When you walk into a supermarket or a local grocery store, most shelves brim with brightly packaged foods — a testament to how deeply processed foods have woven into our daily lives. This explosion of ready‑to‑eat and ready‑to‑cook options is largely driven by small and mid‑sized food entrepreneurs seizing gaps in the market.

Satya Majhi, founder of Punjab Delight, shared how he initially budgeted around $23,000–29,000 for his mid‑sized restaurant but ended up spending close to $35,000 due to unexpected civil work, kitchen upgrades, and marketing overruns. He now recommends adding at least a 15% buffer to any projected investment. Satya also admitted he underestimated local competition — placing his first outlet too close to a college canteen offering similar food at lower prices.

From miscalculating costs to realizing how critical hygiene and inventory practices are, his journey is a crash course for any aspiring food business owner.

In this guide, we’ll break down everything you need to prepare for launching your own food-processing venture — from concept and location to licensing, supply chain, and soft launch best practices.

Let’s dive in.

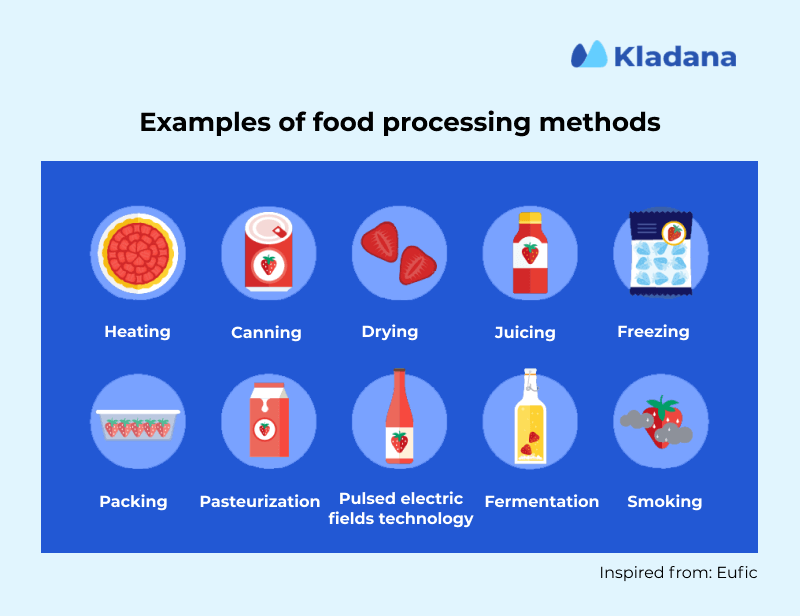

What is Food Processing?

Food processing is a method where raw agricultural products are transformed into familiar food items, converting them from one type of food into another. This transformation can happen through a range of techniques such as washing, chopping, heating, freezing, pasteurizing, fermenting, milling, extruding, and packaging.

Often, other ingredients are added to enhance flavor, texture, or shelf life.

Food processing can be done at home and out‑of‑home (for example, in restaurants and cafeterias) and even at an industrial scale. From homemade bread to ready‑to‑eat meals in supermarkets, most of the food we consume undergoes some degree of processing.

