A scenario we’ve witnessed so many times. A person gets inspired by an idea, enthusiastically opens a business, and does everything on a budget to save money. They get their first sales, and their family and loved ones are proud of them. The entrepreneur is making plans for the future, looking for investors, when suddenly major problems arise.

A large batch of expensive goods is lost in the warehouse, a client receives the wrong variant of an item, a hyped product was purchased without first analyzing customer demand, barcodes aren’t scanned correctly, and after each inventory count 10% of the stock does not add up. This nightmare is growing like a snowball.

In this article, we’ll examine how to reduce such risks and manage inventory wisely. We’ll answer 11 of the most common inventory management questions — in short for those who want to skim the basics, and in detail for those who’re eager to go deeper. Use the table of contents below to switch to the most relevant questions.

For the most patient and attentive readers — you can download a 100% free inventory management template below.

- What Is Inventory Management and What Are SKU, UOM & COGS?

- How Can Inventory Management Help a Business?

- What Are the Consequences of Incorrect Inventory Management?

- What Are Different Types of Inventory?

- What Are Inventory Management Methods?

- What Are Inventory Management Techniques?

- How Does Inventory Management Work Step by Step?

- What Are Inventory Management Challenges?

- What Are the Best Inventory Management Practices?

- What Are the Trends & the Future of Inventory Management?

- Summing up

- Frequently Asked Questions on Inventory Management

Inventory Management Question #1. What Is Inventory Management and What Are SKU, UOM & COGS?

In short: Inventory management basics reflect the state of all trade operations: procurement, storage, sales, stock movement, returns, and others. If one doesn’t know what product groups are available, they can’t make the right decision to purchase or write off goods.

In detail: Inventory control is about tracking and managing all items in a company’s facilities (warehouses, stores, factories) & outside (suppliers’ & customers’ facilities). The main idea is to keep a record of every single item in order not to run out of supplies suddenly and not to deal with excess of goods that are soon going to expire.

When dealing with inventory management, you will come across multiple terms. Let’s examine some of them.

SKU

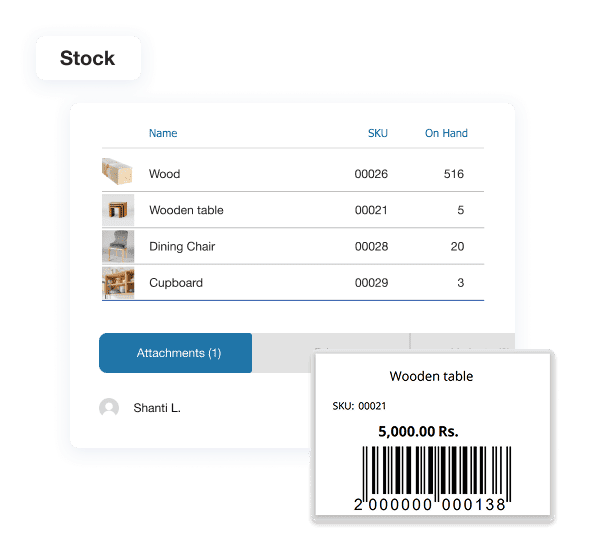

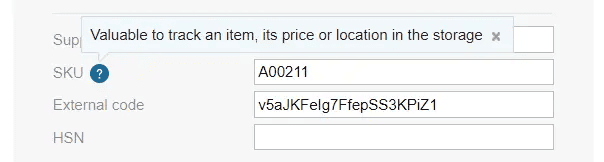

Stock keeping unit is, simply speaking, a personal ID of an item used to distinguish goods from one another and track inventory. Usually, SKU consists of 6–9 digits & letters. We explained the difference between SKU & serial number in our post on LinkedIn.

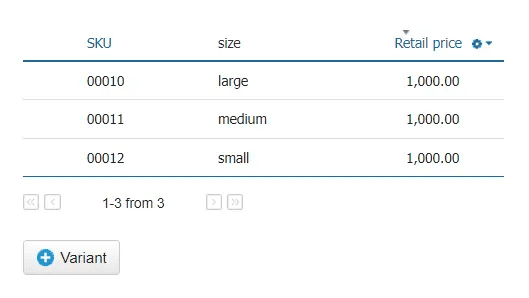

Item Variant

A version of the same good with alterations like colour, size, material, etc.

