Stock control, or managing your inventory, is a key part of keeping your business running smoothly. The goal? Make sure you have the right amount of stock at the right time without having too much or too little on hand.

When done correctly, stock control helps avoid two common problems: overstocking and stockouts. Both can seriously impact cash flow and customer satisfaction.

To put this into perspective, out‑of‑stocks account for 56% of the $818 billion lost annually due to inventory issues, which equals a staggering $456.3 billion. On the flip side, overstocks represent the remaining 44%, or $362.1 billion.

But here’s the good news: by managing stock better, your business can save a ton of money, work more efficiently, and keep customers satisfied.

Let’s dive in and break down stock control in detail, looking at different methods, systems, and the benefits it can bring to your business.

- What is Stock Control

- Stock Control Methods

- FIFO vs LIFO in Stock Control

- Inventory Control vs Inventory Management

- Classification of Inventory Control

- Stock Control Systems

- Tools and Technologies in Modern Inventory Control

- Key Features for Automation

- Benefits for Business

- Benefits of Using a Cloud‑Based Inventory Management System Like Kladana

- 5 Tips For Effective Stock Control

- Using RFID for Inventory Control, Stock Security and Quality Management

- Stock Ordering Process

- How to Control the Quality of Stock

- How To Administer Stock For Its Security

- How Can You Find the Right Stock Strategy

- Most Common Questions on Stock Control

What is Stock Control

Stock control is all about managing the flow of goods in and out of your business. It involves tracking what you have, how much you have, and where it is.

Businesses that rely on manufacturing, packaging, and transporting goods will have to track stock, have an idea about when to reorder, and ensure they always have enough products to meet customer demand without overloading their storage.

For those businesses, stock control is the backbone that provides smooth operations and makes sure customers are satisfied.

Types of Stock

Stock comes in many forms, depending on the nature of your business. Here are the most common types of stocks you’ll encounter:

- Raw Materials: The base materials used to produce your final products.

- Work‑in‑Progress (WIP): Items that are currently being manufactured but aren’t yet complete.

- Finished Goods: Products that are ready to be shipped and sold to customers.

- MRO Goods (Maintenance, Repair, and Operations): These are items that help maintain and repair equipment or facilities, such as tools or spare parts.

- Safety Stock: Extra inventory kept on hand to account for unexpected increases in demand or supply chain issues.

Why is Stock Control Important?

Stock control is a crucial aspect for businesses dealing with buying and selling products since it helps in different ways:

- Prevents Overstocks and Stockouts: Effective stock control helps your business avoid the costly mistake of having too much stock, which ties up your cash flow, or too little stock, which leads to missed sales.

- Reduces Wastage: Tracking stock so that the items don’t get wasted due to expiry or obsolescence, mainly if you are dealing with perishable goods.

- Boosts Profitability: With proper stock control, you can optimize your inventory levels, freeing up capital that would otherwise be tied up in excess stock.

- Enhances Customer Satisfaction: By ensuring the right products are always available when customers need them, you keep them happy and coming back for more.

- Improves Cash Flow: Stock control ensures you don’t have more inventory than necessary, which improves cash flow by freeing up funds for other areas of your business.

Stock Control Methods

You can adopt different methods to manage your stock efficiently. But, choosing the right one requires you to analyze its strengths and how they can help your business.

Let’s explore these in detail.

