Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.

Warehouse

Management

Software for SMEs

Multi‑location WMS with inventory tracking, shipping and receiving management solutions, and OMS. Conduct regular inventory counts, control stock movements, and use barcoding for quick order collection and accurate storage.

Receivings and

shipments

Inventory

counts

Stock adjustments

and write‑offs

Internal

transfers

Ideal for Stock Management

and Warehouse Operations

Kladana WMS is just the job if you’re unsure where specific goods are stored, picking sales orders is always slow, warehouses are cluttered, barcodes don’t match particular product variants, and you dread and delay inventory counting

Tidy Storage Space

- Increase visibility with bin storage to organize warehouse space and quickly locate necessary goods.

- Use pick lists during receivings or shipments to ensure the set is complete.

- Print warehouse documents, price lists, thermal labels, and price tags to smooth warehousing operations.

Inventory Transactions under Control

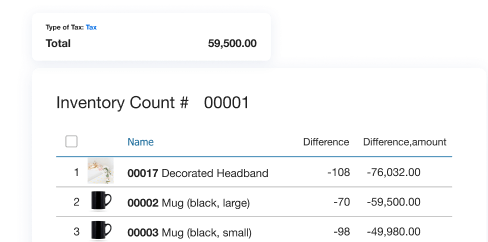

- Conduct regular inventory counts to track stock levels.

- Make stock adjustments for discrepancies and write‑offs for expired or damaged products.

- Manage transfers and internal orders to move products between warehouses.

Planning and Analytics

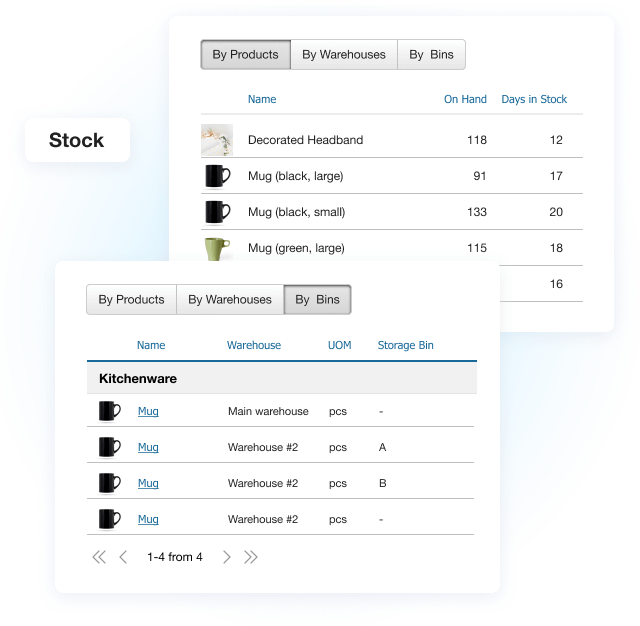

- Filter stock and stock movement reports by products, warehouses, counterparties variants, and other specifications.

- This helps you stay aware of available, committed, or incoming goods.

- Plan purchases based on demand forecasts, your personal sales trends, and raw material consumption to avoid overstocking.

Warehouse Management Tools and Features

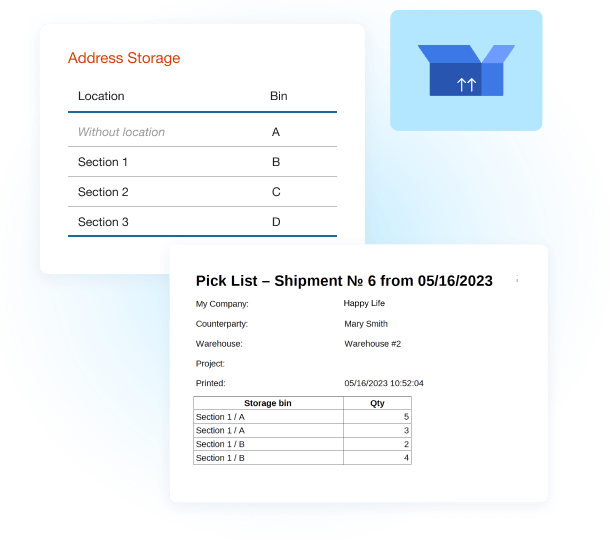

- Storage Bins: Assign bins to products and batches, and record a unique ID for each bin to help warehouse staff locate items quickly and accurately

- Barcoding: Generate or upload barcodes for products, batches, packaging, and storage bins to boost productivity and avoid errors

- Pick Lists and Packing Slips: Locate items quickly and ensure precise order fulfillment

- Reorder Points: Get automatic alerts when stock is low and need replenishment

- Negative Stock Restriction: Prevent stock levels from going below zero by restricting transactions that would decrease inventory beyond the available stock

