Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

One ERP for production, sales, purchasing, inventory, and warehousing — with a free shop floor app, from $47 a month

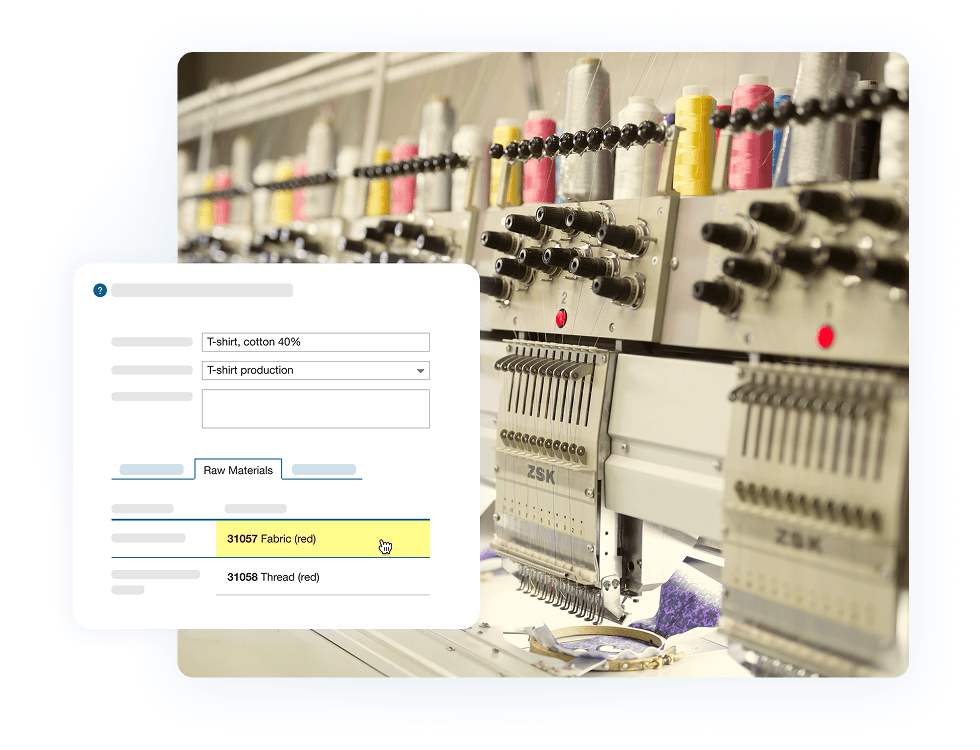

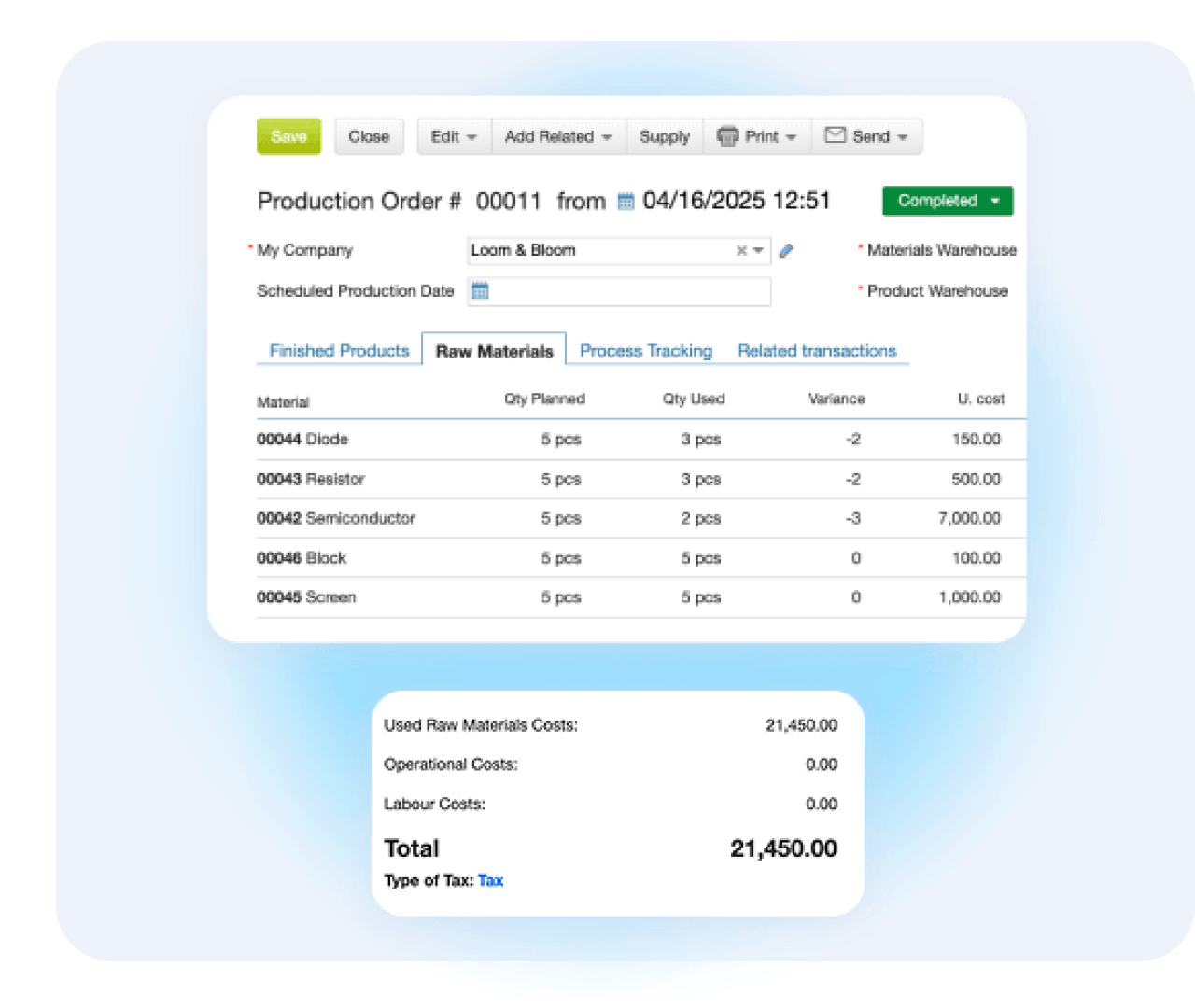

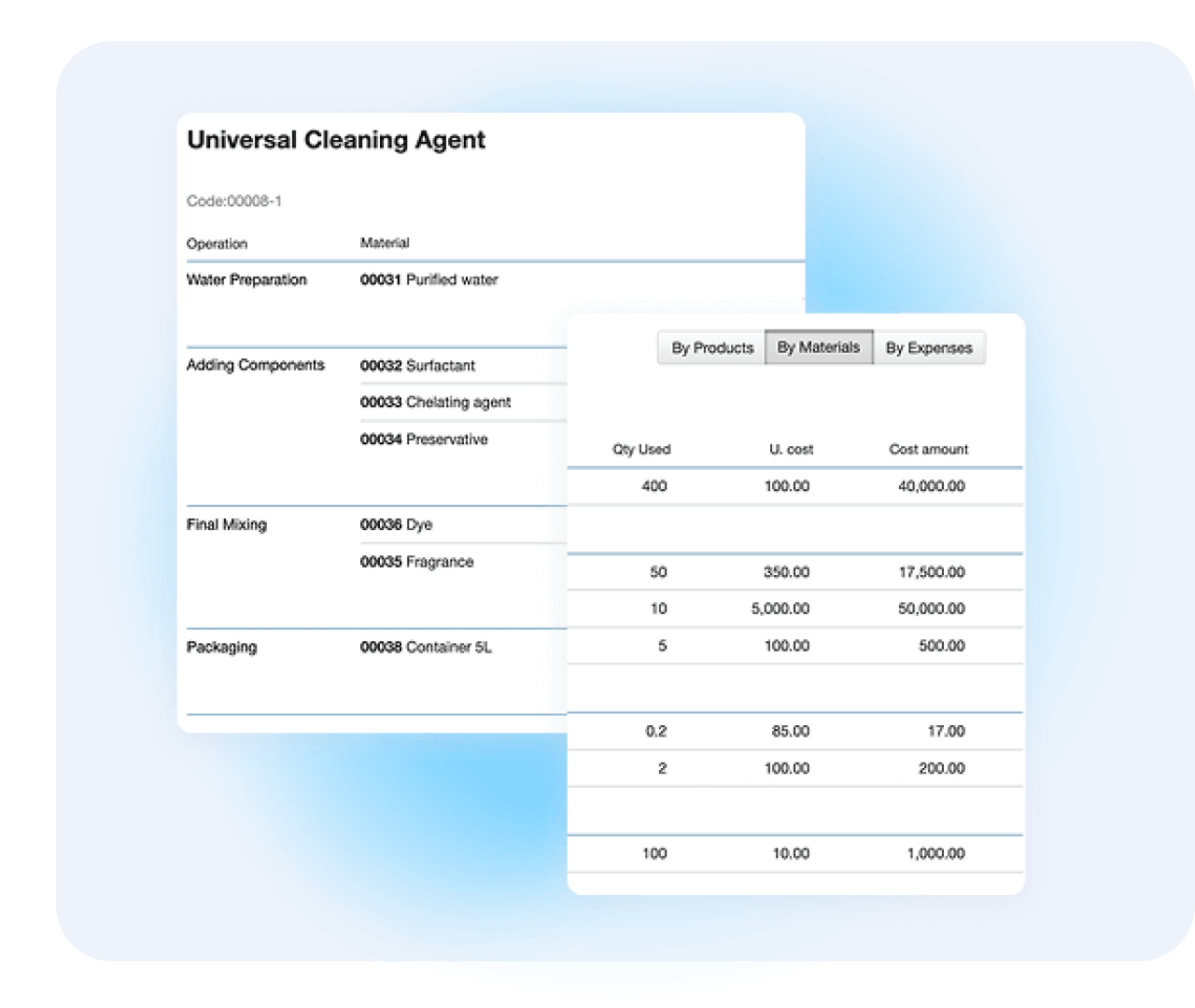