UOM

Unit of measurement lets one indicate how an item is measured in kilos, grams, pieces, liters, sacks, bundles, etc.

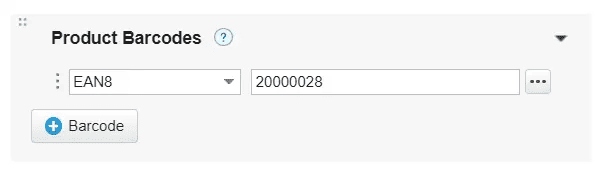

Barcode

A combination of unique symbols that indicates a certain product. Barcodes are used for scanning and tracking inventory items.

Reorder Point

Level of stock that can be set in order to keep enough product on hand. Whenever this level is reached, it’s high time to order new supplies manually or automatically. It’s calculated the following way:

Reorder point = average daily usage × average lead time in days

Bundle & Kit

Way of grouping items. Thus one can sell a bundle of 6 lemonade bottles with different flavours, or a kit containing a keyboard & a mouse. A bundle is sold under one SKU.

Unit Cost

The prime cost of one produced item which is calculated the following way: raw materials cost + operational cost + labour cost.

COGS

The cost of goods sold also tells us about the price of finished goods. It contains all direct costs, including delivery, packaging, tooling, and equipment maintenance. Marketing, distribution, and other indirect costs are not included.

Demand Forecasting

If proper software is used for inventory management, its automation tools usually allow one to make forecasts regarding the future need of items. It’s based on sales data and helps one plan purchases, sales, and production better.

Dead Stock

Items that are in stock for too long and remain unsold. They take space and don’t bring profit to the company. Usually, they are written off or sold at a large discount.

Stock-Taking (Inventory Counting)

A process of checking and recording all inventory items on hand. Whenever any discrepancies are found, goods can be written off, or stock adjustments can be made.

Kickstart Your Inventory Setup — with Help from the Pros

🧩 Learn by doing. Whether you’re building a system or fine‑tuning stock reports — our inventory checklist gets you started.

Also includes a promo code for 30‑day trial of Kladana (no credit card needed).

Inventory Management Question #2. How Can Inventory Management Help a Business?

Some entrepreneurs ask whether basic inventory management actually works or if it’s a tricky software owners’ trap. So, let’s scrutinize inventory management benefits which are not that evident.

In short: Inventory control makes all warehouse operations transparent: everything is recorded, calculated, and in its place. An entrepreneur can see what products are the most & the least profitable, stop theft among their employees, and make customers satisfied more than ever.

In detail: A few inventory management benefits must be highlighted here.

- To track stock transactions

One will know when the purchase was made, how much they paid for the goods when they sold products, and how much revenue they received.

After nearly nine months of using Kladana, one of the most rewarding moments came last month when we calculated our profit. A standout feature in the sales module allowed us to analyze profit margins for each order. It was amazing to see the system provide detailed insights, such as logistics percentage, gross profit (GP) ratio, and net profit ratio. This level of transparency and data accuracy was a game changer.

- To systematize purchases & increase profit margins

One is aware of how many items are left in stock. This will help one buy only what is in demand. Thus, inventory management can lead to profit maximization.

I used to sell 80 beauty care goods on marketplaces. I tried to utilize Excel sheets, but inevitably made crucial mistakes. Then i realized that i could process no more than 20 products manually.

After six months of using Kladana, i started selling 300 goods, and the turnover increased from $23,000 up to $57,000. I also analyze what goods are the most and the least profitable ones.

- To stop freezing money

After optimizing purchases, there will be no dead stock anymore, so one will be able to manage working capital wisely: reduce warehouse costs, and increase profitability.

In Kladana, we analyze each customer and scrutinize what and how they buy. Sometimes the seller wants to purchase a certain product, but according to our data, it sells badly. Then we discourage them and advise them to pay attention to other goods. Or, for example, we monitor new products and offer to try them. Now those who are just about to open their first gadget shop ask us to pick up a showcase for them.

- To increase customer satisfaction

When goods are not properly calculated, entrepreneurs often have to cancel sales orders, prolong delivery time, and make returns in case of mixing product variants. Eventually, customer dissatisfaction leads to bad reviews and negative comments on social media.

- To reduce the likelihood of staff fraud

Fraud or theft is harder to spot when processes are in disarray. Inventory management will allow one to quickly determine the causes of shortages and identify dishonest employees. One will be able to control inventory and understand how much money should be in the cash register at the end of the day.

