Material purchasing is not the same as procurement, though many use the terms interchangeably. Procurement covers everything from sourcing to negotiating contracts to managing suppliers.

However, material purchasing focuses specifically on acquiring the raw inputs, such as fabric, steel, or ingredients, that go directly into your finished goods.

For SME manufacturers, this step is mission-critical. Poor purchasing doesn’t just delay production, it disrupts your entire supply chain, affects product quality, and eats into your margin. Late deliveries, unclear costs, or missed MOQs can lead to overstock and cash flow issues, etc.

That’s why more manufacturers are moving toward automation and connected workflows. According to Grand View Research, the global smart manufacturing market, which includes ERP, MRP, and digital procurement systems, was valued $349.8 billion in 2024 and is projected to reach $790.9 billion by 2030, growing at a 14% CAGR.

In this guide, you’ll learn:

- How material purchasing fits into the manufacturing workflow

- What your process should look like from requisition to delivery

- Industry-specific examples that reflect real sourcing problems and solutions

- What Is Material Purchasing?

- Why Material Purchasing Matters

- Material Purchasing Workflow

- Types of Materials Procured

- Key Stakeholders and Their Process

- ⚠️ Common Challenges in Material Purchasing

- How to Optimize the Material Purchasing Process

- Use Cases by Industry

- 📊 Key KPIs for Material Purchasing Performance

- 🧠 Summary

- Frequently Asked Questions on Material Purchasing

- List of Resources

What Is Material Purchasing?

Material purchasing is the process of acquiring the physical inputs needed to manufacture your products. These are known as direct materials, such as items like raw fabric for apparel, metal components for tools, or cocoa powder for food production. Without them, your production line comes to a halt.

This function is a subset of procurement. While procurement encompasses broader activities such as vendor selection, contract negotiation, and compliance, purchasing focuses on execution, including identifying what is needed, placing orders, receiving goods, and verifying quality.

Let’s say you run a homeware brand. Procurement involves building relationships with textile mills and negotiating annual rates. On the other hand, material purchasing is when your store manager raises a purchase requisition for 500 meters of cotton, and you place the PO with the right vendor from your approved vendor list (AVL)

You typically engage in material purchasing when:

- You’re restocking essential raw materials

- You’re producing to order and need to source inputs just in time

- Your material requirement planning (MRP) signals a shortfall.

Why Material Purchasing Matters

Material purchasing is more than just placing orders; it’s the engine that powers your production schedule, cost efficiency, and supplier relationships. Every decision you make in the procurement of raw material affects lead time, inventory accuracy, and how well you meet delivery commitments.

When this function lacks structure, it leads to unclear MOQ terms, delayed raw material supply, and poor visibility in your material planning. And when vendors aren’t tracked or contracts aren’t standardized, even the best sourcing strategy falls apart.

To stay competitive, manufacturers require a purchasing system that aligns with Material Requirement Planning (MRP), tracks performance throughout the procurement cycle, and supports cost control through tools such as an Approved Vendor List (AVL).

Here’s why getting material purchasing right is essential for your business.

1. It Directly Impacts Costs and Margins

Raw material costs often make up the most significant portion of your product’s cost of goods sold (COGS). If your supplier’s prices fluctuate or you overbuy due to unclear minimum order quantities (MOQs), your profit margins shrink quickly.

For example, if you plan to manufacture 2,000 T-shirts, each requiring 1.5 meters of fabric. That’s 3,000 meters total. But your supplier only sells in lots of 5,000 meters due to their MOQ.

You buy the whole lot to avoid delays, typing up cash in 2,000 meters you don’t immediately need. The excess sits in storage, pushing up holding costs and increasing the risk of spoilage or design changes making it obsolete.

📍Recommended Read: Costing Methods and Approaches: A complete guide for Manufacturing & Inventory — Confused by standard, job, or activity-based costing? This guide breaks down key costing methods so you can price smarter and protect your margins.

2. It Affects Inventory and Production Planning

Purchasing timing is not just about making a purchase. It is about aligning with your production calendar, demand forecasts, and material shelf life. Many SMEs face costly mismatches because they lack a live system that connects inventory to actual manufacturing needs.

For example, you run a small batch-based food production unit. A buyer places an order of 100kg of perishable ingredients based on last month’s volumes. But this month, you are only producing half the quantity due to a drop in demand.

Without a real-time forecast, the extra 50 kg remains unused and expires before the next batch arrives. That’s direct cash lost, plus added complexity for the next purchasing cycle.

📊 Optimal Order Quantity = (Forecasted Usage x Lead Time) + Safety Stock

So, when this formula is applied through a material requirement planning (MRP) system, your purchasing adjusts automatically to reflect real demand, stock on hand, and timing. This prevents you from overbuying, wasting, and supply gaps.

3. It Determines Lead Time and Delivery Reliability

When your team places orders based on assumptions rather than real-time data, even a minor delay can disrupt production and turn a routine purchase into a costly recovery mission.

For example, at your packaging unit, the purchasing team places an order for imported cardboard based on a supplier’s usual 7-day delivery window. But the shipment arrives four days late due to port congestion. The machines are ready, the job is scheduled, but your raw material isn’t on site. You miss your production window, pay overtime to catch up, and fast-track dispatch to avoid losing the client.

After this disruption, your team reviews the vendor’s past performance inside your ERP system and notices a trend: deliveries have averaged 10–12 days for the last three months.