Current market scenario of the global food processing industry

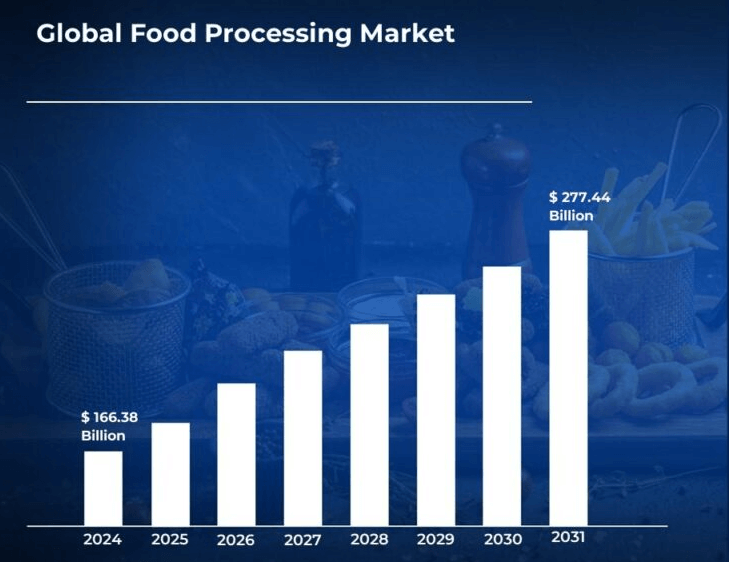

The global food processing and manufacturing industry is valued at $166.38B in 2024 and is expected to grow at 6.6% CAGR to reach $277.44B in 2031.

Market Drivers for the Food Processing Industry

The food processing industry is poised for growth, driven by three key factors:

- Technological advancements: Continuous innovation in processing technology is making food production faster, safer, and more efficient.

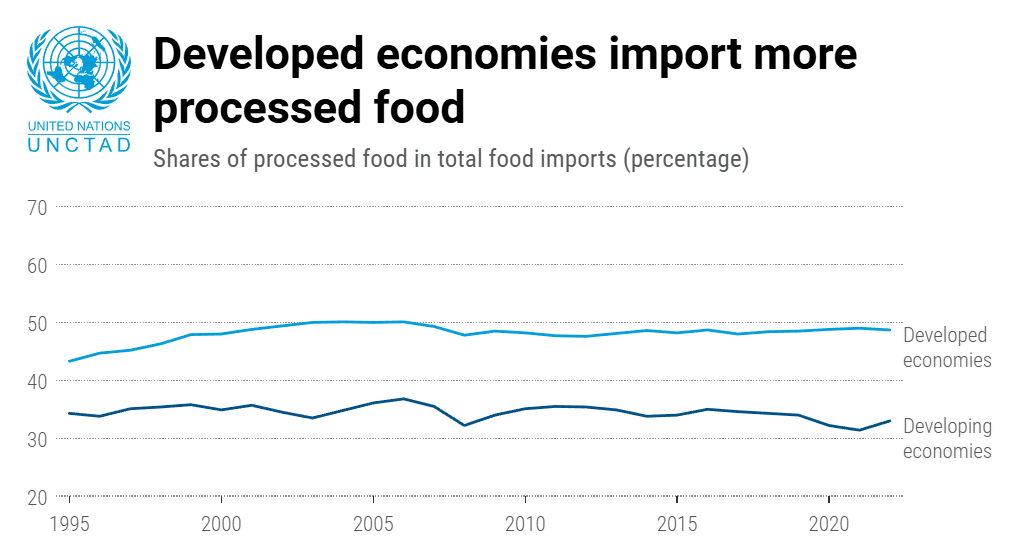

- Rising demand for processed foods: Busy lifestyles have left no option but to force consumers to seek convenience. Developed economies import 48% of processed foods compared to around 35% of developing economies.

- Increased R&D investment: Companies are investing heavily in research to develop better processing equipment and machinery, boosting production capacity and efficiency.

As a result, the demand for packaged, ready‑to‑eat, and pre‑prepared foods continues to rise steadily. However, there are two dramatic changes that we can witness in the food processing industry:

- Health risks of processed foods: High sugar, salt, and preservatives in processed foods are linked to chronic diseases, prompting consumers to seek healthier alternatives.

- Changing preference towards healthier options: Demand for organic, vegan, and clean‑label foods is rising, pushing companies to innovate healthier, plant‑based processed food options.

Types of food processing businesses

Food processing has plenty of sub‑industries, the majority of which can be classified into eight types:

1. Meat processing

It is aimed at reducing the enzyme activity in the meat, retarding oxidation of the fat, and preventing spoilage by microorganisms. These aims have been achieved through drying, curing with salts, or smoking meat.

