In countless Indian homes, clothing is more than just fabric. It carries memory, identity, and inheritance. A mother’s kurta, passed down and tailored anew. A sibling’s wedding outfit, carefully folded, then altered for another celebration. And often, that emotional connection to clothing sparks something bigger — a business idea. It might begin with a simple compliment: “Where did you get this stitched?” Or a casual chat over tea: “What if we started selling these?”

India’s deep-rooted textile tradition makes garment manufacturing a natural choice for many first-generation entrepreneurs. Not because it’s easy — but because it’s full of possibility. It’s one of the few industries where a single machine and one idea can launch something sustainable.

Because behind every kurti in a boutique, every t-shirt brand trending on Instagram, and every stitched school uniform — there’s a real system:

- 600 square feet of workshop

- Machines, labor, orders, deadlines

- And someone who makes it all work

That someone could be you.

As Deeba Abidi, founder of Riwayat Studio and expert contributor to this article, discovered, real market understanding doesn’t come from Google searches. She spent six months on the ground — visiting local markets, learning how buyers think, and understanding fabric pricing firsthand. Her advice: skip the shortcuts. Go offline to get it right. In this guide, Deeba shares hard-won insights:

- When is the best season to sell ethnic wear?

- How can a newcomer stand out in this competitive space?

- Should you buy fabrics online or from physical suppliers?

- How to check fabric quality without hiring experts?

- Who can start with ₹15–20 lakhs — and when is ₹30–40 lakhs more realistic?

- What kind of marketing actually works in garment production?

We’ll walk you through every step of starting a garment manufacturing business in India — from setup to sourcing, production to pricing, clients to cash flow. Let’s begin.

- Overview of the Garment Manufacturing Industry

- Garment Industry Structural Composition

- Garment Manufacturing Market Analysis

- Garment Manufacturing Business Planning

- The Role of Garment Production Clusters

- Government Focus and Support Schemes for Garment Industry

- Setting Up Your Garment Manufacturing Unit

- Setting Daily Production Targets

- Marketing and Sales Strategies for Garment Manufacturing

- Challenges and Solutions

- Conclusion

- Scale Your Garment Business Smartly with Kladana ERP

- Frequently Asked Questions on How to start a garment manufacturing business in India

- List of Resources

Overview of the Garment Manufacturing Industry

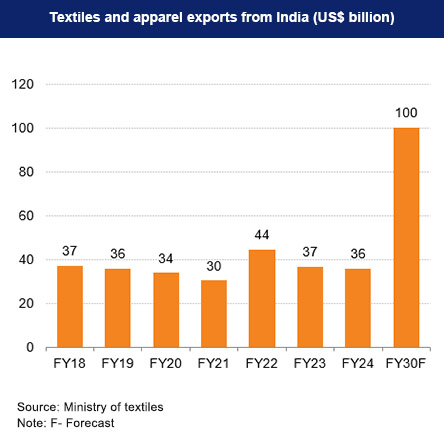

According to the report by IBEF, India is the third-largest exporter in the textile and apparel industry. The market is expected to grow at 10% CAGR to reach $350 billion by 2030. It shows a massive long-term opportunity. The missing point here is not the demand, it is execution. And that is where small, well-run manufacturing units are stepping in and winning big. It’s not always mandatory to have a fashion background. What you need is structure, clarity, and proper execution.

India’s garment manufacturing sector is one of the most diverse and decentralized in the world. While most global fashion brands are often associated with Europe or the US, a large portion of their production happens right here in India, through small and mid-sized units. It is clustered across key Industrial zones.

As of 2023–24, India’s textile and garment sector stands as one of the most powerful engines of economic and social impact:

♦️ It contributes 2.3% to the national GDP and 13% to total Industrial production

♦️ This Industry employs over 45 million people directly. There are many from rural areas, and a significant proportion are women. It indirectly supports almost 100 million livelihoods

♦️ India’s exported textiles were worth $34.4 billion in 2023–24, with apparel making up to 42% of that, followed by the raw materials (34%) and finished non-apparel (30%)

♦️ The Ministry of Textiles reported that India’s textile exports were a 7% year-on-year increase, including handicrafts, between April and December 2024, compared to the same period in 2023

These figures point to a crucial insight. It is not only being shaped by large manufacturers or exporters but also by ambitious small manufacturers in every region.

Garment Industry Structural Composition

India’s garment industry is divided into two broad sectors:

- The organized sector is typically certified in large-scale factories, export houses, and corporate players, who are registered under industrial acts and operate with automated machinery, following certification to ISO and SA 8000 standards. This certification serves both the International and domestic market scale.

- Unorganised Sector: Micro and small units that might be home-based or cluster-based. These include job workers, tailors, and family-run operations. This sector forms a significant portion of MSME activity and supports domestic value chains, especially in low-price segments.

Garment Manufacturing Market Analysis

Before investing in machines or tailors, you should first understand the market landscape, such as who you are manufacturing for. The garment manufacturing market in India is very vast. You should understand the demand and identify your buyers.

