When you run an e-commerce business, growth brings opportunity but also complexity. As orders increase and sales expand across Shopify, Amazon, WooCommerce, and other channels, you face challenges that spreadsheets and basic inventory and warehouse software can’t handle. Overselling, mispicks, and late deliveries cost more money and erode the trust of the customers.

That’s why many scaling brands invest in an e-commerce warehouse management system. Unlike generic ones, it is specifically designed to synchronize your warehouse operations with online sales channels, allowing you to ship faster, reduce errors, and scale with confidence.

The scale of this adoption is evident in market data. MarketsandMarkets estimates the global warehouse management system market was worth $4 billion in 2024 and will reach $8.6 billion by 2029, showing that companies worldwide are putting fulfillment efficiency at the center of their growth plans.

This guide will show you what a warehouse management system for e-commerce is, why it’s essential, the key features to look for, and how to choose the right solution.

What Is an E-commerce Warehouse Management System?

An e-commerce warehouse management system (WMS) is a software that helps you organize and control day-to-day warehouse operations. It is designed for e-commerce warehousing, where accuracy and speed directly impact customer satisfaction.

A WMS for e-commerce typically manages:

- Stock receiving and put-away

- Storage and inventory tracking

- Picking and packing orders

- Shipping and delivery updates

- Returns and restocking

- Record keeping and reporting

By consolidating these tasks in one system, an e-commerce WMS ensures that inventory and order data remain accurate across all your sales channels. This reduces errors, speeds up fulfillment, and ensures customers receive the right product on time.

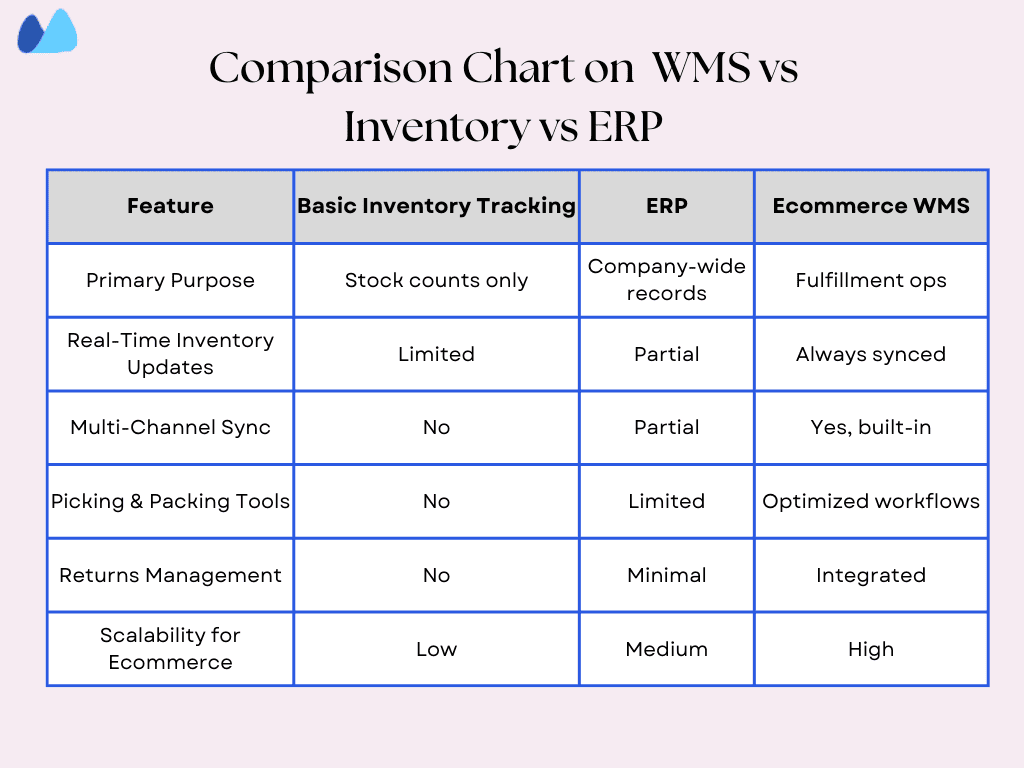

WMS vs Basic Inventory Tracking

Basic tools or standalone inventory apps provide a snapshot of stock levels, but that’s where they typically stop. They don’t guide your team through the process. They also can’t keep multiple sales channels synchronized in real time.

