Traceability for food products, from sourcing ingredients to packaging, is not just about checking a box on a compliance form. Instead, it focuses on how your food business can remain accountable, safe, and prepared.

So, whether you’re tracking batches, handling audits, or managing recalls, you’ll know exactly where your ingredients came from and where your products are headed.

What’s often missing, though, is clarity on how traceability systems actually work — or what they should cover. This guide breaks it down.

Let’s explore what to expect from food traceability software, what can be tracked (and how), and which features actually make a difference.

What is a Food Traceability System?

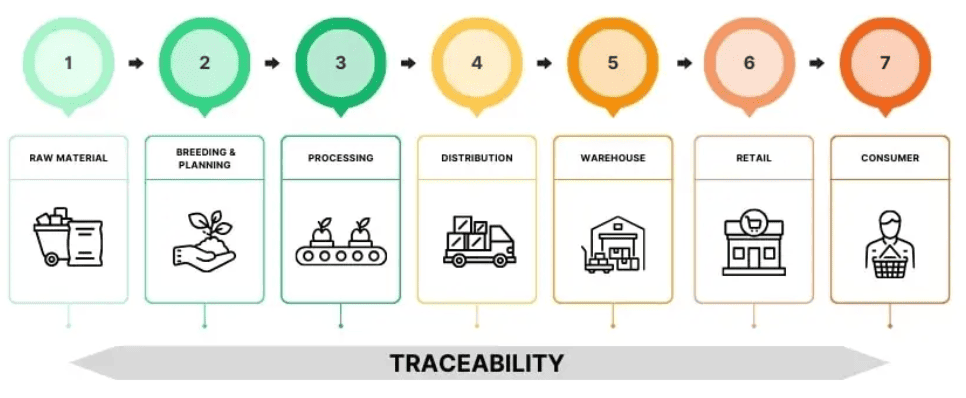

A food traceability system helps your business know exactly where every ingredient comes from and where every product ends up. It brings clarity across the supply chain, right from the source to the customer’s hands.

The main goals?

Ensuring safety, building transparency, and limiting exposure to risks.

When a food traceability system works well, your team can trace ingredients back to their origin (backward traceability) and follow a product’s path from production to the point of sale (forward traceability).

This makes it easier to recall products, identify potential sources of contamination, and stay on top of supplier accountability.

What Can Be Tracked and How?

A traceability system in the food industry gives you clear control over every stage of movement, from raw materials to packaged units. Here’s how it usually works:

Batches, lots, ingredients

Each batch or lot gets assigned a code that links it with all related inputs — like origin, quantity, date of entry, and expiration. Ingredients can also be tracked individually for cross-checks.

Farm-to-fork traceability

Whether you’re working with eggs, spice blends, or dairy, the traceability system for food manufacturing captures each touchpoint — farms, processing facilities, packaging units, and distributors.

Serialization and labeling

Unique identifiers (like QR codes or barcodes) are applied at the item, carton, or pallet level. These tags carry forward through the chain, giving complete traceability in one scan.

Manual vs. automated tracking

Manual systems rely on handwritten logs and spreadsheets. Automated systems update data in real-time, reducing errors and making information instantly accessible across teams.

Real-time vs. delayed updates

Real-time traceability software captures data as events occur — ideal for recalls or quality alerts. Delayed systems rely on periodic syncs or batch uploads, which may miss critical incidents.

Why Traceability Matters in the Food Industry

Traceability software food industry players rely on is more than a nice-to-have — it’s now a must.

Whether you’re selling locally or across borders, traceability helps you reduce business risk and build credibility.

Regulatory landscape

Food laws across countries now require full traceability. For example:

- In the US, the FDA’s FSMA Rule 204 outlines the requirements for recordkeeping related to high-risk foods.

- In the EU, Regulation (EC) No 178/2002 sets the general principles and requirements for food law, including traceability

- In India, the FSSAI mandates the tracking of food products across the chain through its compliance framework.

Recall preparedness

When a recall is needed, traceability software for food manufacturing makes it easier to isolate affected batches and inform the right channels without shutting down your operations.