Expert

Deeba Abidi is the founder of Riwayat Studio, an Indian ethnic artisanal clothing brand launched in 2024. With a focus on cultural craftsmanship and quality, she brings real-world experience in setting up and running a garment business, balancing creativity with innovative, resourceful business practices

“I spent six months researching by visiting offline markets to understand what fabric costs, what buyers expect, and how people make purchases.”

Her market research revealed that:

- Consumers buy ethnic clothes mostly during festivals

- Design differentiation is significant to stand out in a saturated ethnic wear market

Key Segment in the Indian Apparel Market

According to a report by Statista, India’s clothing market is expected to reach $109.45 billion by 2025 and grow at a rate of about 3% annually by 2029.

The growth is not in volume, but in category sophistication — niche products, performance wear, conscious fashion, gender-neutral clothing, and regional styles are all gaining traction. For manufacturers, it means there is no room to specialize.

Demand Trends Shaping the Garment Market

Rise of Small-batch Production

- With the rise of digital fashion labels and influencer-led clothing lines. The demand for MOQ (Minimum Order Quantity) production is increasing.

- This is helping small manufacturers for more growth and opportunities, who can deliver quality at high speed.

Ethnic and Occasional Wear

- The regional fashion continues to thrive.

- The growth is massive, especially during the festive season.

Athleisure and Functional Apparel

- Athleisure is now a year-round category. These are mostly fitness wear, such as gym wear, lounge sets, etc. UV-protected fabrics are no longer a trend exclusive to urban areas; they are going mainstream.

- The demand for cotton and polyester manufacturers is high

Garment Manufacturing Business Planning

Starting a garment manufacturing business is not as simple. Before buying a rental unit or equipment, ensure you have a solid business model. Your business model will determine your capital needs, production margin, and client base.

This section will guide you through creating a practical and scalable business plan tailored to the Indian garment Industry.

Here are three standard models in the Indian Context for you to understand.

| Model | How it works | Best for |

Job work/ contract manufacturing |

You stitch garments for another brand or label using their fabric and design |

It is best for new manufacturers with a low-risk entry, with a basic setup |

Private Label Manufacturing |

You make garments and sell them under another brand’s label (B2B) |

Units with small-to mid-scale capacity and some design flexibility |

Own brand |

You design, produce, and sell garments under your label (D2C or via marketplaces) |

It’s best for designers and entrepreneurs who want to control everything from end to end. |

Plan Your Garment Business Capacity and Pricing

When starting your new manufacturing business, be sure not to overestimate capacity and underprice your output.

Start lean: When you start your manufacturing unit, it’s better to begin with a minimum number of machines, such as 10 to 15.

For example, assume a daily production capacity of 300 to 600 garments, depending on the design complexity. You can build your pricing model backward:

- Fabric cost per piece

- Labor cost per piece

- Overheads such as electricity, rent, admin, etc

- Profit margin, depending on the model

Garment Pricing Formula (Basic T-shirt Example):

Fabric cost (₹55) + Stitching labor (₹18) + Overheads (₹10) = Total cost: ₹83

→ Minimum selling price: ₹95–100 (excluding GST)