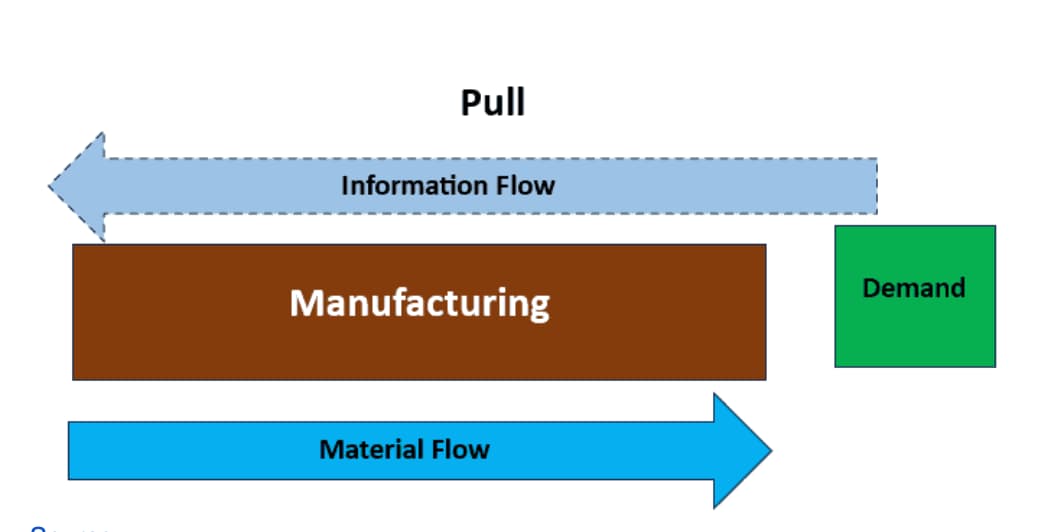

The Pull Strategy

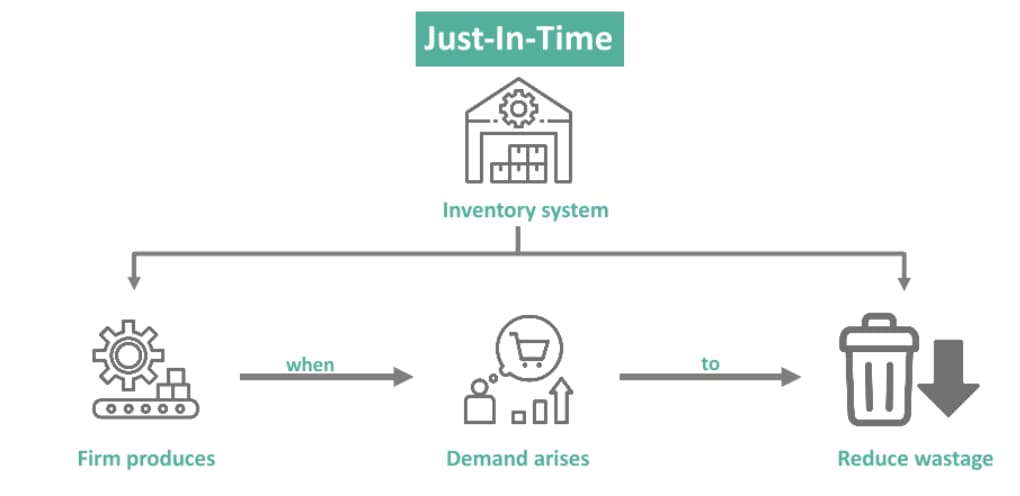

The pull strategy will require aligning stock replenishment directly with customer demand. It is a well‑timed process where each step happens only when there’s actual demand — a method similar to the just‑in‑time (JIT) approach.

Here, the stock is “pulled” through the supply chain based on real orders rather than being stocked in advance based on forecasts.

For instance, consider an eCommerce fashion store that operates using JIT principles.