Brand trust and export-readiness

If your products reach overseas markets, traceability becomes part of your reputation. Exporters with strong tracking systems get easier clearance and better partner credibility.

Food fraud prevention

Ingredient-level tracking helps identify inconsistencies, such as cheaper substitutions or mislabeling, that could go unnoticed in a manual setup.

Better vendor/ingredient control

The right food traceability system gives visibility into supplier quality, delivery timelines, and consistency, helping you pick reliable partners.

Key Features of Food Traceability Software

A traceability software food industry manufacturers can count on is one that simplifies how you monitor inputs, processes, and outputs without added complications.

End-to-end batch tracking

Track goods from raw material to final product in one system. Make it easy to match finished goods to their ingredients.

- Track each product through every stage — raw materials, in-process handling, and final packaging.

- Match batch numbers to raw ingredient sources and finished product destinations.

- Spot any inconsistencies early by reviewing logs connected to each batch lifecycle.

Barcode-based traceability

Use barcode traceability to tag batches, shipments, or containers and trace their movement with a quick scan.

- Generate unique barcodes for raw ingredients, production lots, and packaging units.

- Enable instant look-up by scanning a label, giving access to its entire movement history.

- Reduce human error by eliminating manual data entry and linking scanned inputs with digital records.

Ingredient-level traceability

Know exactly which lot of spice, preservative, or base was used in which batch. Ideal for allergen tracking and cross-batch control.

- Log each ingredient’s source, supplier, and batch number at the point of entry.

- Track which ingredient went into which final product, even when used across multiple batches.

- Detects allergen exposure risks and mislabeling in blended or processed items.

Audit trail and operator logging

Capture who performed each task, when, and where. These logs can be referenced during vendor audits or compliance checks.

- Record who handled what, when, and at which workstation — linked to specific batches.

- Help during food safety investigations or external audits with clear task-based records.

- Identify operator-level patterns tied to quality or compliance concerns.

Recall reports and supplier alerts

Automate alerts for expiry, low stock, or vendor non-compliance. Get ready-to-download recall reports in minutes.

- Flag batches nearing expiry or flagged for recall automatically.

- Notify procurement or QA teams when a vendor’s delivery fails to preset quality rules.

- Download structured recall reports, including batch details, timelines, and affected products.

Reporting for compliance audits

A good food safety traceability system will generate logs, certificates, and reports aligned with country-specific food safety standards.

- Export reports aligned with regional food laws and inspection formats.

- Consolidate audit trails, supplier records, and processing logs into one place.

- Prepare for internal or third-party audits without scrambling for paper logs.

A good food safety traceability system will generate logs, certificates, and reports aligned with country-specific food safety standards.

Real-World Scenarios

Here’s how food traceability software shows up in real workflows.

Example 1: Small jam producer exporting to the EU

A jam producer in India plans to export to Europe. With a food safety traceability system in place, they map batch codes to ingredient lots and get through EU audits faster.

What do they need to do?

- Link every jar of jam to the exact batch of fruits, sugar, and pectin used.

- Track suppliers by ingredient lot, including harvest dates and processing facilities.

- Assign batch codes during packaging and apply barcode labels for each unit.

- Generate digital batch reports aligned with EU audit requirements.

- Store operator logs and hygiene checklists tied to each production run.

Example 2: Local bakery with FSSAI compliance needs

A local bakery complies with India’s FSSAI standards by tagging every dough batch and logging operator hygiene checks.

This is what their ideal process would look like:

- Tags every dough batch with a unique code linked to flour, yeast, and other ingredient lots.

- Log operator names, shift timings, and sanitation checks before production.

- Apply barcode labels on final packaging for easy trace-back if needed.

- Generating ready-to-print records for FSSAI spot checks or license renewal audits.

Example 3: Overinvesting in a system without clear workflows

A mid-sized snack brand invested in a complex food traceability system software but skipped mapping internal workflows. Result: Overhead rose, but traceability gaps stayed.

- Operators remain untrained on when and how to scan or log data, leaving gaps.

- Ingredient sourcing data will remain incomplete due to missing vendor input fields.

- Batch reports couldn’t reliably match finished goods with raw input logs.

- The cost of maintaining unused features will be added to overhead without improving control.