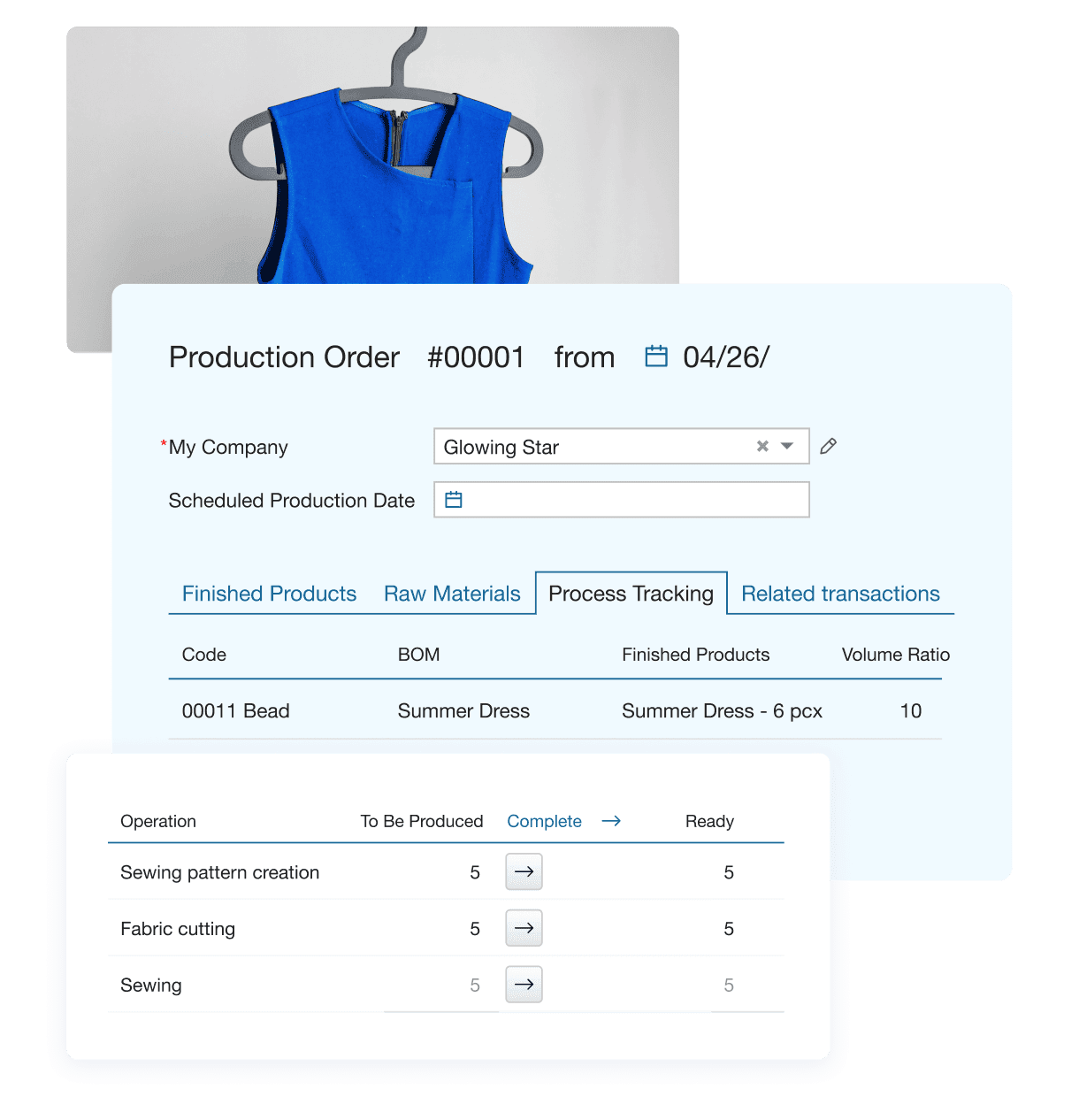

Manage the Full Garment Production Cycle in Kladana

👕 Create BOMs for both finished garments and components. Unit costs are auto-calculated based on raw materials, operations, and labor.

🧵 Issue production orders and track progress with operation reports. Use subcontracting or partial production to sell finished items without waiting for full order completion.

👖 Assign workshop tasks and track employee earnings with Shop Floor App.

🧶 Record scrap and low‑quality fabric to monitor quality and control production costs.