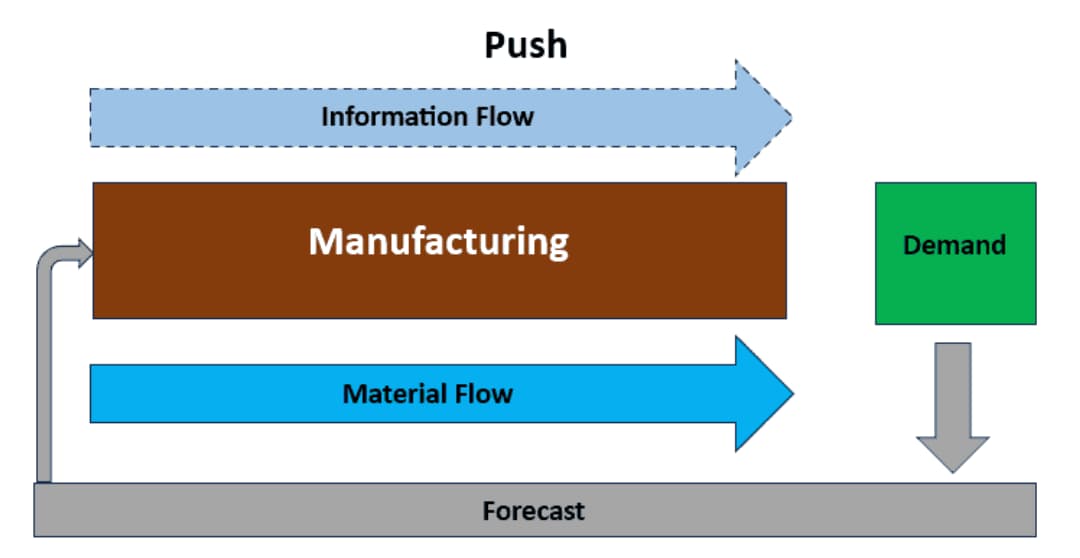

The Push Strategy

This strategy relies on anticipating future demand based on past data to predict what customers will need. You’ll have to look at previous patterns to get ahead of future trends.

Take, for example, an online retailer that specializes in holiday decorations can analyze sales data from previous years to predict the surge in demand for festive items.

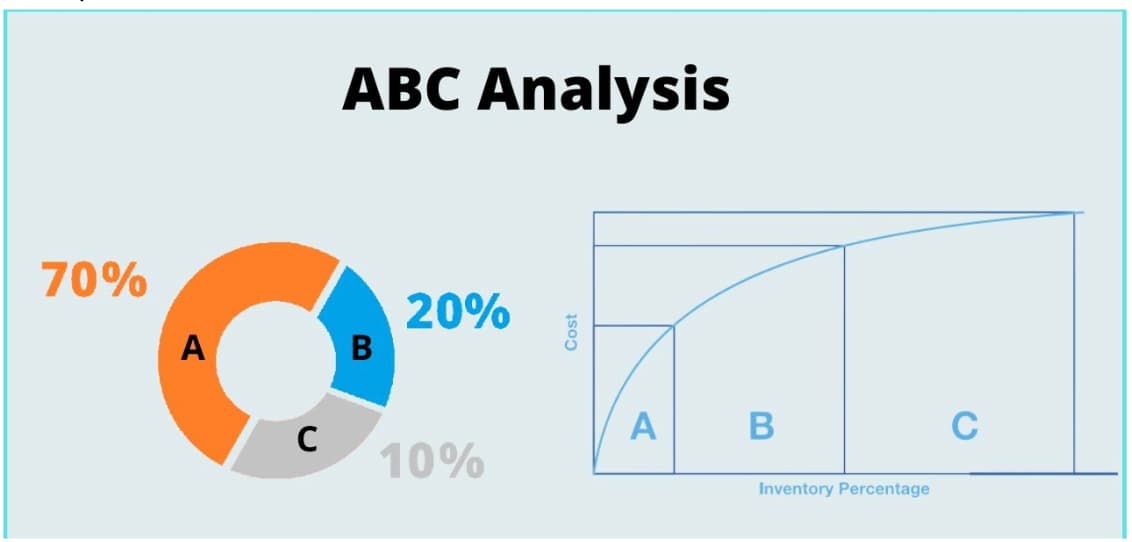

ABC Inventory Analysis

This is an inventory analysis method that categorizes stock into three tiers based on its value and importance:

A‑items — This makes up a smaller portion of your inventory but has the most significant impact on revenue.

B‑items — Mid‑value items falling between A and C in terms of both value and quantity.

C‑items — Low‑value items make up for the majority of your stock but contribute less to revenue.

