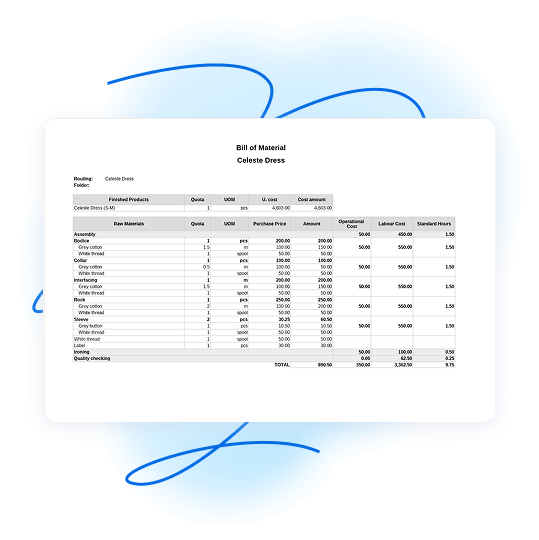

Spreadsheets are hard to maintain and easy to misread — leading to wrong builds and wasted materials

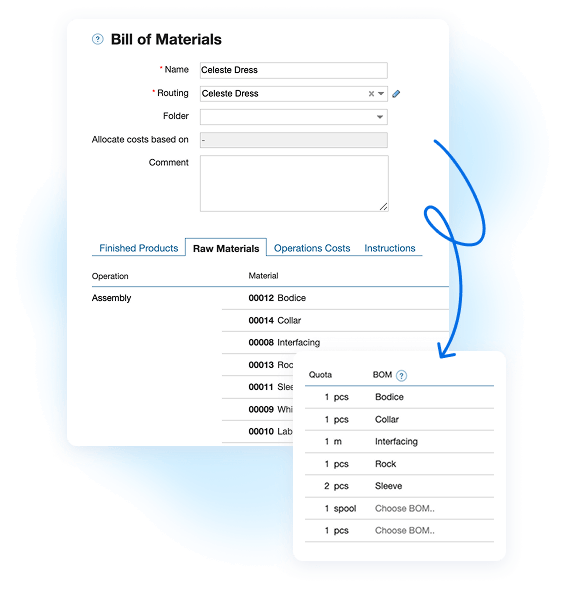

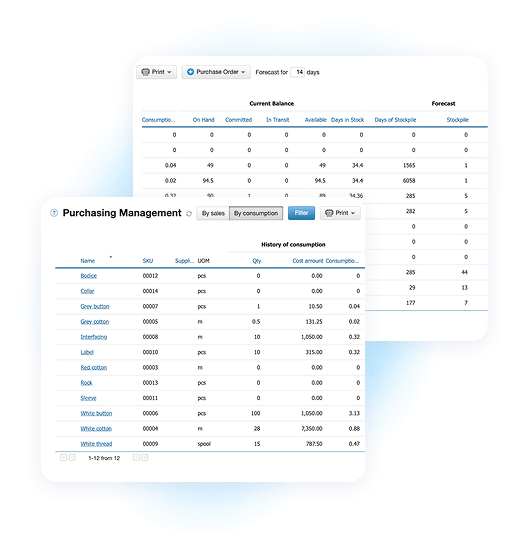

Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.