chaos. I have full stock visibility, fewer stockouts, and better cash flow. I’m very happy with Kladana.