Body Motion, a South African sportswear and medical apparel manufacturer, adopted Kladana after evaluating over 40 ERP systems — and found its answer in one thing: real-time, responsive support.

In just six months, founder Riëtte Meyer transitioned from scattered spreadsheets to streamlined weekly planning, eliminated double buying, and improved cash flow. Implementing the system solo, she likened the setup to baking a cake for the first time — but with immediate support and video tutorials, it became manageable. This is the story of how automation brought visibility, control, and calm to a fast-growing apparel business.

It All Started with Zippers

Running a growing garment manufacturing business on spreadsheets eventually hits a limit — and for Riëtte Meyer, it was zippers, other raw materials, and finished goods tracking that broke the system. With dozens of zipper variants by colour, length, and material, keeping accurate stock in Excel became a daily struggle.

“We reached a point where spreadsheets just couldn’t keep up. We were buying things we already had — simply because no one knew they were there. That’s when I decided to find a tool that could help me count all the inventory.”

Double buying led to wasted money and storage space. No one knew exactly where particular items were located in the storeroom. Time was spent searching instead of producing. Riëtte knew she needed a proper clothing inventory control system to track what was in stock — and where.

She evaluated over 40 tools and trialed six. In the end, one factor tipped the scale: Kladana’s immediate, responsive, support. Other ERPs either took too long to reply or didn’t respond at all. Since Riëtte planned to handle the implementation herself, those options felt overwhelming — while Kladana’s hands-on support made all the difference.

| Aspect | Excel Hurdles | How Kladana Helped |

Inventory Tracking |

🚫 Scattered records, blind spots, double buying |

✅ Real-time visibility, reduced shrinkage, better inventory accuracy |

Cash Flow |

🚫 Working capital tied up in excess materials, unclear stock levels |

✅ Freed-up cash thanks to smarter purchasing and clear stock levels |

Production Oversight |

🚫 Manual updates, missed or delayed orders |

✅ Centralized dashboard for tracking orders and planning production |

Subcontractor Tracking |

🚫 Manual and disconnected |

✅ Bill of Materials (BOMs) include custom embroidery, printing, and other branding tasks |

Let’s now dive into Body Motion’s growth story — from wedding dresses to custom scrubs — and see how inventory challenges shaped its next phase of scale.

From Custom Wedding Dresses to a Thriving Scrubs and Sportswear Brand

Riëtte Meyer’s business journey began with a love for detail and craftsmanship. In the 90s, she created wedding and graduation gowns — beautiful, bespoke pieces, but it wasn’t mass production. Eventually, she paused the business to raise her four children and run another venture.

Her return to fashion came years later, sparked by a personal experience. During her daughter’s gymnastics competition, the leotard supplier failed to deliver on time, and several children had to perform in plain black outfits.

“That night, I told my husband: ‘This won’t happen again.’ I decided to launch a business making sportswear — especially using lycra, which most people avoided. I bought straight-stitch, overlock, and cover-seam industrial machines and started making samples.”

That turning point led Riëtte to pivot from special occasion wear to functional sportswear and, eventually, medical apparel. Today, her South African-based business produces scrubs and activewear for clinics, schools, medical students, and even sports teams.

Business Snapshot

- Industry: Sportswear and medical apparel

- Founded: 1990s (originally in bridal wear)

- Brands: Body Motion Clothing Manufacturers, Scrubs in Motion Medical Wear

- Team: Founder, admin, production manager, seamstresses, cutters, trimmers, ironers, packers

- Sales Channels: Instagram, website, direct sales to B2B clients

- Key Clients: Clinics, hospitals, medical students, schools, sports teams

- Partners: Plastic surgeon, Ferrari

Custom Fit and Quality Fabrics: A Strategy to Win the Market

What makes Body Motion stand out in South Africa’s competitive apparel space is a clear focus on custom fit and fabric quality. While most local manufacturers stick to standard sizing, Riëtte’s team offers made-to-measure adjustments — whether it’s a size small with extra length or shortened sleeves. Body Motion specializes in modern, high-quality scrubs designed for comfort and functionality — ideal for healthcare professionals who wear them daily.

Some clients also request branding, such as hospital or company logos. Branding tasks like embroidery and printing are done by trusted subcontractors.