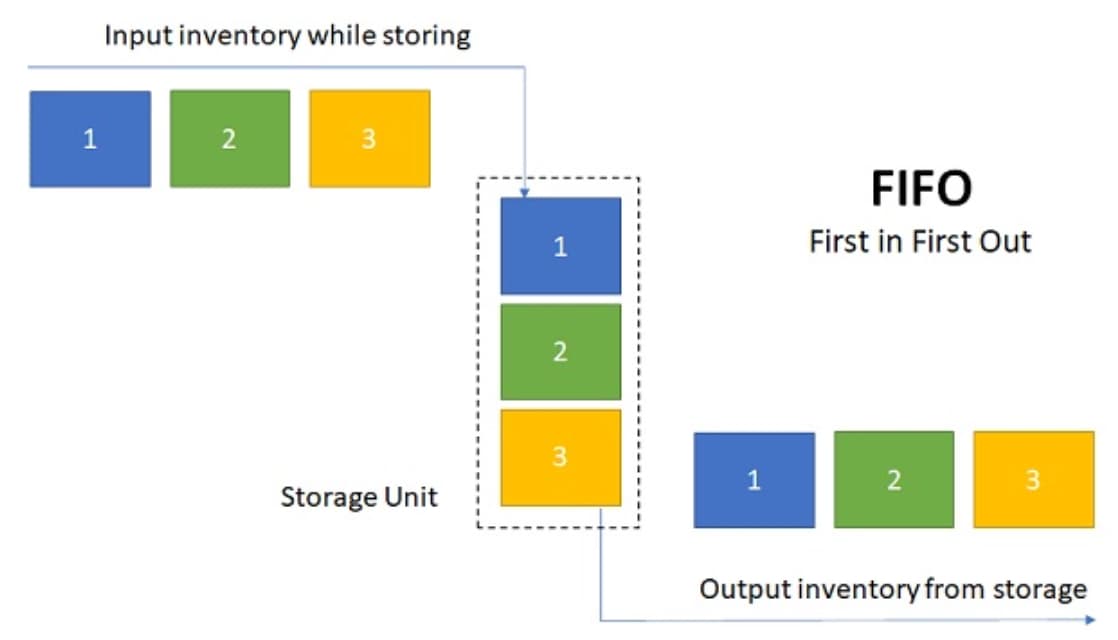

FIFO (First In, First Out)

FIFO (First In, First Out) needs you to manage inventory in a way that sells or uses the oldest stock first, reducing the risk of spoilage, especially for perishable goods.

It’s helpful for industries like food, pharmaceuticals, etc., that have products with expiration dates.

Just‑In‑Time (JIT) Stock Control

This method requires focusing on ordering stock only when it’s needed. It is an ideal method for businesses looking to minimize storage costs and avoid having too much capital tied up in inventory.

For example, manufacturing businesses can allocate space and cost to operate lean and efficiently.

Economic Order Quantity (EOQ)

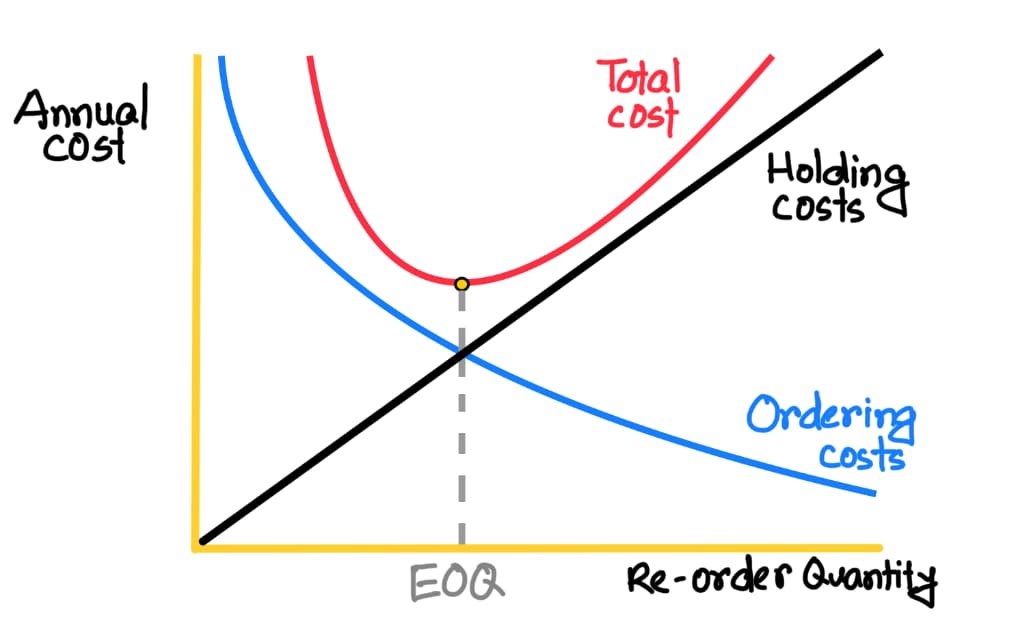

Economic Order Quantity (EOQ) is a stock control method that emphasizes optimal order size to minimize costs associated with ordering, holding, and stock shortages.