2. Dairy products

Transforming raw or farm fresh milk into consumables — pasteurized milk, cream, butter, cheese, ice cream, yogurt, and more — all comes under manufacturing dairy products. All of these have at least a 50% milk component.

3. Baked goods

Baking is a food cooking method that uses prolonged dry heat by convection rather than by thermal radiation. Heat is gradually transferred from the surface of cakes, cookies, and bread to their center.

4. Snack foods

Snacks can be manufactured in three ways, which are also referred to as generations:

- First‑generation technique: Using simple extrusion without further processing. Snacks like nuts, dried fruit, potato chips, or popcorn fall into this category.

- Second‑generation technique: Creating high‑fiber, high‑protein snack products made of extruded materials like puffed corn products, corn chips, curls, and balls.

- Third‑generation technique: Used to prepare fried and flavored snacks produced from extruded pellets, such as breakfast cereal. Snack pellets are non‑expanded and made from raw materials like potatoes, grains, and vegetable powder. Manufacturers further process these semi‑finished products to create ready‑to‑eat snacks.

5. Beverages

Beverage manufacturing is the process of transforming raw ingredients into ready‑to‑drink beverages, such as soft drinks, juices, alcoholic beverages, and bottled water. Its goal is to create shelf‑stable products that are safe for consumption and have a long shelf life.

6. Confectionery

Confectionery is the art of making sweets using sugar and a carbohydrate-based binding medium. It is prepared using flour, sugar, milk, chocolate, or other ingredients and appropriate mixing, cooking, or freezing equipment.

7. Frozen foods

It involves chilling and freezing produce to slow down bacterial growth and packaging it for ease of storage or transportation. Produce is kept in different types of cold storage facilities to maintain optimal temperatures for long‑term preservation, transportation, distribution, and production.

8. Canned and preserved foods

Canning is the process of preserving many different foods by placing them in jars or cans and heating them properly to a specified temperature. The high heat destroys microorganisms and inactivates enzymes, protecting the food’s safety and quality.

Things to know before starting a food processing unit

Now that you have a basic understanding of what food processing is, let’s consider the factors you need to take into account before starting a food processing unit.

Decide on the business structure

First, all food businesses should be set up as private limited companies or LLPs so that the promoters’ liability is limited and the industry has easy access to bank financing.

Identify your niche

As discussed earlier, there are multiple types of food processing businesses. You have to decide whether you want to open a confectionery unit or produce frozen foods. This decision will largely be affected by your geography — if you’re in the Middle East, opening a frozen food business will make much more sense than starting a dairy.

Once you have a clear idea of the nature of your unit, you can move on to the next steps in starting a food production unit. Let’s discuss those now.

Steps to Start a Food Processing Business

After finalizing a concrete idea of establishing a food processing business, take care of the following aspects:

Conduct thorough market research

Before starting a food manufacturing business, you need to research and understand the market to choose the right product to manufacture. You should research the economic and industrial outcomes of the current units of food processing.

When selecting a food product, consider its availability or viability in the market. This will help you determine your competitors, current trends, and market size.

Decide on the type of business

Starting a food processing business requires clarity on the type of products you will manufacture and the business model you’ll follow. The kind of food processing business you choose will require you to do the following:

- Choose between B2B and B2C — Will you supply businesses (restaurants, retailers) or sell directly to consumers

- Check profitability — Research pricing, raw material costs, and projected margins

- Plan for future scaling — Pick a model that allows business growth without excessive reinvestment

Understand the rules and regulations

Make sure your food processing business remains compliant when it comes to law adherence and maintaining safety standards. The lack of proper licenses and certifications for selling processed food is illegal in most countries.