Kladana stopped the theft in our company. When we switched to Kladana, many facts about dishonest employees came to light. If all processes in the company are transparent, and every action is reflected in the system, employees work differently, and the atmosphere changes.

- To deal with seasonal demand & a wide product range

Inventory management is especially necessary in clothing and footwear stores, auto parts, building materials, and grocery stores.

Inventory Management Question #3. What Are the Consequences of Incorrect Inventory Management?

In short: Incorrect inventory tracking will lead to supply failures, cash flow gaps, wrong management decisions, and, ultimately, loss of money and time.

In detail: It will become unclear how many products are in stock and in which warehouse they are located, what goods are on display, and which items one will run out of soon. In addition, the company can be fined if, for example, a customer receives expired goods.

We have a large range of goods — 10 000+ items. The goods were kept in the warehouse for weeks, employees did not have time to put products on sale, and sometimes they simply forgot about it. It took 2-3 working days to place 50 products on the marketplace, and after automation in Kladana, it took 2-3 hours. Also, the company’s annual turnover increased by 103%.

Now, if we look at the possible negative outcomes more thoroughly, we can point out the following issues:

- Dead Stock

Poor inventory management can quickly lead one to storing items that customers buy unwillingly. It may seem ok at the start, however, even if an entrepreneur has large warehouses, sooner or later they will get occupied with goods that no one wants.

- Lack of Goods in Demand

Incorrect inventory management can lead to multiple problems: one may forget to purchase supplies in time, not monitor expiry dates, miss theft, waste & scrap, etc.

- Excess of Goods

Sometimes, entrepreneurs buy too many raw materials or hyped products. Later, they find out that they don’t need them. However, the warehouse is already cluttered.

Inventory Management Question #4. What Are Different Types of Inventory?

In short: Products, services, raw materials, and MRO.

In detail: Now let’s go over everything in order.

⚙️ Raw Materials

Fabric, cogs, auto parts, foodstuff, and other items needed to produce goods.

📦 Packing Materials

Boxes, bags & bubble wrap can be considered raw materials, or represent separate inventory units.

🔄 WIP

The work-in-progress inventory indicates goods that are currently being produced but are not finished yet.

🎁 Finished Products

Produced goods that can be stored, sold, etc.

🧰 MRO

Maintenance, repair & operations inventory consists of tools, equipment, spare parts, uniforms, and such services as cleaning.

🚚 Services

Packing, delivery, assembling, and other services can have their SKUs & other identification.

Inventory Management Question #5. What Are Basic Inventory Management Methods?

In short: There are two main methods of keeping inventory records: periodic inventory management and perpetual inventory management.

In detail: To make the difference clearer, we suggest comparing the two methods.

|

Periodic Inventory Management

|

Perpetual Inventory Management

|

|

Vikas owns a souvenir store He uses the periodic inventory management method. Using a notebook, he writes down the goods received from a supplier with the total cost. Vikas calculates profit as the difference between revenue and costs. |

Naomi runs a clothing store She follows the perpetual inventory management method. Naomi records the name and price of each item, as well as the number of items sold and stock. |

|

Stock Vikas knows that he has $179 worth of goods left. But he has to calculate how many T‑shirts and mugs he has left, and their costs. |

Stock Naomi can clearly see that she has 10 T‑shirts worth $22 and 20 blouses worth $68 left. |

|

Procurement Vikas monitors what products are left in short supply, but he doesn’t know exactly how quickly the goods have been sold out. So, Vikas makes his purchase ordering decisions based on approximate data. |

Procurement Naomi counts the difference between the receiving of goods and the sales. This way she can see how quickly her products are being sold out and which batch is about to run out. She makes purchase orders from the supplier based on accurate data. |

|

Analytics Vikas assesses the profitability of a retail outlet based on data on income and expenses. At the same time, he doesn’t know exactly how to expand the product range, how to better control his staff, and reduce shortages. |

Analytics Naomi assesses demand based on reports on revenue for the period, the number of goods sold, and changes in sales activity. She can see at what stage the shortage occurred. |

|

Pros Vikas knows the revenue and profit. |

Pros Naomi knows the revenue, profit, stock, which items are sold better, and at what stage there was a shortage. This data allows her to analyze the efficiency of the store and gives her an understanding of how to increase profitability. |

|

Cons There is no accurate data about stock and reasons for shortages. It is impossible to analyze the store’s performance. |

Cons It is inconvenient to keep records manually. Naomi needs inventory management software. |

We’ve made our top 20 inventory management software. Choose the most affordable and feature-enriched one. Use our comparison table to weigh all the pros and cons.