It’s a formula‑driven approach that needs striking a balance between ordering too frequently (which increases costs) and holding too much stock (which ties up cash flow).

FIFO vs LIFO in Stock Control

FIFO (First In, First Out) ensures older stock is sold first, reducing the risk of spoilage or obsolescence. LIFO (Last In, First Out), on the other hand, assumes the most recently purchased items are sold first. While both are methods of valuing and controlling inventory, their financial and operational impact differs significantly.

- Impact on Costs and Profitability: FIFO usually lowers the cost of goods sold (COGS) in inflationary periods, resulting in higher profits on paper. LIFO raises COGS during inflation, which reduces reported profits but can create tax advantages.

- Compliance Considerations: FIFO is globally recognized and permitted under both IFRS and GAAP, making it the safer choice for international businesses. LIFO is restricted to U.S. GAAP, which limits its use for companies operating in multiple regions.

- Best Use Cases: FIFO works best for perishable goods such as food and pharmaceuticals, where expiration is a real risk. LIFO is suited for industries facing rapid price increases, such as petroleum or construction materials, where tax savings can offset the complexity.

- Cash Flow Implications: Under LIFO, companies retain more cash in times of inflation because of lower taxable income. FIFO, while boosting profitability, can lead to higher tax obligations.

Inventory Control vs Inventory Management

When it comes to handling stock, there’s a fine line between inventory control and inventory management.

Here’s a quick comparison:

| Aspect | Inventory Control | Inventory Management |

Focus |

Ensures stock levels are accurate and accounted for |

Oversees the entire process of managing and forecasting stock |

Objective |

Prevents stock discrepancies, theft, or spoilage |

Ensures that the right products are available at the right time |

Scope |

Limited to monitoring current stock and tracking items |

Broader, involving demand forecasting, ordering, and supplier management. |

Responsibility |

Deals with counting and safeguarding physical stock |

Requires planning, purchasing, and optimizing stock flow |

Key Metric |

Accuracy of stock levels |

Efficiency of stock turnover and availability |

Classification of Inventory Control

Inventory control can be classified into multiple frameworks depending on how businesses track, organize, and secure stock. Understanding these categories helps companies choose systems aligned with their operations.

- Perpetual vs Periodic Control — Perpetual systems record transactions in real time, suitable for high-volume businesses. Periodic control involves scheduled counts (monthly, quarterly) and works better for SMEs with simpler operations.

- Centralized vs Decentralized Control — Centralized systems maintain inventory records at one location, ensuring consistency. Decentralized systems distribute control across branches or warehouses, increasing flexibility but requiring tighter coordination.

- Manual vs Automated Control — Manual tracking relies on spreadsheets and human checks, which may be affordable but error-prone. Automated control with ERP or WMS ensures accuracy and saves time with real-time data.

- Quantitative vs Qualitative Control — Quantitative measures include stock counts, reorder levels, and turnover ratios. Qualitative control ensures items meet storage and handling standards (e.g., food safety, shelf conditions).

- Hybrid Approaches — Many SMEs adopt a mix, such as automated quantitative tracking with manual qualitative checks, striking a balance between cost and accuracy.

Stock Control Systems

Stock control systems provide the necessary tools and methods to manage inventory accurately and efficiently.

There are two main types of systems: periodic and perpetual, each with its own advantages.

Let’s break them down.

Periodic System

The periodic system in stock control requires counting inventory at regular intervals, such as monthly or quarterly. It is ideal for smaller businesses that don’t need real‑time tracking or have lower transaction volumes.

Perpetual System

The perpetual system is more advanced and provides real‑time updates on inventory levels. Every time a product is sold or received, the system automatically adjusts stock numbers.

Businesses dealing in high transaction volumes, like retail or eCommerce, can know exactly what they have on hand to reduce the chances of stockouts or overstocking.

How to Choose System

Now, when you have these two options, the choice would certainly depend on your business’s needs.