Using that insight, they update the vendor’s lead time setting in the system. Now, every new purchase requisition and PO automatically factors in this buffer, and materials arrive when needed, not when expected.

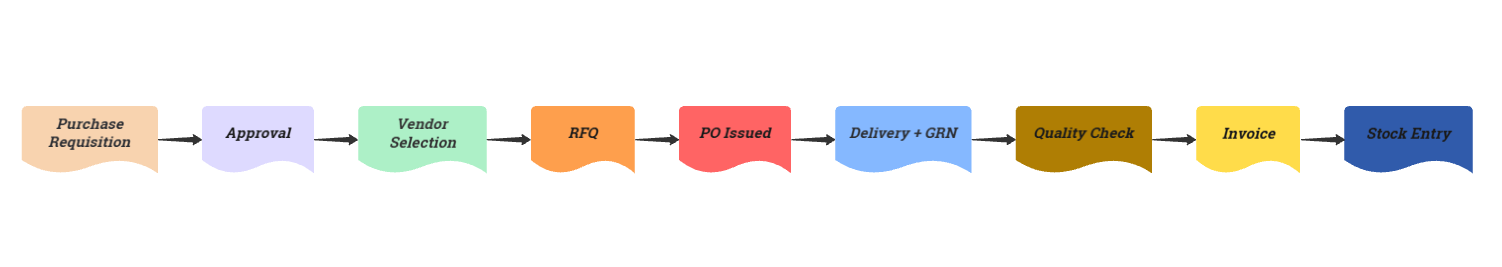

Material Purchasing Workflow

Efficient material purchasing follows a well-defined cycle. From identifying a need to storing materials for production. Here’s what the process looks like in a typical SME manufacturing setup.

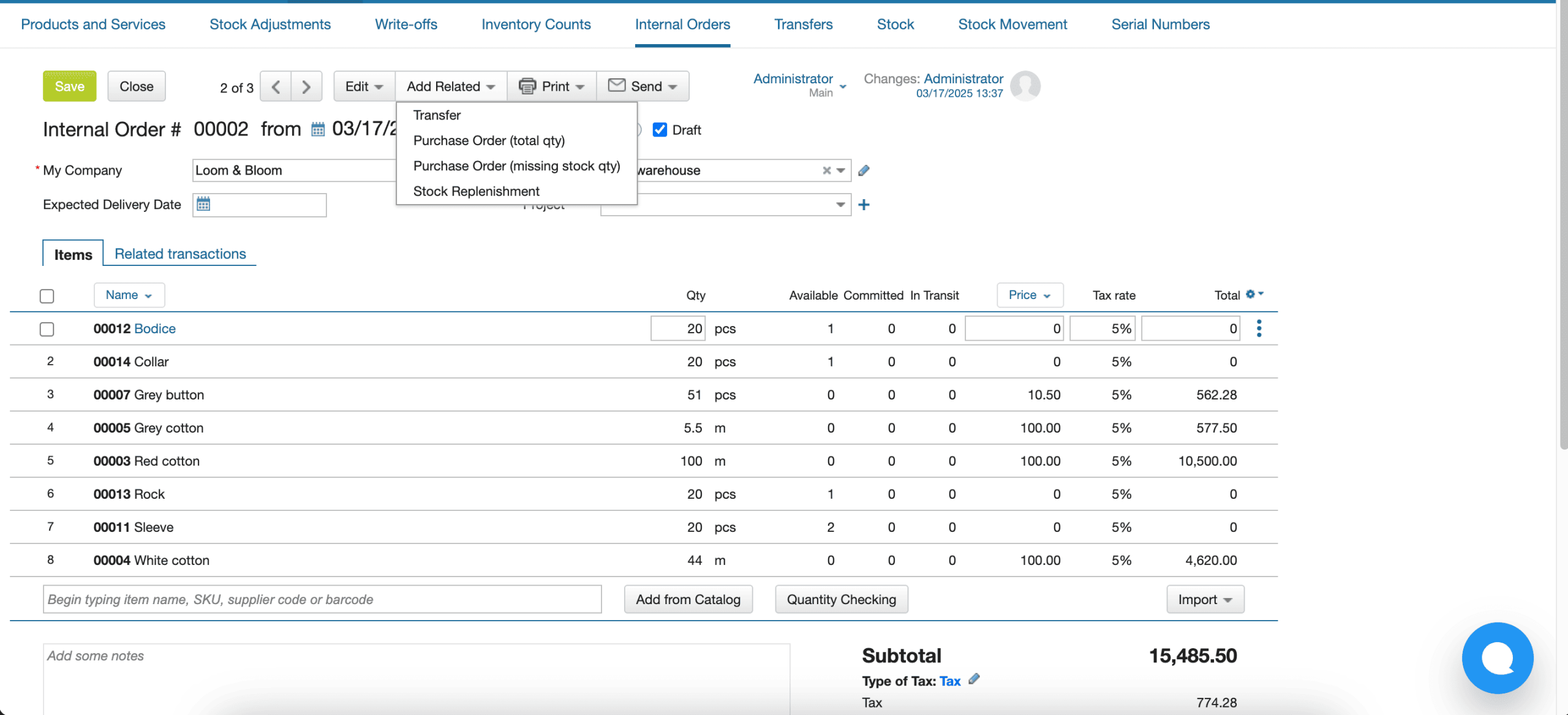

1. Purchase Requisition Raised

The production or store team flags the need for raw materials through a purchase requisition (PR), often triggered by low stock alerts from an MRP system.