Explore Garment Production Features

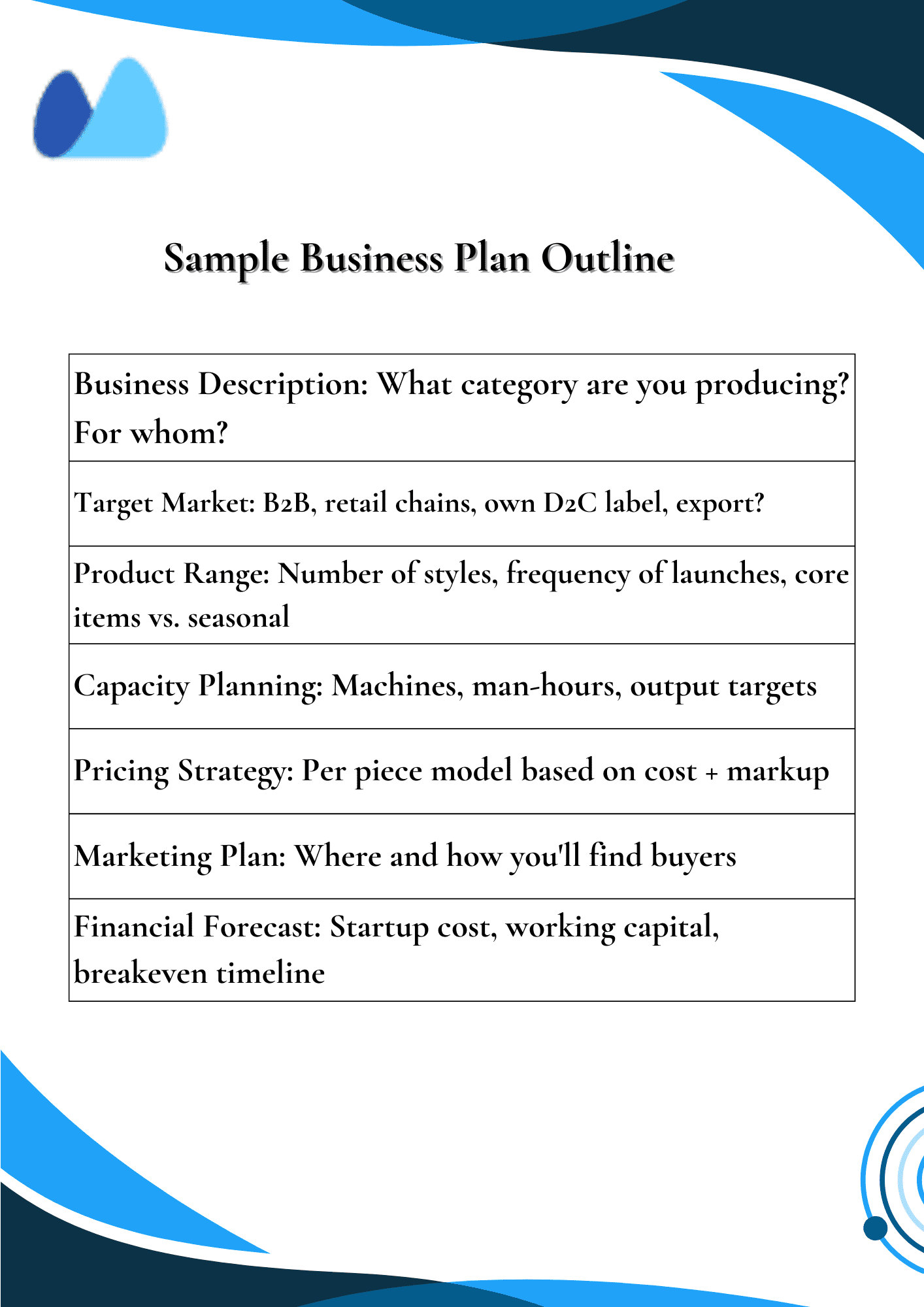

Here you can check and analyze the sample plan for your business

The Role of Garment Production Clusters

Garment Production in India thrives on regional ecosystems, also known as a manufacturing cluster. These clusters are not just geographic. They are functional. They bring together raw materials, suppliers, tailors, dyers, printers, logistics providers, and exporters in a compact supply chain.

You can check below India’s key clusters:

| Region | Focus | Specialized Product | Example |

Kolkata |

Ethnic wear and home furnishing |

Kurtis, dhotis, bed linen, and embroidered textiles |

|

Ludhiana |

Woolen |

Sweater, thermal wear, cardigans |

|

Surat |

Synthetic fabrics and mass-market sarees |

Printed sarees and dress material |

|

Delhi, NCR |

Westernwear, uniforms, private label work |

Shirts, trousers, jackets, and school uniforms |

|

Bengaluru, KA |

Private label and export garment units |

Woven topics, women’s westernwear, high street fashion |

|

These clusters matter because they reduce the entry barriers. If you’re a new manufacturer, you don’t need to build every part of the supply chain from scratch. Instead, you can just plug into a ready-made ecosystem.

Government Focus and Support Schemes for Garment Industry

The government of India has identified the textile sector as a priority for its ‘Skill India’ initiative. You can go through the schemes and identify those that are best for you and suitable for your business.

| Scheme | Objectives | Target Beneficiaries | How to apply? |

Create world-class integrated textile parks |

Investors and manufacturers seeking extensive infrastructure |

||

Support for modernising machinery |

MSMEs and larger units investing in tech |

||

Micro-finance for small units |

Tailors, fabricators, and job workers |

Apply via banks, Micro Finance Institutions Non-Banking Financial Companies |

|

PMEGP (Prime Minister’s Employment Generation Programme) |

Generate employment through micro manufacturing units. |

New entrepreneurs and rural youth |

|

Skill development for the garment and textile trades |

Youth aged 18+, especially women |

Apply via the training centres and the textile ministry website. |

Legal Setup & Compliance

Before you begin your production, sell your first batch or apply for government support. Your garment business must be appropriately registered. Legal compliance helps you with:

- You can have access to MSME benefits and subsidies

- You can open a business bank account

- You can even apply for tenders, contracts, and export licences

- You can avoid penalties and shutdown risks

Business Structure Options

You can choose a legal structure based on your ownership style, funding plans, and risk appetite:

| Structures | Best use for | Features |

Sole Proprietorship |

Solo founders, low-scale units |

It is easy to register. Profits are taxed as personal income |

Partnership |

Two or more people managing together |

Limited Liability Partnership offers limited liability. The partnership is simple, but it has more legal risk |

Private Limited Companies |

Fundraising, large private label, or export plans |

Higher compliance, but preferred by investors and large buyers |

Mandatory Registrations & Licenses

Here are some of the essential registrations that you need to make before starting your business:

| Registration | Purpose | How to register | Documents requirement |

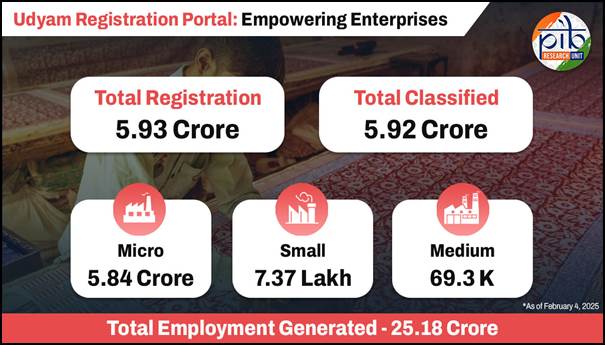

Udyam Registration |

It classifies your unit as a micro, small, or medium enterprise |

Aadhaar, PAN, and bank details |

|

GST Registration |

It might require a turnover of ₹40 Lakh, or if interstate supply |

PAN, address proof, and a Utility bill |

|

Shops and establishments’ license |

Mandatory for all workplaces |

The State Labour Department depends on the state-by-state |

Rent agreement, photo ID, business proof |

Factory License |

It will require 10+ workers with power usage |

Local Municipal Corporation or State Directorate |

Layout plan, ownership/rent documents. Worker details |

Import Export Code (IEC) |

Needed for the export of garments or raw materials |

PAN, bank account, business proof |

Common Compliance Mistakes You Should Avoid

📍Not registering early — You will miss schemes like MUDRA and PMEGP

📍Unregistered workers — If you don’t register, there will be a chance of inspections or accidents