An e-commerce warehouse management system goes much further. It not only tracks inventory but also manages workflow from bin locations to shipping labels, by connecting every step from end-to-end. A WMS for e-commerce eliminates guesswork and speeds up order fulfillment.

How It Differs from ERPs

An ERP (Enterprise Resource Planning) system is built to manage company-wide processes such as

- Finance and accounting

- Human resources

- Purchasing and procurement

- High-level inventory reporting

But running fulfillment only on ERP leaves gaps. ERPs are not designed for the speed and precision required in e-commerce warehousing. That’s where an e-commerce warehouse management system adds value.

Instead of just reporting stock numbers, a WMS ensures real-time accuracy in inventory, directs warehouse staff through daily operations, and syncs order updates instantly across sales channels.

For many businesses, the two systems work best together. The ERP manages finances and overall business planning, while the WMS for e-commerce keeps warehouse operations accurate, fast, and customer-ready.

☑️ Tip: If you already use an ERP, don’t duplicate warehouse functions in it. Instead, integrate a WMS for e-commerce and let the two share data. This avoids double entry, reduces errors, and ensures both financial operational records stay aligned.

📚 Recommended Read: Want to see how ERP and WMS work together in practice? Check out our guide on ERP for Warehouse Management

Why E-commerce Businesses Need a WMS

Running an e-commerce warehouse is different from traditional retail. Orders are smaller but far more frequent, product assortments change quickly, and customers expect same-day accuracy. In this environment, spreadsheets or basic inventory tools fall short. Mistakes multiply, labour costs increase, and delivery speed slows as operations grow.

This is why e-commerce businesses need a warehouse management system. It provides the structure and automation to keep pace with rising demand, maintain accuracy across operations, and protect margins as order volumes increase.

The three challenges most e-commerce businesses face as they scale are:

- Managing high-order volumes without bottlenecks

- Keeping inventory accurate across multiple channels

- Reducing mispicks and costly returns

The following section breaks these down and shows how a WMS for e-commerce addresses each challenge.

1. High-Order Volume Challenges

In e-commerce, order volume doesn’t grow steadily; it spikes. Flash sales, holiday peaks, or influencer promotions can double or triple daily orders overnight. Without the right systems, warehouses scramble to keep up, staff rush through tasks, and mistakes multiply. Hiring extra staff helps temporarily, but it often increases costs without addressing the underlying workflow issues.

This is where an e-commerce warehouse management system adds value. Instead of scaling labour endlessly, it increases throughput by creating optimized pick routes, batching similar orders, and synchronizing them in real-time. The same team can process more orders per shift, with fewer delays and errors.

2. Managing Multi-Channel Inventory

Selling across multiple platforms is crucial for growth, but it also introduces complexity. Each channel, whether your own online store, a marketplace, or a third-party platform, needs accurate data. When updates are done manually, even slight delays or mistakes can result in overselling, canceled orders, or stockouts that frustrate customers.

