Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

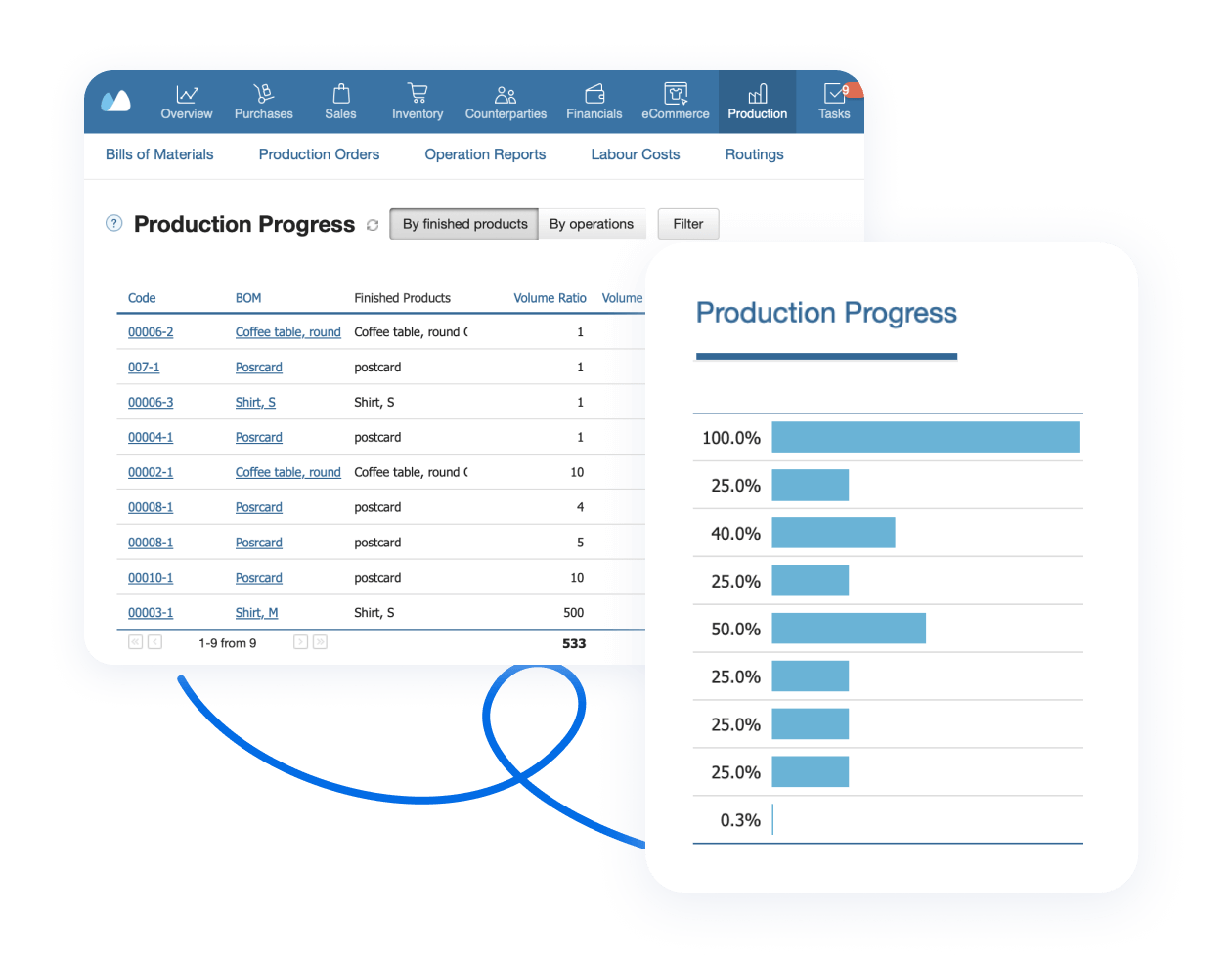

Control raw materials, work orders, and