The business is powered by a small but capable team:

- An admin manager handling client communication and order coordination

- A production manager overseeing seamstresses, cutters, trimmers, and packers

Purchase management is an ongoing challenge. Riëtte buys fabric and haberdashery in bulk from wholesalers across Johannesburg, Durban, and Cape Town. To qualify for free delivery, she has to order at least 300 meters — which means planning orders carefully to avoid both stockouts and excess. They have to be very strategic — enough stock to fulfill orders, but not so much that it ties up cash or wastes space.

Riëtte is also on the lookout for breathable fabrics with light stretch — ideally with 3–4% elasticity. She often examines garments from other brands to study their materials and finishes, always trying to improve the balance between comfort, durability, and fit.

Sales Channels, Clients, and Growth Partners

Body Motion operates in B2B sales, working with schools, hospitals, care homes, and sports clubs. Some clients, like schools, can be unpredictable — they often switch suppliers depending on the teacher in charge. But hospitals and care workers are steadily shifting to scrubs, which presents a stronger long-term opportunity.

“ECG Clinical Wear has been with us for 10 years — they order scrubs regularly. Another is the shooting team who needs shirts, jackets, vests, and towels for international competitions. They’re always ordering something, and it’s never the same set of items.”

The company’s primary sales channels are its website and Instagram. They previously tried Google Ads, but results were underwhelming. Now, they’re investing more into Instagram Scrubs in Motion — with a new photo shoot planned to boost brand visibility.

Leads from Instagram are directed to the website. There’s no pricing listed yet — clients fill out a form and receive a price list directly.

Body Motion recently partnered with a plastic surgeon who requested Ferrari-themed scrubs. This brand-inspired apparel project is opening up new creative and commercial opportunities.

Looking ahead, the company hopes to onboard a nearby school for a full uniform contract — including sportswear. They’re also working with a new gymwear client who provides imported fabric. Still, custom medical scrubs remain the business’s core focus. Post-COVID, more professionals are prioritizing comfort in daily wear — and scrubs are meeting that need.

When Excel Failed Riëtte

As the business grew, so did the complexity of inventory. Riëtte had to manage hundreds of fabric rolls, zippers, buttons, and finished goods — all in varying sizes, colours, and materials. With everything tracked manually in spreadsheets, it became impossible to spot errors, missing items, or duplicates.

“I had so many zips — different sizes, colours, types. I couldn’t keep track in Google Sheets anymore. We were double buying stock because we didn’t know what we had.”

Lack of inventory visibility led to costly double purchases, cluttered shelves, and delays in production. Missing components often meant incomplete or late orders — a serious risk in B2B apparel manufacturing.

A Search Across 40+ Systems — Why Kladana Won

When Riëtte set out to find ERP software, she evaluated more than 40 tools and trialed at least 6. Some offered sleek design. Others had impressive features. But none matched Kladana where it mattered most: support.

“One system had great features, but no one ever got back to me. With Kladana, I had support that replied within seconds. That made all the difference.”

Since Riëtte planned to implement the system herself, fast and responsive assistance became non-negotiable. Kladana stood out by combining usability with a support team that was always there when needed.

The Setup: Like Baking a Cake for the First Time

Riëtte bought Kladana just before a long holiday — not the best timing. But she used the break to dive into the platform and learn how it worked. It became her “second job,” alongside running day-to-day operations.

“It’s like baking a cake for the first time — you need all the ingredients in place. The hardest part was entering everything — products, sizes, fabrics, BOMs. It took weeks. But once done, the process got faster. Now it runs smoothly”.

Here’s how she approached the ERP implementation:

- Started with uploading inventory data and organizing storage bins — down to every single button.

- Moved on to setting up Bills of Materials (BOMs) and production routings.

- Migrated all customer and supplier contact details.

- Connected purchase and sales orders with the right production workflows.

Kladana’s copy-paste features, video tutorials, and especially the support team helped her stay on track. What started as an intimidating task turned into a workable system — and a daily business tool.