📍No GST while selling B2B — Many buyers will refuse you if you are not able to issue GST invoices

📍Skipping local licenses — You should not skip this part of your journey. For example, states like Maharashtra, Karnataka, and Tamil Nadu are stringent on factory registration

Setting Up Your Garment Manufacturing Unit

Once you have completed the legal compliance and registrations, the next step is to set up your actual production space. It will include choosing the correct location, buying essential machinery, planning your workflow, and sourcing your raw materials. A well-structured unit will not only improve your productivity but also help you reduce waste, errors, and delays.

Step 1: Choosing the Correct Location

Location matters more than anything else. It affects all your access to raw materials, labor, transportation, and especially client services. Here is what you should evaluate:

| Factors | Why does it matter | What to look for |

Access to labour |

Skilled employees and tailors are very important |

Proximity to garment clusters or semi-urban areas |

Connectivity |

For incoming materials and outgoing finished goods |

Near highways, courier hubs, or logistics zones |

Industrial Zoning |

It helps in getting easy and faster approvals |

Check for textile parks, MSME zones, or apparel hubs |

Water and power supply |

It is essential to have an uninterrupted supply of stitching, pressing, and washing |

You should check for stable electricity as well as backup power options |

📌 Tip: If you are starting a small business, a 500–800 square foot rented unit with scope to expand later is a cost-effective starting point.

Step 2: Sourcing Raw Materials for Garment & Managing Vendors

Your raw materials account for half of your costs, so choosing the right vendor is essential.

Industry Expert Insight:

“Fabric sourcing was my toughest and most critical phase. I collected swatches from every ethnic clothing market in Delhi. Even figuring out how lace quality holds after washing took weeks of testing.”

Deeba also emphasized that early-stage entrepreneurs must:

- Visit the physical market more than the online market

- Talk to multiple vendors to understand the market

- Test fabric for shrinkage, dye bleed, etc

| Material | What to check | Location to source |

Fabric |

You need to cross-check the colorfastness, shrinkage, and quality of weaving |

You can source in Surat for synthetics, cotton in Delhi, and in Ahmedabad |

Trimming |

You need to check the quality and compatibility with garments |

You can source from Gandhinagar, Delhi, and Chennai |

Packaging materials |

You need to check polybags, barcodes, cartons, and paper tags |

You can also source from local vendors or online as well |

📌 Tip: Always test your sample before bulk buying. Negotiate for staggered delivery and try to maintain 2–3 vendor relationships per material.

