Supply chains are moving faster than ever, leaving no room for errors or delays. With omnichannel retail, global sourcing, and rising customer expectations, warehouses now play a central role in keeping operations on track. This growing importance is also reflected in the market. According to Grand View Research, the Global warehouse management system (WMS) market was valued at $2.88 billion in 2024 and is expected to reach $8.38 billion by 2030.

In this guide, you’ll learn how a WMS helps you improve efficiency, boost accuracy, and gain real-time visibility across operations. You’ll see how it connects with systems like ERP and Transportation Management System, how different industries apply it, challenges during implementations, insights into the future of WMS, from AI and robotics to cloud-based platforms.

- What Is a Warehouse Management System?

- Why WMS Is Essential in Modern Supply Chains

- Role of WMS in Supply Chain Management

- Functions of a WMS in Supply Chain Management

- Benefits of Using a WMS

- WMS Integration with Other Supply Chain Systems

- WMS in Different Industries

- Challenges of Implementing a WMS

- Future of WMS in Supply Chain Management

- Sample Case Study: WMS Driving Efficiency in E-Commerce

- Kladana Integration Solution Focused

- To Sum Up

- Frequently Asked Questions on WMS in Supply Chain Management

- List of Resources

What Is a Warehouse Management System?

A warehouse management system is a software that helps you manage the daily flow of goods within a warehouse. Its purpose is simple. It helps you in giving an accurate, real-time picture of inventory and streamlining the processes of moving products in and out.

At its core, a WMS helps you track inventory, guide order picking, and generate reports that show exactly what’s happening on the warehouse floor. They give you the visibility you need to cut down errors and react quickly when demand changes.

It’s also important to understand how a WMS differs from an ERP. ERP connects business functions like finance, procurement, and sales. WMS focuses on the day-to-day work inside the warehouse by receiving, storing, and shipping goods. When integrated, the two systems complement each other.

📦 Control Your Entire Supply Chain from the Warehouse

Kladana’s warehouse tools give you real-time visibility across stock, orders, and suppliers — the backbone of any supply chain

- Track every item from receiving to delivery with barcode scanning

- Sync stock updates instantly across sales and purchase orders

- Avoid shortages or overstock with smart reorder alerts

- Analyze supplier lead times and incoming shipments

Why WMS Is Essential in Modern Supply Chains

The role of WMS in supply chain management goes beyond warehouse efficiency. Many supply chain delays begin in the warehouse. If your inventory records are off, order picking is slow, or you lack visibility, those issues ripple outward and cause late deliveries and unhappy customers.

This kind of control does more than make your warehouse run smoothly. It directly affects your work process. PWC’s Smart Moves report found that companies adopting advanced supply chain capabilities, such as WMS, recover their investment in about 22 months.

You see these returns because fewer errors lower your costs, better visibility helps you use assets more efficiently, and reliable fulfillment builds customer trust.

This is why the specific functions of a WMS matter, since they show how the system strengthens supply chain performance step by step:

1. Growing Complexity in Global Supply Chains

Supplier networks now span countries and regions, which makes it hard to control things manually. Without a system in place, delays and errors can quickly ripple through your supply chain.

2. Rise of E-commerce and Omnichannel Retail

Selling across multiple platforms, including online stores, marketplaces, and physical outlets, requires precise stock control. A slight mismatch can create overselling or slow fulfillment across channels.

3. Customer Demand for Speed and Accuracy

Buyers expect their orders to arrive on time and without errors. Same-day or next-day delivery leaves very little room for mistakes, which means you need firm control at the warehouse level.