Inventory Management Question #6. What Are Basic Inventory Management Techniques?

In short: The choice of a technique depends on the business type, customer demand, seasonality, etc. Some companies prefer one and only technique, while others mix them, or try different ones until they find the most suitable solution.

In detail: There are various basic inventory management techniques and approaches but we shall focus on 11 most widely implemented ones.

| Technique | Description | Pros | Cons |

|

1. ABC |

Goods are segmented into three groups according to their profitability, where A accounts for the best‑performing items, B — mid‑level, and C — the least‑performing products. |

— Focus on the profit margin — Low error level due to the simplicity of the technique |

— Products are not analyzed according to other factors such as ranking of goods by customers, seasonal demand, etc. — No demand forecast is made |

|

2. FIFO — First In, First Out |

Goods that were received or produced earlier are being sold first. |

— Simple & logical inventory control — Products won’t be kept in the far corners of warehouses or backs of shelves |

— Isn’t suitable in case of volatile pricing & inflation isn’t taken into account |

|

3. FEFO — First Expire, First Out |

Goods that are going to expire sooner are being sold first. |

— Suitable for goods with expiry dates — Waste and expired products are minimized |

— More complex warehousing management |

|

4. LIFO — Last In, First Out |

Goods that were received or produced recently are being sold first. |

— Suitable for seasonable trade or hype goods demand for which increases rapidly |

— Earlier received or produced goods expire or get broken, and they must be written off or sold with a large discount |

|

5. JIT — Just‑In‑Time |

Storing as little goods as possible. Raw materials are purchased only when they are needed for production, and goods are purchased when a sales order occurs. |

— Waste and expired products are minimized — Money on warehousing (storage, transfers, stock‑takings) is saved |

— Insufficient products & raw materials in case of multiple or urgent orders — Customers & production employees have to wait longer for the new supplies |

|

6. JIC — Just‑In‑Case |

An opposite inventory management technique which involves storing as many goods as possible. |

— A company won’t run out of products suddenly |

— Expired or out‑of‑order goods on hand — High expenses on warehousing & labour — Cash flow issues may occur due to the fact the company keeps a lot of unsold goods — No work is done on consumer demand prediction |

|

7. Dropshipping |

Goods are stored in the supplier’s facilities. Whenever a customer places a sales order, the supplier ships an order directly to the customer. |

— Money on warehouse lease, employee wages storing & processing goods are saved, overheads and carrying costs are no longer a headache — Suitable for micro companies that want to try their hand at sales |

— Low level of control over the goods: they can be damaged, shipped later than planned, etc. — The entire flow depends on a third‑party company |

|

8. EOQ — Economic Order Quantity |

Having an adequate number of items on hand. |

— Running inventory management procedures timely and cost‑savvy |

— Isn’t suitable for seasonal trade — Doesn’t allow to adapt to fast‑changing consumer demand |

|

9. Safety Stock |

Having extra stock on hand may become helpful in case demand forecasts turn out to be inaccurate or other factors will influence customer demand. |

— Stockouts are minimized |

— Storing problems due to excess of goods — Increased write-offs due to possibly expired items |

|

10. Consignment |

Products are transferred to third‑party stores. Only after they are sold, the owner receives their money. If goods are not sold, they are returned to the owner. |

— Money on storage can be saved — Customer demand can be measured in case of new item release |

— There is no actual money in the cash flow before the first sales occur |

|

11. Backordering |

Sales orders are accepted even when there are no items on hand — they are to be produced or purchased. |

— Customer expectations are met |

— If a company has many backorders, shipment delays are inevitable. Thus, a company will lose the trust of its clients. |

✅ Thinking of switching from manual methods to a proper inventory system?

Our checklist + 30‑day trial help you test and transition smoothly.

Inventory Management Question #7. How Does Inventory Management Basics Work Step by Step?

In short: There are different approaches with 3–10+ steps required. A company may use any model that seems more applicable to its business routines.

In detail: We are going to describe roughly seven inventory control stages.