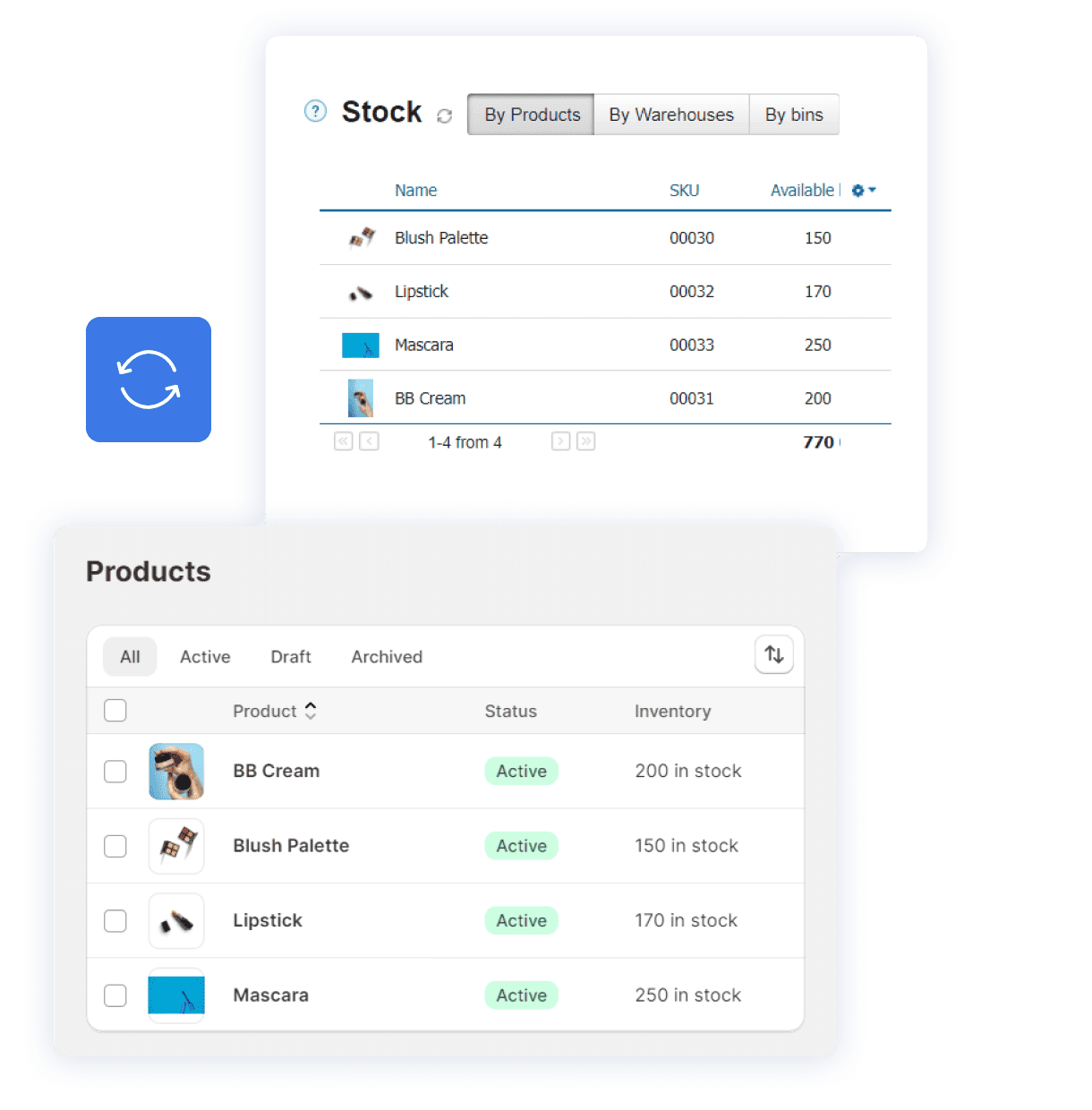

An e-commerce warehouse management system keeps inventory synchronized across all channels automatically. Every sale, return, or adjustment is updated in real time. So that customers can see accurate availability, and your team doesn’t waste time reconciling stock manually.

3. Reducing Mispicks & Returns

Mispicks, or sending the wrong item, always frustrates the customers. They add a direct, larger challenge of e-commerce returns. Every incorrect shipment incurs additional costs in shipping, repackaging, and customer follow-up. Returns are already a massive issue for the industry. The National Retail Federation (NRF) reported that in 2024, retailers lost nearly $890 billion to returned goods.

This shows how costly even minor errors can become when multiplied across thousands of orders. An e-commerce warehouse management system helps prevent these avoidable returns by validating items before they leave the warehouse, flagging mismatches, and keeping records updated in real time. By stopping mispicks at the source, businesses reduce costs and maintain customer trust.