Hence, consider the following:

- Obtain required food business licenses — FSSAI (India), FDA (U.S.), HACCP, or local food permits

- Comply with zoning laws — Ensure food production is allowed in your chosen location

- Get quality and safety certifications — These improve credibility and help with large‑scale distribution

- Understand taxation rules — Register for GST/VAT if applicable

Lay down your production process

A structured production workflow goes a long way in maintaining efficiency, product consistency, and compliance with safety regulations.

A clear plan based on the following areas can help manage costs and labor:

- Define each step of production from sourcing to packaging, and create a detailed workflow

- Choose between manual, semi‑automated, or fully automated processes based on your budget

- Optimize batch sizes to ensure meeting demand while minimizing food waste

- Train staff on Standard Operating Procedures (SOPs) to maintain consistency.

Work on your financing options

Starting a food processing business requires significant investment in machinery, raw materials, and operations. Securing the right funding is essential to sustain initial expenses.

You can think of the below action items:

- Estimate startup costs — Land, machinery, labor, permits, and marketing expenses

- Explore funding sources — Bank loans, government grants, angel investors, or crowdfunding

- Apply for industry-specific subsidies — Some governments offer incentives for food processing units

- Consider leasing equipment — Reduces initial capital investment

Initially, I estimated around $23,000–29,000 USD for a mid‑sized restaurant, but we ended up spending close to $35,000. The excess came from unexpected civil work costs, upgraded kitchen equipment, and marketing overspend.

It’s always wise to add a buffer of at least 15% to your projected investment.

Choose the right location

The location of your food processing determines production costs, logistics, and ease of distribution.

Choosing this wisely requires the following considerations:

- Pick a site close to suppliers — Reduces transportation costs for raw materials

- Ensure good transport connectivity — Highways, rail, or ports for smooth distribution

- Plan for future expansion — Avoid the need for relocation later

- Consider access to skilled labor — A location with an available workforce reduces hiring difficulties

At first I underestimated the importance of location-specific competition — our first outlet was too close to a college canteen offering similar food at lower prices.

Source raw materials and ingredients

Maintain product quality with reliable sourcing to ensure steady production with minimal disruptions.

Action items:

- Find trusted suppliers — Compare pricing, quality, and reliability

- Secure long‑term contracts — This ensures stability in pricing and supply chain

- Prioritize freshness and shelf life — Essential for maintaining food quality

- Verify certifications — Ensure compliance with food safety and organic standards

We work with local vendors for daily produce and with wholesale distributors for dry goods. Storage is done based on FIFO (First In, First Out) principles, and we maintain a cold chain for perishables like dairy. Every delivery is inspected by the kitchen supervisor, and spoiled stock is immediately returned or recorded. Cleanliness and proper labeling are non‑negotiable in our storage areas.