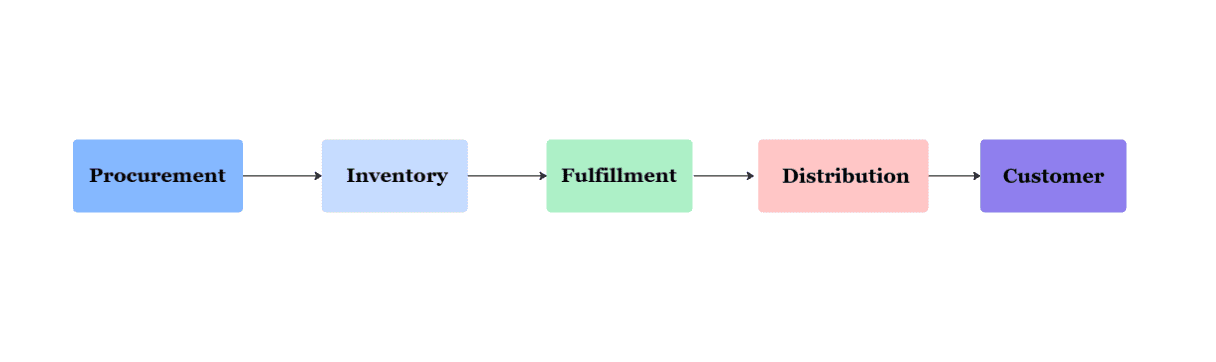

Role of WMS in Supply Chain Management

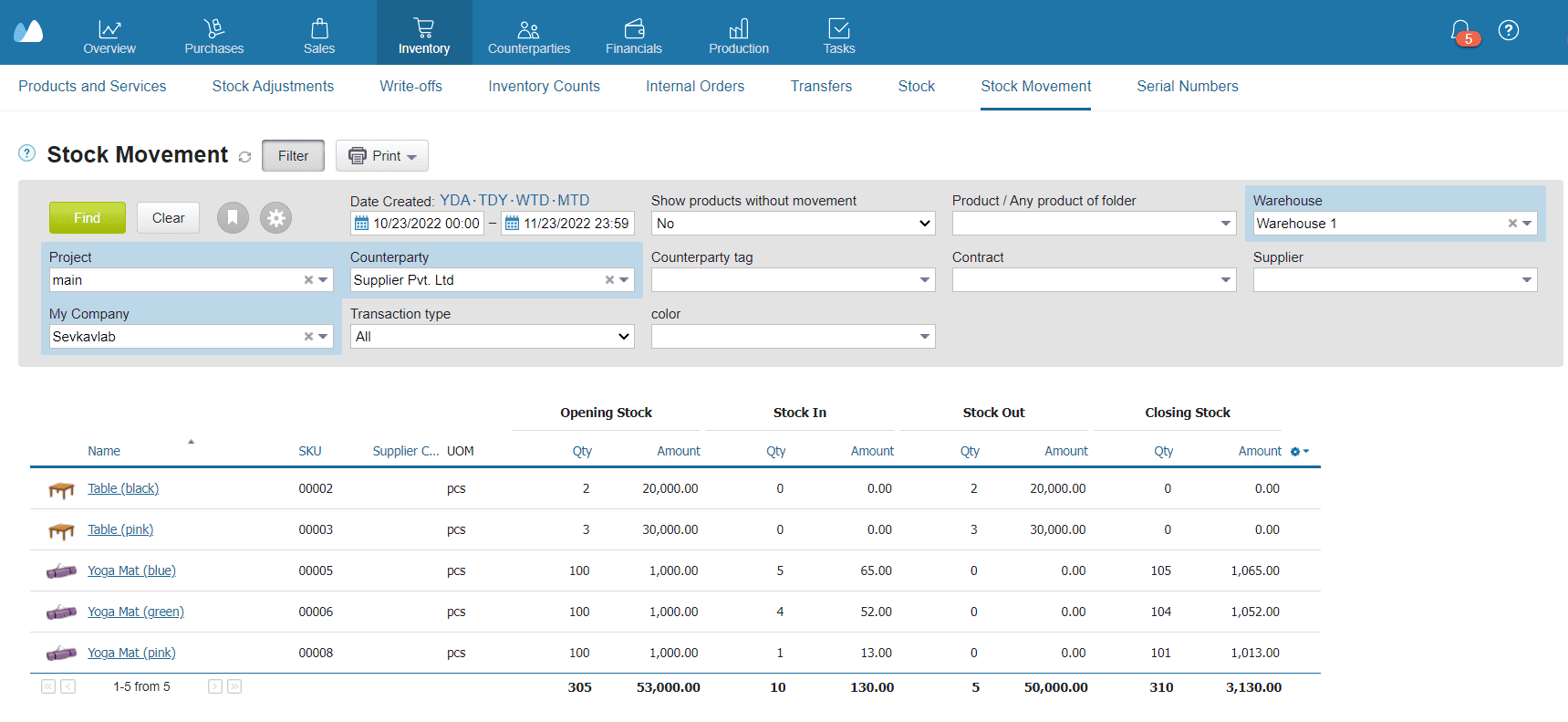

1. Real-Time Inventory Visibility

Inventory data updates the moment goods are received, moved, or shipped. This helps you avoid double-selling in e-commerce, keeps safety stock accurate, and gives suppliers confidence that your numbers can be trusted.