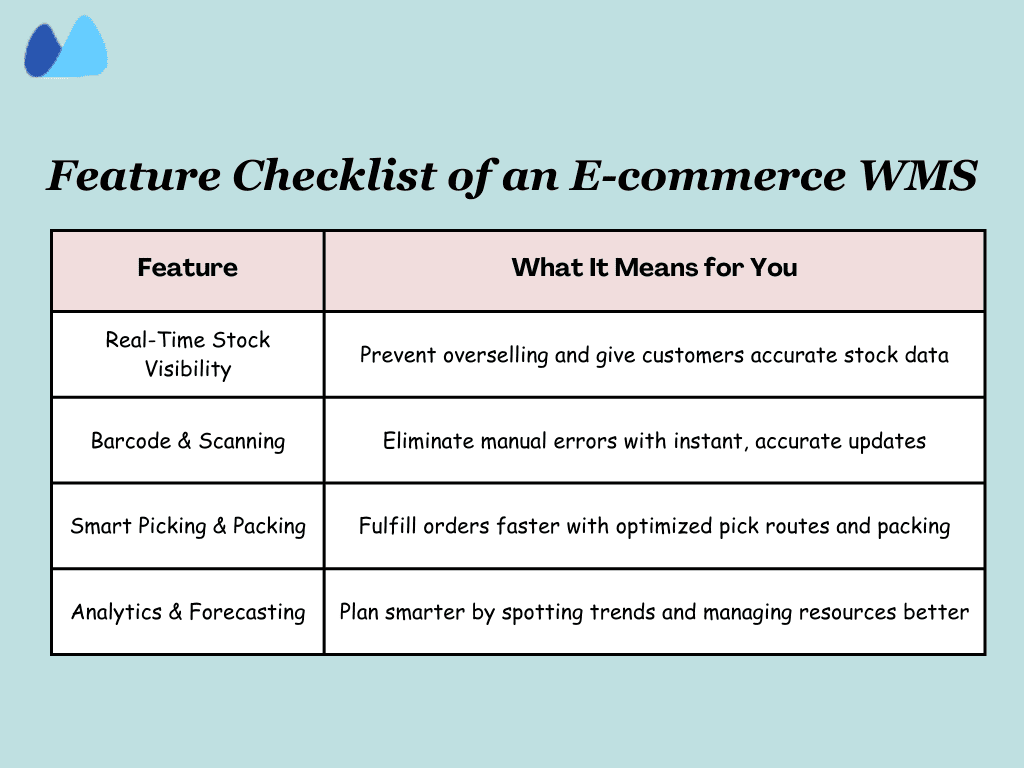

Key Features to Look for

When evaluating an e-commerce WMS, the feature list matters as much as the price. The right warehouse management software will streamline your daily operations, reduce errors, and support long-term scalability. Below are the core features that every e-commerce-focused business should include, along with their implications for your business.

1. Real-Time Stock Visibility

Without real-time data, you risk overselling and backorders. A Warehouse Management System for e-commerce provides instant transparency into what’s actually available, where it’s stored, and how much has already been allocated to open orders.

For example, imagine you sell your product both on Shopify and Amazon. A customer buys the last unit on Amazon, but your Shopify site still shows as “in stock”. With an e-commerce WMS software, the inventory deduction happens quickly across both platforms, which helps in preventing overselling and customer disappointment.