2. Approval by Management or Accounts

The PR goes through a defined approval chain — usually the purchase manager and finance team for budget clearance and necessity validation.

3. Vendor Selection

The buyer selects a supplier from the Approved Vendor List based on pricing, quality history, lead time, and MOQ compatibility.

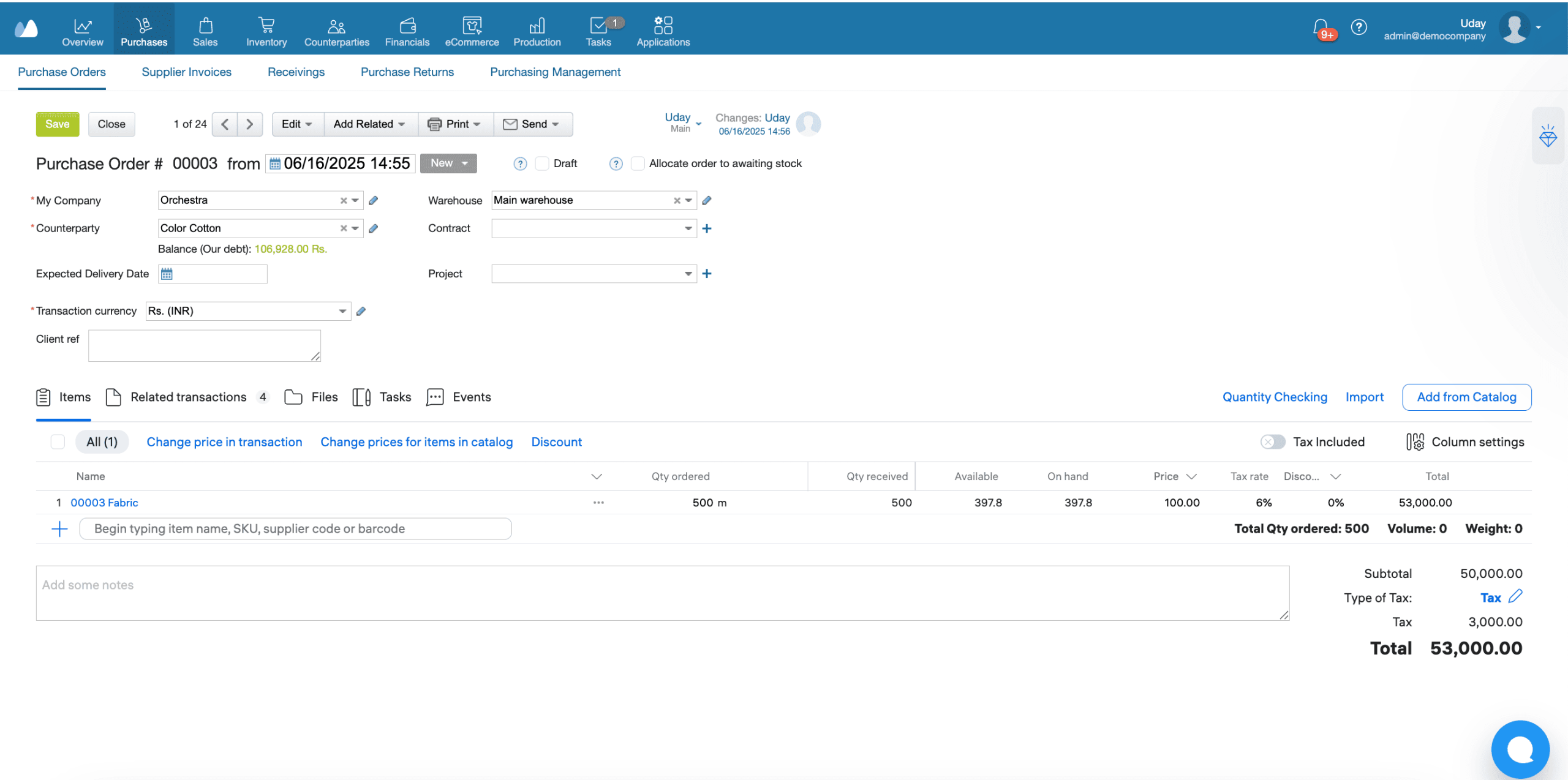

4. Purchase Order Issued

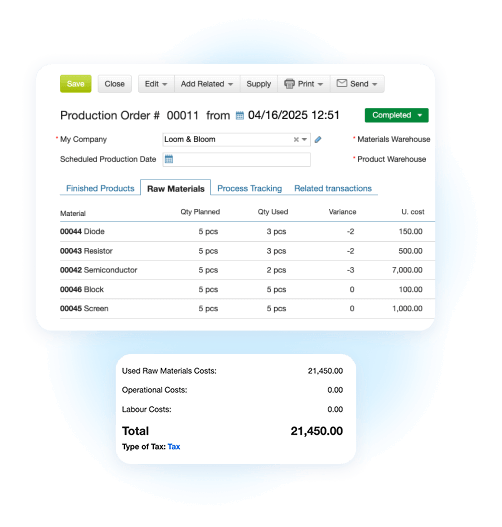

Once finalised, the PO is generated and shared with the chosen supplier. The ERP or purchasing tool tracks its status

5. Material Delivery and Goods Receipt Note

The supplier delivers materials, and the store team records them in inventory through a GRN. This step also triggers quality checks.

6. Quality Inspection

Materials are inspected to ensure they meet the required standards. Rejected batches are returned or replaced.