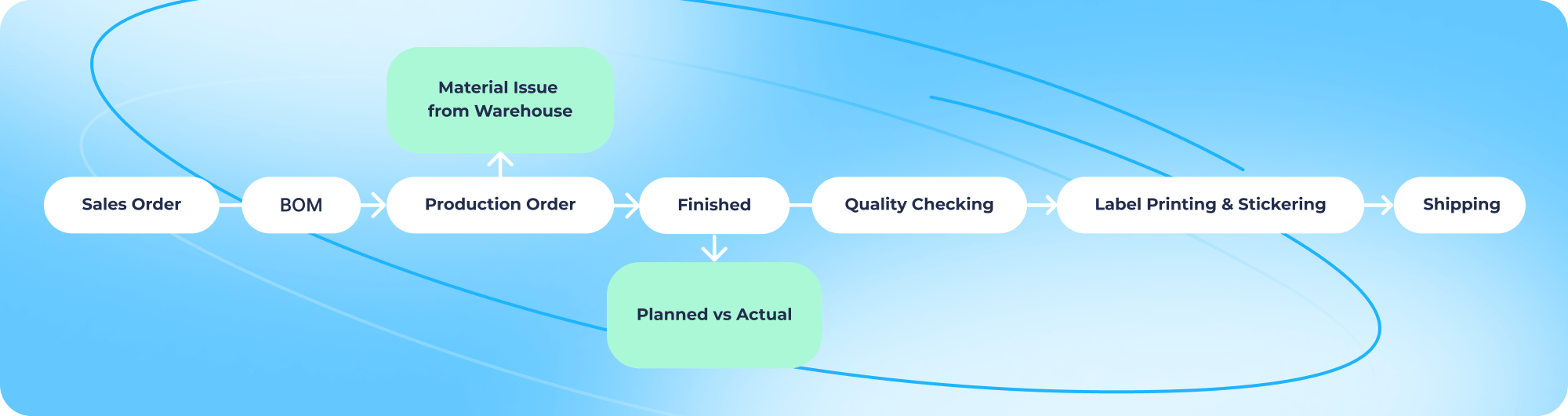

Plan and schedule production orders, assign shop floor tasks, and manage BOMs, MRP, wages, costs, and quality checks

