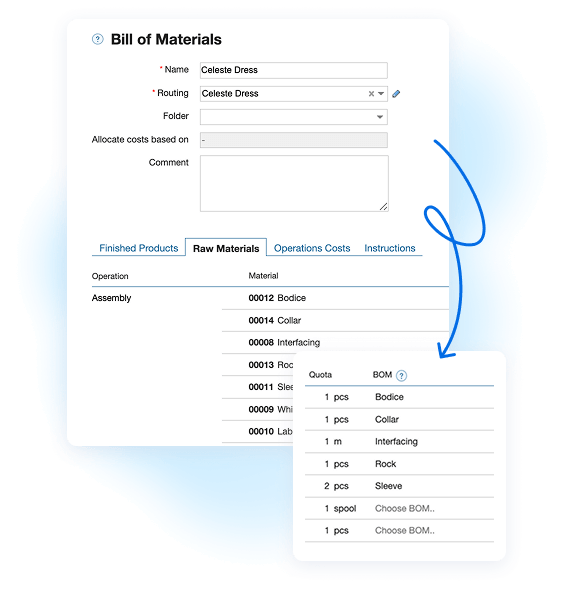

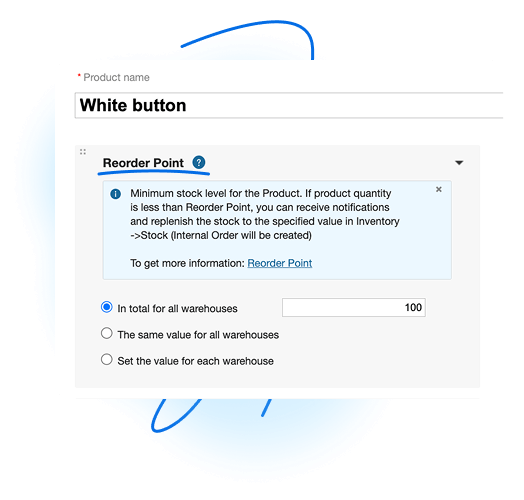

Production halts due to missing components. Inventory looks full, but key parts are unavailable

Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.