Here are a few other points to consider:

- Business size and transaction volume

- Budget

- Inventory accuracy needs

- Complexity of operations

- Integration with existing tools like accounting or point‑of‑sale systems

- Frequency of stock updates

📘 Recommended Read: Learn how SMEs can stay competitive with Managing Production in SMEs.

Tools and Technologies in Modern Inventory Control

Modern inventory control has shifted from manual spreadsheets to technology-driven systems that provide accuracy, efficiency, and real-time visibility. Leveraging the right tools allows SMEs to scale without losing control of stock.

- ERP Systems (e.g., Kladana) — Unify sales, purchases, and stock into one dashboard, enabling automation of orders, live reporting, and integration with accounting.

- MRP Software — Connects material planning with production schedules, ensuring the right materials are available when needed. This reduces bottlenecks and production delays.

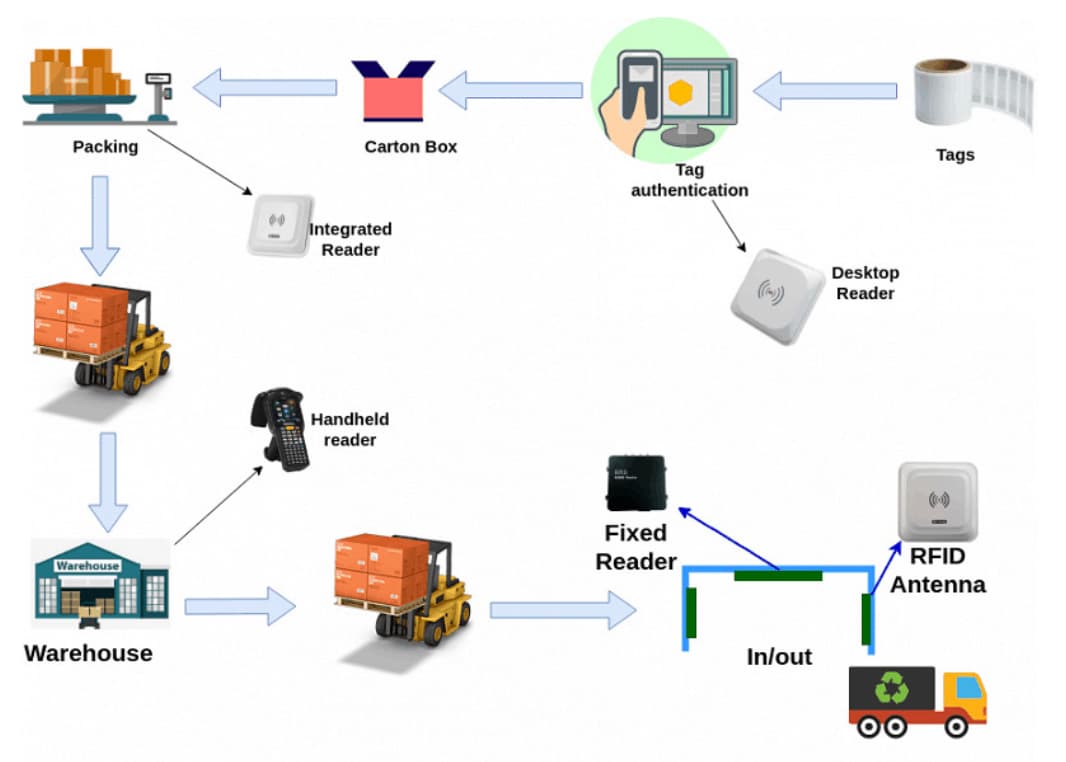

- Barcoding & RFID — Automate identification, reduce manual entry errors, and speed up audits. RFID adds real-time tracking and enhances security in large warehouses.

- AI & Forecasting Tools — Use historical sales data and market trends to forecast demand more accurately, preventing overstocking or stockouts.

- IoT Sensors — Monitor environmental conditions like temperature and humidity, essential for pharmaceuticals, food, and agriculture products.

- Cloud Integration — Cloud-based inventory tools allow multi-user access, real-time collaboration, and scalability for growing businesses.

Together, these tools give businesses agility, visibility, and control over operations, helping them compete with larger enterprises.