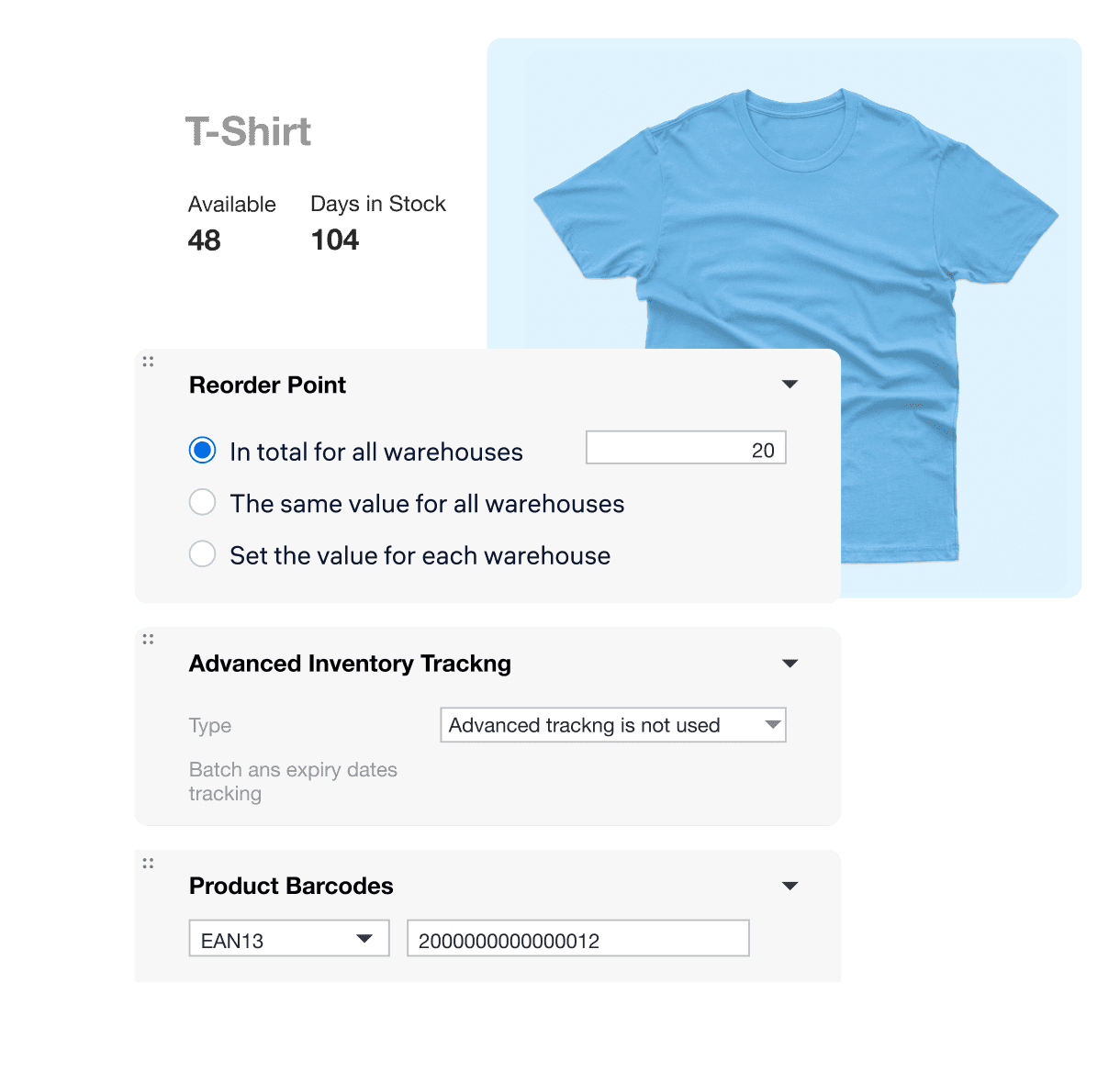

Manage Raw Material Purchasing in Kladana

🧵 Set reorder points to get automatic alerts when fabrics, threads, or zippers run low. Use demand forecasting reports to restock accurately.

📦 Create and manage purchase orders, track their statuses, and receive goods into specific storage bins to keep your stock organized.

💰 Monitor unpaid invoices and offer personalized discounts to your best-performing suppliers.

📇 Keep a detailed supplier database with contact info and order history for streamlined communication.

Step 3: Operations Management in Garment Manufacturing

Once you’re done setting up your physical unit, the next challenge is running smoothly. Operations management in garment manufacturing involves balancing time, quality, labor, and cost daily. If you don’t maintain a proper system in place, delays will occur, and you will easily drain your profit margin.

This section will guide you through managing your workforce, optimizing production processes, and ensuring quality control at every stage.

Industry Expert Input:

- Deeba recommends that tailoring for control in the early stages is important

- Keeping backups ready in case a vendor or tailor drops out.

- Vendor dependence ruins everything, so plan B is needed

Step 4: Hiring The Right Team

Garment manufacturing is labor-intensive, and your output quality is only as good as your team. A 10–15 machine setup typically requires:

| Roles | Responsibilities | Ideal Ratios per 10 Machines |

Tailors |

Operate your machines to assemble garments |

10–12 |

Cutting master |

Cuts bulk fabric based on makers and their designs |

1 |

Helper |

Assisting tailors, handles thread cutting and pressing |

2–3 |

Finishing staff |

Trims, Irons, folds, and packs finished pieces |

2 |

Quality checker |

Inline and endline quality check |

1–2 |

📌 Tips for hiring sources:

- Local ITI colleges (Industrial Training Institutes)

- Migrant labor hubs via known vendors

- Workers’ references from nearby units

Setting Daily Production Targets

Your daily targets help prevent bottlenecks and keep the team accountable. You can use ERP-integrated solutions to track their progress and assign daily tasks.

For example:

- Round neck t-shirt, a simple knitwear: 20–25 pieces per tailor per day

- Straight cut kurta: 18–20 pieces per tailor per day

Targets do vary by design complexity. If the productivity is low, audit cutting accuracy, machine maintenance, or helper-to-tailor ratios