Inside the System: How Body Motion Uses Kladana

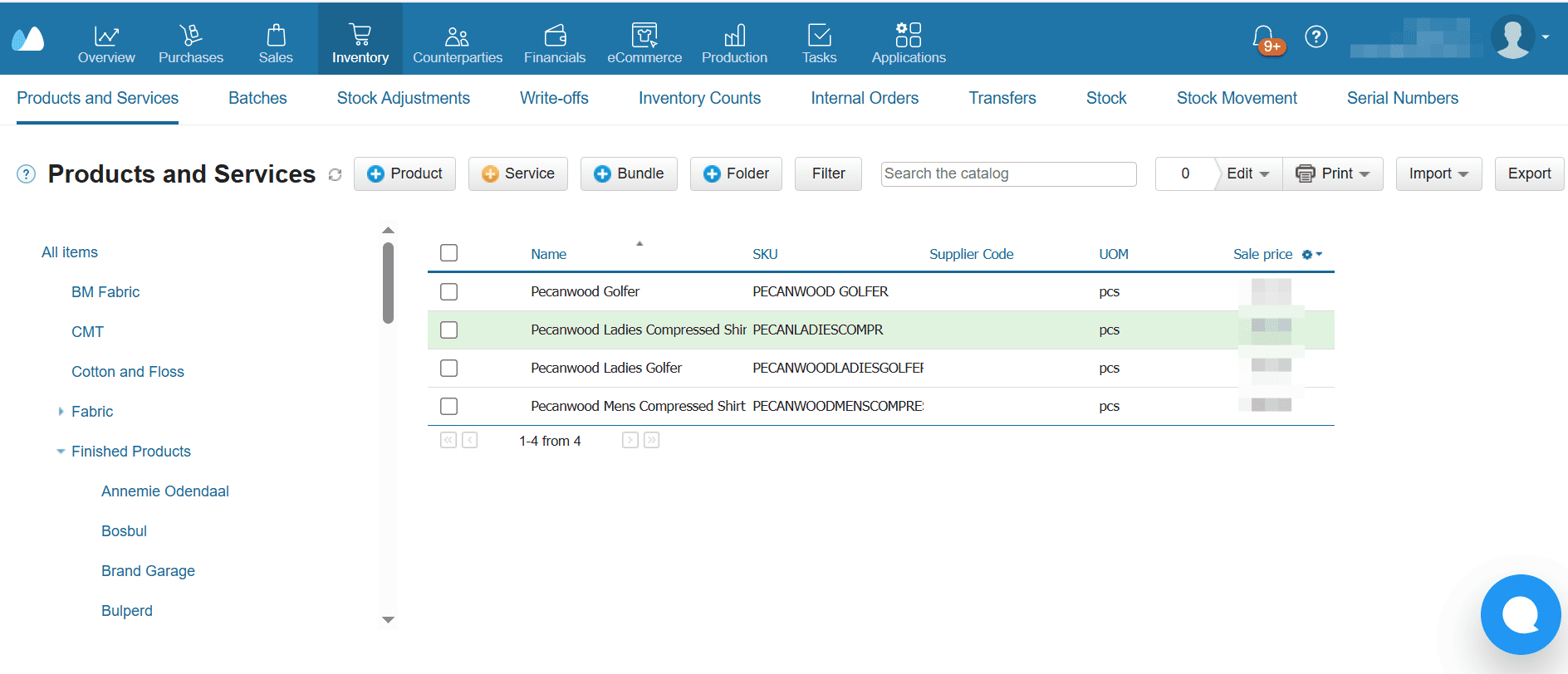

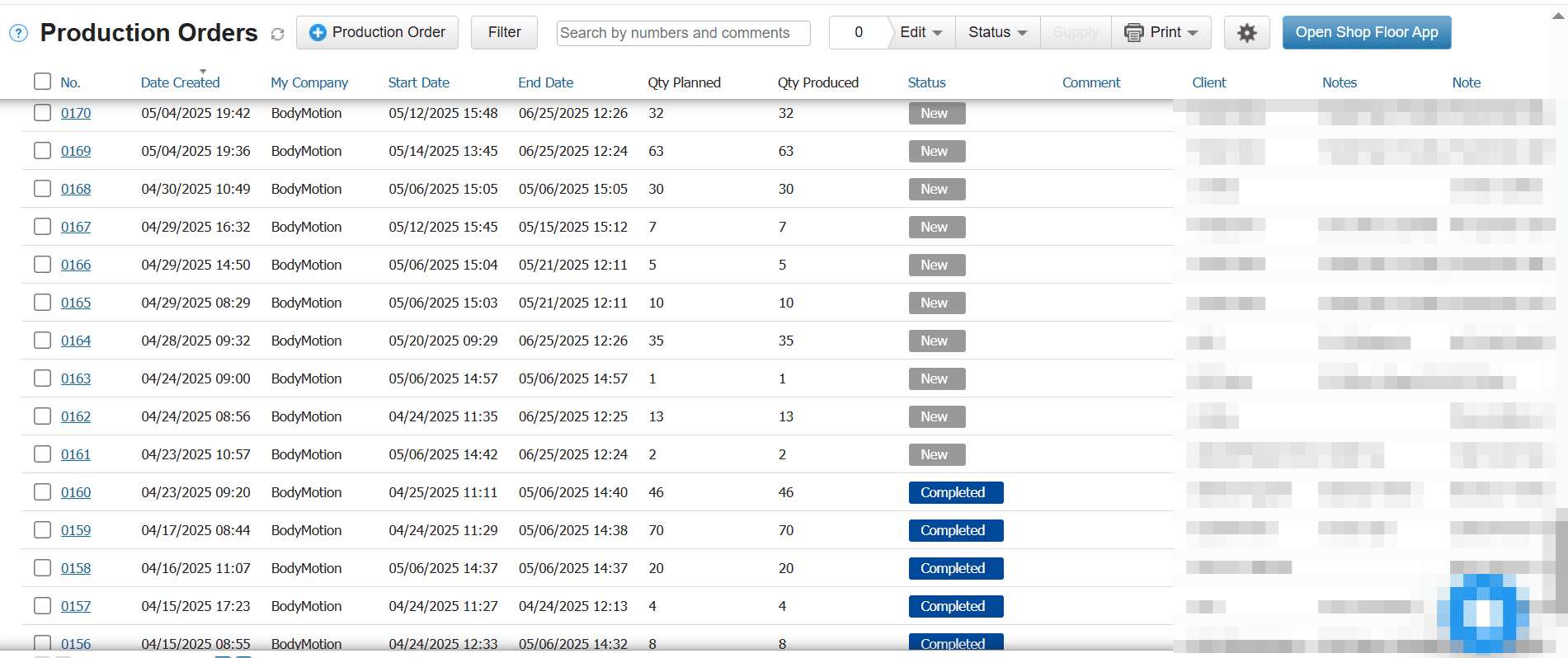

Body Motion now runs its operations using all key Kladana ERP modules:

- Production Module — All production orders and routings are in place. Bills of materials include client-specific notes: which subcontractor to use and what type of branding (e.g., embroidery, printing) is required.

- Inventory Module — Used daily to maintain visibility and avoid double purchases. Every item — from fabric to zippers — is tracked and stored in organized bins.