Key Features for Automation

Automating stock control improves the way your business manages inventory with the below features in a stock control automation tool:

- Real‑time inventory updates based on automated tracking of stock levels

- Automated reordering based on stock levels

- Demand forecasting to predict future stock needs

- Low stock alerts share automatic notifications on low stock levels

- Detailed reporting and analytics for in‑depth insights into stock movement

When you use an automated system like Kladana, it helps to generate stock reports within minutes. Check this video out to know how you can automate stock reporting:

Benefits for Business

Automating stock control can affect how your business operates since it contributes to both operational and financial advantages.

Here are some key benefits of automation in stock control.

- Enhanced Efficiency: Simplify repetitive tasks like stock counts and reordering, which will free up valuable time for your team to focus on more strategic activities.

- Better Accuracy: Reducing human errors in stock tracking for more reliable inventory data and fewer discrepancies.

- Better Cash Flow Management: Optimal stock maintenance levels ensure that you don’t tie unnecessary funds to excess inventory or lose sales due to stockouts.

- Real‑Time Data and Insights: Businesses get immediate access to current stock levels for better decision‑making and accurate forecasting.

- Optimized Space Utilization: Helps keep stock levels in check to avoid overcrowding storage areas.

Ready to put theory into practice? Use Kladana’s real‑time stock control module — automate ordering, get live inventory insights, and eliminate manual errors.

Benefits of Using a Cloud‑Based Inventory Management System Like Kladana

With real‑time insights and automated tools like Kladana, you can stay ahead of demand as it helps unlock the following benefits:

Quick Access: Cloud‑based stock management systems help you monitor and manage stock levels from any device on the go.

Real‑Time Updates: Tools like Kladana track inventory levels in real time, so you always know what’s in stock and can make quick yet informed decisions.

Ensured Scalability: As your business grows, a cloud‑based inventory management system can easily scale to provide flexibility in managing and expanding inventory.

Reduced IT Costs: Eliminate costly on‑site infrastructure, as you need no servers or maintenance for cloud-based systems.

Top‑Notch Collaboration: Cloud‑based inventory systems enable multiple team members to access and update stock information in real time, driving efficiency across departments.

Gain control of your warehouse stock and inventory with an all‑in‑one ERP solution.

5 Tips For Effective Stock Control

Keeping your stock in check can feel overwhelming. Especially because too much inventory ties up cash, and too little would risk disappointing your customers.

These seven tips can help refine your approach and run a well‑managed business stock.

Prioritize Best Sellers

Start by focusing on your top‑selling items, as running out of them can mean lost revenue. Set up tighter monitoring and automatic reordering for these key products to keep them moving seamlessly.

Use Real Data

It’s easy to think you “know” what’s selling and what’s not, but relying on instinct alone is difficult. Use data from your sales history to guide your decisions based on patterns like seasonal demand or rising trends.

Set Minimum and Maximum Stock Levels

Set clear boundaries for how much stock you need at any given time to stay away from overbuying or understocking. Set minimum stock levels so you know when to reorder, and maximum levels to prevent tying up cash in unsellable goods.

Schedule Regular Stock Checks

Schedule regular manual stock checks to verify what’s really on your shelves. Catching discrepancies early will cause fewer surprises and smoother operations when it comes time to fulfill orders.

Get Rid of Dead Stock

Dead stock is just money sitting on the shelf, collecting dust. If a product isn’t selling, it’s time to clear it out — whether through discounts, bundles, or promotions. For instance, bundle slow‑moving items with best sellers.

Using RFID for Inventory Control, Stock Security and Quality Management

Radio Frequency Identification (RFID) tags each product with a chip that gives you real‑time updates on what’s in stock, what’s been sold, and what needs to be reordered.

Don’t just use it to track; use it to boost security.

With RFID, you can get the following:

- Improved stock security makes it easier to monitor your stock and reduce the risk of theft or loss by tracking items as they move.

- Faster inventory audits give you quick, accurate updates without the hassle of manual checks.

- Better quality control of products throughout the supply chain reduces errors in packaging, handling, and shipping.

- Faster identification and retrieval are needed in large warehouses, where finding an item quickly is crucial for timely deliveries.

Stock Ordering Process

Below, we’ve outlined a clear, step‑by‑step process for mastering your stock ordering process, with a focus on timing and precision.