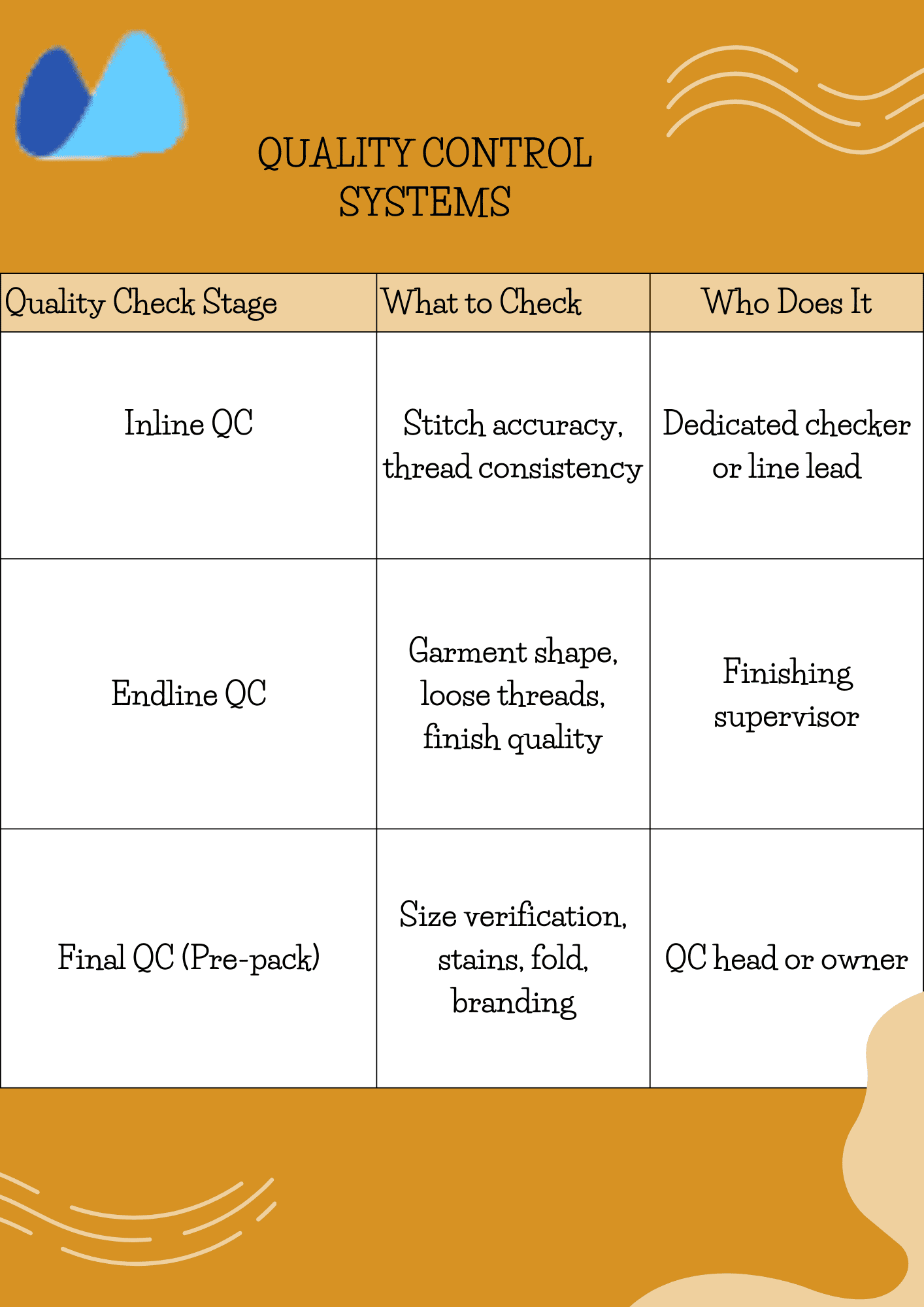

Before facing any quality issue you should implement this three-stage quality control system.

📌 Tip: Use a red tag for rejects and a green tag for passed pieces. Keep a reject log to spot recurring issues.

Attendance, Payroll & Incentives

Labor incentive units need consistent attendance and morale. Here is how you can keep it structured:

- Proper register-based attendance / biometric

- Weekly payout or bank transfer

- Incentives for zero error output or high productivity

- Safety compliance, for example, fans, drinking water, or adequate lighting

Financial Planning

Garment manufacturing may have a relatively low entry barrier, but poor financial planning can quickly derail operations. You should understand your upfront capital needs, ongoing costs, and funding options. And if your business is running on low margins and cash flow depends on client payment cycles, then you shouldn’t neglect it and should start planning.

In this industry, financial planning doesn’t just mean raising money; it’s also about spending wisely. Poor cash flow will be one of the top reasons for small businesses to struggle. You must understand the difference between a brand that sustains itself and one that burns out quickly.

🧵 Hey Baby, a women’s business attire brand, started with a $51,000 loan to launch a small workshop. In just one year, they doubled their turnover from $125,000 to $262,000 — here’s how they did it.

Key expense categories:

- Raw materials

- Sampling and inventory (initial batch production)

- Website setup

- Photoshoots and visual assets

- Packaging and branding materials

- Dispatch and logistics tools

- Contingency

Industry Expert Insight:

«If you are very careful about where you spend, keeping your budgets in control, then you will be able to manage ₹15–20 lakhs. But for premium brands with bigger ambitions, ₹30–40 lakhs is realistic.»

Marketing and Sales Strategies for Garment Manufacturing

When you don’t have a steady pipeline, you are going to struggle in any way. Building a marketing and sales strategy is not about flashy advertising. It’s about creating trust, offering reliability, and positioning yourself as a dependable production partner.

This section will help you understand how to generate leads, convert your clients, and establish your brand.

Industry Expert Insight:

Deeba emphasized: “Offline events such as exhibitions were key to building trust — people could touch the fabric, try the outfits, and connect the brand in a real way. I wore my costumes, which naturally drew attention and led to direct sales.”

On the digital front, she handled it all by herself — “I was the model, editor, and photographer. It was tiring, but I couldn’t afford a team. Still, my content helped build a loyal following.”