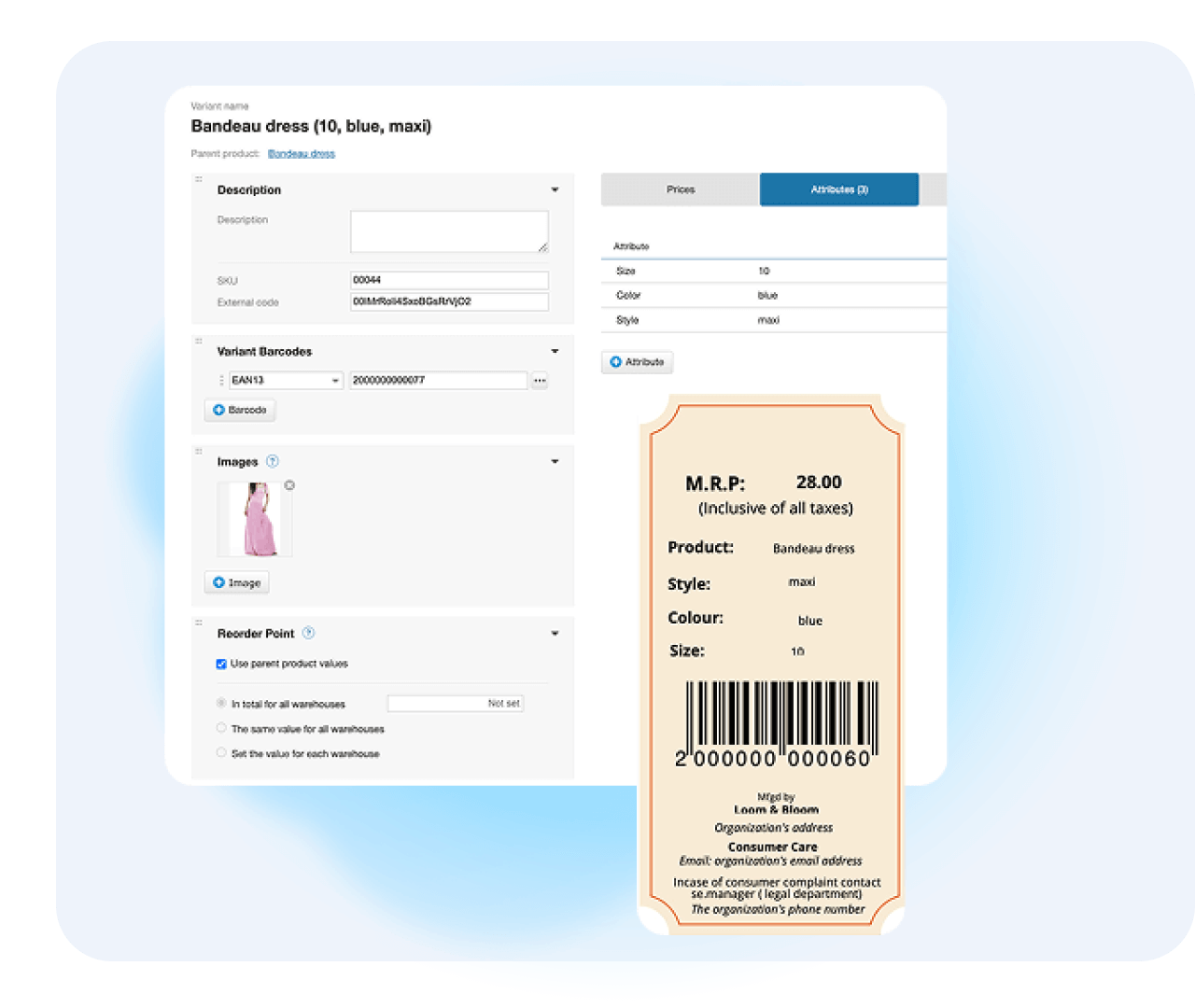

Control stock levels of raw materials, WIP, and finished goods across warehouses and facilities. Track expiry dates, batches, and serial numbers. Generate barcodes and print labels