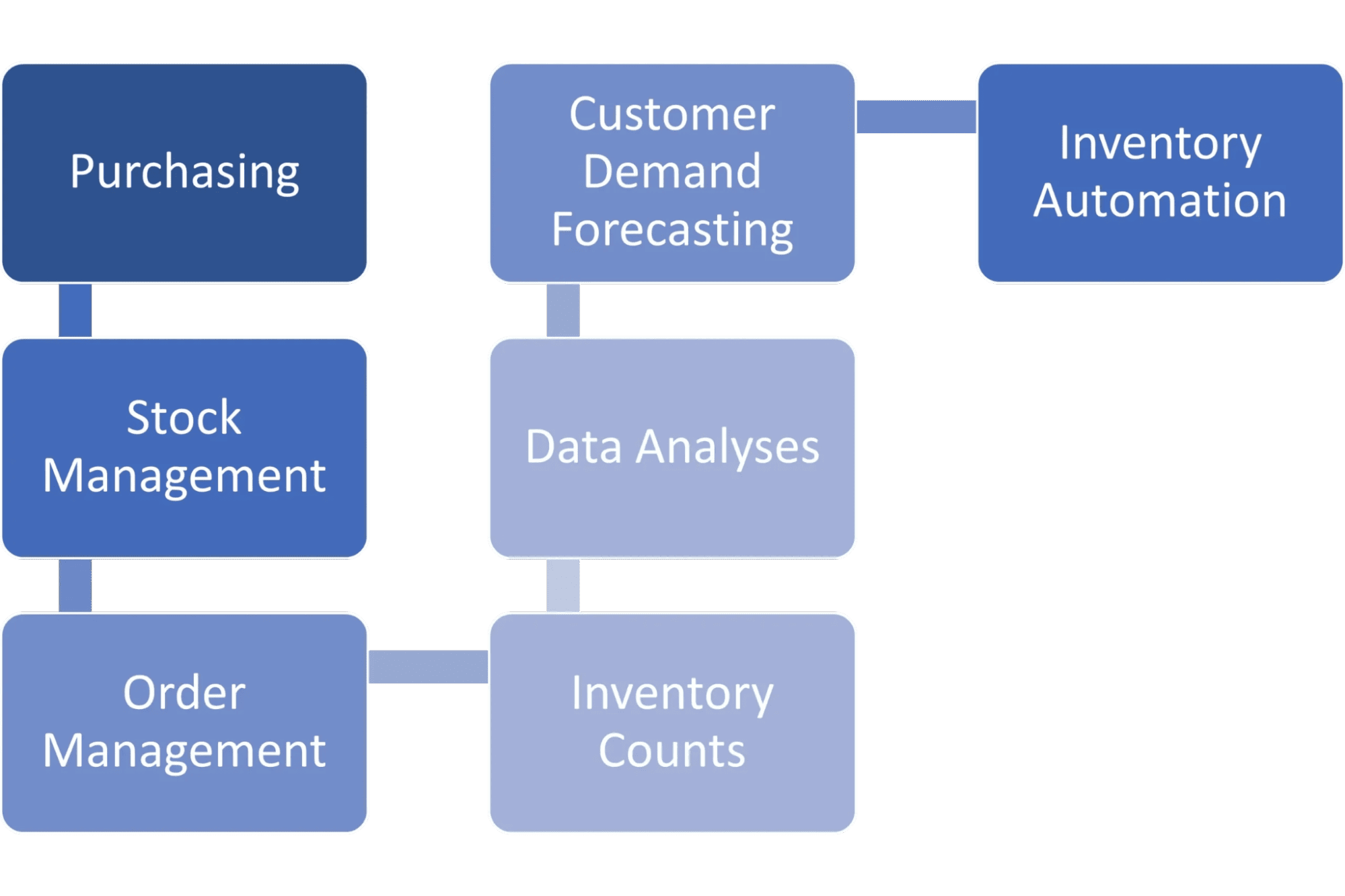

Stage 1. Purchasing

Products are bought from suppliers.

Stage 2. Stock Management

Goods are received and stored at the warehouses (bin storage is preferable) and tracked with serial numbers, batches, barcodes, expiry dates, etc. Days in stock are calculated.

Stage 3. Order Management

Sales orders are received and managed. Payment, invoices, shipment, returns, and other procedures are processed.