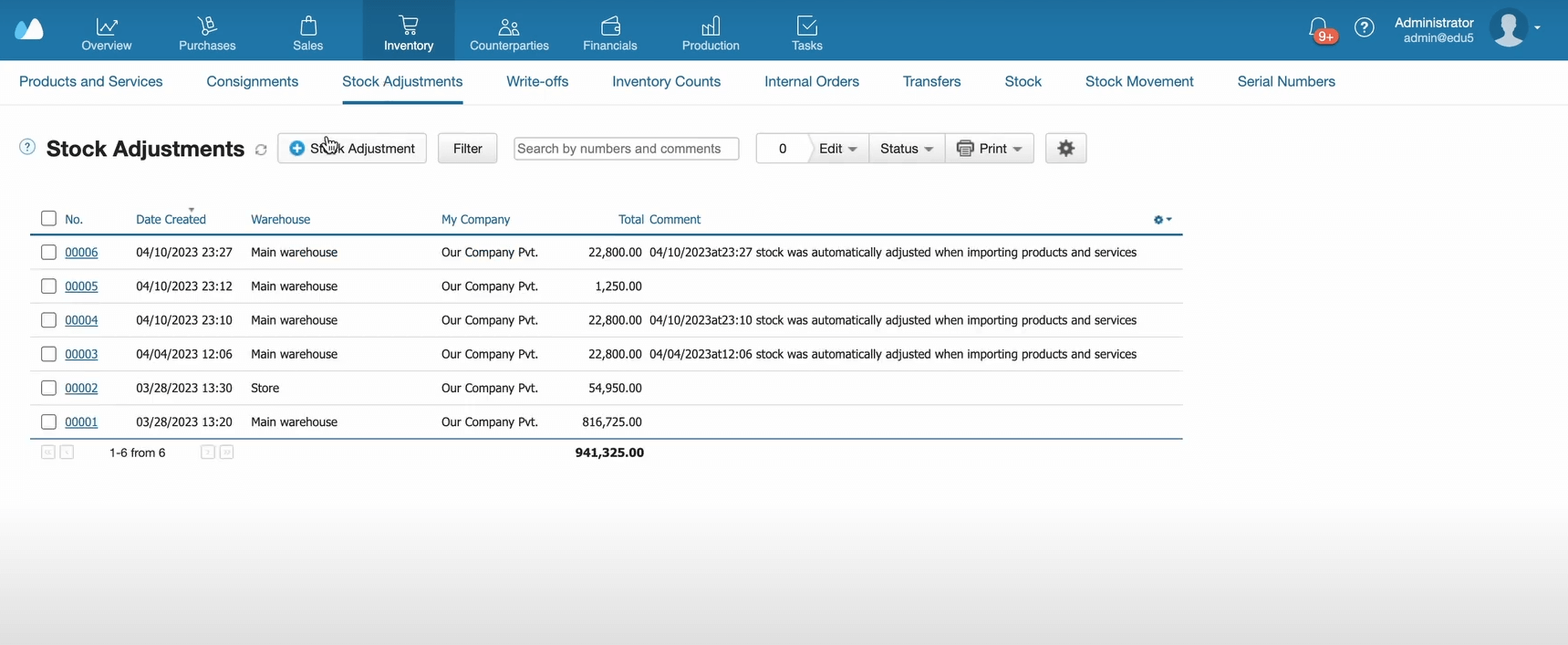

Select warehousing and inventory management solution

Choose an efficient warehousing and inventory system to prevent losses due to spoilage and ensure a smooth supply chain.

You’ll consider:

- Temperature-controlled storage for perishables

- Adopting FIFO method (First In, First Out) to prevent stock aging

- Implementing inventory tracking software to monitor stock levels and avoid shortages

- Consider outsourced warehousing if you lack storage space

Establish your branding and marketing strategy

A competitive food industry requires branding and marketing to influence customer preference

- Develop a memorable brand identity — Name, logo, and packaging design

- Leverage digital marketing — SEO, food bloggers, and social media campaigns

- Offer in‑store promotions — Free samples, discounts, and bundle deals

Start food production

Once everything is in place, operations can begin. Initial production runs will focus on quality control and process efficiency.

Take the following steps here:

- Conduct test runs to validate recipes, shelf life, and packaging

- Train staff on food safety and hygiene protocols

- Monitor production logs for efficiency improvements

Build a distribution network

Create a strong distribution network to ensure product availability and business scalability. With the right partners and the below aspects in mind, you can set your food processing business up for success.

- Partner with wholesalers and retailers — Supermarkets, grocery stores, and convenience stores

- Explore direct‑to‑consumer (D2C) sales — Via your website or marketplaces

- Optimize logistics and transportation — Cold storage trucks for frozen goods, eco‑friendly packaging for organic products

Ship your first batch

Once production is complete, it’s time to deliver your products to customers. The first shipment must set the tone with a quality management system for reliability and customer satisfaction.

- Perform final quality checks to ensure packaging and labeling meet regulations

- Choose reliable logistics partners for timely and safe delivery

- Track shipments and gather customer feedback to refine future processes

Launching a restaurant involves multiple phases, starting with concept development — defining the cuisine, format (fine dining, casual, cloud kitchen, etc.), and target market.