Real‑Time Stock Management

Perform full and partial inventory counts across specific warehouses, and set statuses (e.g., to do, completed, postponed) to track progress

Generate and print the lists to monitor stock discrepancies within a set time frame

Create stock adjustments to address discrepancies, and write‑offs to manage damaged or expired goods

Helpful during receivings, shipments, transfers, inventory counts, and other warehouse operations

Enhance quality control, reduce costs, and avoid potential legal and reputational risks

Efficient Analytics and Insights

- Stock Report: View the inventory state for a specific date, broken down by products, warehouses, and storage bins

- Real‑Time Stock Levels: Track the actual stock levels, keeping informed about on‑hand, committed, or in‑transit goods

- Average Inventory Days: Access data on the average number of days goods remain in stock before being sold, helping optimize inventory turnover

- Stock Movement Report: Monitor the opening and closing stock over a defined period to track changes and manage stock efficiently

Kladana WMS Case Stories

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

In Kladana, we found the functionality we were looking for. In combination with affordability, it worked as a decisive factor. Another important area is tracking the amount of yield our company is getting. In this respect Kladana is suitable to our requirements, and we are going to start using the Financials module of the solution.

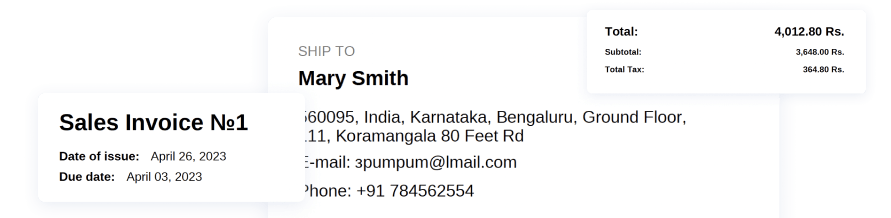

In Kladana we process sales orders, make sales invoices in pdf, and manage shipments. All bills of materials are stored in the software. All production stages are reflected in Kladana.

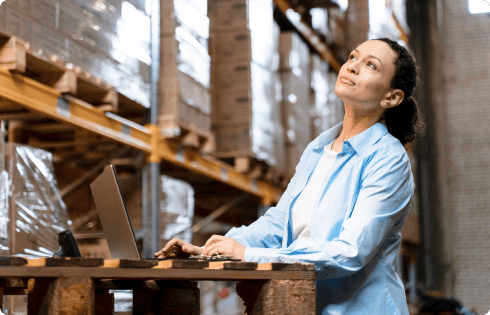

We have three warehouses: one for raw materials, one for production, and one for finished goods. We add the purchased materials to Inventory in Kladana, and the raw materials are transferred to production. In production, they are processed in a production order. Then the finished goods appear in another warehouse. Thus, 1,500 bottles are moved from one warehouse to another in a couple of clicks.

Smooth Processes and Workflows

Manage and track operations across multiple warehouses, including raw materials, WIP, finished goods, and products in various locations like branches or retail stores

Generate and customize warehouse documents (pick lists, price tags, thermal labels, supplier invoices) with personalized fields and label designs, then print them as needed

Set up approval processes and define access roles for employees to protect sensitive data and track every action taken in the system

Use workflow templates to automate routine operations by defining triggers that initiate specific actions, streamlining processes across your team

Kladana ERP with Free WMS Module

Affordable

The WMS module comes at no extra cost for Kladana users with paid plans. Enjoy a 14‑day trial, access the free plan, or get basic features for just $60/year

Integrations & App Catalogue

Integrate with third‑party platforms like WooCommerce, Borzo, and Zoho Books. Use the Kladana Online Order App for direct sales without a website. An API is also available for custom integrations

User‑Friendly Support and Onboarding

1–3 onboarding sessions based on the selected plan, with free support via live chat, email, or form submission for all paid plans, responding in 5–15 minutes

All Business Operations in One App

Manage warehouses, inventory, sales, purchase, and production seamlessly in one app. No need to switch between multiple solutions

Kladana WMS Testimonials

We have been using the service for a year. Previously we used an Excel to track products and stock. The interface is clear and simple. Customized templates and reports for printing — guys from Support can help you make them for free. Profit and loss reports, contacts cards, flexible access rights for employees, safe database — everything is great!

We’re a saree manufacturing factory, responsible for managing production, purchasing raw materials, storing and tracking them, and overseeing manufacturing and sales processes. Previously, we relied on spreadsheets, but constant errors made us exhausted. Kladana helps us to solve all these tasks now. And saves a whole bunch of time and effort.