Stage 4. Inventory Counts

Regular stock-taking is maintained in order to find out all the discrepancies, waste, and expired goods. As a result, write-offs and stock adjustments are made.

Stage 5. Data Analysis

Reports & dashboards are being monitored in order to bring the most profitable items to light, to decrease expenses, to find vulnerabilities, etc.

Stage 6. Customer Demand Forecasting

Using analytics tools, companies make approximate purchasing forecasts which help one to avoid mistakes made during the previous purchasing stage.

Stage 7. Inventory Automation

Using inventory management software, entrepreneurs can get notifications when stock has to be replenished and set specific workflows that trigger particular actions, e. g. a new sales order → a sales invoice is automatically sent to a customer.

Handy Tip

In Kladana, you can automate the entire inventory management basics flow. Receive alerts when you are running out of supplies. Schedule regular stock‑takings. Manage orders, receiving, shipment, returns, and write‑offs. Find out the most profitable items. Keep goods in storage bins.

Inventory Management Question #8. What Are Basic Inventory Management Challenges?

In short: Human errors, inaccurate entry points, cluttered warehouses, and stock issues.

In detail: Let’s point out five key stock management challenges.

Errors in Manual Inventory Control

However accurate your employees are, they will make mistakes from time to time which can be insignificant in some cases and crucial in other ones. A digital solution reduces human error to almost zero. We don’t urge you to immediately buy inventory management software. Some of them offer free plans or trial periods.

Phantom Inventory

This term describes a situation when an item exists in the Excel file or a notebook but it is no longer physically present. It could have been sold, written off, returned to a supplier, etc. However, there is no record indicating what happened to the item.

Overstocking and Understocking

Wrong usage of stock control techniques may lead to the lack or excess of certain items. Reasonable safety stock can prevent an entrepreneur from understocking.

Inaccurate Customer Demand Forecasting

Without thorough analytics, forecasting is going to be subjective and may only seem plausible whereas plenty of factors are not taken into account.

Messy Warehouses

If one doesn’t use storage bins, incorrectly processes the receiving of goods, and stores goods in a random way, it’s going to be a problem. It becomes extremely apparent when a company decides to introduce, say, FIFO, but it’s impossible to do in an untidy cluttered stockroom.

Inventory Management Question #9. What Are the Best Inventory Management Practices?

In short: Accurate catalogue & product cards, regular stocktaking, warehouse layout & safety stock are considered to be optimal choices.

In detail: Note 5 best stock control practices that can significantly improve inventory management.

Organize Tidy Catalogue

Make product cards with variants, different prices, SKUs, barcodes, etc. Use batches, bundles & folders in order not to miss any items.

We have an absolutely free inventory management template in Excel. You can download it and adjust it to your needs using our instructions. We’d be glad if you find it useful.

Set the Reorder Points

We recommend doing it for your entire inventory or at least those items which are in high demand. Thus, you can automatically replenish the stock in time.

Conduct Regular Inventory Counts

Schedule weekly or monthly stocktaking to find the discrepancies, and make relevant stock adjustments and write-offs. Try not to skip inventory counts, otherwise, you won’t have the correct data about the stock.

Think over the Warehouse Layout

Depending on the inventory management technique you use (FIFO, FEFO, LIFO, etc.), the layout is going to be different.

Use the Safety Stock Technique

Experts argue which inventory management techniques are the best. However, the vast majority votes in favour of having safety stock in order to avoid demand surge troubles.

Inventory Management Question #10. What Are the Trends & the Future of Inventory Management?

In short: Inventory management is going totally digital and uses all cutting-edge technologies to improve the daily stock routines.

In detail: We’ll take a look at three main trends. Some of them have already been implemented by trend-setting companies.

Artificial Intelligence in the Inventory Management

Lots of inventory management software offer AI tools for stock control. AI-based forecasting algorithms are based on previous experience, current market trends, and other factors that make customer demand forecasting extremely precise.

Also, AI-powered tools allow one to digitize replenishment: new purchase orders will be made automatically and will minimize overstocking and understocking. AI in inventory control can be used to calculate reasonable safety stock and to choose the stock management technique properly.

Internet of Things in Stock Control

One of the most habitual IoT examples is the usage of cloud-based solutions. In contrast to the on-premise software, cloud ERP stores all data in the cloud which makes data secure, transparent, and easier to analyze.