costs across all production stages —

anytime, anywhere

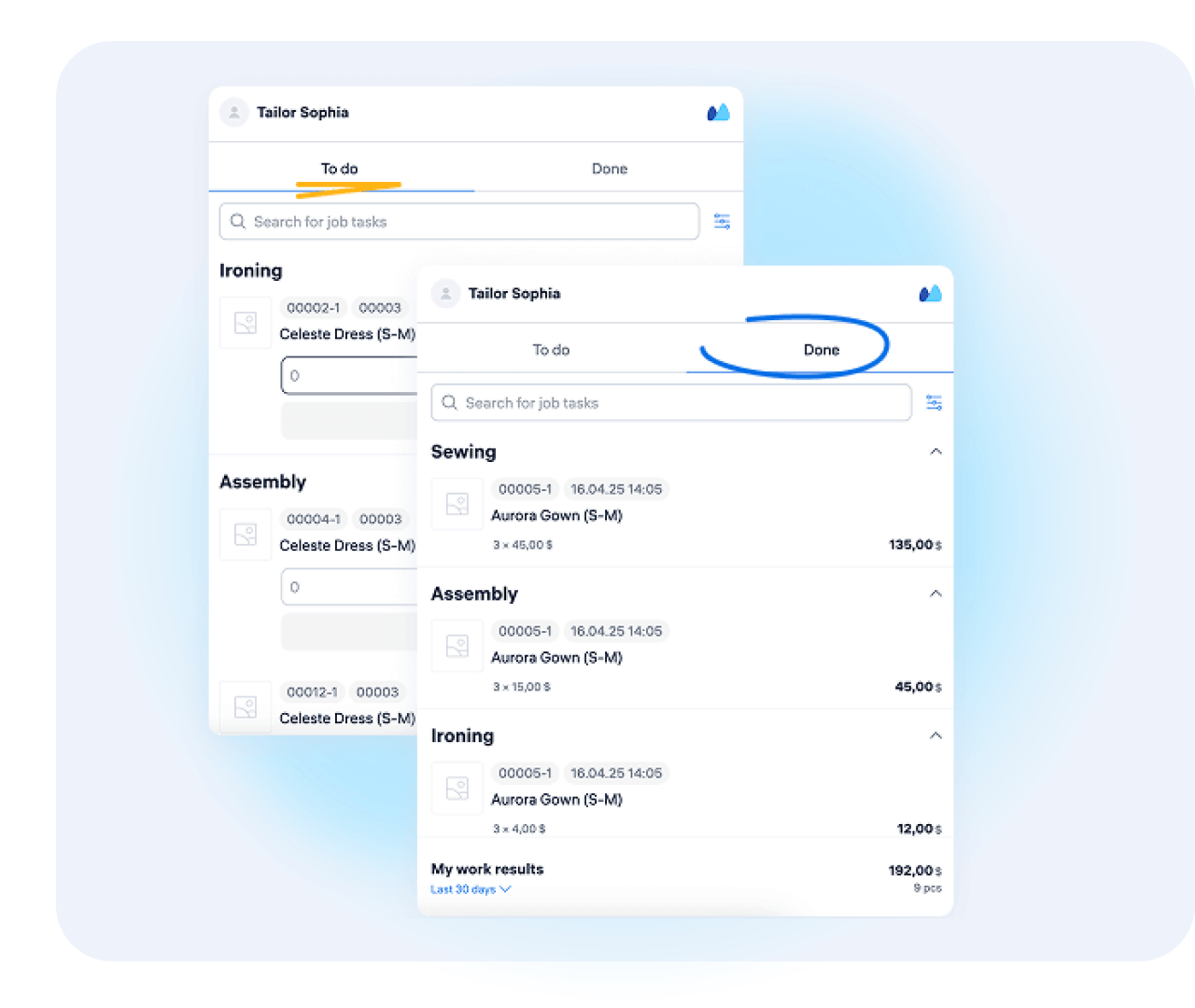

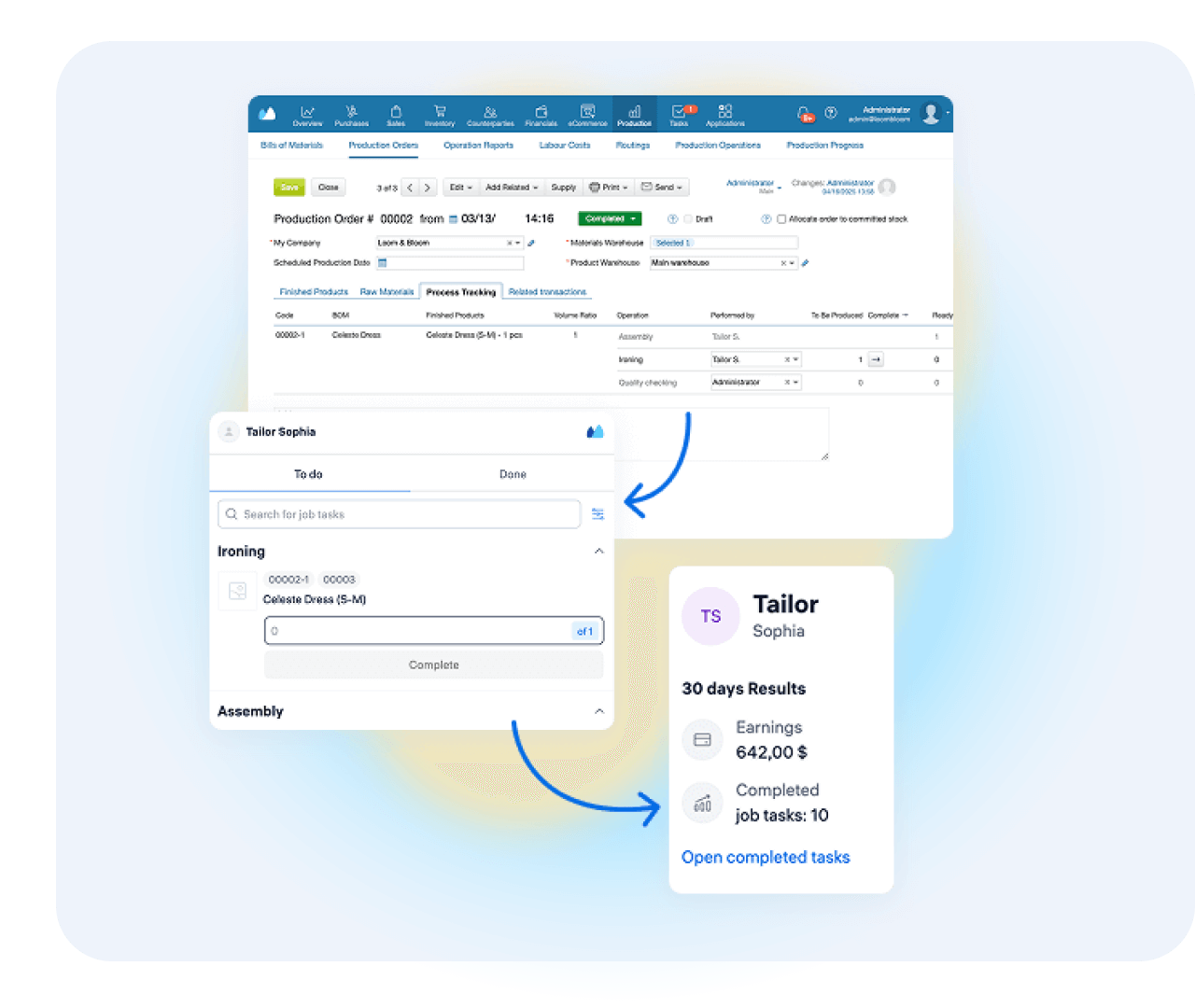