Choosing the Right Traceability Software

Getting the right traceability software for food manufacturing isn’t about picking the flashiest one — it’s about fit.

Below, we’re featuring some essential aspects that go into picking the right traceability software that matches your business needs.

A. Questions to ask:

Start by asking the questions that matter, targeting the ways you’d use and leverage the food traceability software.

Some of these include —

- What exactly do you need to track — just batches or also operators and ingredients?

- Who should access this data — QA teams, warehouse, production, or all of them?

- Are you working with the US, EU, India, or other compliance standards?

B. Cost vs. features

Many brands overspend on features they don’t need. Compare what you actually use — like batch tracking and audit trails — against what’s bundled.

- Watch out for premium tools layered into high-tier pricing that add no real value to your workflows.

- For small to mid-sized teams, paying for complex compliance engines or advanced analytics can drain budgets without solving core traceability issues.

C. Cloud vs. on-premise

- Cloud options offer easier scaling and access across locations. On-premise might work for facilities with strict data control policies.

- On-premise setups offer more control over sensitive operational data and may be preferred in regulated or high-security facilities.

- Weigh infrastructure readiness, IT support costs, and downtime tolerance before choosing either direction.

D. Support for barcode

Look for traceability software food industry businesses can use with existing barcode or QR tools.

You don’t need to change your labeling process.

- Check if the software integrates with existing barcode printers or scanners your team already uses.

- Make sure you can assign barcode labels at raw material, batch, and final product levels.

- Look for flexibility in label formats and support for QR, linear, or data matrix codes.

E. Country-specific compliance compatibility

If you’re exporting, ensure the traceability software supports audit templates or reports recognized by local regulators.

- Built-in formats aligned with FSSAI (India), FSMA (US), or EC No 178/2002 (EU) can speed up compliance reviews.

- The right system should also let you attach certifications, lab test results, and supplier declarations to traceability logs.

Some software supports specific audit formats and report templates required by FSSAI, FDA, or EU regulators.

Why Choose Kladana as a Food Traceability Software?