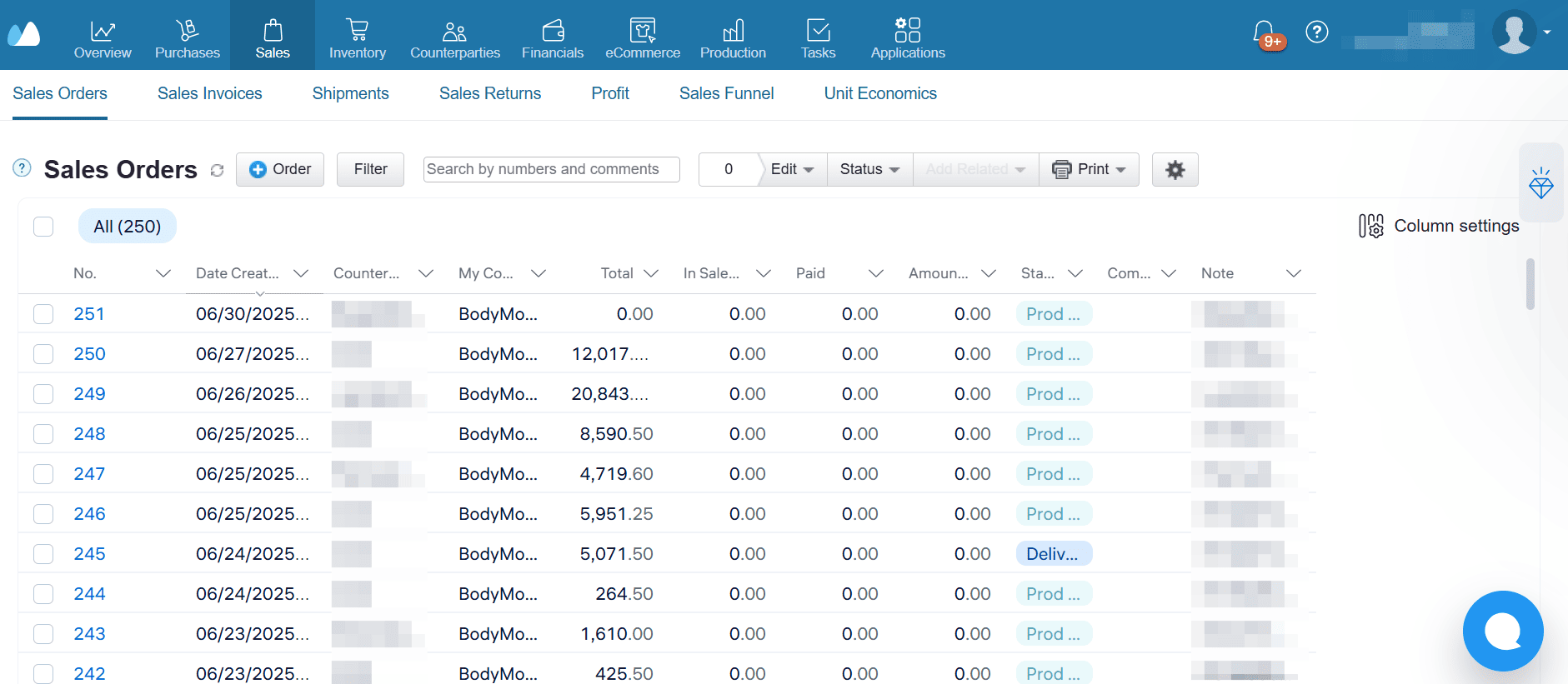

- Sales & Purchase Orders — Orders are streamlined with real-time updates. Colour-coded status blocks and dashboards show the progress of each order at a glance. Invoices for suppliers and customers are generated directly from the system.

- Stock & Sales Reports — Used to monitor cash flow, track sales performance, and spot bottlenecks early. Riëtte especially values being able to pull up past orders without digging through paperwork.

Riëtte first trained herself, then taught her admin and production managers to use the system. Each team member has a defined access level:

- Riëtte has full control

- The production manager handles manufacturing workflows

- The admin manager manages operations but can’t delete records

With everything in order, Riëtte moved from daily firefighting to weekly planning.

Tangible Changes in 6 Months

After adopting Kladana, the changes came — and they were groundbreaking:

- Remote inventory access → Easier decision-making

- No more double buying → Better cash flow, fewer stockouts

- Weekly production lists → Less daily micromanagement

- All orders in one dashboard → No lost or missed production runs

- Centralized planning → Smoother operations

“Before, I had to ask someone to check if we had this or that. Now I can see everything from home and control business processes without a hassle.”

Next Steps for Automation Improvements

- Integration with Xero is on the roadmap.

- Seamstress invoicing: Riëtte wants to link payment to output more easily. The Kladana team is working on a solution to add seamstresses into the system for automated invoice generation.

- Performance improvements: Speed during late evening sessions is a known issue, and the team is looking into it.

Try Kladana Free for 14 Days

Experience real-time visibility, easier production planning — and support that actually shows up.

Final Thoughts

Riëtte plans to keep growing Body Motion’s sportswear and scrubs lines. She’s not just aiming for smoother operations — but for a brand that feels as modern, flexible, and functional as the garments they produce.

“I’m very happy. Kladana helped us grow without chaos.”

Read‑alikes

Neytthomes’ Journey: Managing Stock Across 10 Locations and Setting Up Store Inventory in 30 Minutes

How to Create a Clothing Brand and Increase Turnover from $125,000 up to $262,000 in a Year

How To Start a Clothing Line in India — Step-By-Step Guide with Expert Tips

How To Start a Garment Manufacturing Business in India: Costs, Licenses & Expert Insights