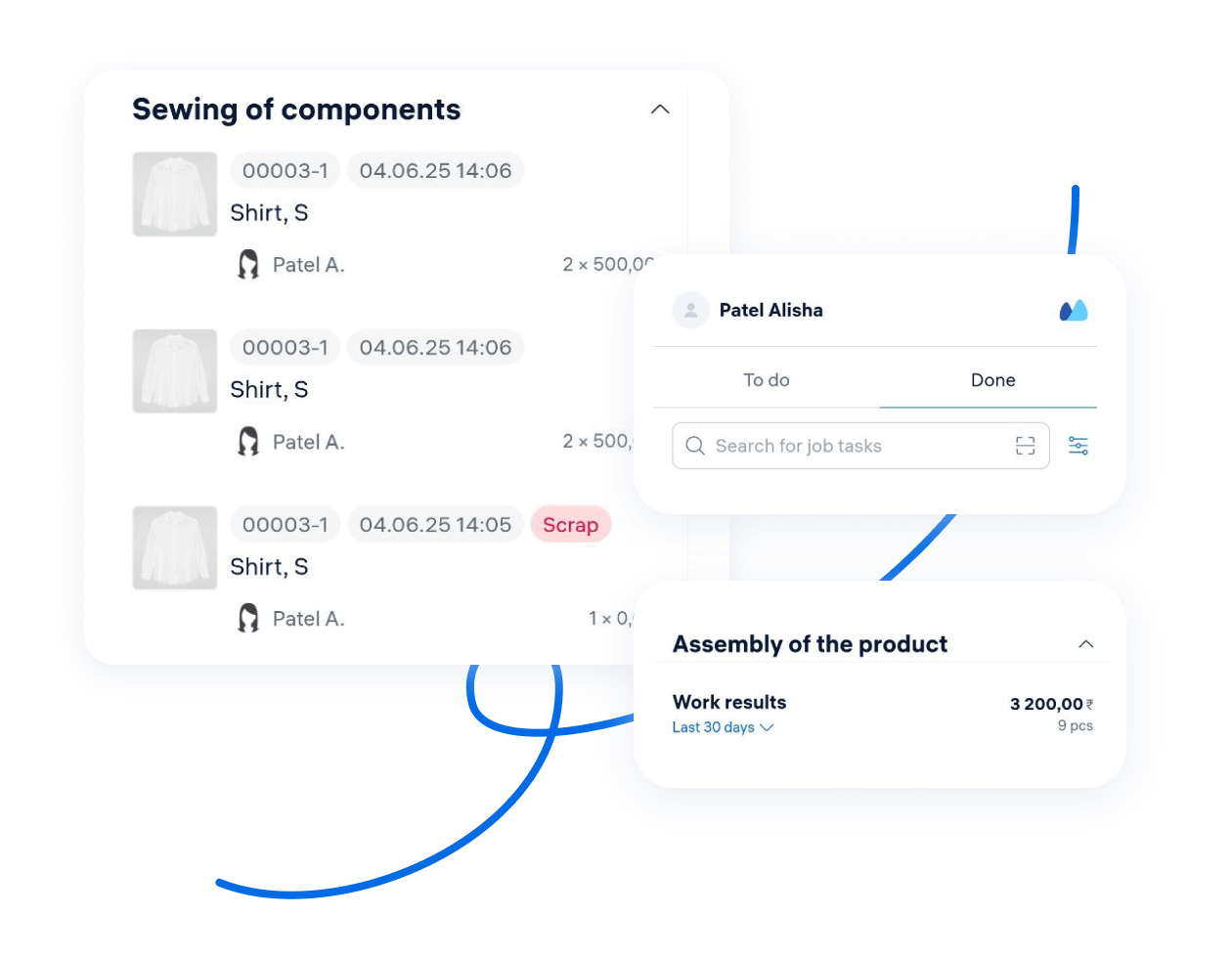

Monitor operations, deadlines, and job cards with Shop Floor App. Assign tasks to workers and follow progress step by step