The next step is location selection, which should align with the concept and target audience.

Once the location is finalized, licensing (like FSSAI, GST, trade license, fire safety, and pollution control) is crucial and must be initiated early. Then comes the design and layout of the kitchen and dining areas, procurement of equipment, and hiring and training staff. Finally, a soft launch helps test operations before a grand opening.

Essential Tools & Equipment To Start Food Manufacturing

The base of any processing unit is the equipment it possesses. So, be it baked goods, dairy products, or frozen meals, every stage of production relies on specialized machinery to ensure efficiency, safety, and consistency.

Below, we’re listing the must‑have equipment to help you get started.

Mixing, Cutting, Blending Equipment

From dough kneading to spice grinding, food processing starts with breaking down and combining ingredients.

The essentials here:

- Industrial mixers — Essential for dough, batter, and emulsions

- Choppers and slicers — For fruits, vegetables, meats, and nuts

- Blenders and grinders — Used for sauces, purees, and spice blends

- High‑speed homogenizers — Ensure consistency in dairy and liquid products

- Automated portioning machines — Reduce waste and standardize product sizes

Refrigeration Equipment

Temperature control in food processing helps maintain freshness, prevent spoilage, and comply with safety regulations. Proper refrigeration can extend shelf life and ensure that food remains safe for consumption.

There can be:

- Walk‑in refrigerators — for large‑scale storage of perishable goods

- Blast chillers — To rapidly lower food temperature and prevent bacterial growth

- Deep freezers — For frozen foods, meats, and seafood

- Cold storage rooms — Maintaining bulk inventory at optimal temperatures

- Refrigerated transport units — Ensure cold chain integrity during distribution

Heating and Cooking Equipment

Heating is essential for cooking, pasteurizing, or sterilizing food products. The right equipment provides consistency in taste and quality while meeting food safety standards.

Some of the key tools over here are:

- Industrial ovens — For baking bread, pastries, and confectionery items

- Steam kettles — For soups, sauces, and stews

- Continuous fryers — For snacks, chips, and fried food products

- Pasteurizers — Ensures milk, juices, and sauces are safe for consumption

- Boilers and autoclaves — For sterilization and large‑scale cooking processes

Packaging and Labelling Equipment

Packaging preserves food quality, prevents contamination, and enhances shelf appeal. There are a few automated packaging solutions to speed up production that comply with labeling regulations.

Major equipments are:

- Vacuum sealers

- Shrink‑wrapping machines

- Filling machines

- Automated labellers, etc.

📍 Not sure which type of business to start? Check out our article on 20+ Profitable and Scalable Production Business Ideas.

Automation in Food Manufacturing With Software

Automation is applicable in the food manufacturing industry since it streamlines operations, reduces waste, and ensures quality control.

Tim Barthel, Executive Vice President at Cybertrol Engineering, has highlighted the importance of data‑driven process automation in the food industry in a Cybertrol blog interview.

His interview highlights that integrating automation from the factory floor to enterprise resource planning (ERP) systems enables businesses to make informed decisions, optimize production, and enhance profitability.

Software solutions can handle inventory tracking, production planning, minimize human errors, and improve efficiency. They offer real‑time data, barcode scanning, and automated reporting to help manufacturers optimize their supply chains.

Here’s more to it.

Inventory Tracking and Management

Inventory management with tracking enables the monitoring of raw materials, work‑in‑progress, and finished goods, which is essential in food manufacturing. Automated inventory management software ensures you never overstock or run out of crucial ingredients.