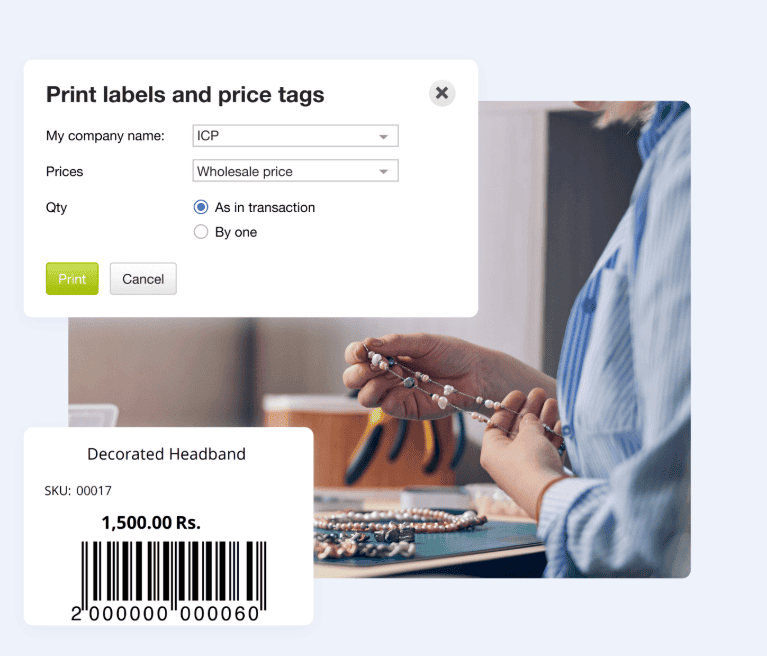

2. Barcode & Scanning Integration

Manual entry is slow and error-prone. With barcode scanning, you confirm every item during receiving, picking, and packing. Each scan updates the warehouse control system automatically, cutting down on mistakes and saving time.

For example, A beauty products retailer reduced fulfillment errors by introducing handheld scanners connected to their warehouse management software. Items were confirmed at pick and pack, eliminating costly mis-ships and helping drive down returns.

Buyers checklist:

- Does the inventory and warehouse software support both 1D and 2D barcodes?

- Can it integrate with mobile scanners or just desktop stations?

- Does it work offline if your Wi-Fi drops?

Why it matters: Reliable barcode integration ensures accuracy at scale. Instead of adding more staff to check, you can trust the system to validate every product and keep fulfillment flowing smoothly.

3. Smart Picking & Packing

As order volumes grow, the way you pick and pack has a direct impact on efficiency. A fulfillment management system generates optimized pick routes, creates batch or wave pick lists, and confirms items before packing.

For example: During holiday sales, a fulfillment startup switched from a single-order picking warehouse control system to driven wave picking. Instead of handling orders one by one, staff picked items for multiple orders in a single aisle walk. This helps reduce walking time and speed up order processing.

📚 Recommended Read: For a deeper look at proven methods, explore our blog on Pick and Pack Warehouse Processes

➡️ Kladana’s WMS module generates optimized pick lists, integrates barcode scanning, and updates inventory instantly across your e-commerce channels.

4. Analytics & Forecasting

A comprehensive inventory and warehouse software solution doesn’t just help with today’s fulfillment, but also enables you to plan for tomorrow. Analytics on stock turnover, order patterns, and supplier lead time give you the insights to buy smarter and allocate labour effectively.

For example, an electronics business used warehouse management software forecasted that a specific SKU consistently spiked during the school season. By adjusting purchase orders earlier, they avoided stockouts and captured more sales.

Buyer Tip: Look for a warehouse control system reporting that goes beyond inventory counts. You should be able to track key fulfillment KPIs, including pick accuracy, order cycle time, and labour productivity.

How a WMS Works in E‑commerce Fulfillment

A warehouse management system for e-commerce is not just a tracking tool. It is also the backbone of your fulfillment process. From the moment an order is received until the package reaches the customer, and even if it’s returned, the fulfillment management system keeps every step synchronized and visible.

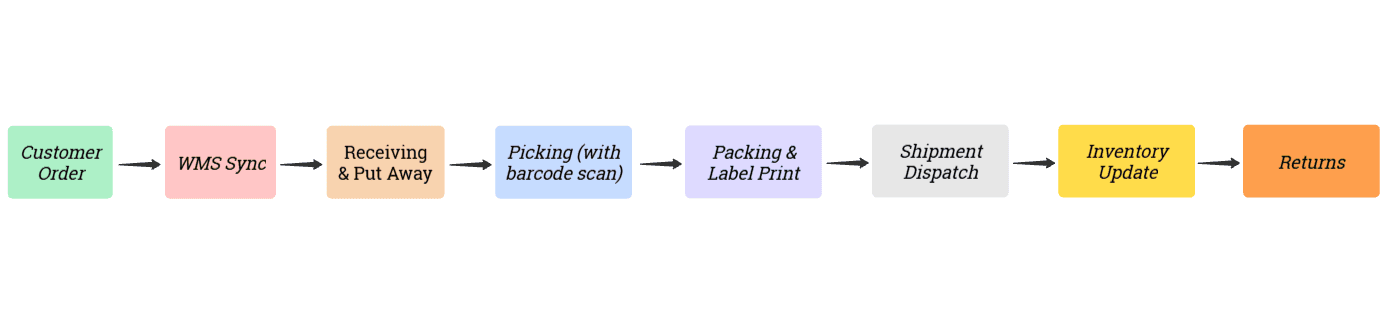

1. From Order Sync to Delivery

Here’s how a typical workflow looks when you use e-commerce WMS software:

➔ Order sync: As soon as customers’ orders from Shopify, WooCommerce, or Amazon are received, the WMS captures them automatically. So, there will be no manual entry, and everything will be automated.

➔ Receiving & put-away: Incoming stock is scanned into the warehouse control system, assigned to storage locations, and instantly reflected across all sales channels

➔ Picking: Employees receive optimized pick lists on handheld devices, guided by the WMS to reduce walking time and errors.

➔ Packing: Barcode scans confirm that items match the orders. Labels and shipping documents are generated directly from the warehouse management software.

➔ Shipping: Carrier integration, such as Borzo, UPS, FedEx, DHL, etc, with push tracking details to the customer automatically

➔ Returns: Returned items are scanned back into the inventory, keeping the stock accurate in real-time.

⚡ Slash Errors, Speed up Orders — Run Your Warehouse with Kladana

Automate picking and packing with barcode accuracy and keep every shipment on track

Example workflow of WMS

Choosing the Best E‑commerce WMS

Not all warehouse management software is the same. The right choice depends on your business model, order volume, sales channels, and long-term growth plans. When evaluating vendors, focus on more than one feature, such as integrations, support, ROI, and scalability.

Questions to Ask Vendors

Before signing a contract, you should dig deeper with practical questions like:

- Does the warehouse management system for e-commerce integrate natively with Shopify, Amazon, or WooCommerce?

- Can the fulfillment management system scale if my order volume doubles next year?

- How easy is it for the employees to learn? Like, ask about onboarding and training times

- Does the system offer mobile scanning support for real-time updates?

- How often is the software updated, and are the updates included in the subscription?

Buyer checklist:

- Clarify pricing, such as per user, per order, or flat subscription

- Confirm integration with your carriers

- Ask for customer case studies in your industry

Typical Cost & ROI

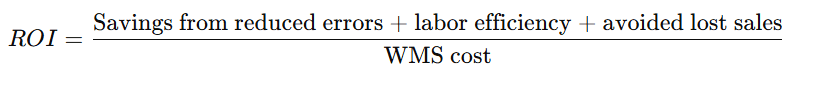

The cost of e-commerce WMS software can range from low monthly SaaS fees to enterprise-level licenses. However, the most important measure is ROI, which refers to the amount the system saves you compared to its cost.

A simple way to calculate ROI for a warehouse management system for e-commerce is:

Breakdown of savings sources:

- Reduced errors: calculate your average cost per return x number of mispicks per month. A WMS reduces this significantly

- Labour efficiency: estimate hours saved per month x average labour cost per hour.

- Avoided lost sales: if overselling or stockouts previously led to cancellations, estimate lost revenue per month.

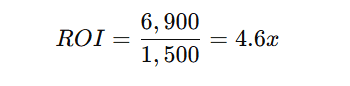

Sample Example

- Current mispicks: 300 per month x $8handling cost = $2,400 losses

- Labour saved: 200 hours x $15/hour = $3000

- Avoided cancellations: $1500 revenue retained

- Total monthly savings = $6,900

But if your WMS costs $1,500/month, then:

This means the system pays for itself multiple times over each month

👉 Kladana ROI Insight: Merchants using Kladana typically see 20–30% faster order processing within the first 2 months

Sample Case Study

A mid-size electronics brand sold headphones, chargers, and accessories through Amazon and its own website. The launch days were chaotic, as employees had to update stock manually, overselling was common, and customers often received the wrong products, which led to more returns.