Pay workers automatically based on completed operations

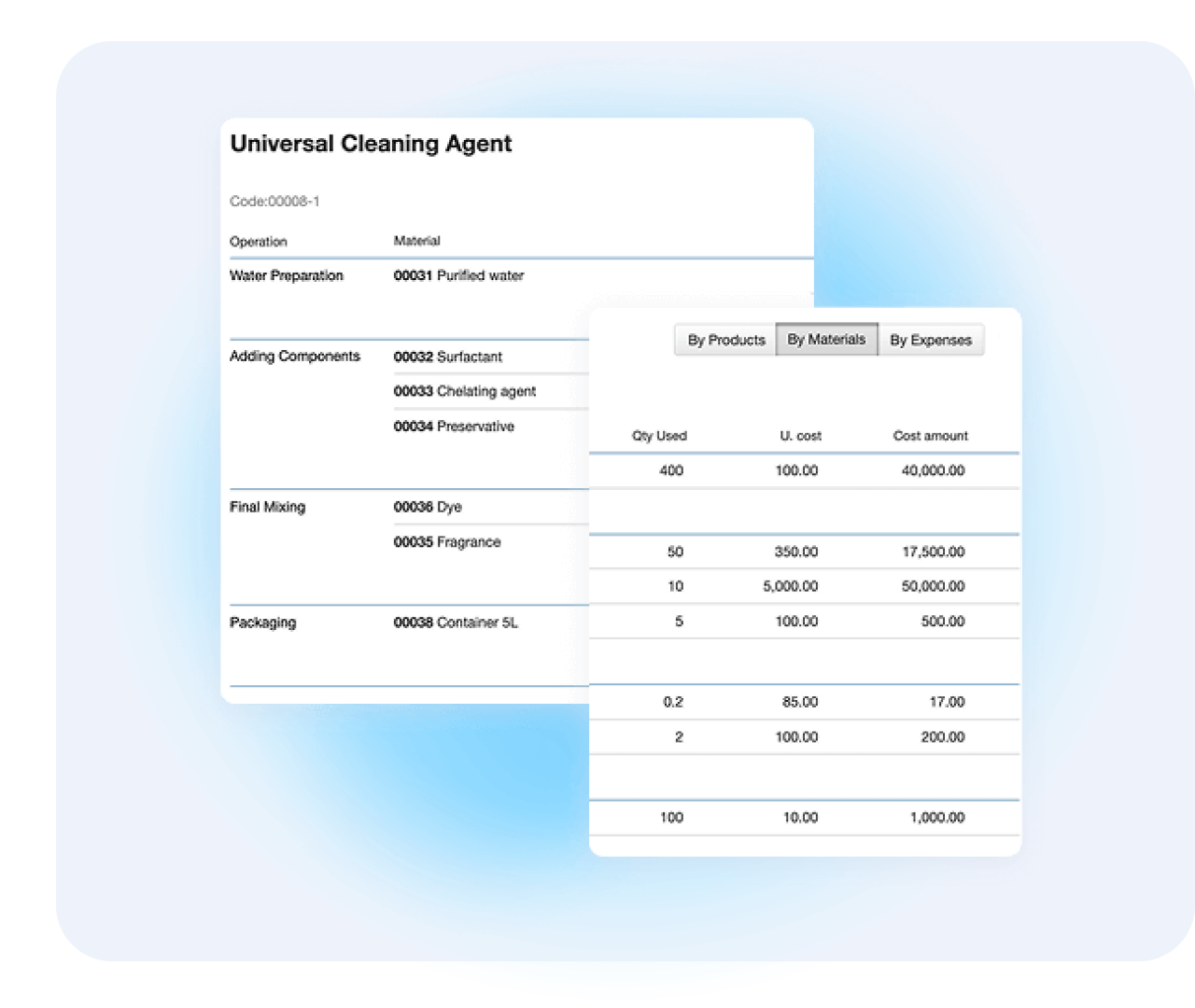

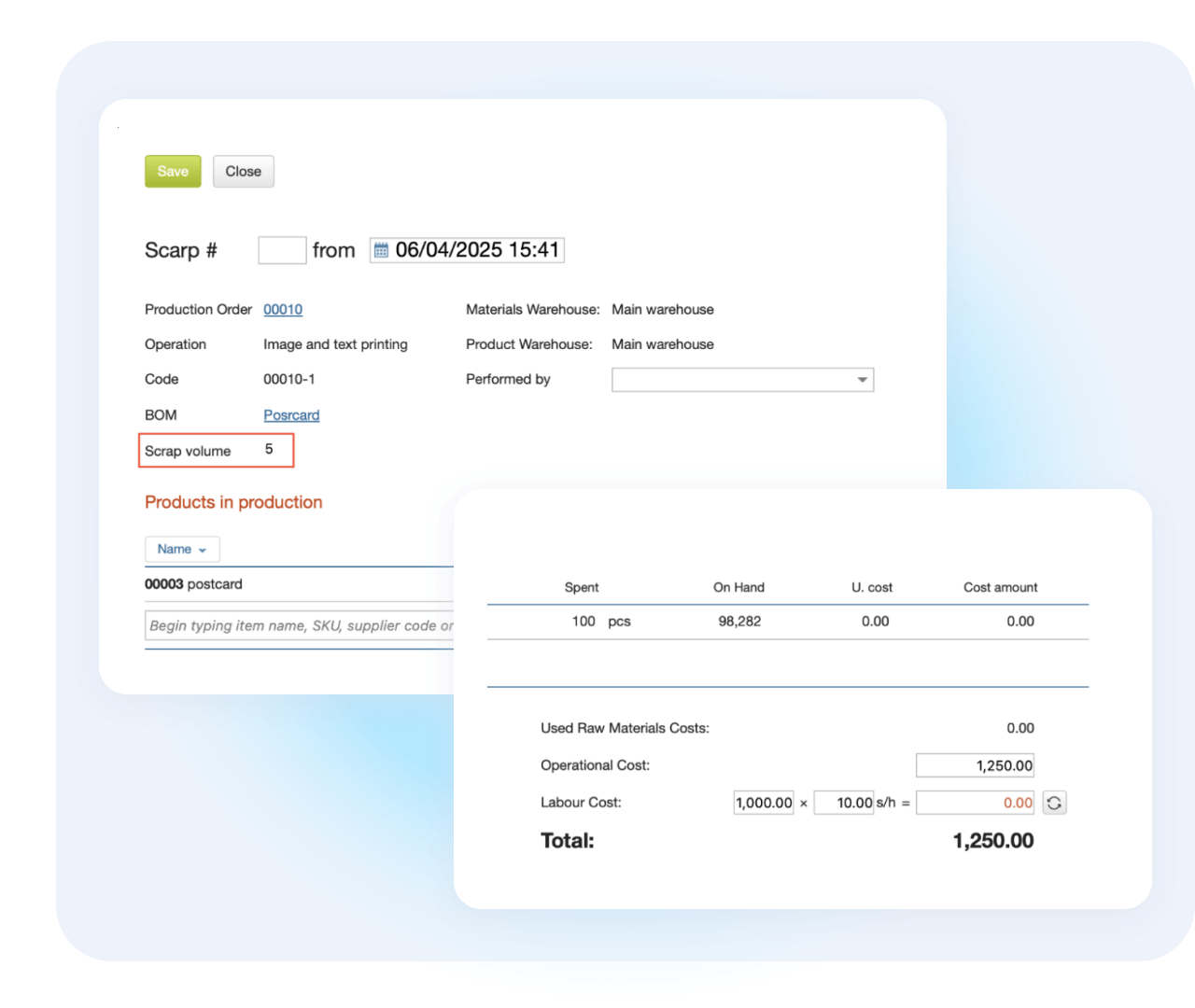