- Real‑time stock tracking that shows what’s in stock at all times

- Expiry date monitoring to prevent wastage of perishable items

- FIFO (First In, First Out) automation to first use older stock

- Low stock alerts that notify you before running out of crucial supplies

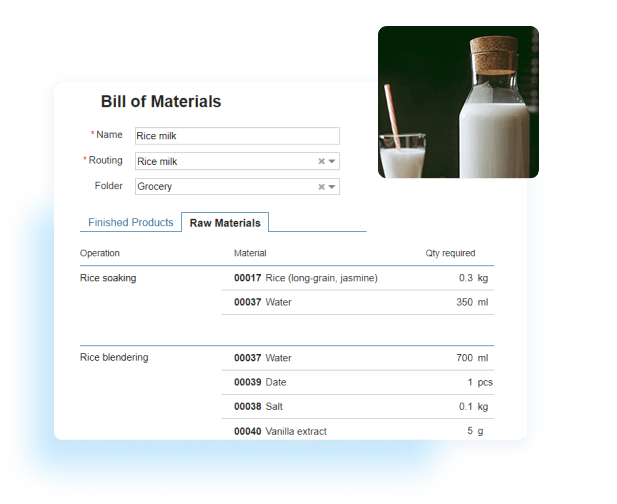

Bill of Materials (BOM)

A Bill of Materials (BOM) is the foundation of food production, listing ingredients, quantities, and processing steps. Automating BOM ensures accuracy and consistency in every batch.

It provides the following:

- Detailed ingredient tracking to maintain recipe accuracy

- Automatic cost calculations for monitoring production costs per batch

- Allergen and nutrition tracking that complies with food safety regulations

- Multi‑level BOMs that support complex recipes and sub‑assemblies.

Barcode and Labeling

Barcodes and labeling systems improve traceability, compliance, and efficiency in food processing. Automated barcode generation and scanning software for accurate labeling enable them for both internal tracking and consumer packaging.

This includes:

- Barcode scanning for instant updates.

- Batch and lot tracking to recall food safety compliance

- Custom label printing that generates ingredient lists, expiry dates, and allergens

- Integration with POS and ERP systems to keep all operations connected

Purchase Orders

Automating purchase order (PO) management facilitates vendor interactions and prevents raw material shortages, offering timely procurement without manual intervention.

Here’s what to consider:

- Auto‑generated POs wherein system detects low stock and creates orders

- Supplier price comparisons to optimize costs by selecting the best vendor

- Approval workflows so that only authorized purchases go through

- Order tracking for real‑time updates on pending shipments

Sales Receipts

Automated sales receipt systems to improve customer transactions and revenue tracking by eliminating manual data entry.

The receipts include:

- Instant invoice generation to create receipts as soon as orders are fulfilled

- Tax and discount calculations for accurate pricing

- Digital receipts & e‑invoicing to reduce paperwork

- Integration with accounting software like Kladana that syncs transactions with financial records.

Integrations

Software integrations connect different functions in food manufacturing to create a seamless, fully automated workflow.

The common integrations are:

- ERP & CRM integration that syncs production, sales, and customer management

- Supplier portals to automate vendor communication and procurement

- E‑commerce connectivity that links online orders to production and inventory

- Financial software integration for real‑time accounting and cost analysis

Best Practices for Running a Food Manufacturing Business

A food manufacturing business requires maintaining efficiency, quality, and compliance at every step. Below, we’re highlighting the best practices for food safety, loss minimization, enhanced operational efficiency, and building trust with consumers.

Let’s explore these.

Ensure proper hygiene and sanitation

Poor hygiene can lead to contamination, recalls, and regulatory penalties. Centra Foods had an interview with Holly Mockus, who spent over 30 years in the food industry at companies like ConAgra, Kellogg, and Sara Lee. She emphasizes that overcoming challenges for newcomers requires comprehensive training—including facility tours, mentoring, and interactive sessions.

Maintaining strict sanitation protocols requires the following actions:

- Implementing daily cleaning schedules to keep production areas, machinery, and storage spaces sanitized

- Enforcing hygiene policies like the use of gloves, hairnets, and proper handwashing for workers

- Using food‑grade disinfectants to prevent bacterial buildup on surfaces

Provide adequate training to employees

Well‑trained employees are important for maintaining quality, efficiency, and workplace safety. Regular training keeps them updated on best practices as mentioned below:

- Train staff on food safety & handling

- Educate on machinery operations

- Encourage cross‑training that helps employees manage multiple roles and reduce production delays.