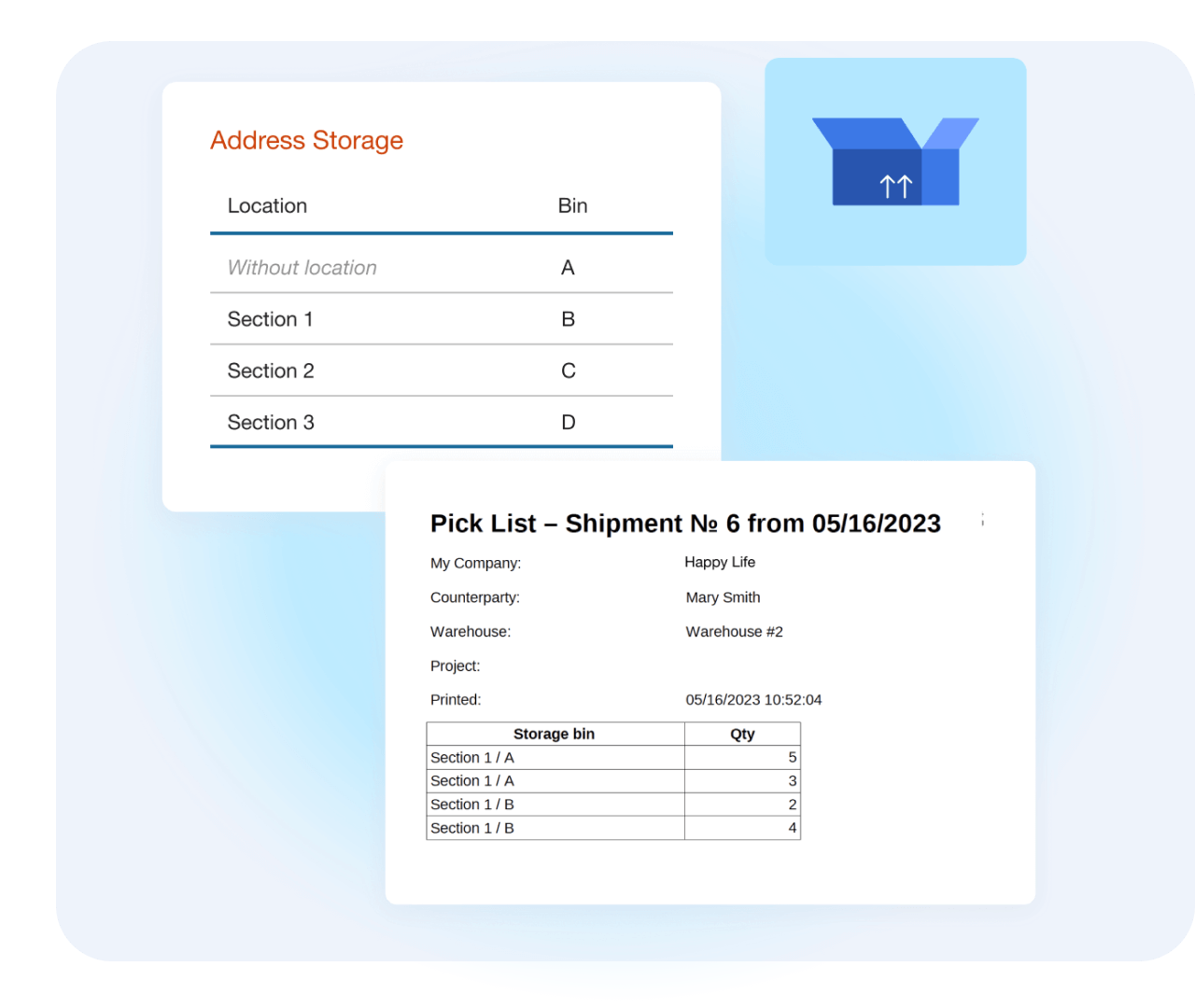

Manage multi‑location warehouses, organize bin storage, and track stock movements. Handle receiving, shipping, and transfers

Forecast demand based on your sales history, set reorder points, run purchase orders, and control material costs