7. Invoice Received and Payment Processed

Once materials are accepted, the invoice is matched with the PO and GRN. The accounts team then schedules the payment according to the agreed-upon terms.

8. Storage or Issue to Production

Finally, approved materials are moved to storage bins or issued directly to the shop floor.

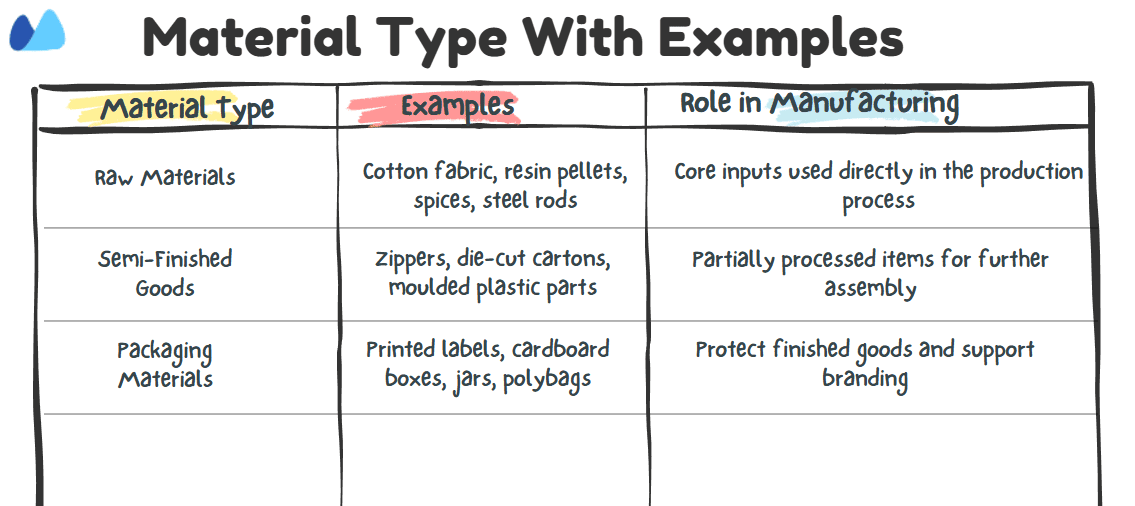

Types of Materials Procured

Material purchasing isn’t limited to just raw inputs. Depending on your product and industry, you may need to source a mix of direct, semi-finished, and packaging materials. Categorizing them correctly helps streamline planning, budgeting, and vendor management.

📍Recommended Read: Raw Materials Inventory Management: Best practices — A deeper dive into storing, tracking, and managing raw material stock for manufacturers

