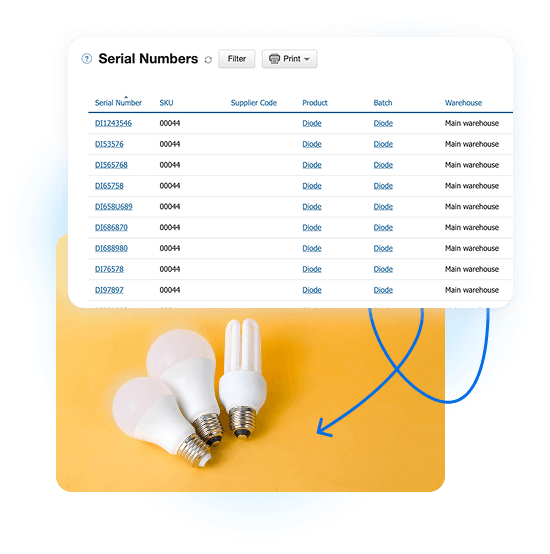

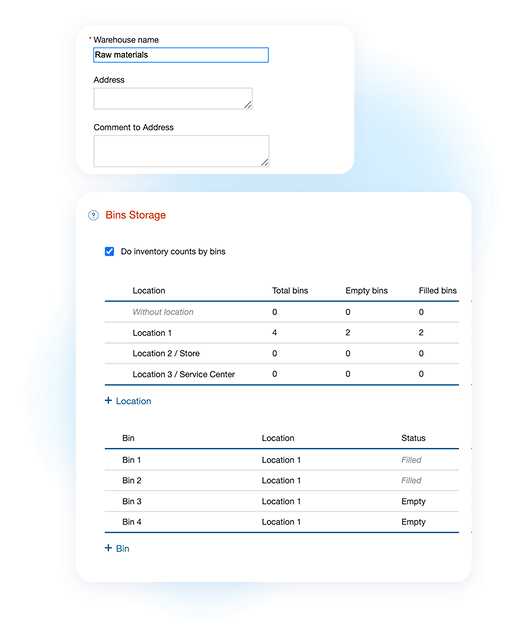

You don’t know what’s available, what’s reserved, or what’s about to run out

Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.