Every purchase your company makes should follow a defined path from request approval to payment. But when that path isn’t mapped, problems multiply, and spending goes untracked; then suppliers get mixed signals, and internal teams lose time resolving preventable issues.

Purchase order management is the process that helps to provide that structure. It ensures that every order is authorized, documented, and aligned with budget and delivery expectations. It links procurement with finance, inventory, and vendor operations.

This helps to create a single workflow that supports compliance, cost control, and operational efficiency.

This shift toward structured purchasing is reflected in global trends. According to PwC’s 2024 Digital Procurement Survey, procurement teams aim to digitize up to 70% of their workflows by 2027.

If you are still handling purchase orders manually, you are missing out on the visibility and compliance that digital systems provide.

This guide will show the purchase order management process and how automation and reporting tools can reduce manual effort.

You’ll also learn how businesses like Neytthomes and Body Motion applied these principles using modern tools to streamline procurement across departments.

- What Is Purchase Order Management?

- Purchase Management Meaning and Scope

- Role in Budgeting, Vendor Coordination, and Compliance

- How PO Management Fits into the Procure‑to‑Pay (P2P) Cycle

- Types of Purchase Orders

- Steps in the PO Management Process

- Purchase Order Management System Overview

- Integrations with ERP, Inventory, and Accounting

- Benefits of a PO Management System

- PO in Supply Chain Optimization

- How to Choose a System

- To Sum Up

- Frequently Asked Questions on Purchase Order Management

- List of Resources

- Read‑alikes

What Is Purchase Order Management?

Purchase order management is the controlled process of creating, issuing, tracking, and closing purchase orders within your organization.

It ensures that every order is reviewed, approved, and reconciled against budget, delivery, and invoicing. A well‑managed PO system makes it easier to manage your purchasing at scale without sacrificing control.

Core Definition and Goals

The primary goal of purchase order management is to introduce consistency, visibility, and accountability to the purchasing process rather than relying on informal requests or disconnected systems.

Key Objectives Include

- Preventing unauthorized or untracked spending

- Ensuring timely approvals

- Aligning purchases with budget forecasts

- Reducing disputes with vendors

- Improving internal coordination between departments

Difference between Purchase Order and Invoice

It’s common to confuse a purchase order and an invoice, but they serve very different functions:

| Document | Created By | Purpose | When It’s Used |

Purchase Order (PO) |

Buyer |

To request goods/services and confirm terms |

Before delivery |

Invoice |

Supplier |

To request payment for delivered goods/services |

After delivery |

☑️ A PO is what you send to authorize a purchase. An invoice is what the vendor sends to bill you after fulfilling the order. Matching these documents is a key control mechanism. One that sounds like PO systems automate using 2‑way or 2‑way matching workflows.

PO in Supply Chain and Procurement

In procurement, a PO acts as a transactional checkpoint. It confirms what has been ordered, at what price, and from which supplier, and locks in delivery expectations. This supports better vendor negotiations, fewer fulfillment issues, and precise documentation.

In the supply chain, POs signal upcoming inventory, coordinate with warehouse schedules, and align financial planning with operational execution. A properly managed PO can help reduce lead times, optimize reorder points, and keep logistics teams ahead of demand.

Purchase Management Meaning and Scope

While purchase order management deals with the transaction layer, such as tracking and closing orders.

Whereas purchase management refers to the whole operational and strategic process behind how your business acquires goods and services. It’s the discipline that determines what gets bought, from whom, at what price, and under what terms.

📖 Recommended Read: Struggling with the raw material flow? Dive into Material Purchasing in Manufacturing to learn how to align purchase orders with production schedules and supplier timelines.

Definition of Purchase Management

Purchase management is the end‑to‑end oversight of procurement activities, including vendor sourcing, negotiations, contract management, and order execution.

It ensures that purchasing aligns with business needs, financial policies, and compliance standards, not just isolated transactions but across the entire buying lifecycle.

A well‑structured purchase management function covers:

- Vendor evaluation and onboarding

- Price and contract negotiation

- Approval workflows for purchase decisions

- PO issuance and tracking

- Delivery confirmation

- Payment processing and supplier feedback

Role in Budgeting, Vendor Coordination, and Compliance

1. Budgeting

Without structured purchase management, it’s nearly impossible to track committed spending or enforce department budgets. Every approved PO should reflect an allocated budget, updated in real‑time.

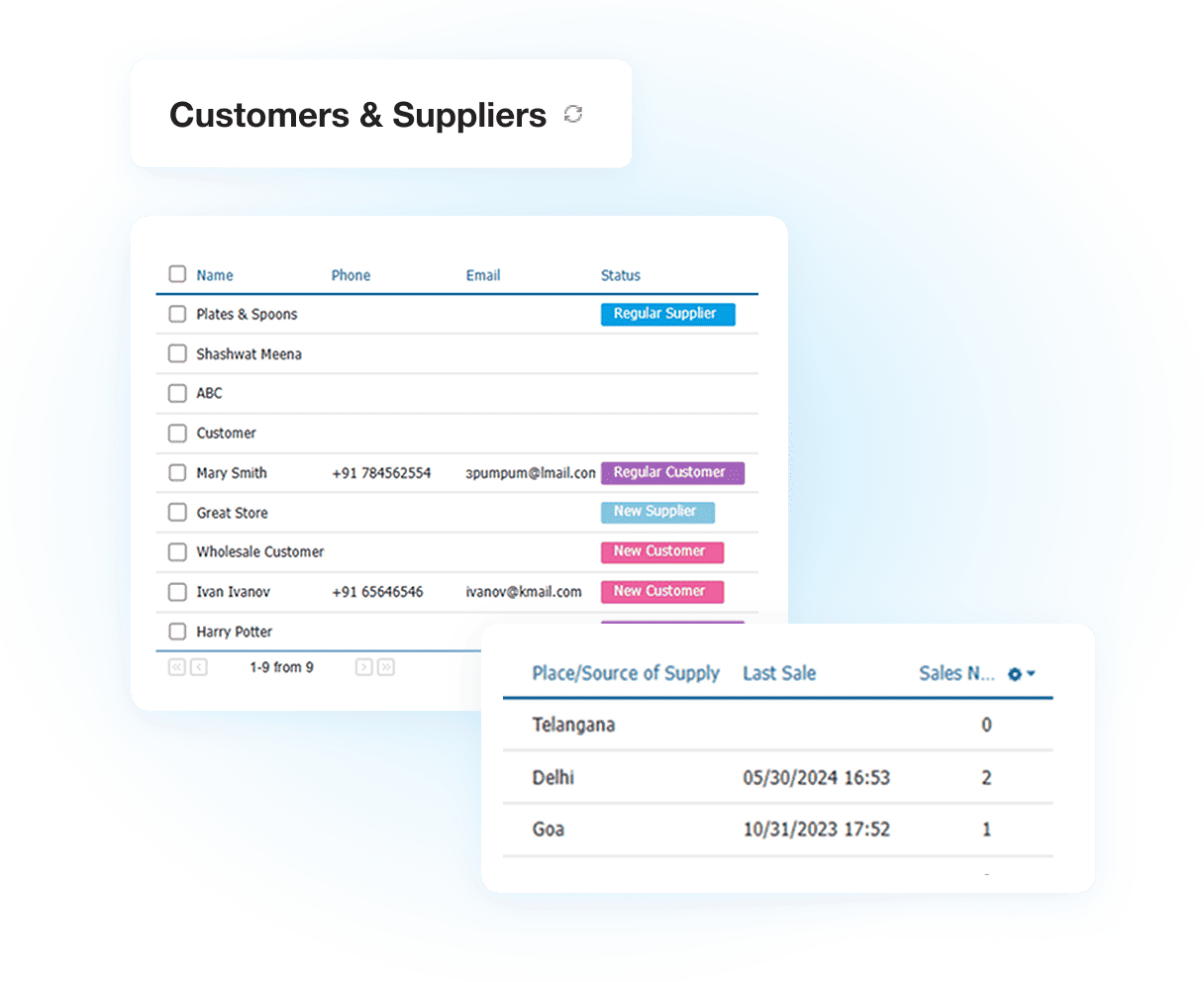

2. Vendor Coordination

Purchase management defines how your company communicates with suppliers. It determines how frequently you order, how you track performance, and how issues are resolved.

Having a central platform for vendor data, order history, and PO status improves communication and shortens resolution cycles.

3. Compliance

You can’t enforce policy if purchases happen outside the system. Purchase management tools establish internal rules, such as multi‑level approvals, threshold‑based routing, or a restricted vendor list, and ensure that every order adheres to these rules.

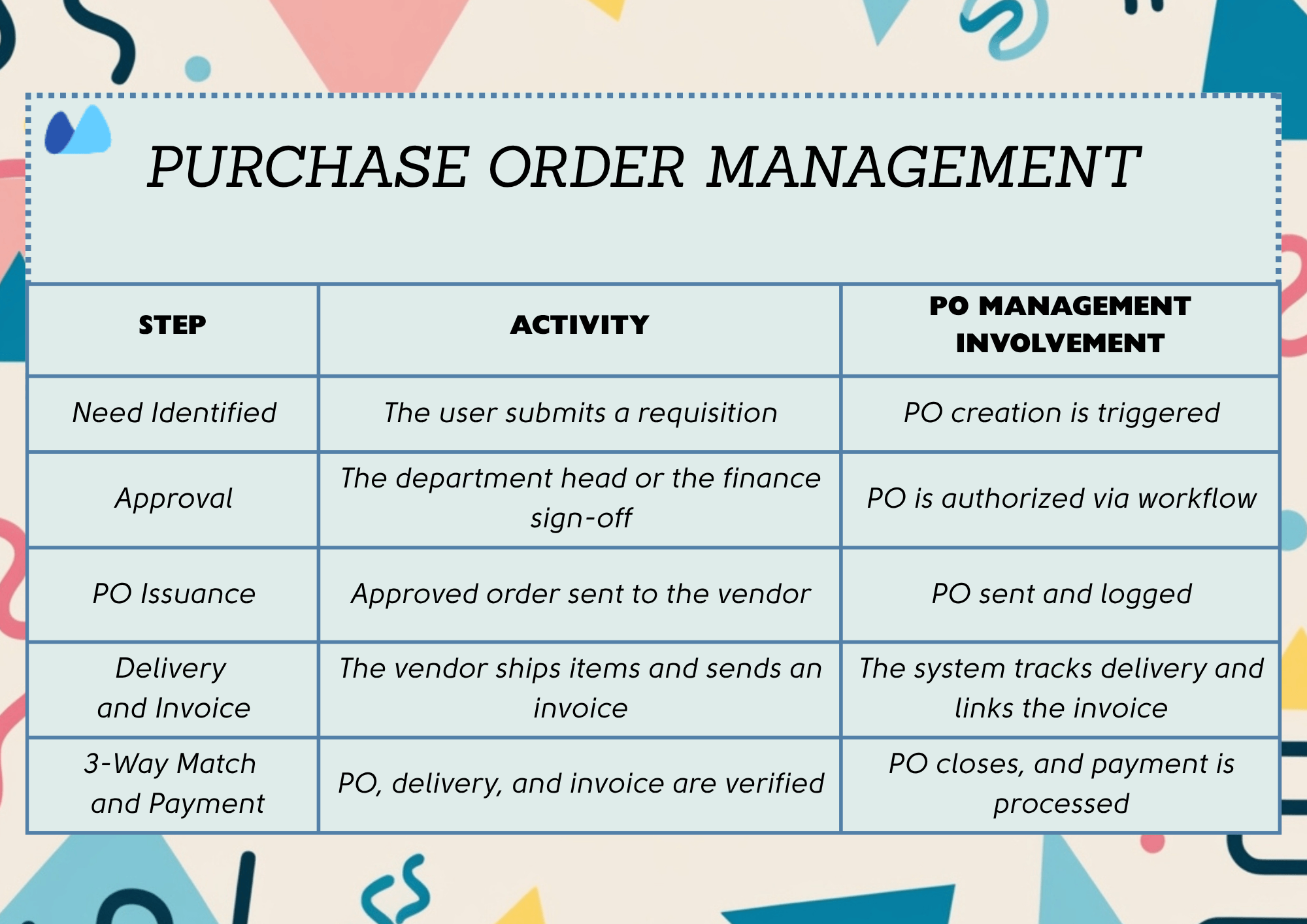

How PO Management Fits into the Procure‑to‑Pay (P2P) Cycle

The P2P cycle encompasses the entire journey, from identifying a need to paying the supplier. Here’s how PO management fits in.

📖 Recommended Read: Want a clear picture of the purchasing cycle? Check out this step‑by‑step guide to the purchasing process with flowcharts, metrics, and automation tips.

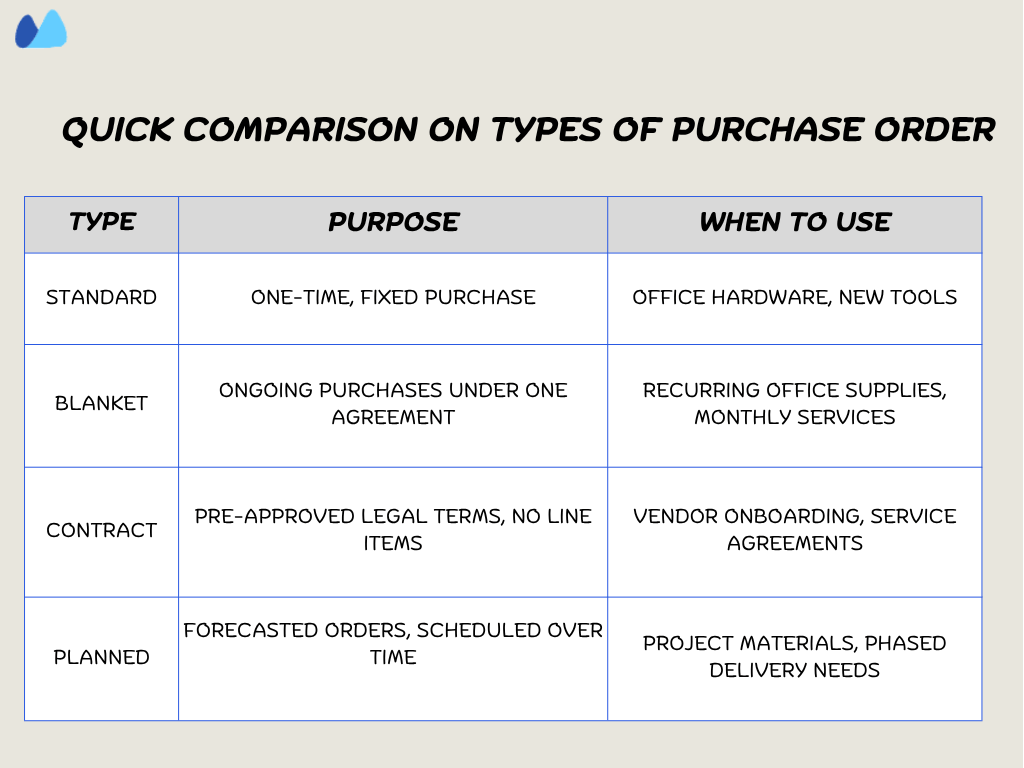

Types of Purchase Orders

Different purchasing needs call for different PO types. Using the right format helps reduce approval delays, prevent overordering, and simplify coordination with suppliers.

Here’s a quick comparison before we break down:

1. Standard PO

Use this when you know exactly what you need. Quantity, price, and delivery. It creates clarity and locks in the transaction.

2. Blanket PO

A blanket PO lets you place multiple orders under one approval. It saves time without losing control.

3. Contract PO

This type outlines commercial terms, not specific items. You set the relationship structure, then issue detailed orders later. It’s beneficial during vendor onboarding or long‑term service partnerships where legal and payment terms are agreed in advance.

4. Planned PO

It works best when you forecast needs but can’t confirm exact delivery dates. You agree on quantities and pricing with the supplier, then release actual orders over time based on demand or project readiness.

For example, Neytthomes, a luxury rug brand, uses planned POs within Kladana to coordinate phased deliveries from multiple suppliers. This setup enables their team to match stock intake with real‑time store requirements without locking up cash or overfilling storage.

By managing these releases in Kladana, they track commitments, timelines, and vendor performance, all while maintaining inventory across 10+ locations.

Steps in the PO Management Process

A robust PO process ensures your procurement is clean, auditable, and efficient. It defines how requests move through your organization and ensures nothing is purchased without visibility and approval.

Here’s how the whole process typically works.

1. Requisition Submission

A team identifies a need, such as raw materials, outsourced services, or restocking supplies, and submits a formal request. This is the start of the process.

In structured workflows, requisitions utilize a standardized format that includes product specifications, vendor suggestions, estimated costs, and quantities. That consistency reduces confusion later in the cycle.

2. Approval Workflows

Once a requisition is submitted, it enters an approval chain, and this is where many organizations face slowdowns. When routing depends on manual emails or unclear authority, routine purchases can take days to clear. A sound PO management system replaces this friction with logic‑based workflows.

With Kladana, for example, you can configure rules that route approvals automatically based on predefined thresholds. If a PO is under $30–60, it can be cleared without review.

Larger orders or those tied up to specific vendors or product types are escalated to the right stakeholder instantly. This level of automation not only reduces approval cycle time but also maintains clean audit trails.

3. PO Creation and Dispatch

Once approved, the system converts the request into a formal PO. It includes all line items, quantities, pricing, tax fields, and delivery expectations.

That PO is then issued to the supplier. Using a PO template ensures every order follows the same structure and prevents details from getting lost or miscommunicated.

📖 Recommended Read: Save time creating POs. Use these ready‑made PO templates to build clean, GST‑compliant orders in Excel, Word, or Google Sheets.

4. Order Tracking and Delivery

After the PO is sent, the vendor processes it and confirms shipment. During this time, your team needs visibility to progress, particularly with partially shipped or delayed items.

However, a connected PO system updates the delivery status and logs the receipt of goods. This helps warehouse, operations, and finance teams stay aligned, especially when multiple departments depend on the same order.

5. Invoice Matching and Closure

Once delivery is confirmed, your system runs a three‑way match that compares the purchase, goods receipt, and vendor invoice to ensure accuracy.

If everything aligns, payment is processed. If not, the system flags discrepancies for review. This step keeps your financials secure, ensuring vendors are paid only after every checkout.

💡 How Body Motion — a South African maker of sportswear and medical scrubs — uses Kladana to stay on top of cashflow and inventory:

✅ Keeps tight control on purchases by tracking every fabric roll and accessory against the system, so they never double‑buy.

✅ Matches invoices with orders and deliveries automatically, cutting out duplicate or wrong payments.

✅ Sees payment status instantly, which means weekly production planning happens without chasing paperwork.

✅ Reviews order and payment history inside Kladana to forecast smarter and spot reliable vendors.

✅ By running invoices through their PO system, Body Motion keeps cashflow clear, approvals on record, and stock movements easy to trace.

Purchase Order Management System Overview

A purchase order management system is a software framework that digitizes and automates your end‑to‑end PO workflow. It standardizes and centralizes the platform as a whole.

What Is a Purchase Order System?

At its core, a PO system is a tool that replaces manual PO handling with structured, digital workflows. It connects the people involved in procurement, including buyers, approvers, suppliers, and finance.

The adoption of PO systems is accelerating across industries. According to Verified Market Reports, the global purchase order software market was valued at $3.6 billion in 2024 and is expected to reach $8.2 billion by 2033, growing at a CAGR of 9.8%. If you are evaluating PO tools, this growth highlights how more businesses like yours are modernizing their procurement operations.

PO cycle time: a key performance metric

One of the most critical indicators of procurement efficiency is the time it takes for a requisition to be converted into an approved purchase order.

PO cycle time refers to the speed at which a purchase request is converted into an approved order. The shorter it is, the more responsive your procurement process will be.

Here’s a simple formula:

PO Cycle Time = PO Approval Date — Requisition Submission Date

In most manual systems, cycle times stretch to 2–4 days. The team loses time chasing approvals, reconciling formats, or waiting on department heads. However, with automation in place, you can reduce this to under 6 hours for repeat purchases.

📌 Example: A mid‑sized electronics distributor recently automated its PO process for orders below ₹10,000. By setting up threshold‑based approvals and centralized tracking, they brought down cycle times from 3 days to just 4 hours. As a result, they avoided bottlenecks during seasonal demand peaks without adding staff or chasing paperwork.

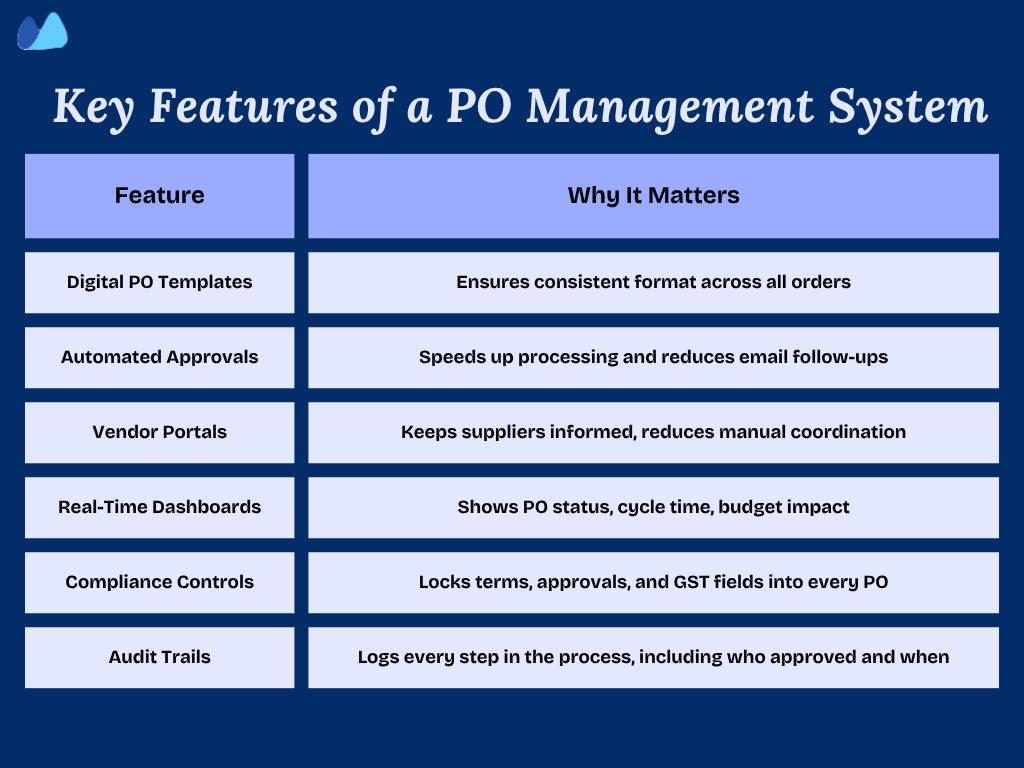

Key Features of a PO Management System

Here are some of the features top‑performing procurement rely on:

Integrations with ERP, Inventory, and Accounting

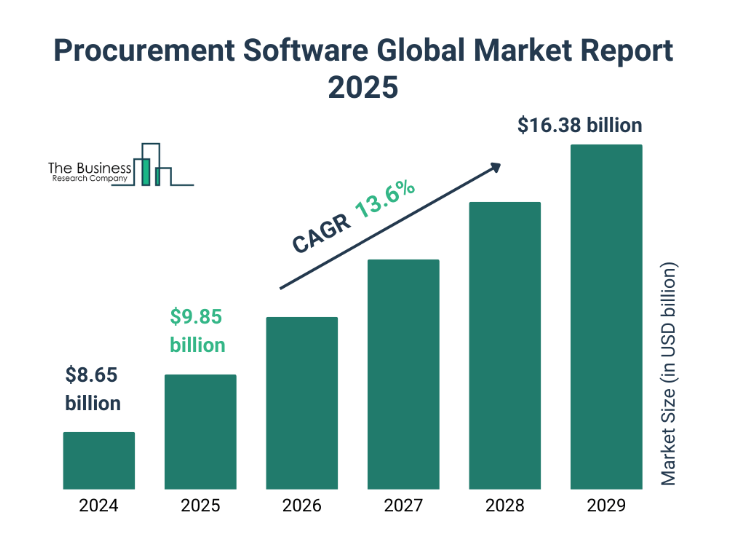

According to the Business Research Company, the Global Procurement Software Market was valued at $8.6 billion in 2024 and is projected to reach $16.38 billion by 2029, growing at a CAGR of 13.6%.

So, integrating your PO system with ERP, inventory, and accounting tools is no longer optional. It’s how you ensure traceability, eliminate duplication, and future‑proof your procurement.

To work at scale, your PO system must talk to the rest of your stack. That means syncing:

→ ERP: To track purchasing against General Ledger codes, cost centers, and overall spendERP: To track purchasing against General Ledger codes, cost centers, and overall spend

→ Inventory Systems: Purchases automatically update stock levels

→ Accounting Software: To link POs to invoices and ensure accurate books

✅ When your PO system is integrated, your team avoids duplication, and finance teams no longer need to reconcile disconnected data sources manually

Examples of PO Management Platforms

Here are a few platforms that companies commonly use based on business size, needs, and integrations:

| Tools | Best For | Notable Capabilities |

Kladana |

Growing businesses, SMES needing cloud ERP, structured and scalable procurement |

Approval chains, PO templates, analytics, local tax compliance |

Oracle NetSuite |

Enterprise-level ERP with built‑in procurement |

Strong reporting, customizable controls |

SAP Ariba |

Large procurement operations with supplier network |

Advanced sourcing, compliance controls |

Zoho Inventory |

Small to mid‑size teams needing simple tools |

Easy setup, works with Zoho Books and CRM |

Benefits of a PO Management System

When your purchasing process runs through a centralized PO system, the gains are immediate and measurable.

You reduce approval delays, eliminate duplicate orders, prevent unauthorized spending, and maintain real‑time visibility into costs, all while improving coordination across teams and vendors.

1. Reduces Maverick Spending

When people purchase outside of the policy or rules, it’s hard to track costs or enforce consistency. However, a PO system brings every request into one standard process, so all purchases are reviewed, approved, and logged.

This not only controls costs but also ensures procurement aligns with preferred vendor terms and budget rules.

2. Improves Audit Trail and Compliance

Audit readiness is no longer about collecting documents at year‑end. With a PO system, everything gets tracked automatically.

Whether you need proof for tax purposes or vendor disputes, every step, from requisition to payment, is stored and time‑stamped.

3. Boosts Procurement Efficiency

Manual PO workflows stall quickly. Requests get lost in emails, approvers forget to respond, and duplicate orders slip through the cracks.

However, implementing a PO system will automate routing, pre‑fill templates, and create clear handoffs between teams.

4. Real‑Time Order and Cost Visibility

Procurement isn’t just about what’s already paid. It is about what’s coming next. The PO system provides real‑time visibility into approved spend, pending orders, and supplier activity.

PO in Supply Chain Optimization

Purchase orders play a crucial role in determining the efficiency of your supply chain. Every approved PO creates a data trail from linking procurement plans to vendor execution, inbound logistics, and warehouse activity.

When this trail is digitized and visible, supply chain performance improves across the board.

Here’s how streamlined POs naturally enhance vendor coordination, expedite deliveries, and streamline warehouse control.

➜ Enhancing Supplier Collaboration

When you send suppliers clear, consistent POs with item details, pricing, and delivery timelines, you eliminate confusion and speed up order fulfillment. With built‑in acknowledgments, both sides stay on the same page. So, you avoid delays, missed items, or last‑minute surprises.

➜ Improving Delivery Planning and Performance

Visibility into upcoming orders enables your supply chain team to plan proactively. Instead of reacting to missed shipments or overstocked SKUs, you can track what’s expected when adjusting internal timelines or warehouse intake schedules as needed.

In high‑volume environments, structured POs linked to delivery schedules help teams batch inventory movements and reduce mid‑cycle interruptions, leading to a smoother procurement‑to‑warehouse handoff.

➜ Connecting with Warehouse and Logistics Operations

Once your purchase order is confirmed, your warehouse team requires the details immediately.

When your PO system connects with inventory or logistics tools, you can schedule incoming deliveries, assign storage space, and prepare resources in advance. Some systems even update stock automatically when the delivery matches the PO, saving time and reducing manual errors.

🚚 Recommended Read: Managing stock across warehouses or online channels? Learn how intelligent supply workflows improve delivery speed and reduce errors in this e‑commerce supply chain guide

How to Choose a System

Not all PO management systems are built the same. Some are built into ERP suites. Others operate as standalone platforms. Before you decide, focus on these key factors that directly impact usability and results.

1. User Experience and Accessibility

Your team won’t use tools that are clunky or confusing. Look for a clean, intuitive UI that non‑technical users in finance, procurement, or operations can navigate without training.

Mobile access is another crucial factor. Teams should be able to review and approve POs on the go, especially in businesses where decision‑makers aren’t always at their desks.

2. Automation and Approval Logic

Choose a system that supports:

- Rule‑based routing, for example, by amount, department, or item type

- Threshold auto‑approvals

- Escalation flows

✅ These features shorten cycle time, prevent bottlenecks, and ensure urgent tasks don’t stall.

3. Integration with Core Tools

A PO system should not operate in a silo. It should sync with:

- ERP platforms

- Accounting tools

- Inventory software

- Vendor databases

✅ Real‑time sync reduces manual entry and enables accurate end‑to‑end traceability from request to payment to audit.

4. Reporting, Analytics, and Dashboards

Look for a system that offers:

- Live PO status reports

- Budget vs. actual tracking

- Cycle time by department or order type

- Vendor performance dashboards

✅ These Insights let you optimize workflows and correct issues before they affect deliveries or budget accuracy.

5. Compliance and Regional Controls

If you are operating across states or countries, make sure the system supports the following:

- Tax compliance and e-invoicing

- Country‑specific workflows and document templates

- Multi‑currency and multi-location logic

✅ This helps avoid legal friction, especially if you are managing multiple entities or reporting.

🚀 Take Control of Every Purchase — without the Chaos

Build purchase orders in seconds, route them for approval, and track everything from one smart dashboard

To Sum Up

If your purchasing process still relies on manual work, you are not only wasting time but also putting your budget and supply chain at risk.

Purchase order management isn’t an admin task. It’s a control mechanism for spending, a visibility layer for finance, and a backbone for supplier performance.

The right PO system will give you structure without complexity. Whether you are scaling procurement across teams or tightening controls in a high‑volume environment, PO management is the system that keeps everything moving accurately, efficiently, and on your terms.

Frequently Asked Questions on Purchase Order Management

1. What is purchase order management?

It’s the process of creating, approving, sending, tracking, and closing purchase orders. With structured PO management, you control spending, enforce purchasing policies, and align finance, procurement, and vendors in a single flow.

2. How does a purchase order work?

The buyer creates and sends the PO to the seller. The seller reviews the PO and, if accepted, provides the goods or services as specified. Once the goods are received, the buyer makes payment according to the PO terms.

3. What are the different types of purchase orders?

There are four main types:

- Standard PO: One‑time order with fixed quantity and price

- Planned PO: Estimated quantity, date, or location

- Blanket PO: Recurring purchases with one supplier under a volume cap

- Contract PO: Legal agreement without specifics used as a parent documents.

4. What are the benefits of a PO?

The benefits of using the purchase order system are:

- Get orders right the first time

- Manage projects and purchases

- Save your employees time

- Allow you to do business with government and local authorities

- Help you streamline your stock

- Discover your super suppliers.

5. What are the 5’s of purchasing?

- Power

- People

- Processes

- Planning

- Prevention.

6. What is a 3‑way match in PO management?

It’s a validation step where the PO, delivery receipt (GRN), and invoice must all match. This ensures you pay only for what was ordered and received. It helps to protect against errors or overbilling.

7. How does a PO become legally binding?

A PO becomes a contract when it’s accepted by the supplier, either formally via acknowledgment or through action such as fulfilling the order. Once received, both parties are bound to the terms stated in the PO.

8. What features define a sound PO management system?

You can check these four features:

- Rule‑based approval workflows

- Integration with ERP, accounting, and inventory

- Auto‑generated POs and invoice matching

- Real‑time dashboards for visibility and compliance.

9. How does PO management integrate with ERP?

Modern PO systems integrate directly with your existing ERP, inventory, and accounting tools. This eliminates double entry, maintains data consistency across teams, and provides complete visibility from purchase to payment.

10. How to audit and track PO performance?

Good systems offer a dashboard that tracks cycle times, approval delays, vendor fulfillment rates, and unmatched invoices. This enables you to optimize workflows, identify errors early, and demonstrate compliance during audits.

List of Resources

- PWC: Digital Procurement Survey

- Grand View Research: Purchase Order Software Market Report

- Business Research Company: Global Procurement Software Market Report

Read‑alikes

- 4 Free Purchase Order Templates with a Step‑By‑Step Guide: Excel, Word, and Google Sheets Format

- ERP Inventory Management — How to Control Stock Efficiently in 2025

- Importance of Inventory Management: Benefits, Control, and Business Impact

- What Is Lead Time in Inventory Management? Meaning, Formula, and Optimization Tips

- Warehouse Inventory Management: A Complete Guide to Tools, Tips, and Systems for 2025

- Smart Food Inventory Management: Slash Waste and Maximize Profits