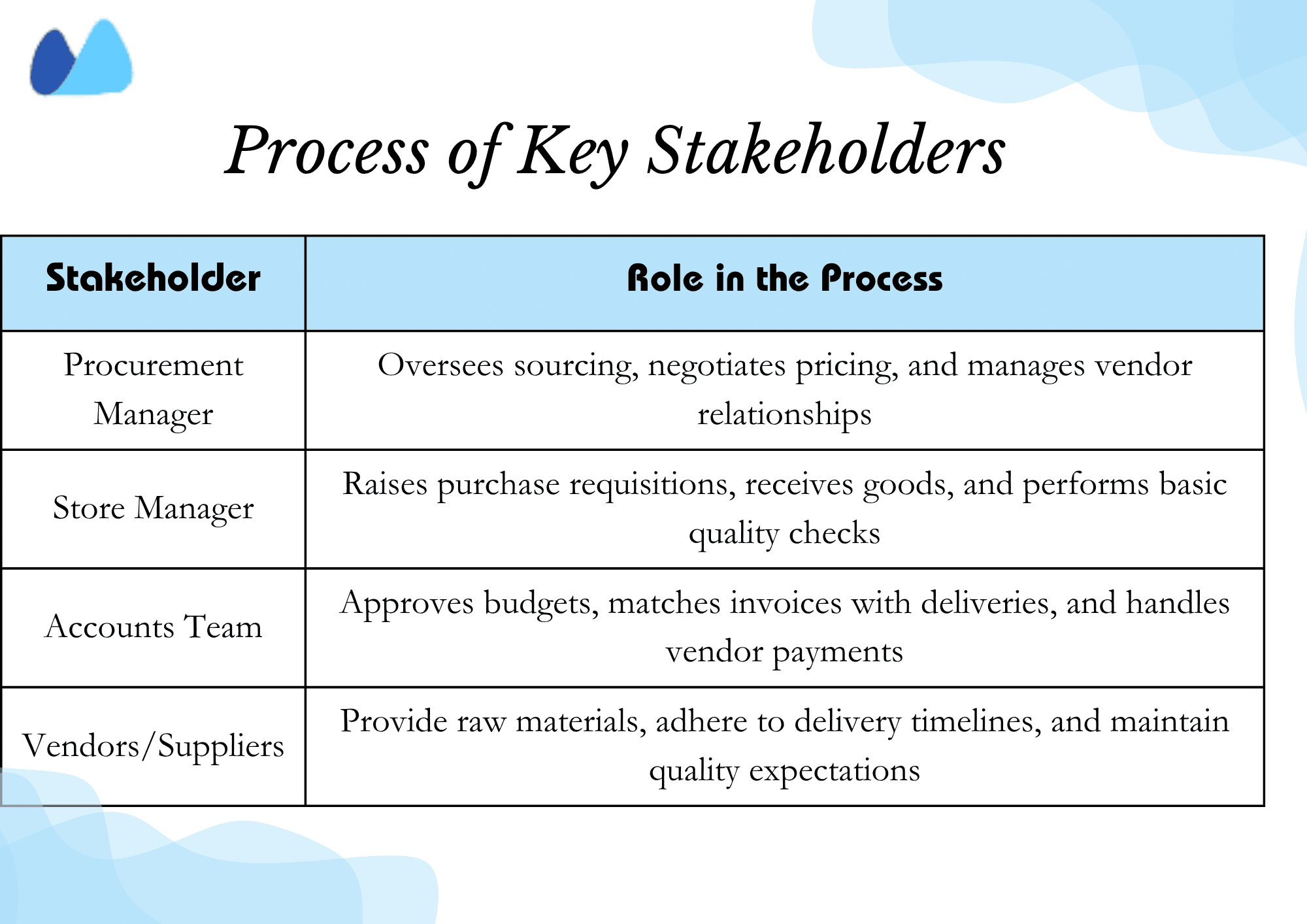

Who’s Involved in Material Purchasing?

Even in small manufacturing setups, material purchasing involves more than just the buyer. Each role plays a crucial part in ensuring that materials arrive on time, meet quality standards, and fit within budget.

Key Stakeholders and Their Processes

Therefore, this clarity in roles helps prevent delays, double ordering, and invoice mismatches, especially when your business scales and more people are involved

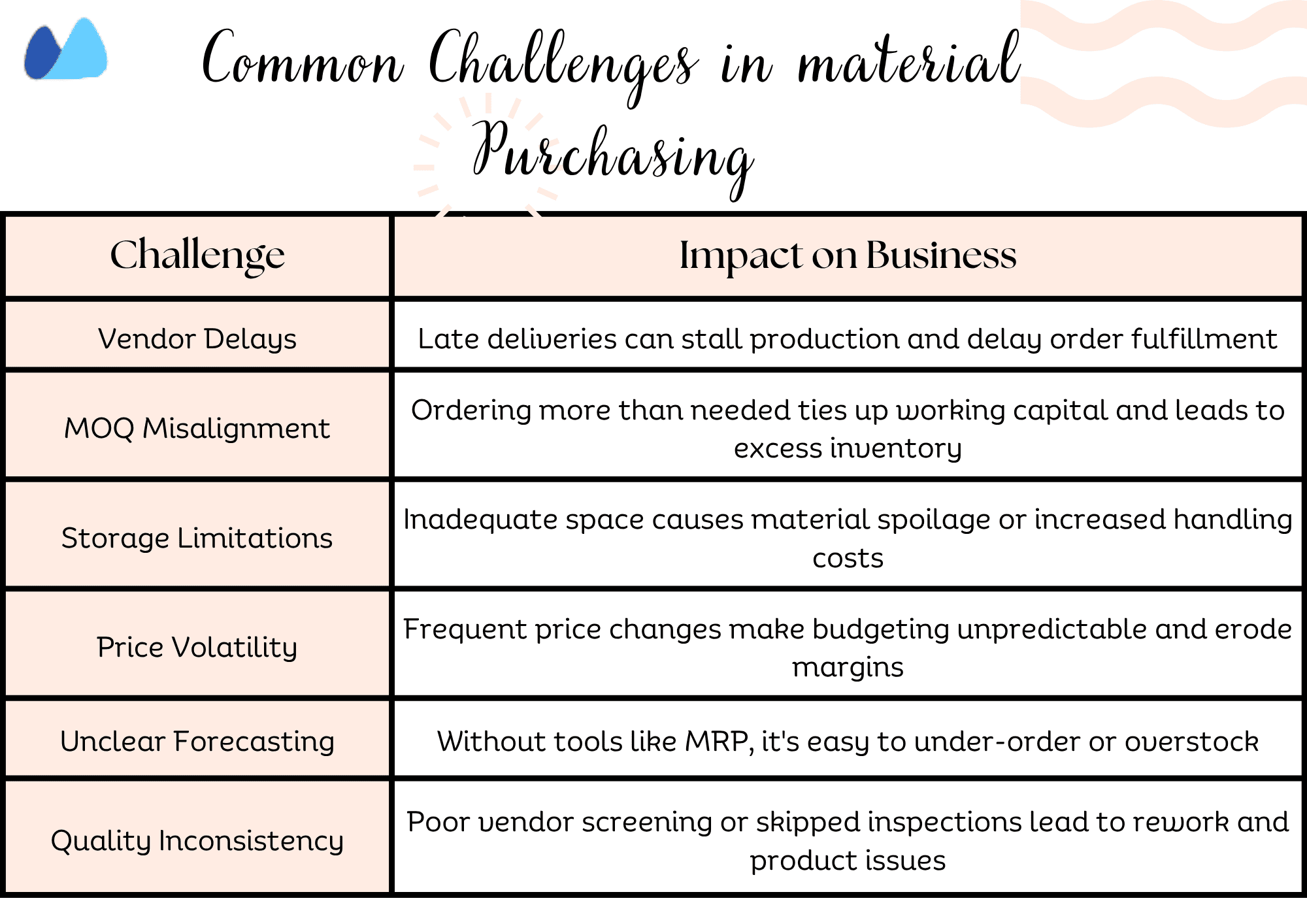

⚠️ Common Challenges in Material Purchasing

Even with a defined process, material purchasing can run into roadblocks that slow down production, waste capital, or compromise product quality. These challenges are prevalent when systems are manual or reactive.

For example: A business overestimates its needs for a seasonal product, ends up purchasing too much due to MOQ constraints, and ends up discarding a large portion due to shelf-life limits

How to Optimize the Material Purchasing Process

If you are still managing purchasing through spreadsheets, manual approvals, or email threads, it’s only a matter of time before things slip through the cracks. The good news?

You don’t need an enterprise-sized budget to resolve this issue. With the right tools and practices, you can gain complete control over your raw material sourcing and reduce costly errors.

The majority of the manufacturers are investing in digital transformation. According to Grand View Research, the global ERP software market reached $64.8 billion in 2024 and is projected to reach $123.4 billion by 2030.

This surge indicates that more businesses, particularly SMEs, are prioritizing tools that integrate purchasing, inventory, and production into a single streamlined process.

Here’s how to streamline and strengthen your purchasing process.

➡️ Implement an ERP System with Purchasing & Inventory Modules

Modern ERP platforms enable you to automate various processes, including purchase requisitions and approvals, vendor selection, and goods receipt.

How it helps:

- Auto-generate purchase orders based on stock levels

- Track lead times and on-time delivery performance

- Sync purchasing with inventory and production modules

📌 Tip: Choose an ERP that includes material planning requirements and supports multi-level BOMs for better visibility.

📍Recommended Read: Understanding Bill of Materials (BOM): A practical Guide for Manufacturers — Learn how the BOM structure directly impacts your material purchasing accuracy

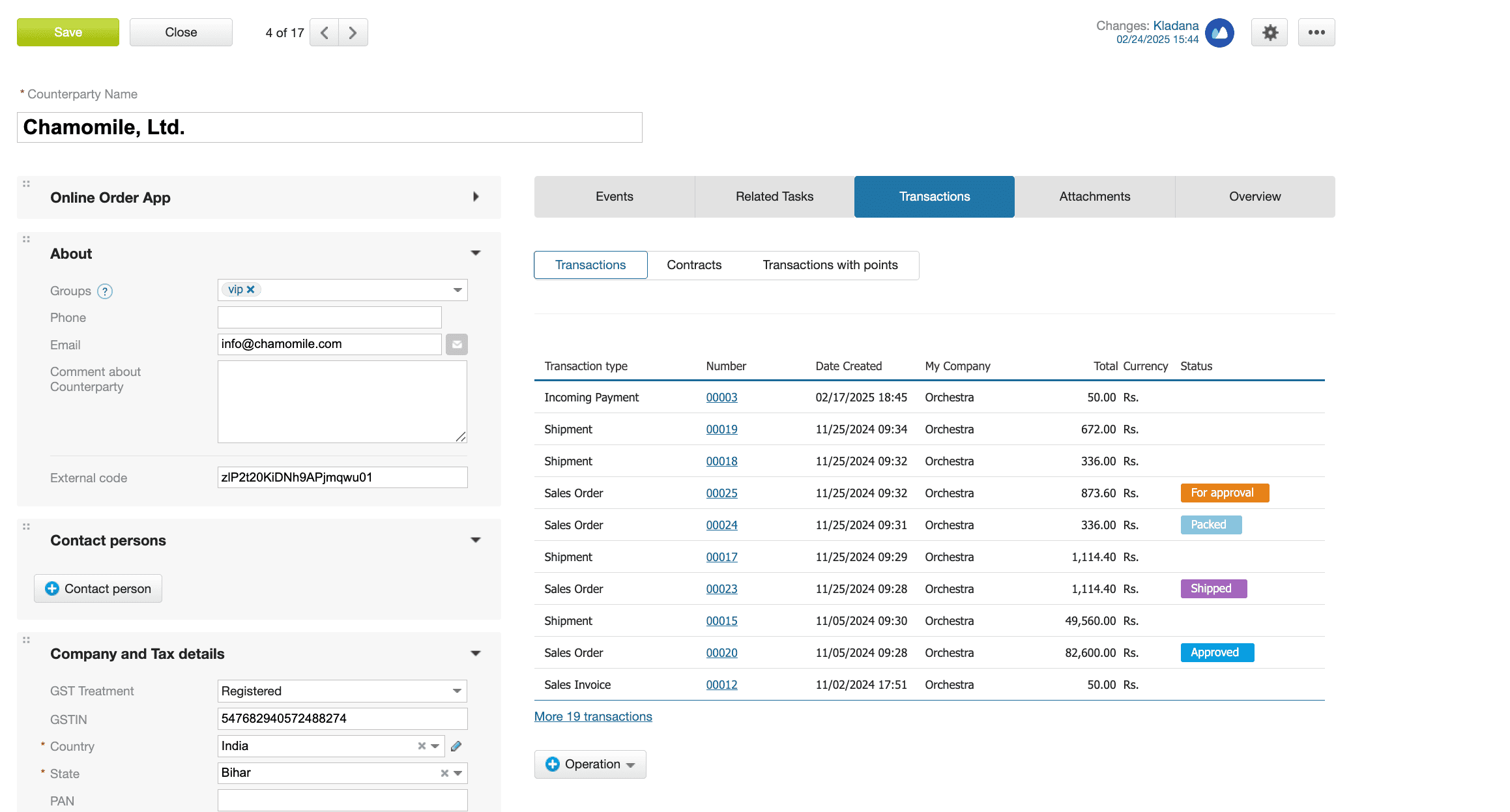

➡️ Use an Approved Vendor List (AVL)

An AVL ensures that you are sourcing from trusted suppliers who meet your quality, pricing, and lead-time expectations.

Benefits:

- Faster purchasing decisions

- Fewer quality or delivery issues

- Easier compliance with internal controls

For example: Your buyer selects vendors only from a pre-vetted AVL instead of relying on personal contacts or rushed decisions

➡️ Forecast Material Needs Using MRP

A material planning system calculates what you need to order and when based on production schedules, sales forecasts, and stock on hand.

Why it matters:

- Prevents overordering or last-minute shortages

- Aligns raw material supply with actual demand

- Optimizes cash flow and warehouse space

➡️ Adopt Just-in-Time (JIT) Purchasing

JIT means ordering material closer to when they are needed in production, reducing storage costs and minimizing waste

Best used when:

- You have reliable suppliers with short lead times

- Your product demand is steady and predictable

➡️ Track Key Metrics to Improve Continuously

Monitoring Key KPIs helps you identify supplier issues early, control material costs, and make more informed decisions over time. Use your ERP dashboard to track

- On-time delivery rate — See how reliably each supplier meets promised lead times

- Purchase price variance — compare actual vs standard costs to track price changes

- Supplier defect rate — Measure how often materials fail quality checks

- Cost per unit over time — Monitor material cost trends to improve pricing and budgeting

Use Cases by Industry

Different industries struggle with various types of raw materials, but the underlying purchasing challenges, such as poor visibility, MOQ misalignment, or lead time uncertainty, are surprisingly similar.

Here’s how structured procurement and ERP tools help you solve them in practical business settings:

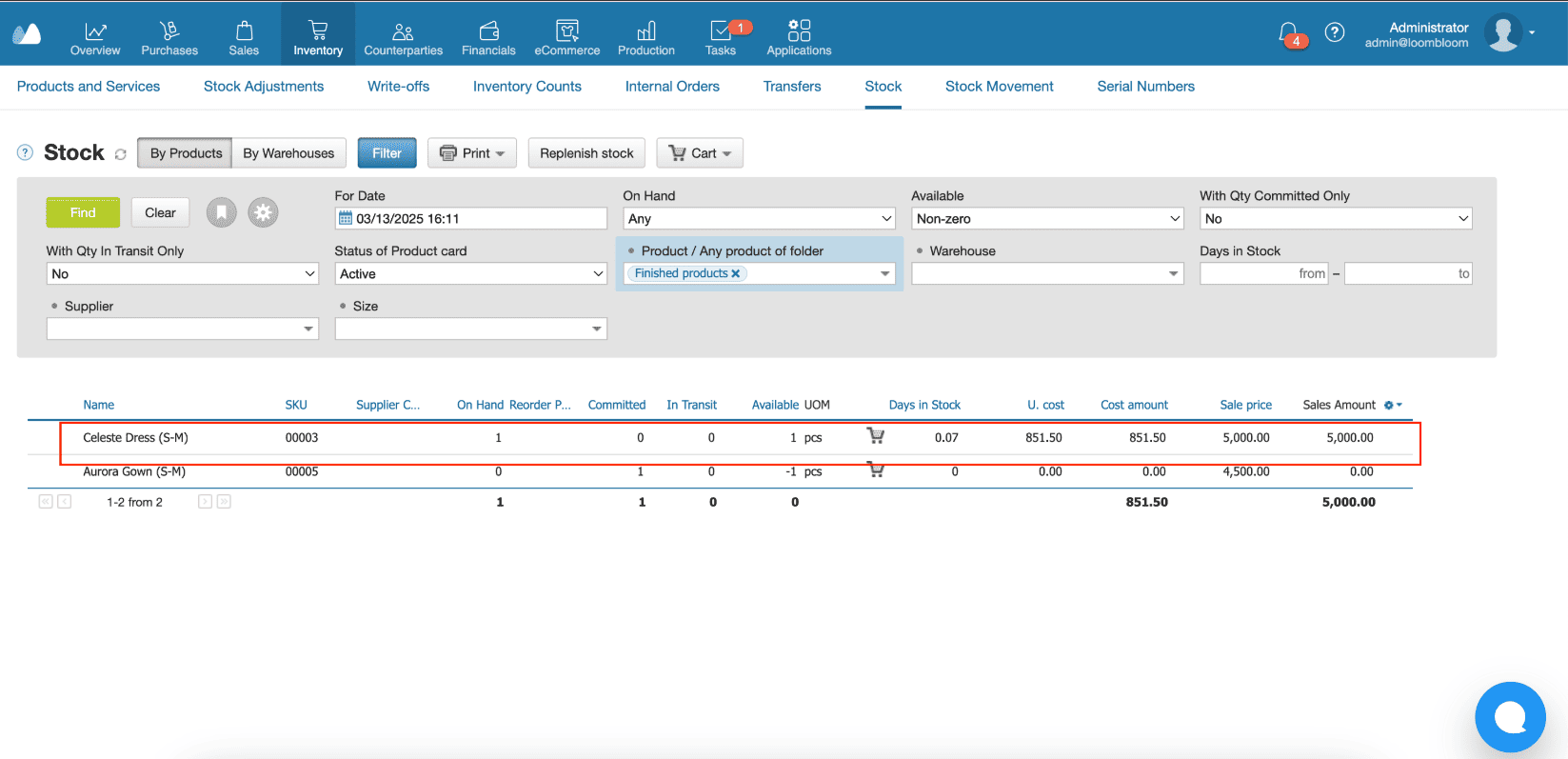

👕 Apparel Manufacturing

| Element | Details |

Challenge |

In garment manufacturing, you don’t always have the right fabric available when production starts, even though other fabrics are sitting in storage, unused |

Root cause |

To meet the supplier’s MOQ, your team orders in bulk without checking which fabrics are needed for the upcoming styles |

Impact |

Delayed production, excess inventory, and capital tied up in non-moving stock |

ERP Led Solution |

|

📦 Packaging Manufacturing

| Element | Details |

Challenge |

In packaging manufacturing, you buy large amounts of resin when prices are low, but it ends up sitting in the warehouse for too long |

Root cause |

You are trying to save money by buying in bulk, but you’re not checking how much resin is being used |

Impact |

Excess stock takes up storage, ties up cash, and eventually becomes a waste if not used in time |

ERP Led Solution |

|

🍲 FMCG Manufacturing

| Element | Details |

Challenge |

Ingredients with short shelf life are often wasted because they are ordered too early |

Root cause |

The purchasing item isn’t checking production dates before placing an order |

Impact |

You waste money, lose ingredients, and place expensive last-minute orders to recover |

ERP Led Solution |

|

📊 Key KPIs for Material Purchasing Performance

Use the following metrics to evaluate and improve your material procurement process over time.

| KPI | What It Measures | Why It Matters |

Cost Per Unit |

Average price paid per unit of raw material |

Helps monitor pricing trends, evaluate supplier competitiveness |

On-Time Delivery Rate |

Percentage of orders delivered on or agreed lead time |

Directly affects production timelines and customer commitments |

Purchase Price Variance |

Difference between the standard and the actual purchase price |

Highlights price increase or negotiation gaps with suppliers |

Lead Time |

Time between PO issuance and delivery of materials |

Affects inventory planning and production scheduling |

Supplier Defect Rate |

Percentage of deliveries that fail quality checks |

Helps assess supplier reliability and long-term quality consistency |

Inventory Turnover Ratio |

Number of times inventory is used/sold, and replenished in a period |

Indicates efficiency in purchasing and stock management |

Make Purchasing a Breeze — Not a Bottleneck

Auto-create requests, track every order, and keep spending in check — from sourcing to paying suppliers

🧠 Summary

Material purchasing is not just about placing orders; it’s the foundation of your entire production flow. If you get it wrong, you risk delays, excess inventory, and hidden costs. But if you plan correctly, purchasing becomes a powerful lever.

So, whether you are running a small factory or scaling a fast-moving product business, material purchasing deserves structure, not spreadsheets. And the right system can help you achieve that without overcomplicating operations.

Frequently Asked Questions on Material Purchasing

What is material purchasing in manufacturing?

Material purchasing is the process of acquiring raw materials, such as fabrics, steel, or resin, that are used directly in the manufacturing of finished goods. It plays a crucial role in ensuring timely and cost-effective production.

What’s the difference between material purchasing and procurement?

Procurement covers the broader process of sourcing, vendor selection, contract negotiation, and compliance. Whereas material purchasing is a subset of procurement that focuses on the actual buying of production materials.

Why is material purchasing important for SME manufacturers?

SMEs often have limited budgets and less room for error. Poor purchasing can lead to stockouts, overstocking, missed deadlines, and reduced profit margins. A well-managed purchasing process maintains stable production and keeps costs under control.

What are examples of raw materials in different industries?

- Apparel: Cotton, polyester, zippers

- Food: Spices, oils, preservatives

- Plastics: Resin pellets, colorants

- Furniture: Wood panels, foam, nails

What types of materials are typically purchased in manufacturing?

- Raw materials for core production

- Semi-finished goods for assembly

- Packaging materials to ship or display the product

What are the common challenges in materials purchasing?

Common issues include vendor delays, poor forecasting, MOQ restrictions, price volatility, and inconsistent quality. These can delay production, inflate costs, and reduce profitability.

How do you manage material purchasing effectively?

Utilize structured workflows, maintain an AVL, and leverage ERP tools with MRP features. Plan purchases based on production schedules and track KPIs to make data-driven decisions.

What tools can help streamline material purchasing?

An ERP system with integrated purchasing, inventory, and MRP modules is ideal. It automates repetitive tasks, tracks KPIs, reduces manual errors, and ensures timely raw material availability.

What is the process of purchasing materials?

The process includes:

- Raising a purchase requisition

- Getting internal approvals

- Selecting a vendor

- Issuing a purchase order

- Receiving Goods and performing quality checks

- Matching invoices and processing payments

- Moving materials to storage or production

Which KPIs should I monitor in material purchasing?

Key KPIs Include:

- Cost per unit

- On-time delivery rate

- Purchase price variance

- Supplier defect rate

- Inventory turnover

List of Resources

- Grand View Research: Smart Manufacturing Report

- Grand View Research: Global ERP Software Market Report

Read‑alikes

4 Free Purchase Order Templates with a Step‑By‑Step Guide: Excel, Word, and Google Sheets Format

Importance of Inventory Management: Benefits, Control, and Business Impact

What Is Lead Time in Inventory Management? Meaning, Formula, and Optimization Tips

Warehouse Inventory Management: A Complete Guide to Tools, Tips, and Systems for 2026

Manufacturing Execution System (MES): The Smart Transformation Your Factory Needs

Smart Food Inventory Management: Slash Waste and Maximize Profits

ERP Inventory Management — How to Control Stock Efficiently in 2026