2. Faster Order Fulfillment

A WMS improves order processing: creates optimized pick lists and assigns tasks automatically, which speeds up processing and reduces errors. This enables businesses to meet the same-day or next-day delivery expectations in e-commerce, retail, and wholesale.

📖 Recommended Read: Supply Chain Management in E-commerce: Strategy & Tools. Explore how e-commerce businesses streamline supply chain operations to keep up with fast delivery promises

3. Balanced Stock Levels

Stockouts frustrate customers while excess inventory ties up your cash. Continuous tracking of demand against available stock and purchase orders alerts you before shortages cause backorders and prevents surplus goods from filling up valuable space.

4. Smarter Use of Warehouse Space

Instead of filling racks randomly, a WMS uses slotting rules to place fast-moving SKUs closer to dispatch and bulkier items in optimal zones. This reduces congestion on the floor, speeds up picking, and helps you delay costly warehouse expansions.

📖 Recommended Read: What Are Warehouse Operations? Definition, Processes, and Best Practices. Learn the key warehouse processes, challenges, and best practices that connect directly with WMS improvements.

5. Stronger Demand Forecasting

By pulling patterns from order histories, returns, and seasonal peaks, the system gives you a clearer view of what’s ahead, when this data flows into ERP or TMS, your procurement, production, and transport planning all line up with actual demand instead of guesswork.

Functions of a WMS in Supply Chain Management

A WMS keeps your warehouse aligned with supply chain goals by managing the critical activities that move goods through your facility. These can be grouped into five crore functions.

📥 Receiving and Put-Away Optimization

A WMS captures every inbound shipment as soon as it arrives, verifies it against purchase orders, and directs staff to the most efficient storage locations. Instead of leaving goods waiting at the dock, the system ensures fast check-in and accurate placement, which sets the stage for smoother inventory management later.

📦 Inventory Management and Real-Time Updates

Every movement, from shifting a pallet to picking a single item, is recorded immediately. The number you see in the system always matches what is actually on your shelves. That accuracy helps you cut down on costly errors, avoid stock shortages, and plan replenishment with confidence.

🛒 Picking, Packing, and Shipping

Once items are picked, packing and labeling instructions guide your team to meet customer and carrier requirements. This reduces wrong shipments and helps you hit delivery deadlines consistently.

🔀 Returns and Reverse Logistics

Returns don’t have to disrupt your workflow. With WMS, every returned item is captured, inspected, and then routed to the right outcome. Whether that’s restocking, repair, or disposal, this keeps your stock accurate and helps you understand patterns behind returns.

👷♂️ Labour Management

The system tracks how work is being done, highlighting bottlenecks and showing where productivity drops. With this insight, you can assign tasks more fairly, improve performance where needed, and increase efficiency without depending on overtime.

💡Smarter Warehouses, Faster Supply Chains — Powered by Kladana

Track stock in real time, speed up order processing, and keep your supply chain running smoothly

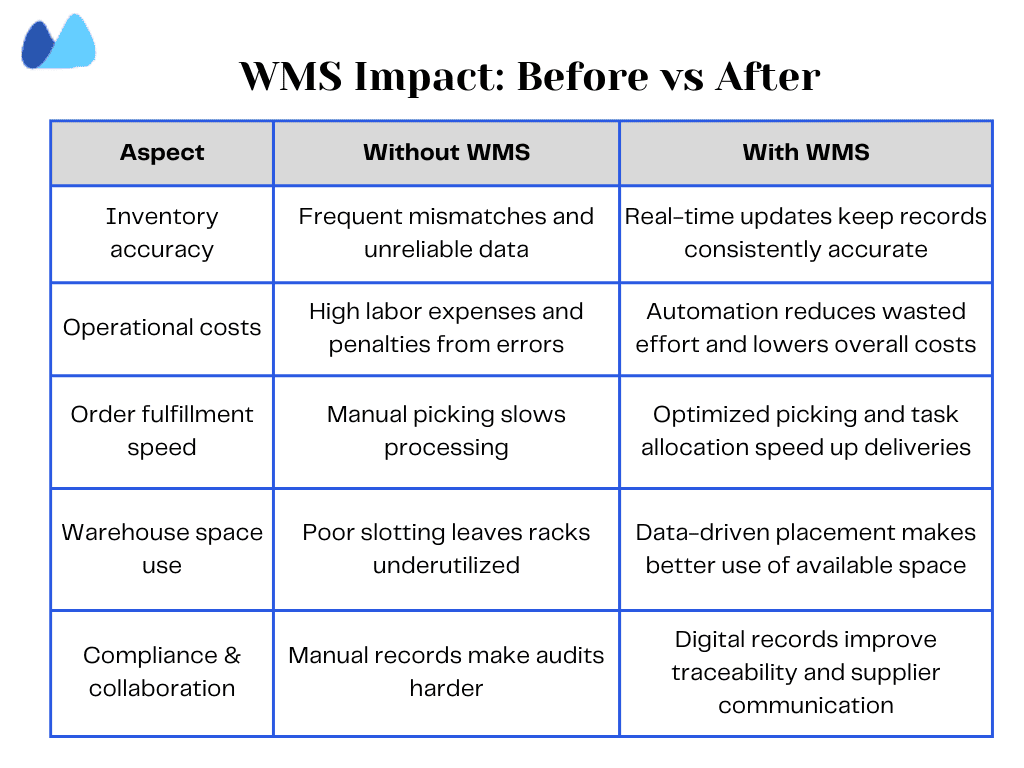

Benefits of Using a WMS

When the core functions of a WMS are put into action, the results go beyond smoother warehouse operations. They translate into measurable business outcomes that strengthen your supply chain. In fact, PWC’s localisation report shows that nearly 71% of companies experience moderate to significant improvements in inventory accuracy and lead-time efficiency when they adopt stronger supply chain practices. That number climbs to 82% as they scale these capabilities.

Let’s examine the key benefits include.

1. Reduced Operational Costs

Every error, delay, or wasted movement adds cost. By streamlining receiving, storage, picking, and shipping, you can minimize labour time per order. It also lowers carrying costs and avoids penalties from missed deliveries.

2. Improved Customer Satisfaction

Reliable stock information means customers get what they ordered without cancellations. Clear tracking updates keep them informed, and accurate deliveries reduce frustration. When expectations are consistently met, trust grows and loyalty follows.

3. Stronger Supplier Collaboration and Compliance

Accurate records of receipts, shipments, and stock levels make it easier to work with suppliers and pass audits. In regulated industries like pharmaceuticals or food, detailed WMS reports also give you the traceability needed to stay compliant.

WMS Integration with Other Supply Chain Systems

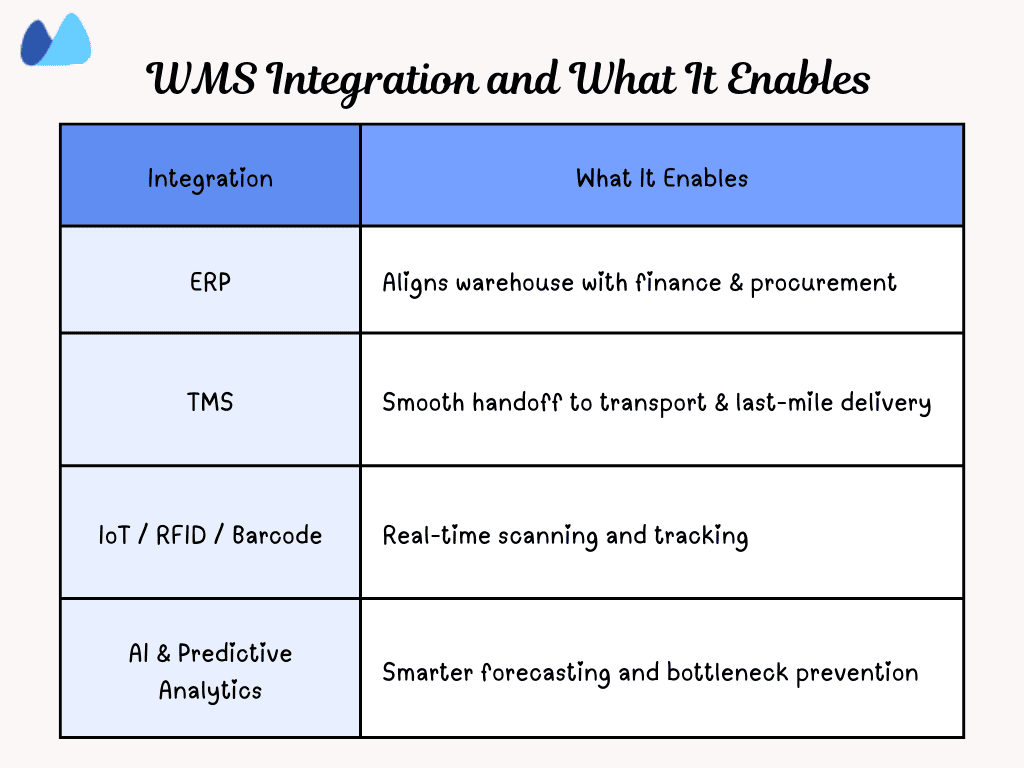

A WMS rarely operates in isolation. Its real value comes when it integrates with other systems across your supply chain, creating a seamless flow of data and actions. The most important integrations include the following.

1. ERP Integration for Financial and Procurement Alignment

An ERP oversees high-level business processes like purchasing, finance, and sales. When connected with a WMS, purchase orders raised in ERP flow automatically into the warehouse, and stock movement updates the ERP in real time. This ensures your finance and operations teams are constantly working with the same accurate data.

2. TMS Integration for Transport and Last-Mile Efficiency

A transportation management system handles routing, carrier selection, and freight cost optimization. When integrated with WMS, shipping orders generated in the warehouse pass directly into TMS. This creates a smooth handoff between order ready and order delivered, and this improves last-mile reliability.

3. IoT, RFID, and Barcode Technologies

Integrating WMS with scanning and sensor technologies removes manual data entry. Barcode and RFID tags update stock levels instantly, while IoT sensors provide real-time insights into the location, condition, or temperature of goods. Together, they provide you with complete visibility across the entire supply chain.

4. AI and Predictive Analytics

When WMS data feeds into advanced analytics platforms, you gain more than operational control. AI can spot demand patterns, forecast labour needs, or predict bottlenecks before they happen. This turns warehouse data into actionable supply chain intelligence.

WMS in Different Business Types

| Industry | Key Challenges | Role of WMS |

| Retail & e-commerce |

|

|

| Manufacturing |

|

|

| Wholesale & distribution |

|

|

Challenges of Implementing a WMS

Even with clear benefits, rolling out WMS isn’t always smooth. There are practical hurdles you’ll need to plan for:

1. High Upfront Cost

Licenses, handheld scanners, and setup fees can make the initial investment heavy. If your workflows need a lot of tailoring, the project may take longer and cost more than expected.

2. Staff Training and Adoption

Moving from manual processes to a system-driven workflow requires time and training. Without proper guidance, your team may resist the change, slowing down adoption.

3. Integration with Legacy Systems

If you’re still relying on older ERP or accounting software, connecting it with a modern WMS can be tricky. Sometimes, additional tools or custom development are required to enable systems to communicate with each other.

4. Data Migration and Accuracy

Transferring records from spreadsheets or outdated systems can introduce errors. If the data isn’t right to go live, you risk disruptions in daily operations.

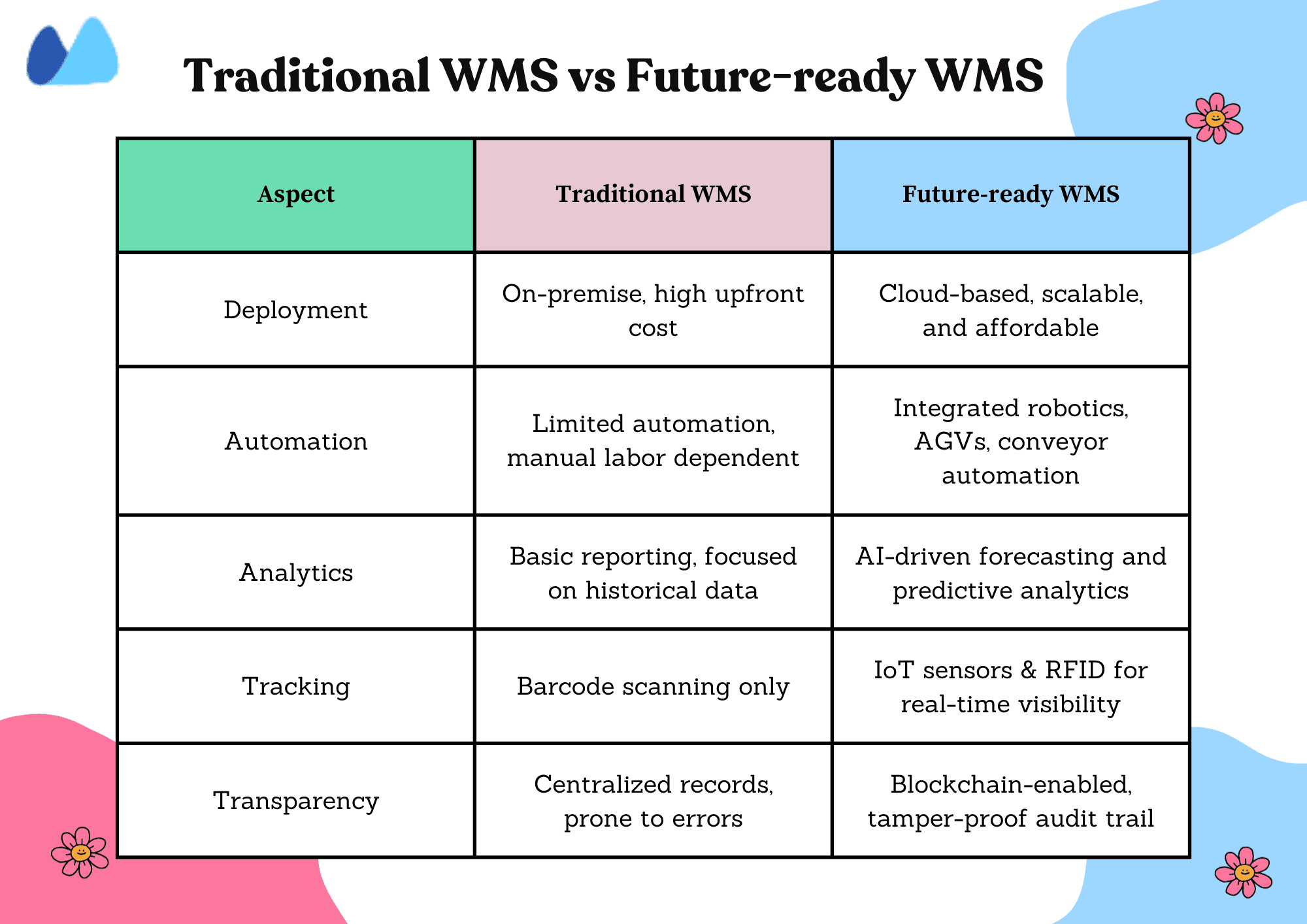

Future of WMS in Supply Chain Management

As supply chains evolve, WMS solutions are moving beyond basic inventory control and becoming smarter, faster, and more connected. Key trends shaping the future include the following.

1. Cloud-Based WMS

Cloud deployment makes advanced WMS affordable for SMEs. It offers faster implementation, easier scaling, and real-time access from anywhere.

2. Robotics and Automation

Automated guided vehicles (AGVs), robotic picking arms, and conveyor systems are being integrated with WMS to reduce manual labor and speed up operations.

3. AI-Driven Demand Planning

Artificial intelligence analyzes historical orders, returns, and seasonality to forecast demand more accurately. This improves stock planning and reduces both shortages and overstocking.

4. IoT and RFID Expansion

With sensors and RFID tags linked to WMS, businesses gain live data on stock location, movement, and even production conditions (temperature, humidity).

5. Blockchain for Transparency

Blockchain integration with WMS creates tamper-proof records of inventory and shipments, increasing trust in industries like pharmaceuticals and food.

Sample Case Study: WMS Driving Efficiency in E-Commerce

| Aspect | ❌ Before WMS (Manual Operations) | ✅ After WMS (Automated System) | Results |

| Order processing | Managed with spreadsheets, frequent delays | Order processed within a single shift | Faster deliveries, no backlogs |

| Inventory updates | Stock updates lagged, and there were frequent mismatches | Real-time sync across all channels | Online listings matched stock, fewer cancellations |

| Delivery timelines | Deliveries are unpredictable, often late | Order shipped on time, often same day | Reliable shipping windows met customer expectations |

| Staff productivity | Overloaded staff and rising volumes are hard to manage | More orders handled without extra hiring | Seasonal peaks managed without temporary staff |

Real-World Industry Examples

1. Amazon

Amazon automates picking with mobile shelving robots, cutting picking time almost by half. This WMS-driven setup enables same-day delivery at a massive scale.

2. Flipkart (India)

Uses WMS-powered just-in-time hubs during peak sales (Big Billion Days). Real-time routing and stock visibility allow millions of orders to be fulfilled within days while keeping inventory lean.

3. Big Basket (India)

Handles highly perishable goods using WMS for temperature monitoring, cross-docking, and live demand tracking — reducing spoilage and accelerating fresh deliveries.

Kladana Integration Solution Focused

1. Stay updated in real time ➞ Every sale, return, or transfer instantly reflects in your stock levels, so you don’t deal with overselling or mismatches.

2. Manage all orders in one place ➞ Whether it’s from your online store, a marketplace, or a showroom, Kladana pulls orders together and reserves stock automatically.

3. Connect warehouse with finance ➞ Purchases, inventory movements, and invoices flow in one system, giving you complete visibility without juggling multiple tools.

4. Work smarter on the floor ➞ Use barcode scanning, smart put-away, and guided picking to speed up daily warehouse tasks and make fewer errors.

⚡ WMS Features, SME-Friendly Pricing. Try Kladana

Automate inventory and order flows with a system that connects suppliers, warehouses, and sales — built for growing businesses

To Sum Up

Warehouse management systems have moved far beyond simple stock-keeping tools. In modern supply chains, they act as the backbone that connects the entire process. From retail and e-commerce to manufacturing and distribution, WMS ensures that goods flow smoothly and data stays consistent at every stage.

The real advantage lies in what a WMS delivers: efficiency in daily operations, scalability to handle growth, and the competitiveness needed to meet rising customer expectations. Businesses that adopt these systems can respond faster to demand shifts, reduce errors that eat into margins, and build trust through consistent service.

Frequently Asked Questions on WMS in Supply Chain Management

What is the role of WMS in supply chain management?

A warehouse management system ensures that effective data and workflows within warehouses align with broader supply chain objectives. It provides real-time visibility, accuracy, and smooth coordination across inventory, fulfillment, and distribution.

What are the key functions of a warehouse management system?

The core functions include:

- Receiving

- Put-away

- Real-time inventory tracking

- Optimized picking/packing/shipping

- Managing returns

- Labour productivity

How does WMS improve supply chain efficiency?

WMS reduces delays, eliminates manual errors, optimizes the use of space and staff, and synchronizes inventory across channels. This leads to faster fulfillment and more reliable deliveries.

What are the benefits of integrating WMS with ERP?

When connected with ERP, a WMS ensures procurement, finance, and warehouse data are in sync. This integration reduces mismatches, improves reporting, and provides end-to-end supply chain visibility.

How does WMS reduce costs in the supply chain?

It lowers labor costs through automation, prevents stockouts and overstocking, reduces errors that lead to returns, and avoids penalties from late or missed shipments.

Is WMS suitable for small businesses?

Yes. Modern cloud-based WMS solutions are scalable, meaning SMEs can start small with essential features and expand as operations grow, without heavy upfront investment.

What technologies enhance WMS today?

IoT and RFID for real-time tracking, AI for demand forecasting, robotics for picking and material handling, and cloud-based platforms for scalability and accessibility.

What is the difference between WMS and ERP?

ERP manages enterprise-wide functions, such as finance, HR, and procurement, while WMS focuses on warehouse execution. Together, they create a complete operational ecosystem.

How does WMS help e-commerce fulfillment?

WMS handles high SKU volumes, prevents overselling by syncing inventory with online channels, and supports fast fulfillment models like same-day delivery and BOPIS.

How do you know if your business is ready for a WMS?

You’re ready when manual processes slow down order fulfillment, inventory mismatches cause cancellations, or scaling operations feel impossible without adding more staff. At that point, a WMS helps you regain control and grow efficiently.

List of Resources

- Grand View Research: Warehouse Management System Market Growth

- PWC: PWC Smart Move Report

- PWC: PWC Localization Supply Chain Report

Read‑alikes

What Is Supply Chain Order Management? Workflow, Tools & Key Strategies

Supply Chain Management in E‑commerce: A Practical Guide

E-commerce Warehouse Management System: a Complete Guide to Smarter Fulfillment

Warehouse Management System Process Flow: Steps, Charts, and SOP Templates

ERP Warehouse Management System: Complete Guide with Features & Benefits