Timely maintenance of machinery and equipment

Equipment breakdowns can disrupt production and lead to costly downtime. So, regular maintenance extends the lifespan of machines, prevents defects, and ensures uninterrupted operations.

Here’s what you can do:

- Schedule preventive maintenance to detect issues before breakdowns

- Keep spare parts available that minimize production delays

- Lubricate and clean machinery regularly to prevent overheating and contamination

- Diagnose and monitor equipment performance by using sensors or IoT tracking to spot inefficiencies early.

Careful waste management and disposal

If not managed properly, food waste, packaging waste, and byproducts can harm profits and the environment. A structured waste management plan minimizes costs and supports sustainability.

- Implement a waste segregation system to separate recyclable, biodegradable, and hazardous waste

- Adopt byproduct utilization to repurpose food scraps for compost or animal feed

- Optimize portioning & storage to reduce ingredient spoilage and overproduction

Maintain healthy relations with your suppliers and distributors

Strong supplier and distributor relationships ensure a consistent raw material supply, fair pricing, and smooth logistics.

Here’s what you’ll do:

- Negotiate long‑term contracts for stability in pricing and inventory

- Communicate frequently to avoid delays and misunderstandings

- Evaluate supplier reliability by choosing vendors with a proven track record

Invest in robust automation software

Automation boosts efficiency, reduces manual errors, enhances traceability, and speeds up production. Kladana is a powerful inventory and production management software designed to help food businesses streamline operations and comply with food safety standards.

Kladana ERP: Smarter Inventory & Order Management

Stay in control with automated inventory and order management. Start your 14‑day free trial today — no credit card needed!

FAQs

Here are some of the major questions answered about setting up a food manufacturing business.

How much investment is needed to start a food manufacturing unit?

Costs vary based on scale, equipment, and location, but a small unit may start from $20,000-$50,000, while large setups require hundreds of thousands or more.

How can automation help in food processing?

Automation, with the help of ERP and inventory software like Kladana, reduces manual errors, improves efficiency, tracks inventory, and ensures consistency in production.

What are the key licenses required to start a food processing business?

You’ll need food safety certifications, such as FSSAI (India), FDA (U.S.), HACCP, and local health permits, depending on your region.

What factors should I consider when choosing a location for my food plant?

Look for proximity to suppliers, transport connectivity, availability of utilities, and zoning regulations for food production.

How much investment is needed to start a food manufacturing unit?

Costs vary based on scale, equipment, and location, but a small unit may start from $20,000-$50,000, while large setups require hundreds of thousands or more.

How do I ensure food safety in my manufacturing unit?

Implement strict hygiene protocols, regular quality checks, staff training, and proper storage conditions for raw materials and finished products.

What packaging solutions are best for food products?

Choose based on product type — vacuum‑sealed for perishables, eco‑friendly for sustainable brands, and airtight packaging for dry goods.

What’s the best way to handle food waste in manufacturing?

Adopt waste segregation, repurpose byproducts, optimize portioning, and partner with waste management firms.

How do I scale my food processing business?

Focus on automation, diversifying product lines, expanding distribution channels, and securing larger contracts.

How do I price my food products for the market?

Calculate the cost of production, packaging, distribution, and competitor pricing while ensuring a profitable margin.

List of Resources

- Verified Market Research — Food Processing Equipment Market Size And Forecast

- UN Trade & Development (UNCTAD) — New UNCTAD‑WHO analysis reveals trends in processed foods trade

- Cybertrol Engineering — Tim Barthel Highlights Cybertrol’s Role in Data‑Driven Manufacturing

- Centra Foods — Learn From Top Food Production Consultant: Interview With Alchemy Systems