After experiencing numerous struggles, the company finally switched to an e-commerce warehouse management system that provided real-time inventory sync and location-based picking. Wrong item complaints suddenly reduced, and employees could process double the daily orders during launches without overtime.

With the new e-commerce warehouse software, the brand expanded into two more marketplaces within six months, and every order was shipped correctly by implementing the right software at the right time.

Comparison Table: Top E-commerce WMS Solutions

| Criteria/Vendor | Vendor A (General WMS) | Vendor B (ERP Add-on) | Vendor C (E-commerce-Focused WMS) |

| Integration with Shopify/Amazon | Limited (via connectors) | Partial | Native, real-time sync |

| Pricing Model | Per user | License + add-ons | SaaS (per order or flat fee) |

| Scalability | Good for a single warehouse | Moderate, ERP-dependent | High (multi-channel, muti-channel warehouse) |

| Picking & Packing Tools | Basic | Minimal | Optimized (batch, wave barcode) |

| Analytics & Forecasting | Inventory only | Financial focus | Fulfillment KPIs + forecasting |

| Onboarding/Training | 2–3 months | Long (ERP complexity) | Weeks (simple UI, e-commerce-ready) |

| ROI Impact | Efficiency gains | Broader business control | Faster fulfillment, fewer errors |

Conclusion

Scaling an e-commerce business isn’t just about selling more; it’s about fulfilling more, faster, and with fewer mistakes. That’s where an e-commerce warehouse management system makes the difference by giving you real-time visibility, automated workflows, and error-proof picking and packing. A WMS turns your warehouse from a bottleneck into a growth driver.

Whether you face high order spikes, multi-channel complexity, or costly mispicks, the right warehouse management software keeps operations under control and customers satisfied. With features like barcode scanning, smart picking, and analytics, you don’t just react to problems; you prevent them.

⚡ Drive E-Commerce Growth With Kladana’s Real-Time WMS

Sync inventory, orders, and warehouse instantly across all your sales channels

Frequently Asked Questions on E‑Commerce Warehouse Management Systems

What is an e-commerce warehouse management system?

A WMS is a software platform that manages inventory, orders, picking, packing, shipping, and return workflows. It is designed to give real-time control over your fulfillment operations.

How is a WMS different from basic inventory software?

Inventory tools track stock levels, but a WMS orchestrates receiving order processing, optimized picking, and shipping with automation and accuracy.

Does a WMS integrate with existing systems like Shopify, ERP, or transportation tools?

Yes. Modern WMS platforms offer integrations with e-commerce platforms, delivery services, and more, ensuring seamless data flow across your tech stack.

Can small e-commerce businesses benefit from a WMS?

Absolutely. Scalable and cloud-based WMS solutions now suit small teams and startups, offering room to grow without overpaying for enterprise features early on.

What are the top 2025 warehouse management trends to watch?

Emerging 2025 trends include cloud systems, omnichannel fulfillment, sustainability, and real-time tracking using IoT and a live dashboard.

What’s the importance of real-time inventory visibility?

It enables you to spot stock issues instantly, avoid overselling, and respond quickly to demand changes.

How can a WMS improve picking efficiency?

By implementing wave or batch picking strategies, where items are picked for multiple orders in one run, travel time is reduced and productivity increases.

Do WMS help with predictive operations and planning?

Yes. Advanced modules, known as warehouse execution systems, analyze fulfillment data in real time to predict issues like stock-outs or staffing spikes.

How does a WMS support omnichannel fulfillment?

A WMS enables a single facility and inventory pool to serve multiple channels, adjusting picking, packing, and shipping as needed to meet the varied requirements of each channel from a single warehouse.

List of Resources

- MarketsandMarkets: Warehouse Management Market Growth

- National Retail Federation: Survey on Consumer Returns

Read‑alikes

ERP Warehouse Management System: Complete Guide with Features & Benefits

Warehouse Inventory Management: a Complete Guide to Tools, Tips, and Systems for 2026

Warehouse Management System Process Flow: Steps, Charts, and SOP Templates

How Does a Pick and Pack Warehouse Work in 2026 — What Improves Its Efficiency?

Warehouse Inventory Management: a Complete Guide to Tools, Tips, and Systems for 2026