Step 1: Check Your Inventory

Know what you have before placing any orders to see what’s running low and what’s not moving. It’s basic to avoid overstocking items that are gathering dust and focus on products that actually sell.

Inventory counting is a breeze with Kladana. Get to know how you can do it, too!

Step 2: Forecast Demand

Inventory management tools will help you analyze real data to predict what you’ll need. Those past sales and trends help estimate upcoming demand. Make smart decisions and stay ahead of the game.

Step 3: Set Reorder Points

Don’t wait until you’re almost out of stock. Set automatic reorder points so your system triggers an order when you hit a certain threshold so that you have enough stock without over‑ordering.

Step 4: Choose a Supplier and Place the Order

Work with trusted suppliers who can deliver on time and offer good terms. Keeping a strong relationship with them can also help you negotiate better deals and get faster deliveries when you’re in a pinch.

Step 5: Track the Order

After placing an order, start tracking it. Stay updated on the shipment’s progress and be ready to react in case of delays so that you’re always prepared and can adjust if necessary.

Step 6: Receive and Inspect Stock

Double‑check your order to make sure you’ve received what you ordered. If anything is damaged or missing, act immediately to resolve it with your supplier.

Step 7: Update Inventory

Once everything’s in place, update your system to reflect the new stock levels. Use automation tools to keep your records up to date to work with accurate numbers.

How to Control the Quality of Stock

Controlling stock quality is about maintaining high standards throughout the product’s lifecycle — from storage to delivery. You’ll have to make sure that every item meets your quality expectations, minimizing losses and customer dissatisfaction.

Here are simple ways to control the quality of your stock:

- Frequently check stock for signs of damage, spoilage, or defects.

- Ensure that products are stored in conditions that preserve their quality (e.g., temperature humidity control).

- Train staff on correct handling procedures to prevent damage during stocking, picking, or shipping.

How To Administer Stock For Its Security

You don’t just have to count and deliver the stocks but also ensure their security. You’ll have to protect your goods from theft, loss, or damage.

Strong stock security measures not only provide security but also keep inventory data accurate and reliable.

Here are some major practices you can adopt for stock security:

Ensure restricted access to limit access for authorized personnel only.

- Install CCTV and surveillance to monitor high‑risk areas and deter theft.

- Adopt inventory management systems to track stock movement in real time and detect discrepancies.

- Implement RFID tracking as discussed earlier, to monitor inventory movements and reduce the chances of theft.

- Provide physical security via secure locks, alarms, and regular checks on storage facilities.

How Can You Find the Right Stock Strategy

You must know how much stock to keep on hand to balance costs and meet demand. These decisions depend on your business model, supplier reliability, and the nature of your products.

Below, we are comparing two common approaches to stock: keeping minimal stock vs holding larger stock levels.

| Stock Strategy | Advantages | Disadvantages |

Minimal Stock (Just‑in‑Time) |

|

|

When to Use |

For fast‑paced industries |

|

— |

— |

— |

Large Stock (Bulk Buying) |

|

|

|

|

|

|

When to Use |

When sales patterns are hard to predict, or products don’t spoil easily |

|

Most Common Questions on Stock Control

Let’s take a quick look at frequently asked stock control questions.

What is stock control?

Stock control involves managing inventory levels to prevent overstocking or stockouts.

Why is stock control important?

With a stock control system, you can meet customer demand while minimizing costs and excess stock.

How are stock control and inventory management different?

Stock control focuses on tracking current inventory, while inventory management covers the full process from ordering to delivery.

What are the main methods of stock control?

FIFO, JIT, ABC analysis, and economic order quantity (EOQ).

How often should stock be audited?

Perform regular audits either periodically or in real‑time with automated systems to maintain accurate records.

Does stock control improve cash flow? How?

Yes! It helps optimize stock levels, reducing the cash tied up to excess inventory.

How to prevent overstocking?

Use demand forecasting and set maximum stock levels to avoid over‑ordering.

What are the benefits of automated stock control systems?

It improves accuracy, reduces human error, and provides real‑time updates on stock levels.

What is the purpose of safety stock?

Safety stock acts as a buffer to prevent stockouts during unexpected spikes in demand.

How does stock control reduce waste?

Managing inventory levels efficiently helps businesses avoid holding onto stock that may become obsolete or expire.