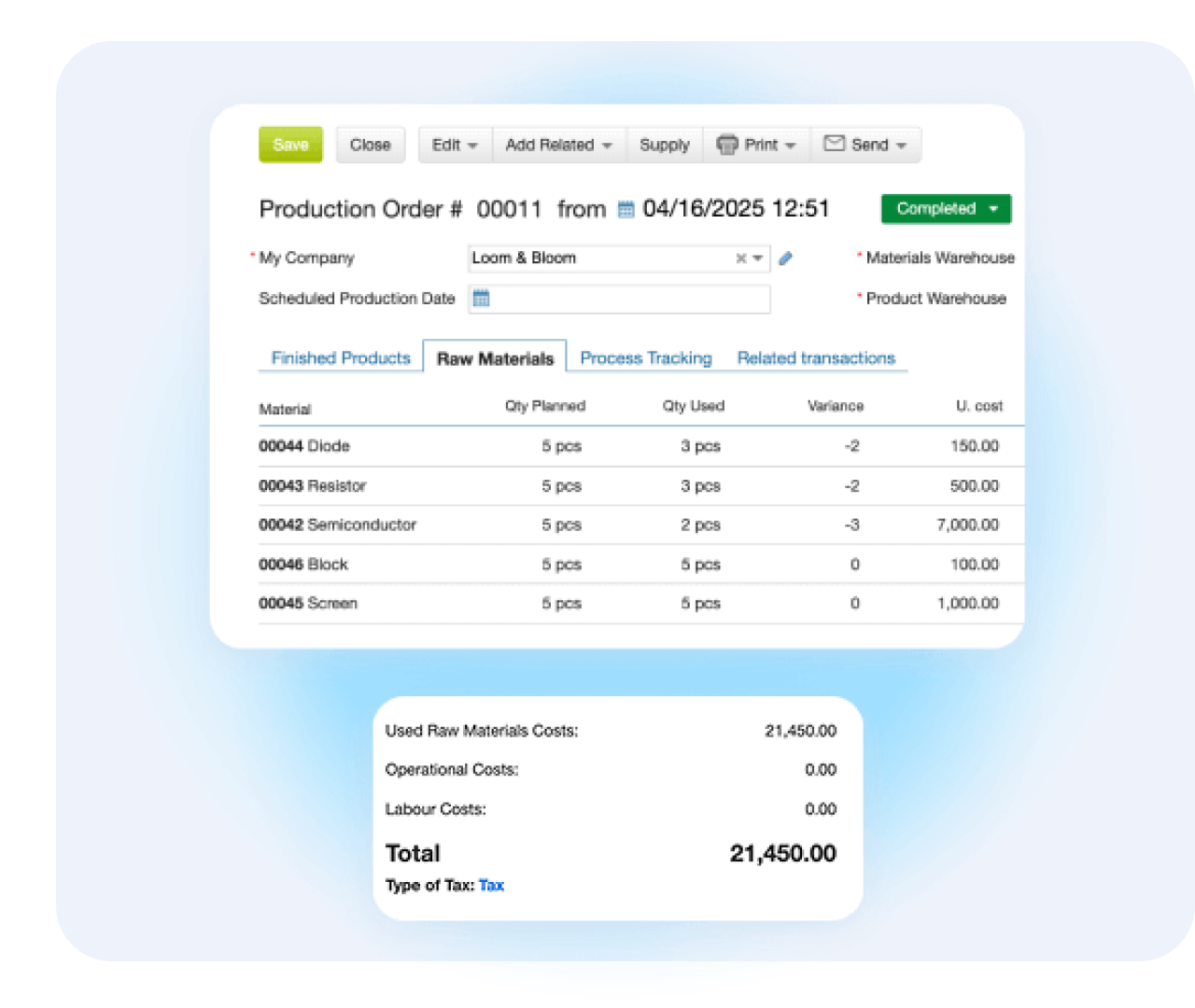

Calculate unit cost automatically in real time: raw materials + operations + labour costs

Record rejects and rework to keep your production predictable

Track raw material consumption, WIP, and finished goods

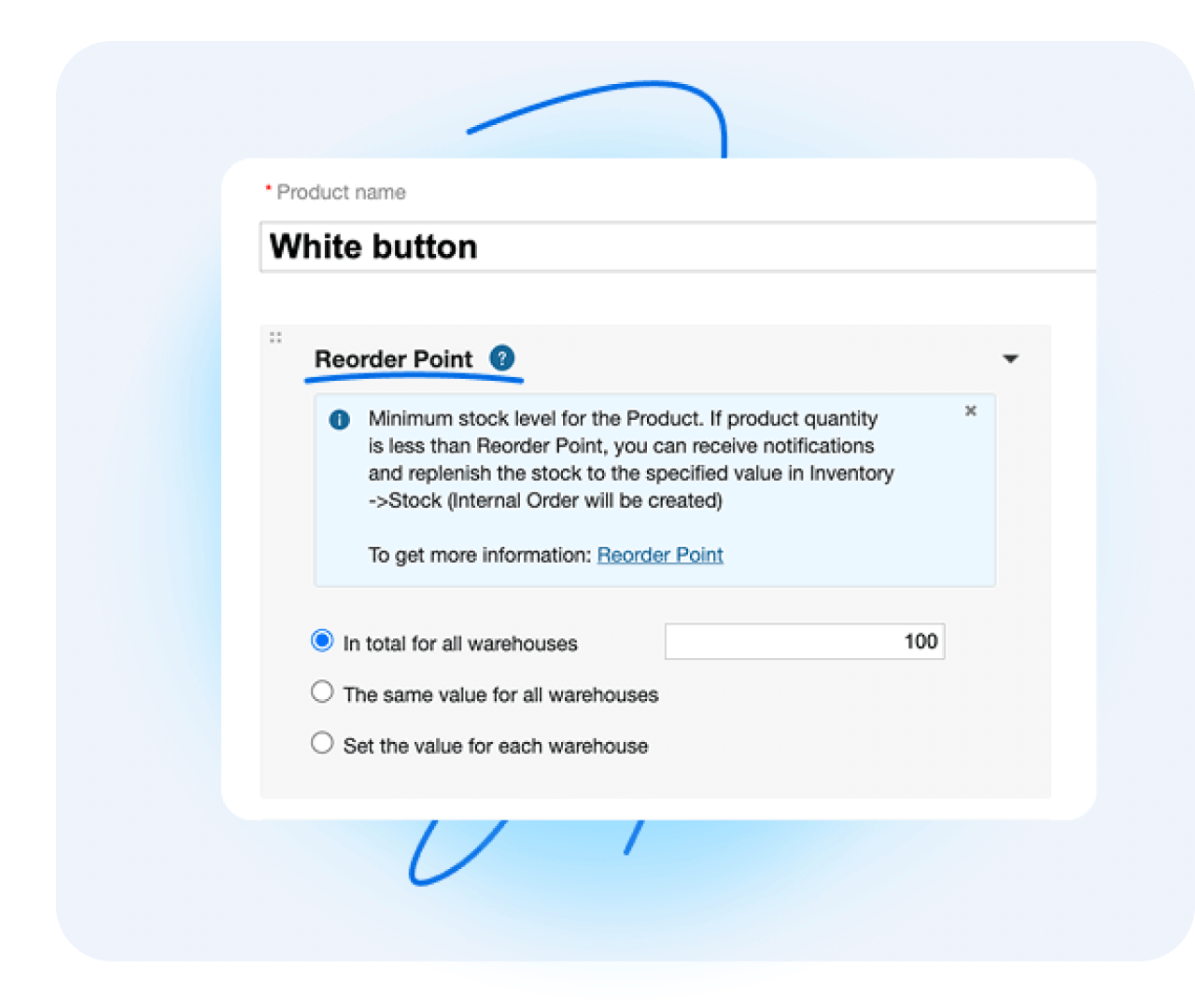

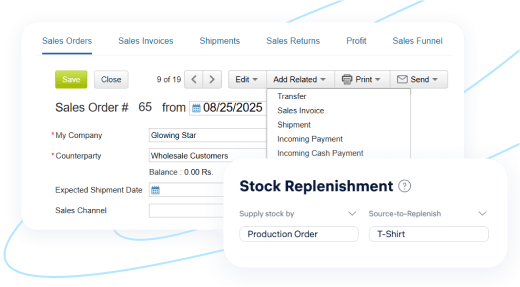

Plan purchases and supplies just in time for production using demand forecasting

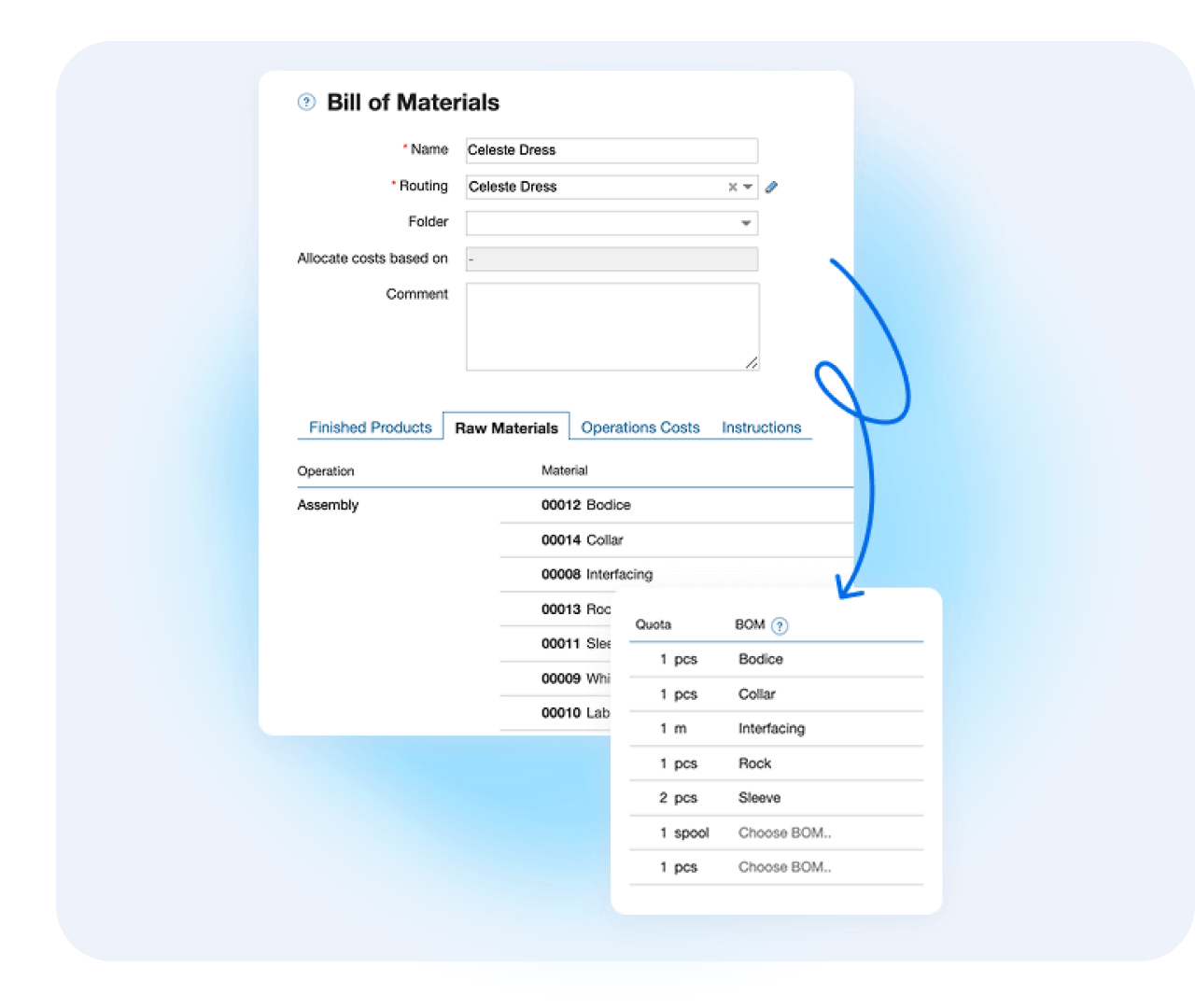

Build operation stages and multi‑level bills of materials for any product and components

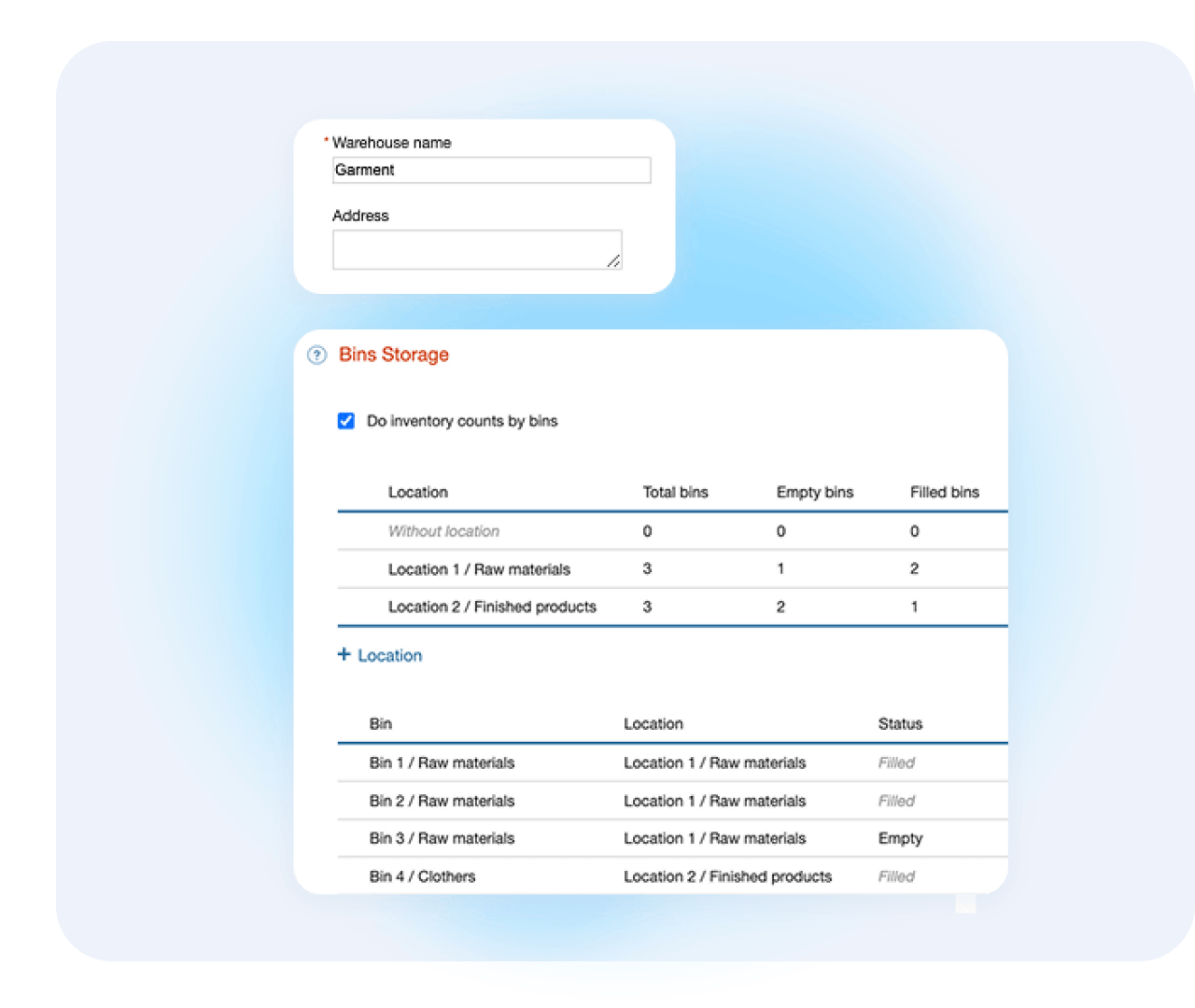

Sync production with inventory, order management, CRM, and warehousing

Immediate Support

I evaluated over 40 ERP systems. Some had great features — but no one ever got back to me. With Kladana, support replies within seconds — that made all the difference. Now I can track every item and plan production with less waste.

User-Friendly ERP at the Right Price

We chose Kladana because of its competitive pricing and easy-to-use interface — especially in the production module. Managing product descriptions and images in one place really simplified things for us.

Customization + Responsive Support

We tried other ERP tools, but only Kladana let us customize formats and interfaces to fit our workflows. And when we had questions, support was right there — quick replies over messenger, no delays.

Using Kladana, we managed to streamline the manufacturing management in whole: production operations became smoother, raw materials planning & purchasing became much easier. Now, a purchasing manager can look at one screen In Kladana, access sales estimates, figure out how many raw materials need to be bought for different items, and make purchase orders straightaway.

Before Kladana, we were doing everything in Excel. All the stock and production records were maintained in spreadsheets. We weren’t able to arrange timely updates for the information about warehouse stocks: the materials we were receiving, the goods we were shipping.

In Kladana, we found the functionality we were looking for. In combination with affordability, it worked as a decisive factor. Another important area is tracking the amount of yield our company is getting. In this respect Kladana is suitable to our requirements, and we are going to start using the Financials module of the solution.

Learn how to arrange business routines for manufacturing, wholesale, retail & e‑commerce