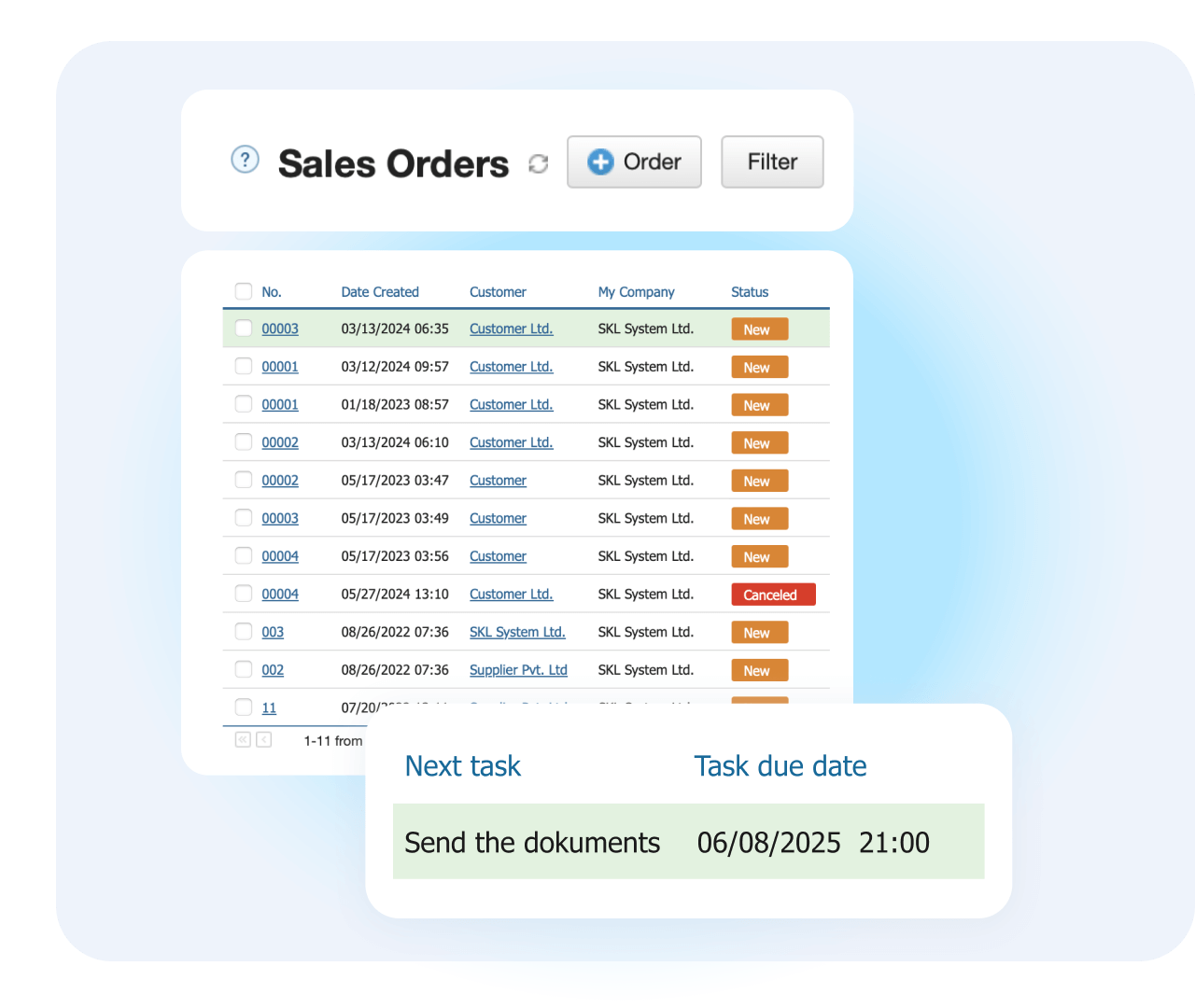

Manage sales orders and client database, launch MTO production, generate quotes and invoices, and monitor best‑selling items

Automatically calculate unit costs, track labour, material, and operational expenses, and analyze profit margins

Kladana supports different types of manufacturing workflows:

Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

Customization + Responsive Support

We tried other ERP tools, but only Kladana let us customize formats and interfaces to fit our workflows. And when we had questions, support was right there — quick replies over messenger, no delays.

Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

In Kladana, we found the functionality we were looking for. In combination with affordability, it worked as a decisive factor. Another important area is tracking the amount of yield our company is getting. In this respect Kladana is suitable to our requirements, and we are going to start using the Financials module of the solution.

It’s a system that helps small manufacturers manage production, inventory, sales, and purchasing in one place. Instead of juggling spreadsheets, you get a single ERP that keeps operations accurate and predictable.

The best ERP systems for small manufacturing companies are affordable, easy to use, and scalable. Kladana is built for small manufacturers: it combines production management, inventory control, sales, purchasing, and CRM — starting at $47 a month.

Yes. ERP is no longer just for large corporations. Kladana ERP is designed for SMEs and workshops that need better visibility and control without complex enterprise systems.

Yes. Kladana offers plans that scale with your needs. The entry plan with manufacturing tools costs $47/month (or $563/year).