What’s more, tracking equipment, tools, storage systems, vehicles, and other assets and uniting them in one digital organism may lead to uninterrupted coordinated work of the entire warehouse. Smart machinery eliminates the risk of malfunction and errors. To be precise, IoT in inventory management involves RFID tags, sensors, and various trackers that connect one asset to the entire digital system.

Warehouse Drones

Self-flying drones can substitute hard human labour: they can work 24/7, flying from one storage bin to another collecting relevant data, conducting inventory counts, seeking errors & understocking, and revealing weaknesses.

Don’t Let Your Stock Play Hide and Seek

Get real-time tracking, smart storage, and fewer “where is it?” moments — with Kladana.

Summing up

1️⃣ Make up your mind about the type of inventory you need (raw materials, WIP, finished goods, assets) and item features you need to record and track (product variants, UOM, barcodes, serial numbers, SKUs, etc.)

2️⃣ Create a catalogue of all your goods. For a start, you may use an Excel sheet.

3️⃣ Choose and follow the basic inventory management method: periodic or perpetual.

4️⃣ Choose the inventory management techniques that suit you best: ABC, FIFO, FEFO, JIT, dropshipping, and safety stock. Implement these techniques and organize the warehouse layout.

5️⃣ Arrive at a decision on the resources you need to launch a proper inventory control system: labour, equipment, facilities, and software.

6️⃣ Set strict rules for the entire inventory management cycle: what process triggers what occasion, what follows next, and what should be done in case of errors and discrepancies. These rules must be followed by all employees. Also, you’d better revise them and add new scenarios, use cases, and rules.

7️⃣ Whenever you make a single change, don’t forget to record all amendments: the price has changed, the item was sold, the item was written off due to damage, a new product variant appeared, some raw materials were received, etc.

8️⃣ Conduct regular inventory counts. The best way is to schedule automatic stocktaking — every week, fortnight, month, etc. If you find any discrepancies, you should analyze what could have caused them. Then you have to deal with them: make stock adjustments or create write-offs.

9️⃣ At least once a month analyze how the entire inventory management system functions: what the weak spots are, and what could be improved.

🔟 Monitor inventory control trends in order to keep your finger on the pulse. However, there is no need to rush with implementing every single trend. Do it only if you really think it’ll meet your demands and you have enough resources to implement it.

Frequently Asked Questions on Inventory Management Basics

Trying to grasp the basics of inventory management can be challenging. We’re here to help by providing answers to common questions.

What is meant by inventory management?

Inventory management is the systematic approach to sourcing, storing, and selling inventory — both raw materials (components) and finished goods (products). It involves overseeing the flow of items into and out of an organization’s inventory.

What is the basic purpose of inventory management?

The main purpose of inventory management is to ensure that there is always enough stock on hand to meet customer demand while minimizing the cost of holding inventory.

Why is inventory management and control important?

Inventory management and control are crucial for maintaining the right balance of stock, avoiding overstock or stockouts, improving customer satisfaction, and optimizing the costs associated with buying and storing goods.

What are the 4 basic steps in inventory management?

- Manual Inventory Management Systems;

- Perpetual Inventory Systems;

- Periodic Inventory Systems;

- Just‑In‑Time Inventory Systems.

What are the 4 main steps in inventory management?

- Forecasting demand accurately;

- Procuring inventory as needed;

- Storing and managing inventory efficiently;

- Fulfilling and shipping orders promptly.

What is simple inventory management?

Simple inventory management refers to basic techniques and tools for tracking the quantities of stock on hand, reorder points, and sometimes sales trends, without the complexity of advanced forecasting or analytics.

What are the main challenges in inventory management?

Key challenges include accurate demand forecasting, reducing the costs of storage and obsolescence, managing supply chain disruptions, and integrating technology for real‑time inventory tracking.

What are the basic guidelines for inventory tracking?

- Keep accurate records of stock levels and movements;

- Regularly review and adjust reorder points and quantities;

- Use technology to enable real‑time tracking and visibility;

- Periodically audit physical inventory to ensure data accuracy.

Read-alikes

Inventory Counting: Step‑by‑Step Guide on How to Conduct and Access the Results

Inventory Management in Excel: Free Template and a Step‑by‑Step Guide

Unicorn Natural Products Manufacturing: a Journey from Spreadsheets to ERP

Cura Pharmaceuticals Manufacturing: Increased Data Accuracy & Business Workflows in 6 Months