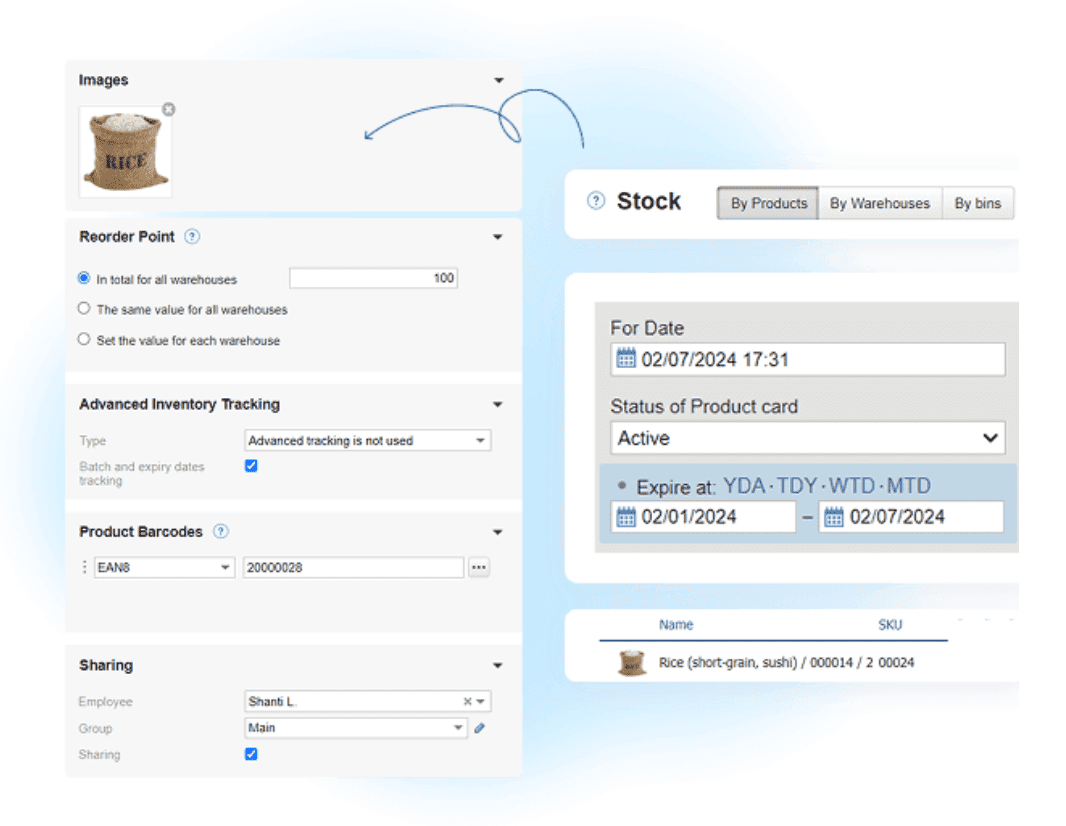

Kladana’s food traceability software supports batch-wise tracking, material origin logging, and operator-level data capture.

While it doesn’t serve as a full compliance engine, it gives SMEs enough visibility to start building audit-ready records.

Kladana Makes Food Traceability Simple and Efficient

Check how Kladana can help you keep track of your food manufacturing operations:

✅ Batch and Expiry Tracking — Track lot numbers and expiration dates to ensure food safety and enable precise recalls when needed.

✅ Barcode Scanning — Automate product tracking from raw material to final packaging with barcode generation and scanning.

✅ Recipe and BOM Management — Manage Bills of Materials for each product to trace ingredients and monitor production inputs accurately.

✅ Real-Time Inventory Reporting — Get instant visibility into stock movement, shelf-life, and usage history for faster decision-making.

✅ Multi-Warehouse Tracking — Monitor ingredient and product movement across multiple storage locations with traceability intact.

✅ Reorder Point Alerts — Receive automatic alerts when critical ingredients run low to avoid disruptions in production and compliance gaps.

Gain complete visibility into your food supply chain with Kladana. Start your 14-day free trial today — no credit card required.

Summary

Traceability in the food business begins with picking the right purpose to track and accordingly choosing the software that fits your needs and budget.

Start by capturing basic data — ingredients, batch numbers, dates — and build from there.

For small and mid-sized businesses, the best food traceability software won’t overwhelm teams. Instead, it should help them grow into traceability.

Traceability Starter Checklist:

- Know what you want to track

- Set batch codes clearly

- Label ingredients properly

- Train operators to log correctly

- Start with basic barcode support

Ready to explore food manufacturing traceability software? Know how Kladana helps you keep it simple, yet audit-ready.

Frequently Asked Questions on Food Traceability Software

What is food traceability?

Food traceability means tracking ingredients and products throughout their journey — from their original source through production to the final customer. It ensures food safety, transparency, and quick response in case of contamination or recalls.

Why is traceability important in the food industry?

Traceability helps businesses comply with food safety regulations, enhances recall effectiveness, prevents food fraud, boosts brand credibility, and ensures accurate ingredient control.

What types of information can a food traceability system track?

Traceability systems track details like batch and lot numbers, ingredient origins, expiration dates, production processes, packaging information, supplier data, and even operator activities.

What’s the difference between manual and automated food traceability systems?

Manual systems use paper logs or spreadsheets and are prone to errors and delays. Automated systems update data instantly, improving accuracy, speed, and real-time visibility across the supply chain.

How does barcode-based traceability work?

Barcodes or QR codes uniquely identify ingredients, batches, and packaged products. Scanning these codes reveals the complete history of product movement, reducing manual entry errors and speeding up traceability.

Can traceability systems help with food recalls?

Yes. Effective traceability systems quickly identify affected batches, reducing the scope of recalls, limiting operational disruptions, and ensuring swift communication with consumers and regulatory bodies.

How does ingredient-level tracking improve food safety?

Ingredient-level tracking helps detect issues such as allergen cross-contamination, mislabeled ingredients, and food fraud, enhancing overall product safety and compliance.

What should I consider when choosing food traceability software?

Consider your specific tracking needs, budget vs. required features, cloud or on-premise preferences, barcode compatibility, and compliance with country-specific food safety regulations.