Yes. Kladana is a fully cloud‑based ERP. You don’t need downloads or servers — just log in from your browser. Shop floor workers use a free web app to get and complete tasks in real time.

You can start simple: add employees, products, BOMs and tasks, and you’re ready to run your first production order. Full ERP implementation usually takes 1–3+ months depending on company size and complexity.

Yes. You can create single- and multi‑level BOMs, run production orders, and link them to sales or purchase orders.

Yes. You can track raw materials, work‑in‑progress, and finished goods across warehouses and production facilities. Kladana also supports batches, expiry dates, and serial numbers to ensure full stock visibility.

Yes. You can forecast demand, set reorder points, and create purchase orders directly from production needs.

Yes. Sales orders can trigger production (make‑to‑order), and you can generate quotes and invoices directly in Kladana.

Yes. Kladana has a built‑in CRM to manage customers, suppliers, quotes, and orders — all integrated with production and inventory.

Yes. You can set up multi‑location warehouses, track bin locations, transfers, receiving, and shipping.

Unit costs are calculated automatically based on raw materials, operations, and wages. Reports show planned vs actual costs and product profitability.

Yes. You can assign operations to subcontractors, provide them with materials, and record their services in production orders.

Yes. You can record scrap, rework, and quality checks in production orders to keep processes predictable.

Yes. Kladana integrates with Shopify, WooCommerce, accounting tools, and delivery services. An API is also available for custom connections.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce