You discover that an essential component is missing just before shipping a sizable order. Production stops. There is a delay in delivery. Consumers are dissatisfied In manufacturing, such circumstances are typical. Typically, it indicates one underlying cause: inadequate material planning.

Systems for Material Requirements Planning (MRP) come into play in this situation. Manufacturers can make sure they have the right materials in the right quantity at the right time with the aid of MRP software. In one location, it manages inventory, plans production, and matches demand with procurement. An MRP system gives you visibility and control over your operations, whether you’re blending cosmetics or assembling bicycles.

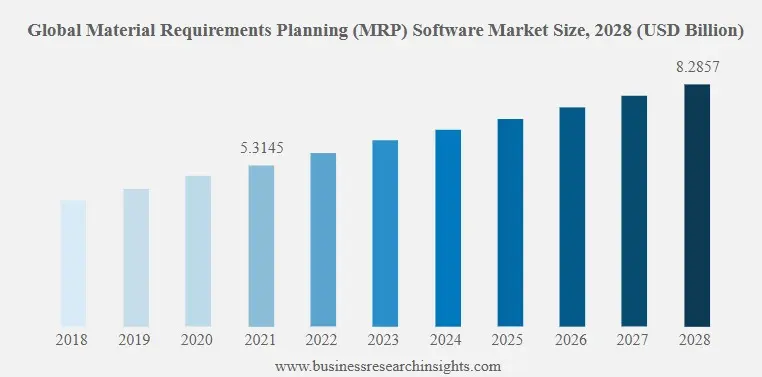

According to Business Research Insights, the global MRP software market is expected to grow to USD 8.29 billion by 2028, with a CAGR of 7.68%. We’ll go over how MRP functions, why it matters, and how to pick the best system in this post.

- What is Material Requirements Planning (MRP)?

- How Does MRP Work (Step-by-Step)?

- Core Inputs and Outputs of MRP?

- What are the Benefits of MRP?

- Challenges and Risks of Using MRP

- Common MRP Errors to Watch Out For

- Types of MRP Solutions (Modern vs Legacy)

- MRP vs ERP: What’s the Difference?

- Who Can Use MRP? (Examples of Users)

- How to Launch an MRP System

- Top MRP Software Tools

- Technologies Enhancing Modern MRP

- History of MRP

- FAQs on MRP Solutions

- List of Resources

What is Material Requirements Planning (MRP)?

Manufacturers use Material Requirements Planning (MRP) to make sure they have the right materials in the right quantities at the right time in order to effectively meet production demands.

Basically, an MRP system helps companies in coordinating procurement, inventory management, and production planning. It provides answers to three important questions:

1️⃣ What materials are required?

2️⃣ How many?

3️⃣ When?

Consider a factory to be an orchestra. Workers are musicians, machines are instruments, and the sheet music is the raw material. Without a conductor, the result is chaos. MRP solutions serve as that conductor, coordinating every aspect of the business to ensure that everything operates as planned.

To generate intelligent purchase and production plans, MRP extracts information from bills of materials (BOMs), inventory records, and customer orders. It helps avoid costly delays, reduce overstock, and keep workflows predictable.

Used correctly, MRP software transforms a reactive manufacturing process into a proactive, data-driven system.

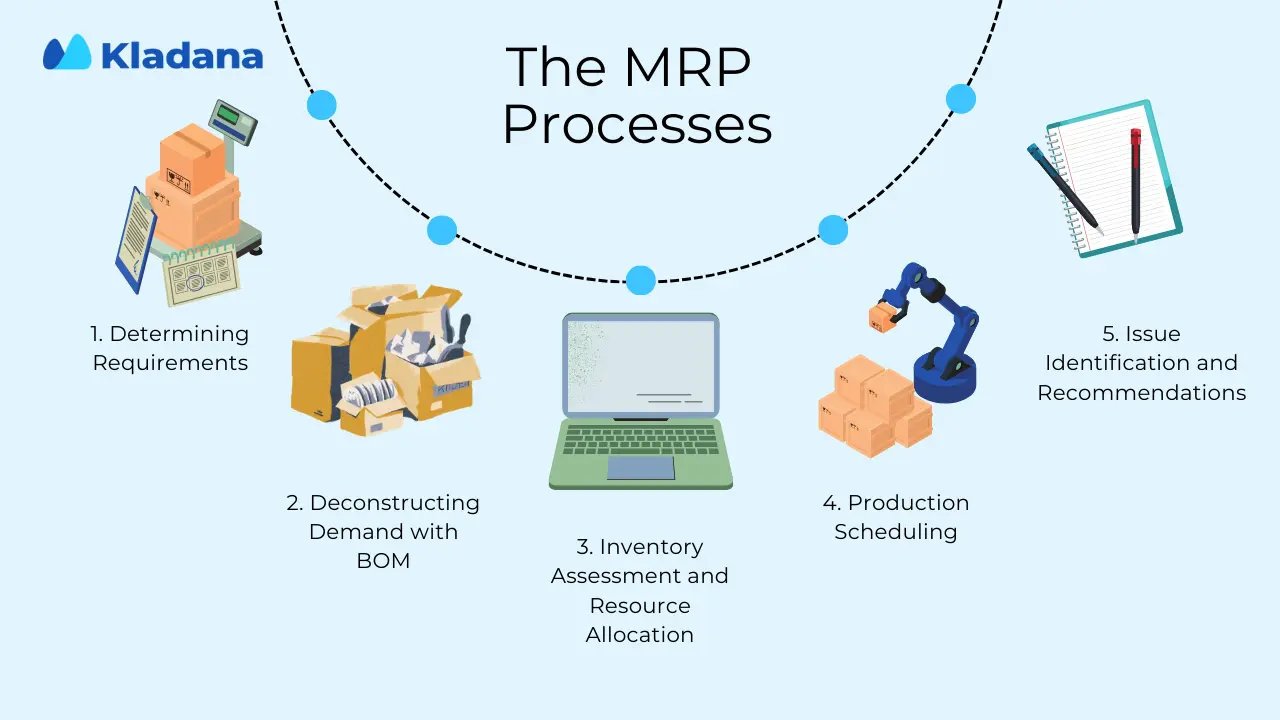

How Does MRP Work (Step-by-Step)?

Five logical steps make up a typical MRP solution that turns customer demand into a smooth production plan:

Step 1. Determine Requirements

It starts by getting real demand signals, like actual sales orders and sales forecasts, to figure out what needs to be made.

Step 2. Break Down Demand via BOM

The system uses the Bill of Materials (BOM) to turn each product into a list of parts and raw materials needed at each step.

Step 3. Assess Inventory & Allocate Resources

MRP examines the stock levels in all warehouses, finds gaps, and makes the best use of the resources that are already there.

Step 4. Schedule Production and Tasks

It makes a production schedule through assigning machines jobs, deciding how long tasks will take, and planning when to buy things.

Step 5. Identify Issues and Generate Recommendations

The MRP software flags potential delays, stock shortages, or overloaded workstations and suggests changes to keep production on track.

In trading, process management is relatively simple: businesses buy and sell goods, calculate profits and losses, and make corresponding records. Production is a complex process, extended over time. Various resources enter the production cycle at separate times. Work in progress is a common situation here.

You use raw materials and other resources, but you don’t get finished products. You need to monitor the production flow, costs, wear and tear, availability of raw materials, the required number of employees, equipment, warehouses, etc.

All this needs to be considered, that’s why you need special software. And the simpler the solution is, the easier it is to use. We are for simplicity.

Core Inputs and Outputs of MRP

An MRP system needs three main inputs to work right:

- A Master Production Schedule (MPS) is a list of the products that need to be made, when they need to be made, and how many of each.

- Bill of Materials (BOM) is a full list of the parts, raw materials, and components that are needed to make each product.

- Inventory Records or the data about what’s in stock, what’s on order, and what’s already used in production.

Using this data, the MRP software creates useful outputs:

- Planned Orders: suggestions for what to buy or make and when.

- Order Releases: signals to begin purchasing or production.

- Changes to Orders: updates or cancellations based on real-time needs.

- Performance Reports: the reports that show delays or missed targets.

- Exception Reports: the reports that point out urgent problems like shortages or late deliveries.

Plan Materials Smarter, Not Harder

Use Kladana to match raw material supply with production needs — without Excel chaos.

What are the Benefits of MRP?

Manufacturers can keep control with the support of a properly set up MRP system. It decreases delays and strengthens material flow.

Key MRP Advantages

- Improves production scheduling through careful task planning.

- Keeps inventory levels balanced through decreasing stockouts and overstock.

- Increases client satisfaction by delivering goods more quickly and reliably.

- Reduces lead time with timely material ordering.

- Improves task planning, reduces idle time, and increases worker and machine efficiency.

Cost Control Benefits

An efficient MRP solution reduces expenses as well. By avoiding excess stock, it minimizes the cost of carrying inventory. It decreases the need for unforeseen, frequently more expensive purchases. Businesses can use employees and equipment more effectively with better planning. This maintains the production budget under control and enhances ROI over time.

‼️ With MRP software, small manufacturers can run smarter operations without wasting money or time.

We were searching for software to manage raw materials and finished goods at ease. We tried several solutions but they mainly offered inventory management for those who buy and resell. Kladana turned out to be one of a few software companies that offered necessary features.

Kladana is quite customizable, easy to manage and understand. We can set all the processes up as we like in order to follow our protocols & to simplify the daily routine.

Challenges and Risks of Using MRP

MRP solutions offer many benefits, but they also come with risks. Especially if set up or used incorrectly.

- Data inaccuracy is a common problem. If inventory levels or BOMs are wrong, the system gives wrong results. For example, a missing part in the BOM can delay the entire production run.

- Complex setup and training can slow down the start. New users may need time to understand the system and follow the right steps.

- The cost of implementation can be high. This includes software fees, training, and possible upgrades to hardware.

- System dependency is another issue. If the software fails or data is lost, operations can stop.

- Some older MRP software tools have no real-time visibility. Users can’t see stock updates or changes until it’s too late.

Common MRP Errors to Watch Out For

Even the best MRP solutions can fail if used the wrong way. These common mistakes lead to delays, extra costs, and lost orders.

- Incomplete BOMs cause missing parts in production. For example, if a small screw is left out, the whole assembly may stop.

- Ignored lead times create scheduling issues. A part that takes two weeks to arrive can delay the build if not ordered early.

- Unreliable demand forecasts lead to overproduction or shortages. If demand is guessed, the plan will be wrong.

- Manual override errors can cancel or change system-generated plans. This breaks the logic of the entire MRP system.

Types of MRP Solutions (Modern vs Legacy)

MRP solutions have changed a lot over the years. Older systems still work but often slow down teams. New tools are faster, easier, and built for today’s manufacturers. Here’s a quick comparison:

| Feature | Legacy MRP | Modern MRP solutions |

Data handling |

Limited, often stored in separate files |

Centralized and integrated across departments |

Interface usability |

Text-based, hard to learn |

User-friendly dashboards with simple menus |

Cloud vs on-premise |

On-premise only |

Cloud-based or hybrid, with remote access |

Inventory sync & speed |

Slow updates and delays |

Real-time sync, fast processing |

Real-time visibility |

Lacking |

Built-in, with live inventory and order tracking |

MRP vs ERP: What’s the Difference?

MRPs and ERPs help manage business operations, but they are not the same. Let’s map out the main differences in the table:

| Feature | MRP | ERP |

Functionality |

Focuses on production planning and materials control |

Works with finance, sales, inventory, CRM, supply chain, and manufacturing |

Scope |

Narrow: made for manufacturers |

Broad: fits many business types and departments |

Integration options |

Can connect to various tools like inventory software |

Has built-in modules, often harder to customize |

Ideal users |

Small to mid-size manufacturers |

Businesses seeking for full company-wide control |

Check out our article about the ERP systems. Learn about the difficulties and possibilities of their integration with other software, their prices, and prospects.

Who Can Use MRP? (Examples of Users)

MRP solutions are not only for large factories. Many types of businesses use them to manage stock, plan tasks, and avoid delays.

- Manufacturers use MRP software to plan raw materials, schedule production, and reduce waste.

- Food service companies track ingredients, match supply to daily menus, and control expiry dates.

- Service providers keep tools, devices, or spare parts in stock use Material Requirements Planning to manage supply and fulfill customer jobs on time.

- Warehouses and fulfillment centers use MRP to assemble custom orders, manage kits, and track bundled stock.

- Facilities managers in offices, hospitals, or schools rely on MRP to reorder equipment and supplies before they run out.

‼️ Any business that builds, assembles, or prepares products can use an MRP system, even if it’s not a traditional factory.

How to Launch an MRP System

To launch MRP implementation, you don’t need complex tools. Start with a few key inputs. Here’s what you need to prepare:

| Requirement | What It Means |

BOM info |

A complete list of all materials and parts needed for each product |

Inventory availability |

Up-to-date records of what you already have in stock |

Quantity plans |

Clear numbers for how much you need to produce and by when |

Scheduling inputs |

Info about work hours, machine availability, and task order |

Shelf life and demand |

Product expiry dates and expected sales or orders |

Tip: Start small. Test your MRP software on a single product or batch. Once it runs smoothly, expand to the full process.

Begin your journey into automated manufacturing management with Kladana: master your inventory and resource allocation, make efficient production plans, and increase your overall profit.

Now is the period when approximately the same goods at the same prices are sold in one place. It is very complicated to compete in this kind of market environment. Correctly built processes can become an additional competitive advantage.

It’s hard to compete with similar products on the market, but if you optimize processes, you can save on purchases and increase productivity, optimize some costs, monitor the deviations, and analyze, eliminate, and expand bottlenecks. Due to this, you can reduce prices and fight for market share.

Top MRP Software Tools

In this paragraph you’ll find brief descriptions of the most popular MRP software vendors. We hope it will help you make the best choice for the efficient management of your production process.

![]()

Kladana presents a comprehensive cloud-based ERP solution with a manufacturing module, tailor-made for small and medium-sized enterprises (SMEs). This user-friendly platform helps businesses go digital and automate their operations within a single, unified application.

A 14-day trial period is offered to choose carefully and try the necessary features before buying. For those who have simpler requirements, to begin with, Kladana has a free pricing plan. New users can master the basics of the application in just 15 minutes.

![]()

MRPeasy has a convenient interface and all the features necessary for a manufacturer: from tracking stock availability to reporting, planning, and forecasting. The solution fits the needs of small manufacturers.

![]()

ERPAG is a cloud-based solution suitable either for small or big enterprises. It’s easy to use yet very powerful. It can also work with popular tools like Shopify, QuickBooks, Xero, and WooCommerce. ERPAG also has integrated CRM and sales modules.

Acumatica is a cloud-based MRP solution for SMEs that helps to satisfy the needs of the enterprise by offering features like financial management, reporting, business analytics, and more. Most of the users mark it as a scalable solution with a reasonable price.

![]()

Katana MRP offers smart features to enhance control over business processes: automated resource distribution, automatic inventory adjustments, etc. Users are satisfied with the excellent work of the customer support team and mention that sometimes Katana accepts and introduces the development suggested by clients.

Epicor Software is known as one of the flexible solutions tailored to coping with complex manufacturing tasks. Key MRP features are good at predicting demand parameters and managing distribution and fulfillment processes.

Genius ERP is a complex solution with a strong MRP module with a long history: it was established over 25 years ago. It offers powerful features good for SMEs. It can convert CAD designs into BOMS.

Oracle NetSuite is a complex MRP solution with an abundance of features the manufacturer can successfully use and adjust to his own needs. It operates with strong intelligence tools, manages and controls inventories and production with automatic status updates, and has convenient forecasting features. The only drawback constantly mentioned by the users is the solution’s price.

![]()

DelmiaWorks, earlier known as IQMS, is an affordable yet rather scalable cloud-based solution that grows together with the enterprise. It offers a variety of business intelligence tools and informative graphic reports. The solution is also famous for its constant innovations based on the requirements of the users.

JobBOSS is remarkable for its flexibility. It is an affordable and manageable MRP cloud-based or on-premise software good for SMEs’ manufacturing needs. Has strong accounting features and helps to predict the results of “what if” scenarios.

If you want to get acquainted with popular production management software, read our compilation article with examples of the 23 best solutions in 2026, and a description of their functions, advantages, and disadvantages.

Technologies Enhancing Modern MRP

Modern MRP solutions use smart technologies to improve speed and accuracy.

- AI and Machine Learning help predict demand better. For example, if sales rise before holidays, the system can adjust the material plan in advance.

- IIoT (Industrial Internet of Things) connects machines, sensors, and stock systems. It gives real-time updates about machine use, stock levels, and order progress.

- Cloud deployment allows remote access, faster updates, and easy scaling. It also reduces the need for on-site servers.

History of MRP

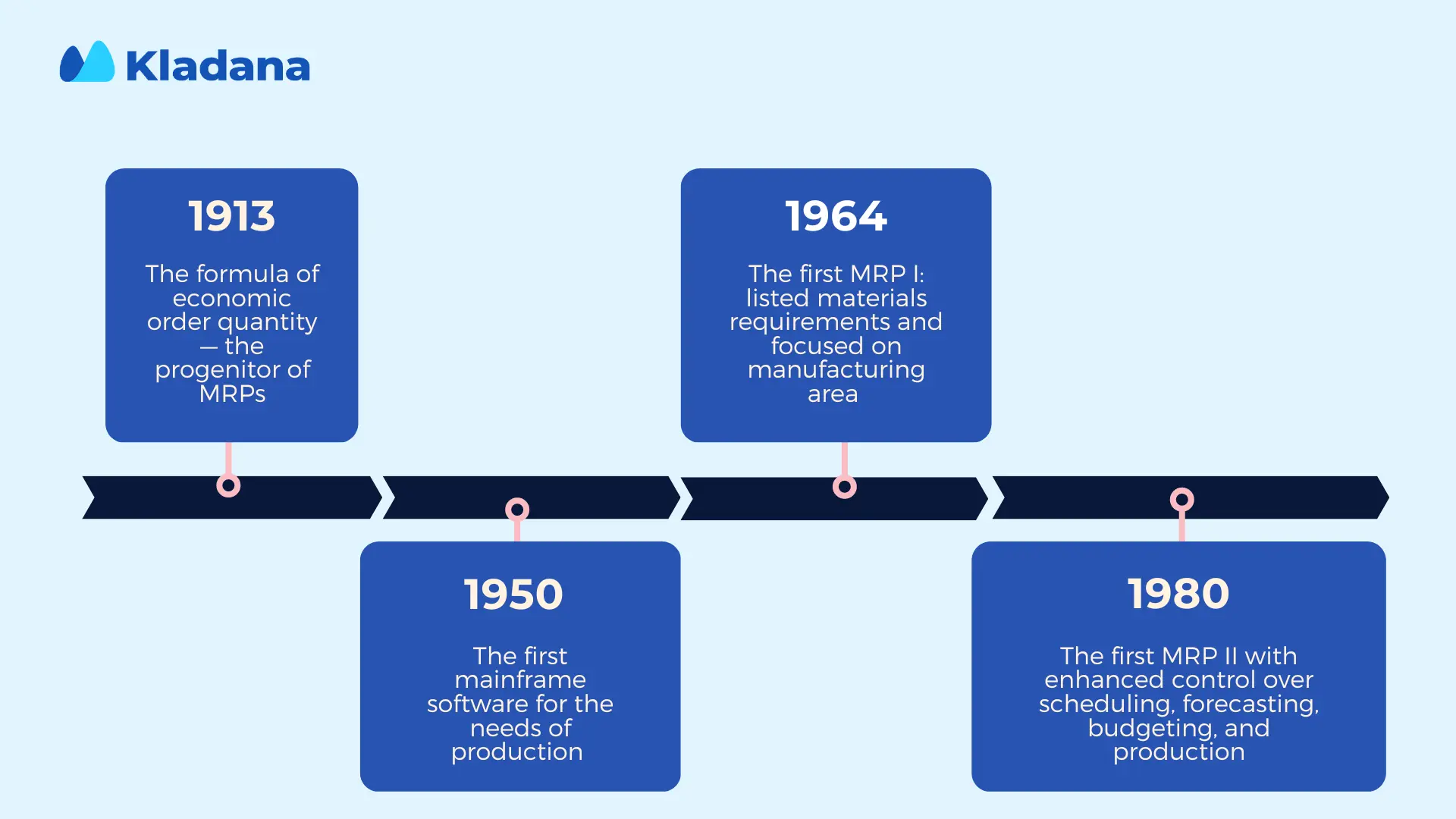

The idea behind Material Requirements Planning (MRP) started in the early 1900s. In 1913, Ford Whitman Harris created the EOQ (Economic Order Quantity) formula to reduce storage and order costs. Around the same time, Henry Ford showed how strict control over materials could speed up mass production.

In the 1950s, early computers helped businesses track stock and orders. This led to the first MRP systems in the 1960s. These tools used sales data and BOMs to plan what materials to buy and when.

In the 1980s, MRP II appeared. It added more functions — including finance, staffing, and capacity planning.

Later, MRP II evolved into ERP systems, which combine all business areas — not just production — in one platform.

FAQs on MRP Solutions

Below, we describe the elements, methods, and challenges of MRP. Additionally, we explain the differences between MRP and ERP, as well as MRP and BoM.

What does MRP mean?

MRP stands for Material Requirements Planning. It is a system that helps businesses plan what materials to buy, how much to buy, and when to use them for production.

What are the 3 basic MRP steps?

- Determine material requirements (from forecasts and orders)

- Check inventory and BOMs

- Create schedules and order plans

What is the difference between BOM and MRP?

The BOM (Bill of Materials) is a list of parts needed to make a product. MRP software uses the BOM to plan material needs and create production and purchase schedules.

What is MRP vs ERP?

MRP solutions focus on production and materials. ERP systems handle more — including sales, finance, HR, and more.

What are the elements of MRP?

The key elements are the Master Production Schedule, Bill of Materials, and Inventory Records.

What are common MRP challenges?

Common issues include wrong data, missing lead times, incomplete BOMs, and poor system setup.

List of Resources

Business Research Insights — Material Requirements Planning (MRP) Software Market Size, Share, Growth, and Industry Analysis