FAQ on WMS

General Questions

An ERP (Enterprise Resource Planning) system integrates various business processes, such as production, sales, and inventory management, into a single platform. A WMS (Warehouse Management System), on the other hand, is specifically focused on managing warehouse operations, including stock control, order picking, packing, and shipping. WMS helps streamline warehouse workflows and provides real‑time insights to optimize efficiency, while ERP offers a broader view of business operations. However, ERP can contain a warehousing module which helps one manage all business processes in a single app.

To choose the best WMS, consider the specific needs of your business. Look for a cloud‑based software that integrates seamlessly with third‑party platforms, such as e‑commerce, accounting, and CRM. The right WMS should offer real‑time visibility into inventory, automate manual tasks, and provide powerful tools for order fulfillment, reducing costs and improving efficiency across your supply chain.

The four main types of WMS are:

- Standalone WMS: Independent system focused solely on warehouse management.

- Integrated WMS: A system that integrates with ERP or other software platforms for seamless operations.

- Cloud‑based WMS: A web‑based platform offering real‑time access, automation, and scalability.

- Hybrid WMS: Combines on‑premise and cloud solutions to optimize functionality and flexibility.

The six key steps in warehouse management include:

- Receiving: Goods are delivered and checked into the warehouse.

- Put‑away: Items are stored in their designated locations.

- Picking: Products are selected based on sales orders.

- Packing: Items are packed for shipment.

- Shipping: Goods are dispatched to customers.

- Returns Management: Handling returned items efficiently.

Key reports for efficient warehousing include:

- Stock Movement Report: Tracks the movement of goods across warehouses.

- Inventory Turnover Report: Measures how quickly inventory is sold and replaced.

- Order Fulfillment Report: Shows the accuracy and efficiency of order picking and packing.

- Demand Forecast Report: Predicts future stock needs based on trends and historical data.

WMS Solutions & Features

Kladana ERP works seamlessly with a single warehouse if that’s all you need. However, many entrepreneurs manage multiple warehouses for different purposes, such as specific production operations, or storing raw materials, finished goods, and WIP in different locations. You might also need to track goods in third‑party locations, or across company branches in different cities, or retail shops. In these cases, Kladana ERP allows you to specify and manage each warehouse individually.

Go to Settings → Warehouse, select the warehouse you want to manage, and edit its details. Here, you can add locations and bins to help you quickly locate items. By using pick lists with specific storage bins, your employees can process shipments, manage receivings, or fulfill sales orders more efficiently. For more details, check out our article on warehouse bins and address storage.

To implement barcoding, assign barcodes to products, batches, and storage bins. Use barcode scanning tools to automate inventory counts, order picking, and shipment processing. Barcoding increases accuracy and speeds up warehouse operations, reducing manual errors and improving real‑time visibility of stock levels.

A picking list is a document that details the products to be picked from the warehouse for a specific sales order. A packing slip is generated once the order is packed, and it includes information about the items in the shipment, ensuring accuracy during delivery and reducing errors in fulfillment.

Inventory & Stock

Managing warehouse inventory efficiently requires regular inventory counts, accurate stock tracking, and automation. Use a WMS with real‑time reporting to monitor stock levels, optimize storage space, and ensure orders are fulfilled on time. Set reorder points to automate stock replenishment and avoid stockouts.

You can perform inventory counts either manually or by using barcode scanning. Make sure all items are labeled with barcodes before starting. Once the counting is done, remember to create write‑offs or stock adjustments if you identify any discrepancies.

In WMS, you can find several types of inventory:

- Raw Materials: Materials and components used in production.

- Work‑in‑Progress (WIP): Items that are in the process of being manufactured.

- Finished Goods: Products ready for sale or distribution.

- MRO (Maintenance, Repair, and Operations): Supplies used to maintain warehouse operations.

Warehouse stock levels refer to the quantity of goods stored in the warehouse at any given time. Key stock levels include:

- On‑hand stock: Available inventory.

- Committed stock: Items reserved for orders.

- In‑transit stock: Goods being transferred to or from other locations.

- Backordered stock: Items that are temporarily out of stock.

Batch tracking in a warehouse involves assigning a unique batch number to a group of products produced or received at the same time. Use a WMS to track these batches through each stage of the supply chain, from receiving to storage, picking, and shipment. Batch tracking helps with quality control, traceability, and compliance, ensuring that products can be traced back to their origin if needed.

Go to the Stock or Stock Movement report. Use the Product filter to select the required raw materials, and apply any additional filters as needed. This will give you a complete overview of your stock.

Open the sales order and check the «Allocate order to committed stock» checkbox to reserve the product for that particular customer.

You can transfer specific goods from a source warehouse to a target warehouse. Before the transfer, you can check the quantity of products available for transfer.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce