Every order your company places, from restocking raw materials to hiring a service vendor, initiates a chain of actions, including someone requesting it, someone approving it, someone paying for it, and someone tracking it. Suppose that the chain isn’t clear, consistent, and controlled. It becomes a bottleneck.

The purchasing process is how you fix those things. It’s the system your business operates from, from “we need this” to “we’ve paid for it and it’s here”, with clear roles, defined steps, and zero confusion.

As you implement a clear, structured purchase procedure, keep in mind that the global Procure-to-Pay market is projected to surge from $8.02 billion in 2024 to $14.07 billion by 2033, growing at a CAGR of 6.5%, according to Grand View Research.

In this blog, you’ll explore the key stages of the purchase department process, understand how companies structure each step, and access flow charts, key metrics, approval workflows, and ERP-based automation tips to streamline your procurement process.

You’ll also receive practical guidance on effective vendor selection and improving supplier relationship management for long-term sourcing success.

- What Is the Purchasing Process?

- How Is It Different from Procurement?

- Why a Defined Purchase Process Matters

- 7 Key Steps of the Purchasing Process

- Use Cases: Purchasing Process in Action

- Common Pitfalls and How to Avoid Them

- Manual vs. Automated Purchase Flow

- Contract Management & Strategic Procurement

- Summary & Action Plan

- Frequently Asked Questions on the Purchasing Process

- List of Resources

What Is the Purchasing Process?

The purchasing process is a structured workflow businesses use to acquire goods or services. It starts when a need is identified and ends when payment is completed after delivery. Every step in between, from approvals to purchase orders to invoices matching, exists to create clarity, control, and accountability in how your company spends money.

For small and mid-sized businesses, having this process is essential. Without this, you deal with stockouts, unapproved purchases, lost invoices, or delays that slow down operations. However, if you have it, you gain a system that helps you manage costs, reduce errors, and improve supplier performance.

How Is It Different from Procurement?

| Aspect | Procurement (Strategic) | Purchasing (Operational) |

Purpose |

Long-term value and cost optimization |

Fulfilling approved purchase needs |

Focus |

Supplier sourcing, negotiation, and contract management |

Requisitions, POs, deliveries, and payments |

Frequency |

Periodic and decision-making |

Repeatable business workflow |

Key activities |

Vendor evaluation, bidding, and relationship management |

Request approval, order placement, and invoice match |

Primary goal |

Build supply-side strength and total cost |

Ensure timely, accurate, and approved purchases |

✅ In short, procurement sets the strategy, and purchasing makes it happen.

Why a Defined Purchase Process Matters

A clear purchasing process isn’t just about structure. It is about control. If you don’t control, purchase slips through the cracks, costs balloon and departments operate in silos. However, if you have a defined purchase process, you create consistency, transparency, and accountability across your business.

Here’s what a well-structured purchasing process helps you do the following.

Reduce Errors and Stockouts

When your team follows a defined workflow, nothing gets missed, such as:

- Low inventory triggers a requisition

- Approved items are ordered on time

- Deliveries are tracked

- You avoid last-minute shortages that disrupt operations or sales

Improve Budgeting and Cash Flow

Every purchase is approved before it happens. That means no unplanned expenses and complete alignment with monthly and quarterly budgets. Finance teams can track committed spend before invoices arrive.

Centralize Communication across Departments

A centralized system ensures that there will be no purchasing lives in email threads or scattered spreadsheets. It will ensure that everyone, from operations to warehouse leadership, works as one cohesive team without any discrepancies.

Ensure Compliance and Accountability

With approval workflows and audit trails in place, every order is documented. You know who requested what, who approved it, what was delivered, and when it was paid. These are all important for audits, financial accuracy, and operational discipline.

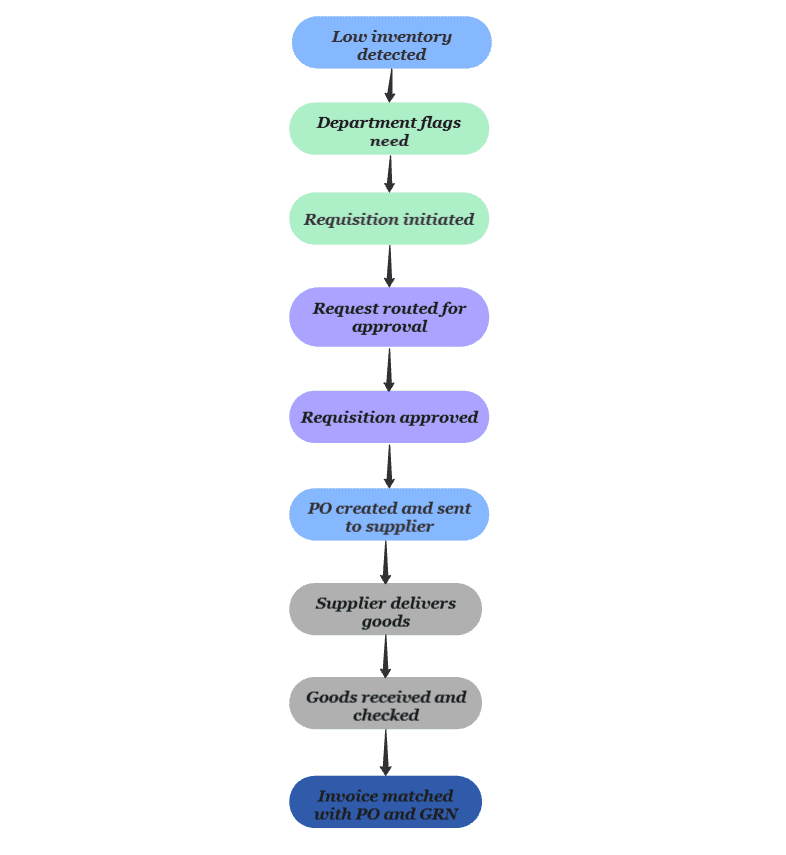

7 Key Steps of the Purchasing Process

Let’s explore and understand the steps of the purchasing process.

Step 1: Identifying the Need

The purchasing process begins when a specific business requirement is identified. This could come from inventory data, a scheduled project, maintenance planning, or a department’s operational demand.

The primary objective of this step is to identify a genuine need that necessitates a purchase. At this stage, the request is still internal. No external action has taken place yet, but clarity is essential. What is needed? How much? By when? And for what purpose?

This information serves as the foundation for the next steps, ensuring that purchasing aligns with operational priorities.

For example:

- You log into your inventory system and notice stock for black cotton T-shirts is down to just 10 units

- A major sale is coming up next week, and last year you sold over 200 units during the same period

- You realize you’ll run out before the sale even starts if you don’t restock in time

- You estimate that 200 more units will be needed and decide to raise an internal purchase request

- In the request form, you enter the item name, quantity, urgency, and reason

- This internal request moves to the next step — purchase requisition for approval

Step 2: Creating a Purchase Requisition

Once a need is identified, the next step is to document and formalize it through a purchase requisition.

This is an internal request submitted by a department or employee, detailing what needs to be purchased, the reason for the purchase, the quantity, the expected delivery date, and any other relevant specifications.

A purchase requisition is not a purchase order. It doesn’t go to a vendor. It goes to the purchasing or finance team for internal review and approval. This step ensures that all procurement requests are routed through a standardized process, reducing the risk of informal or unauthorized purchasing.

For example:

- You are managing a new crew that will start work on-site on Monday.

- Safety helmets and gloves are missing from the current stock, and each crew member requires full PPE before they begin their work.

- You can check with your store team to confirm the quantities needed and fill out a requisition form.

- In the form, you include item names, quantities, project name, and urgency

- You also add a preferred supplier, based on past quality and delivery track record

- The requisition is submitted and automatically routed to operations and finance for approval before a PO is created

Step 3: Supplier Evaluation and Selection

After a purchase requisition is submitted and approved, the next step is to choose the right supplier. This involves evaluating potential vendors based on factors such as price, delivery time, quality, service reliability, and past performance. The goal is to ensure the business gets the best value, not just the lowest cost.

Depending on the item and company policy, this step may involve reviewing existing vendor contracts, comparing quotes (RFQs), or consulting a pre-approved supplier list. Strategic categories may require deeper evaluation, while routine purchases can follow standard vendor rules.

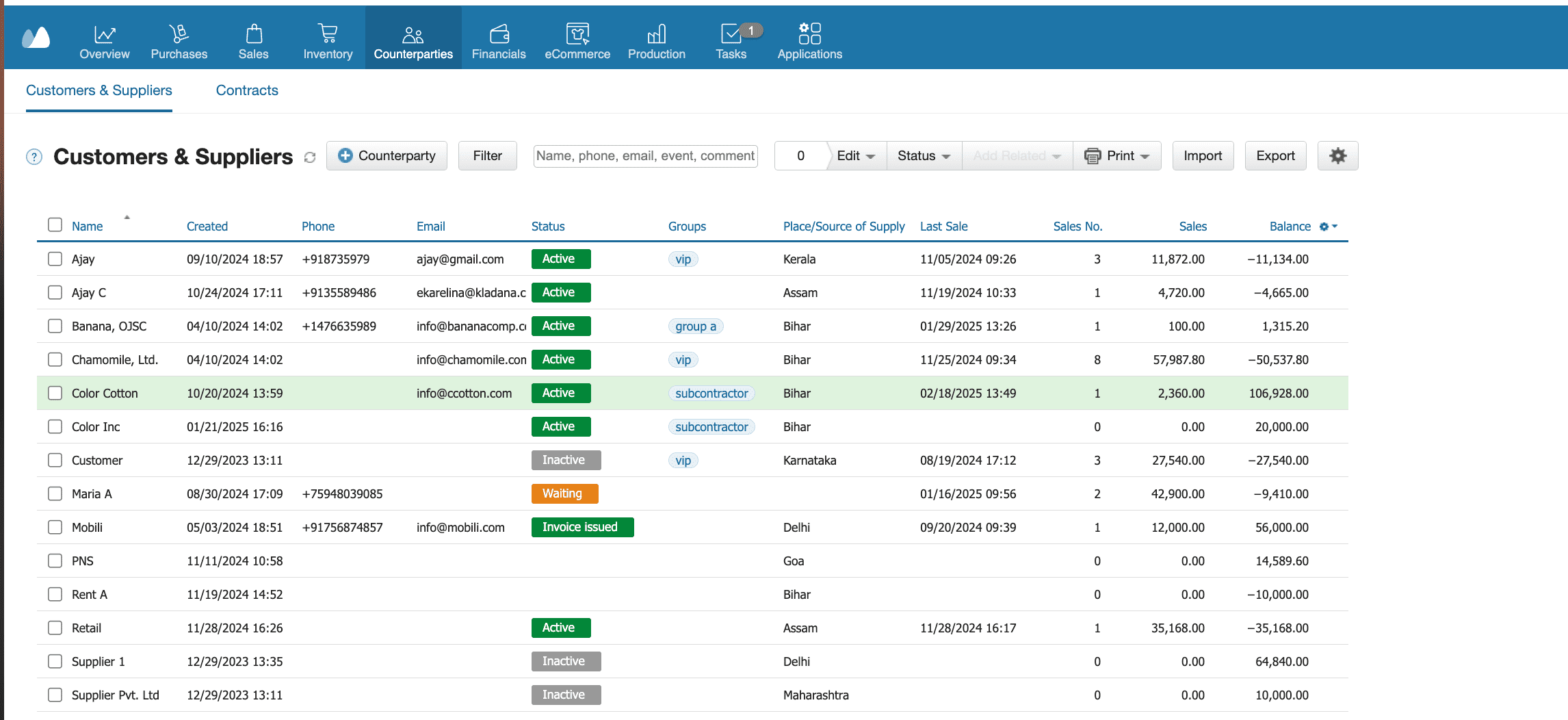

For example, Neytt Homes, a premium brand specializing in rugs and carpets, struggled with scattered vendor data and slow approvals. After switching to Kladana, they centralized supplier info, streamlined their purchase workflows, and gained real-time visibility into every order.

📍Recommended Read: Optimizing Supply Chains: What to Know before Streamlining Your Purchasing & Fulfillment flow

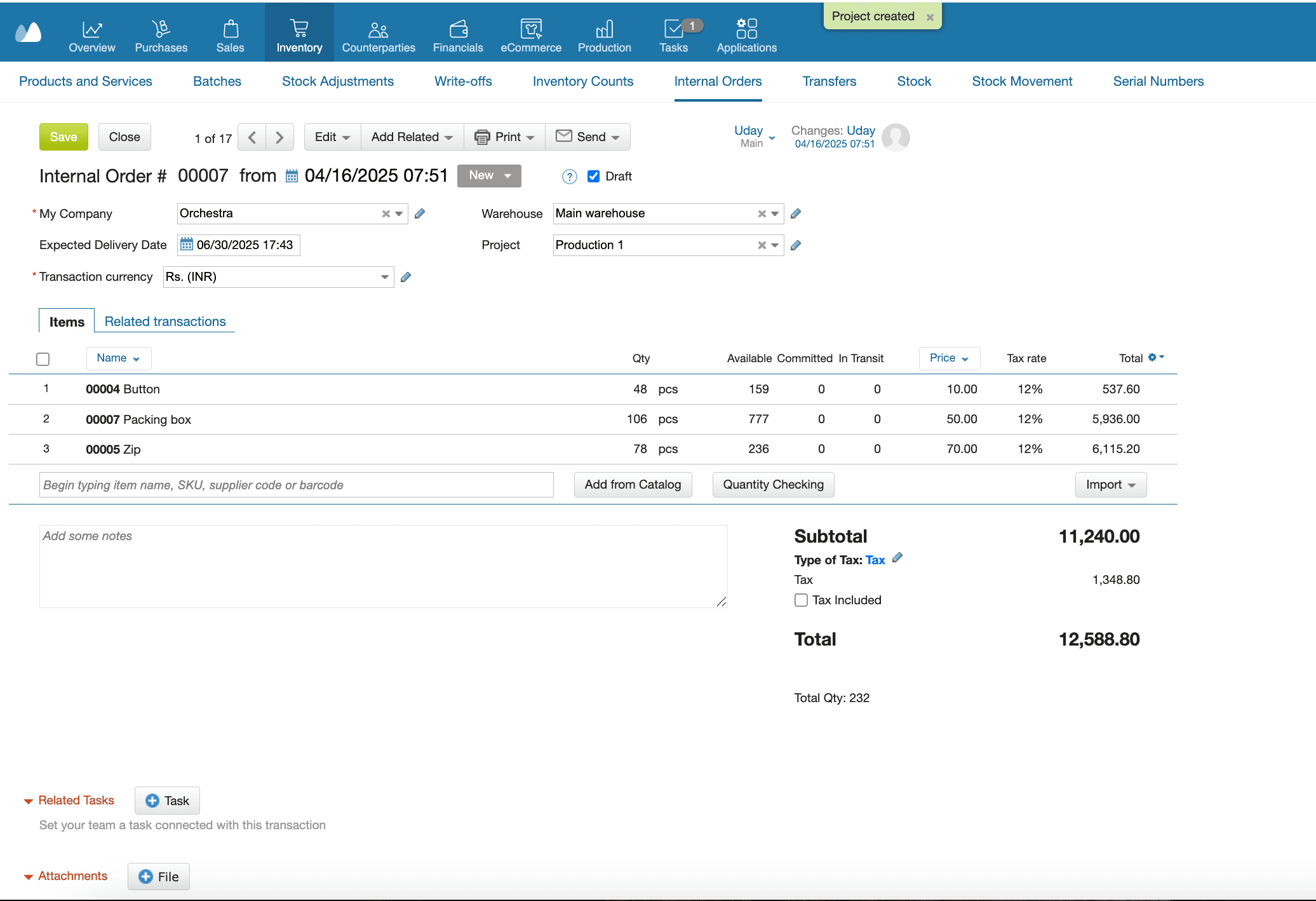

Step 4: Creating the Purchase Order

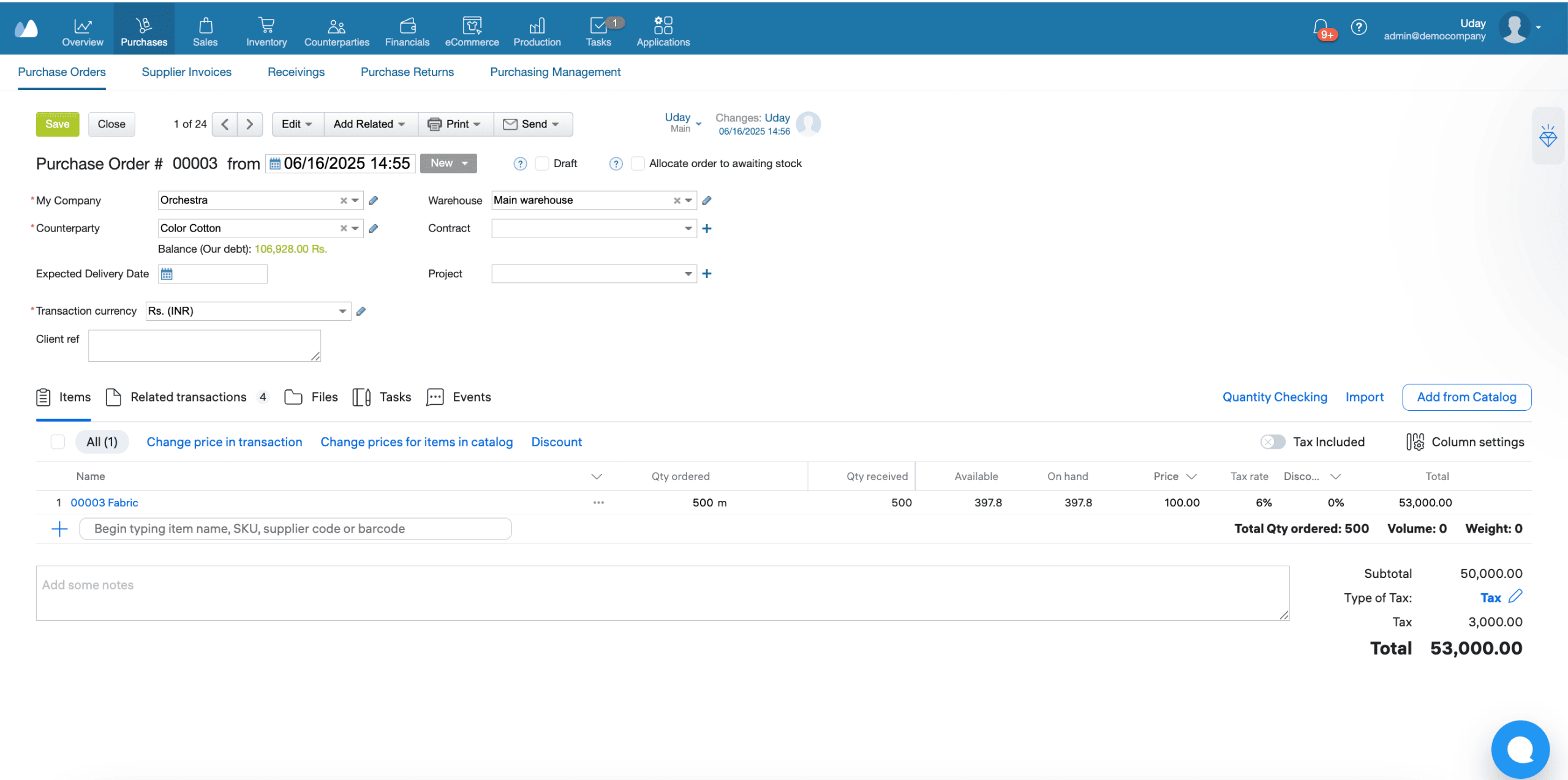

Once the supplier is selected and purchase requisition is approved, the next step is to generate a purchase order. This is a formal, legally binding document that confirms the intent to buy.

It includes key details such as item description, quantity, agreed price, delivery terms, and payment conditions.

The PO is sent to the supplier and serves as the official reference for fulfilling the order. It also serves as the baseline for subsequent steps, such as delivery tracking and invoice matching.

According to PwC’s Digital Procurement Survey 2024, most organizations now integrate directly with PO systems, incorporating invoice capture and supplier collaboration platforms, ensuring that purchase orders seamlessly flow into the final invoice approval stage.

For example:

- Your admin team submits a requisition for 50 ergonomic chairs to support a new office setup

- After approval, you compare quotes and finalize the supplier offering the best balance of cost and delivery timeline

- You generate a purchase order that includes item specs, delivery location, payment terms, and tax details

- The PO is emailed to the selected vendor as an official order confirmation

- The PO will now be used to track the delivery and match against the invoice later for payment

📍Recommended Read: Setting up your purchase order flow? These templates will help you do it faster and save your time

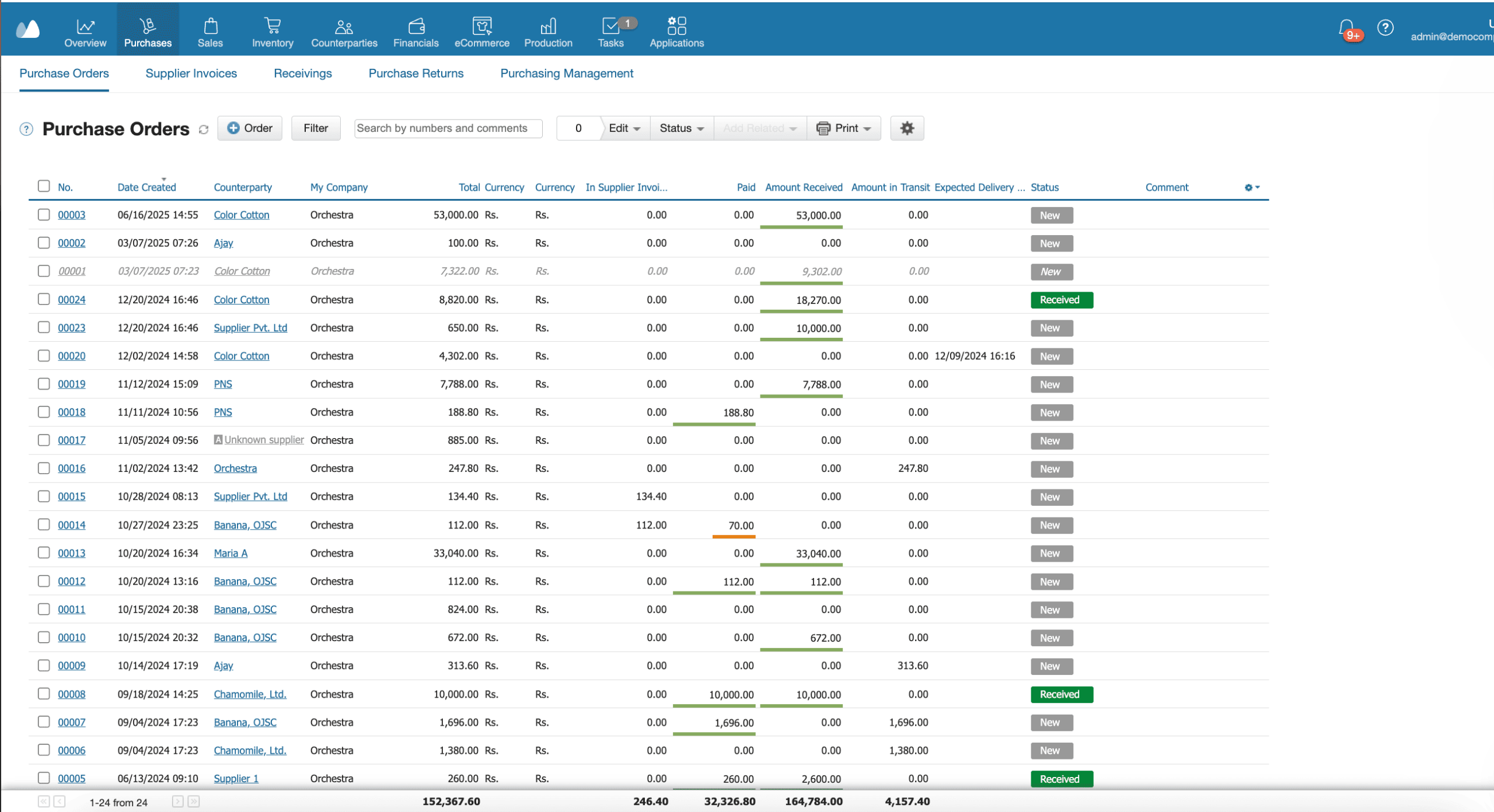

Step 5: Order Tracking and Delivery

After the purchase order is sent, the supplier begins processing the order. Internally, your team now needs to monitor the shipment, tracking its status, ensuring it arrives on time, and preparing for receipt.

Order tracking is especially critical when:

- You are managing just-in-time inventory

- The order involves large volumes of essential materials

- Delays could disrupt downstream operations

For example:

- You issue a confirmed purchase order to the supplier

- The supplier acknowledges it and shares a shipment date or delivery window

- You log the expected delivery date and track the order status

- Your warehouse team prepares storage space and updates receiving schedules

- Any critical dependencies are aligned with the incoming materials

- If tracking shows delays or partial shipment, you proactively notify operations and adjust plans if needed

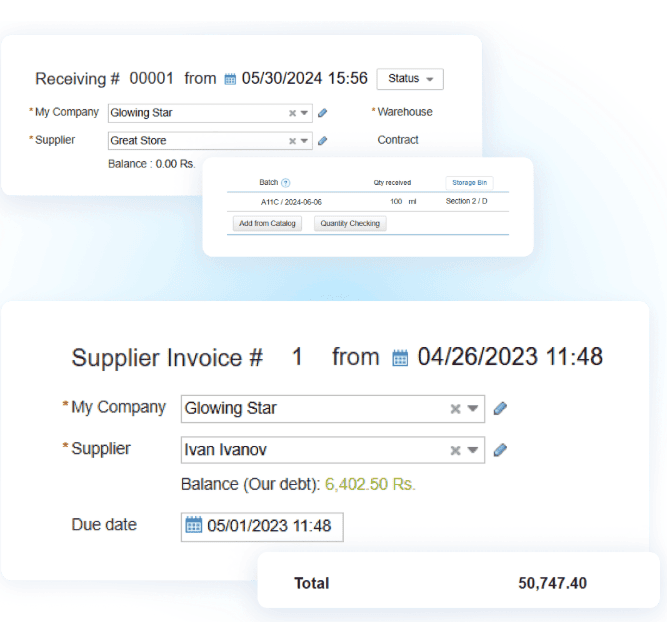

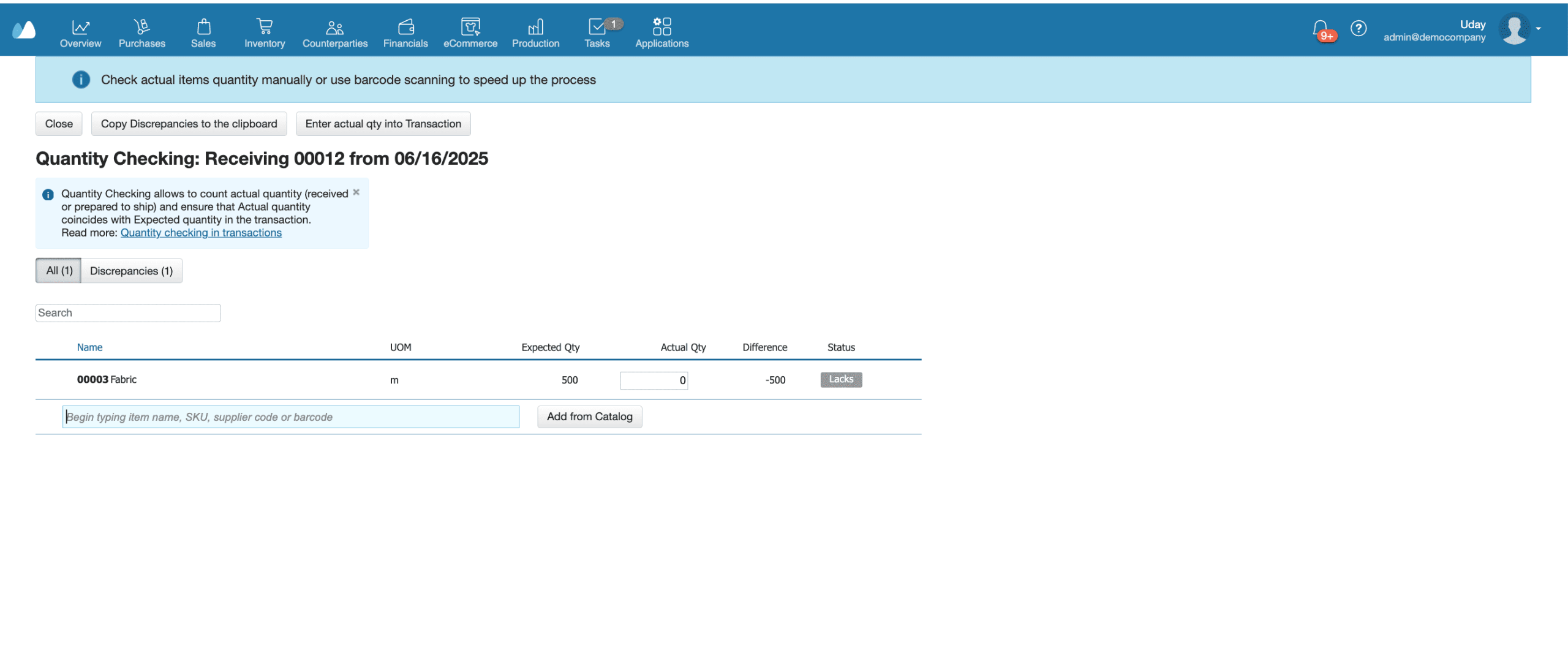

Step 6: Goods Receipt and Inspection

Once the supplier delivers the items, the receiving team must inspect and verify the delivery before it’s accepted into inventory. This step is known as goods receipt, and it confirms that the items received match what was ordered.

The team checks:

- Quantity against the PO

- Product condition and quality

- Delivery timeline compliance

- Any damage, shortages, or excess

Once verified, a Goods Receipt Note (GRN) is created in the system. If issues arise, the team logs discrepancies for follow-up with the supplier. Without this control step, inventory accuracy and financial reporting suffer.

For example:

- You receive 1,000 chargers from your supplier

- During inspection, 40 units are found damaged

- Your team logs the receipt for 960 units only

- A discrepancy report is generated for the damaged items

- Payment is held until the issue is resolved, and you only pay for accepted goods

Step 7: Invoice Approval and Payment

The final step in the purchasing process is reviewing the supplier’s invoice and processing the payment, but only after confirming that what was ordered and what was delivered match the invoice

This is done through a three-way match:

- The Purchase Order (PO) confirms what was ordered

- The Goods Receipt Note (GRN) confirms what was received

- The Invoice confirms what’s being billed

If all three align, the invoice is approved and paid by the agreed-upon terms. If there are mismatches, such as quantity discrepancies or incorrect pricing, the invoice is flagged and returned for resolution.

Before releasing payment, you need to verify that the invoice matches both the PO and the goods received. According to KPMG’s Automation of Invoice Processing report, AI-powered tools now deliver 80–95% data capture accuracy, reducing errors and enabling faster, more reliable invoice approvals.

For example:

- Your accounts team receives an invoice from the logistics provider for $500

- Before releasing payment, they match it against the original PO to check price and terms

- They also verify the goods receipt, which confirms that all shipments arrived as expected

- Since the PO, invoice, and GRN align, the payment is approved

- Finance schedules the transaction under agreed Net 30 terms, ensuring proper documentation and control

Use Cases: Purchasing Process in Action

Now that you have seen the entire process, here are three real-world scenarios that demonstrate how businesses apply these steps to address common operational challenges.

1. Apparel Manufacturer

Challenge: Demand spikes during festival seasons lead to urgent restocks and missed deliveries

How the purchasing process helps garment manufacturers.

- Need Identification: Sales data triggers alerts when fast-moving styles run low

- Requisition and PO: Store managers submit PRs, which are approved centrally and converted into POs

- Goods Receipt and Invoicing Matching: The warehouse verifies each delivery and updates GRNs. Finance pays only for what’s received

☑️ This results in time restocks and a reduction in stockouts during promotions

We’ve explored fashion industry in other articles:

📍 How to Create a Clothing Brand and Increase Turnover from $125,000 up to $262,000 in a Year

📍 How To Start a Garment Manufacturing Business in India: Costs, Licenses & Expert Insights

📍 How To Start a Clothing Line in India — Step-By-Step Guide with Expert Tips

📍 How to Start Garment Manufacturing in Kladana — Step by Step Guide

2. Wholesaler Distributor

Challenge: Frequent stockout of high-volume SKUs due to manual ordering delays.

How the purchasing process helps wholesalers.

- Automation: It automatically triggers PRs when stock hits the minimum level

- Approval Workflow: Each PR is routed by SKU category for faster clearance

- PO Generation: POs are created instantly and sent to vendors with expected delivery dates

- Order Tracking: Delays are flagged in advance, allowing alternate sourcing if needed

☑️ This results in a reorder cycle reduced from 5 days to 1, improving vendor accountability

3. D2C Brand

Challenge: Unstructured purchases by marketing and operations teams leading to budget overruns.

How the purchasing process helps D2C companies.

- Role-based approvals: PRs from different departments follow separate approval processes

- Supplier Evaluation: Marketing uses dynamic vendor scorecards to justify spend

- Three-way Match: Invoice payments are blocked unless they match both the PO and the GRN

☑️ This results in monthly purchasing compliance and marketing spend being tracked and contained

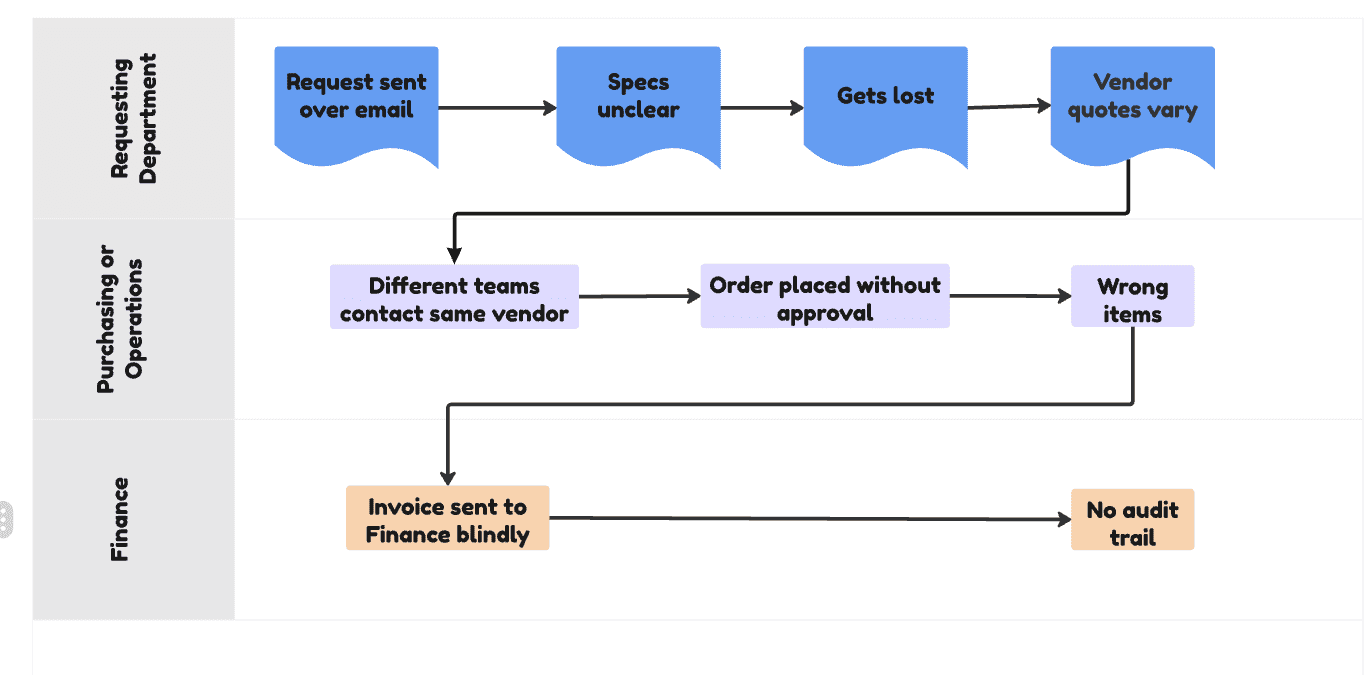

Common Pitfalls and How to Avoid Them

Even with a defined process, purchasing can break down if controls aren’t followed or if the workflow isn’t enforced. Below are the most common issues businesses face, along with solutions to address them.

| Pitfall | What Goes Wrong | How to Avoid It |

Vague supplier requirements |

Wrong items get delivered, or specs are misunderstood |

Use standardized requisition forms with codes, specs, and quantity fields |

No audit trail or approval flow |

Unauthorized purchases, budget overruns |

Set up role-based approval workflows in your ERP or purchasing platform |

Over-ordering or stock hoarding |

Ties up cash flow and leads to wastage |

Implement minimum or maximum stock levels and automatic reorder points |

Late deliveries with no accountability |

No follow-up system, and the vendor repeatedly misses deadlines |

Track supplier performance by PO and lead time benchmarks |

Disconnected teams or data silos |

Warehouse, finance, and procurement work in isolation |

Use a centralized system to unify data and approvals in real time |

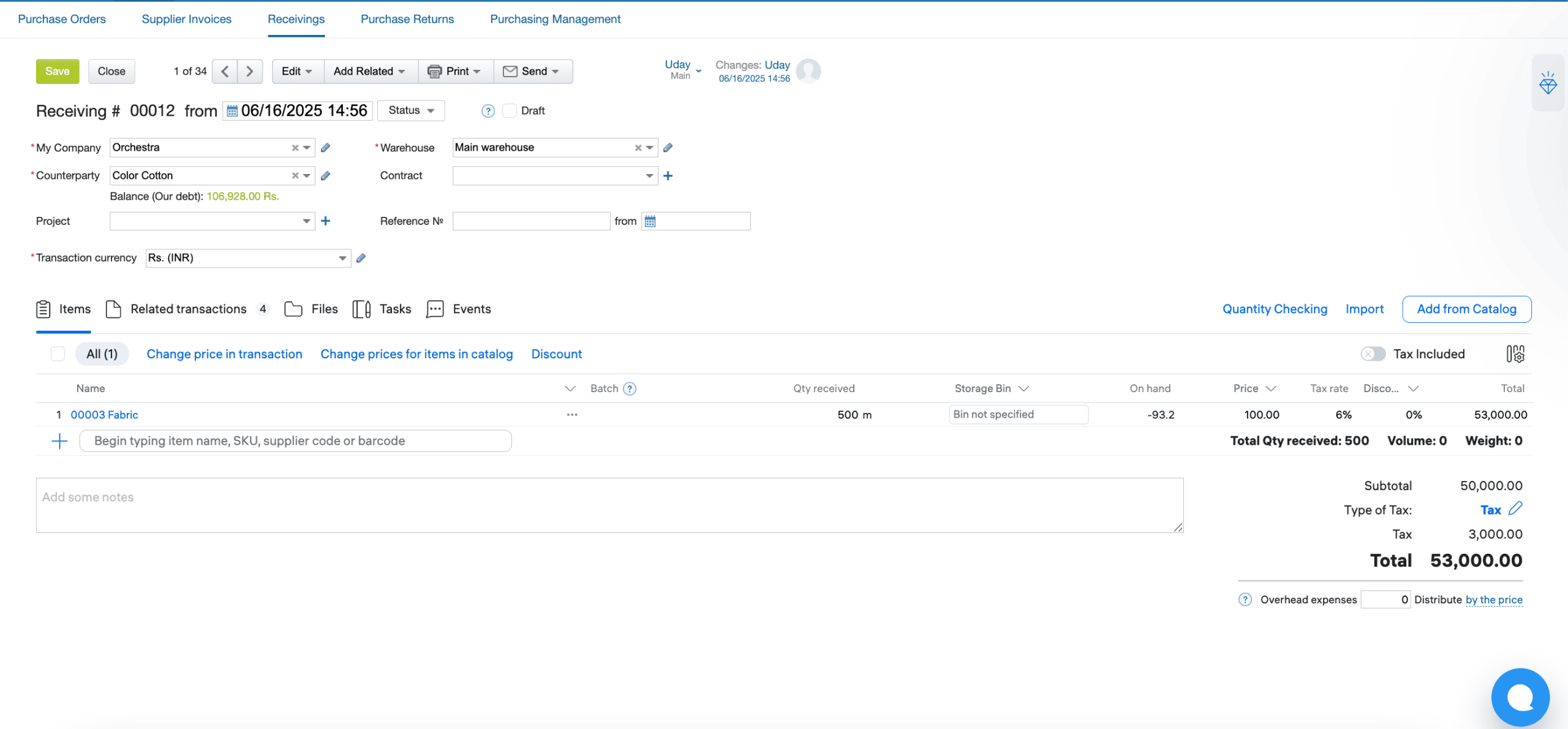

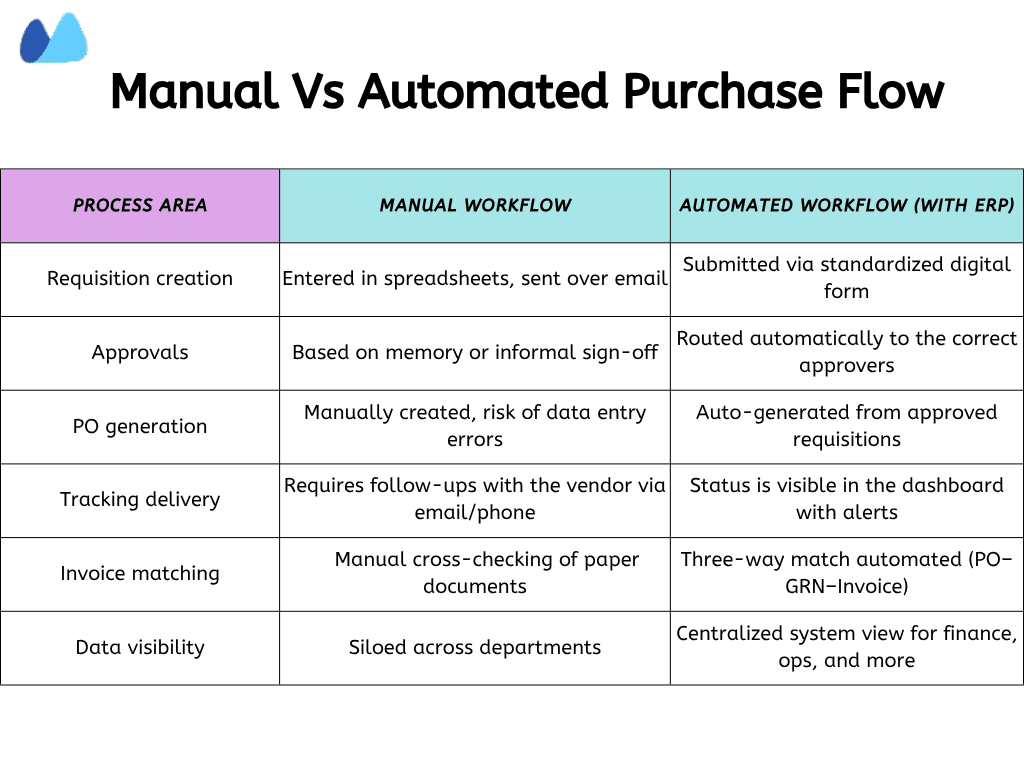

Manual vs. Automated Purchase Flow

A broken purchasing process is usually not due to incompetence. This is due to the use of manual tools and an inconsistent system. If you are still relying on spreadsheets, emails, and verbal follow-ups, here’s how that stacks up against a digital, automated workflow

Contract Management & Strategic Procurement

While purchasing handles the day-to-day flow of orders, strategic procurement and contract management shape the bigger picture. This includes selecting the right vendors, negotiating long-term agreements, monitoring supplier performance, and ensuring contractual compliance.

To strengthen this area:

- Maintain a centralized repository of all active vendor contracts

- Set renewal alerts and track expiry dates

- Define SLAs and performance benchmarks within the agreement

- Use procurement data to negotiate better terms

Why this matters:

Manual processes slow things down, increase your risk, and create confusion. Whereas automating key stages reduces delays, prevents costly mistakes, and gives you visibility into what’s working and what isn’t.

📍 Tip: You don’t need to automate everything on day one. Start with PRs, approvals, and PO tracking, then expand to complete invoice matching and supplier scorecards.

From Spreadsheets to Systems: Choose the Right Purchasing Tools

If you are still managing your business through spreadsheets and emails, then it’s time to switch to digital tools that help you streamline your operations and find a system that matches your stage of growth.

Here’s what evolution looks like:

| Stage | Tool Type | Best for |

Transitional |

Spreadsheets + Email |

Very low volume, one-person oversight |

Process-driven |

Cloud-based P2P platforms |

Growing SMEs that want approval workflows and audit trails |

Integrated & Scalable |

Full ERP systems like Kladana |

Multi-team coordination, inventory sync, and finance linkage |

Ready to Simplify Your Purchasing Process?

Automate requests, track orders, and control spending — from raw material sourcing to vendor payments

Summary & Action Plan

Suppose you want purchasing to stop being a bottleneck and start driving performance. This 7-step process is your foundation.

When every purchase moves through a structured workflow from request to payment, you gain:

- Cost discipline through standardized approvals and supplier terms

- Reliable operations with fewer last-minute stock issues

- Clear accountability at every stage, from requisition to delivery

- Scalable systems that grow with your business

Frequently Asked Questions on the Purchasing Process

What’s the difference between Purchasing and Procurement?

- Purchasing is a strategic process that helps you in supplier sourcing, contract negotiation, and spend analysis.

- Purchasing is tactical and helps you in requisitions, POs, deliveries, and payments.

How many steps are there in a typical purchasing process?

There are seven important steps:

- Identifying the need

- Requisition created

- Supplier evaluation

- PO creation

- Order tracking and delivery

- Goods and receipt

- Invoice approval and payment

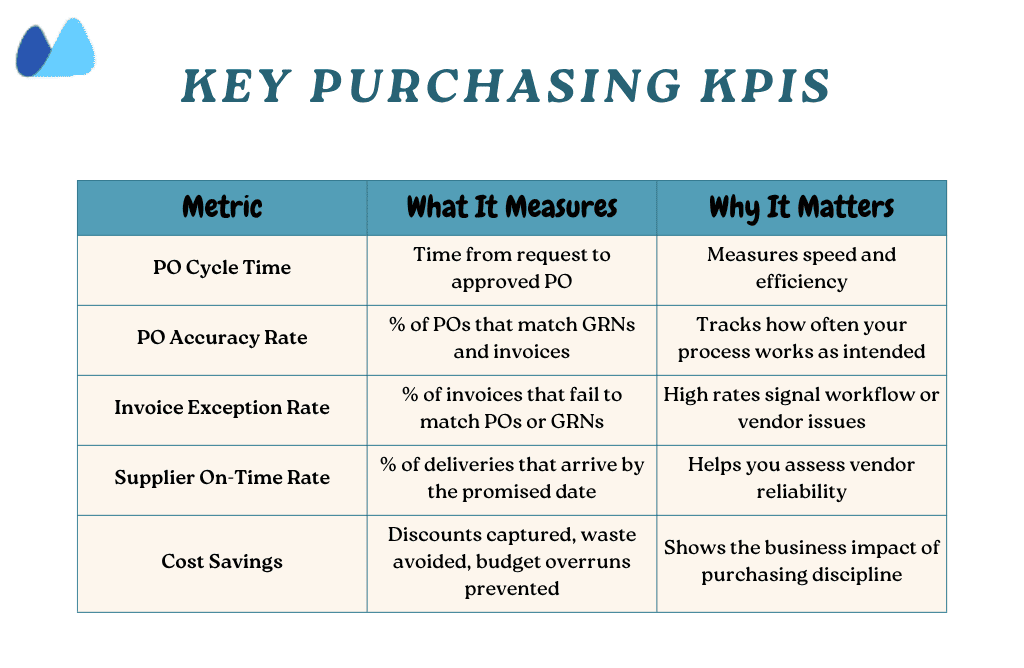

How do I measure purchasing performance?

Track metrics like:

- PO cycle time

- Invoice exception rate

- Supplier’s on-time delivery rate

- Cost savings vs negotiated prices

Can small businesses benefit from a formal purchase process?

Yes. No matter your size, structured purchasing brings:

- Budget oversight

- Fewer mistakes

- On-time deliveries

How does an ERP improve the purchase workflow?

An ERP connects all purchase stages:

- Auto-generated requisitions and POs

- Approval routing built-in

- Delivery & automatic invoicing

What is a three-way match?

A control measure where your system checks if:

- The PO

- The Goods Receipt (GRN)

- The invoice

- If all three align, payment is approved

What is the difference between a purchase requisition and a PO?

- Requisition = internal form requesting a purchase

- Purchase Order (PO) = official order sent to vendor

What are common P2P pitfalls to avoid?

- Missing audit trails and documentation

- Skipping approvals

- Duplicate vendors or invoices

- Over-ordering

What tools help manage purchasing more efficiently?

- Spreadsheets and emails for beginners

- Low-code forms

- P2P platforms like Kladana

- Full ERP systems

What are the benefits of choosing a well-defined purchase process?

- Cost savings

- Improved efficiency

- Reduced errors

- Better supplier relationship

- Better compliance

List of Resources

- Grand View Research: Procure To Pay Solution Market Report

- PWC: Digital Procurement Survey

- KPMG: Automation Invoice Report

Read‑alikes

4 Free Purchase Order Templates with a Step‑By‑Step Guide: Excel, Word, and Google Sheets Format

Importance of Inventory Management: Benefits, Control, and Business Impact

What Is Lead Time in Inventory Management? Meaning, Formula, and Optimization Tips

ERP Inventory Management — How to Control Stock Efficiently in 2026

ERP for Manufacturing Industry in South Africa: Boost Your Profits & Production Control