Understanding Your Apparel Sales Channels

There are multiple ways to sell your manufacturing services or finished goods. You can choose the right channel depending on your business model:

| Channel | Best use for | Platform examples |

B2B manufacturing service |

Job work and private label stitching |

IndiaMART, Trade India, and referrals |

Online market |

Own label or custom garments |

Amazon, Flipkart, Ajio, Meesho |

Institution supply |

Uniforms, bulk production, and contracts |

Direct outreach to schools, hotels, or corporations |

Volume production for foreign clients |

Trade fairs, sourcing agents, and directories |

Challenges and Solutions

Garment manufacturing can be rewarding, but it’s not easy. From delayed payments to raw materials shortages, new manufacturers often encounter bottlenecks that can stall growth. The good news? These challenges are common and can be solved with planning, processes, and the right mindset.

Here is one of the most pressing issues new garment businesses face in India, along with some tips on how to navigate it.

| Challenges | Problem | Solutions |

Irregular orders and inconsistent workload |

You cannot predict workload; some months are packed, others are silent |

You need to diversify clients, offer them premium sampling, and sign at least 1–2 monthly retainers |

Cash flow gaps and late payments |

Most of the time, the client delays payments, especially in bulk supply |

It is better to ask for advance payment, offer early discounts, and use invoice tracking tools |

Shortage of labour or high turnover |

You cannot retain skilled tailors when it is peak season |

You can use flexible contracts, offer incentives, and weekly payouts |

Delay in fabric or quality issues |

When your fabric is poor, it affects timelines and quality |

You need to maintain at least 2–3 vendors per fabric type, inspect all rolls, and keep a buffer if possible |

High rate of rejection |

If you have poor quality control, it damages client trust and increases returns |

You should use 3-step QC (Inline, endline, pre-pack), train tailors, and reward zero-defect performance |

Difficulty in managing beyond 15 machines |

If you lack a system, it becomes hard to grow your operation smoothly |

You can hire a supervisor, set SOPs, and expand your layout in modular stitching bays |

Founder burnout |

If you are managing alone as a founder, it leads to more exhaustion and bottlenecks |

You should hire a junior operation manager or an administrative staff member, use checklists, and outsource finance or compliance work early on |

Conclusion

Starting a garment manufacturing business in India is not just about stitching clothes. It is about stitching the systems together. From the outside, it may seem like a straightforward production game, but building a successful business takes resilience, planning, and a relentless focus on quality and timelines.

You don’t have to implement everything from day 1. It takes time. You need to have a sharp understanding of demand, deliver good work, work consistently, and adapt fast.

Scale Your Garment Business Smartly with Kladana ERP

Manual processes and operational chaos are major reasons small garment businesses struggle to grow — even with steady orders. Delays, stockouts, and miscommunication hold you back.

Kladana solves this

It’s a cloud-based garment manufacturing ERP. Kladana understands your sourcing, stitching, and dispatch pain points.

What You Can Do with Kladana

☑️ Manage full production cycle: BOMs, orders, and shop floor operations

☑️ Track real-time raw material inventory by fabric type, color, supplier

☑️ Assign and monitor job work — both internal and outsourced

☑️ Auto-generate purchase orders and link them to production

☑️ Monitor QC status, order progress, and timelines in one dashboard

☑️ Oversee sales, dispatch, inventory counts, and pending payments

☑️ Create invoices, quotations, pick lists, and custom print labels

☑️ Integrate with Shopify, WooCommerce, and other sales channels

Why Garment Businesses Choose Kladana

- Cloud-based access — use it from anywhere

- Free onboarding & support — fast replies within 5–15 minutes

- Easy to use — get started in just 15 minutes

- Affordable for SMEs — plans start at $60/year

Frequently Asked Questions on How to start a garment manufacturing business in India

How to start my manufacturing business in India?

- Step 1: Conduct essential preliminary research

- Step 2: Create a business plan

- Step 3: Determine the brand name

- Step 4: Choose the correct location for the clothing manufacturing unit

- Step 5: Choose the proper business structure

- Step 6: Register your business

- Step 7: Get your permits and licenses

- Step 8: Select your machinery and raw materials

- Step 9: Market your clothing manufacturing business

- Step 10: Hire trained employees and understand the manufacturing process

Is your garment business profitable in India?

Yes. Your garment business can be profitable in India, particularly if you consider the large domestic market. By targeting your niche audience based on location or region, you can build effective branding and strong marketing strategies, which can lead to a profitable business.

How much investment is required to start a garment manufacturing business in India?

If you’re starting on a small scale, it will typically cost around ₹15–20 lakhs. It includes covering raw materials, basic machinery, packaging, and setup.

Do I need a fashion degree to start a clothing brand?

No. You don’t need a fashion degree to become a successful founder. Strong product sense, market research, and vendor networks can be a good start for you.

What license is needed to start a garment factory in India?

Key registrations include Udyam (MSME), GST, Shops&Establishment license and factory license (if you use 10+ workers with power)

How do I find a reliable source or manufacturer for my brand?

Start researching offline with local vendors. Visit clothing markets, ask for referrals, and test with small batches. You can also build your relationships with tailors, ITIs, or through platforms like IndiaMART.

How do I market my garment brand without a big budget?

You can attend offline exhibitions and leverage AI tools for photoshoots. You can also act as the model for your brand, marketer, and packer in the beginning.

Is it better to start with custom orders or ready-made stock?

For early-stage brands, custom orders reduce dead stock risk. However, pre-making a limited inventory helps ensure faster delivery and builds trust.

What are the common challenges that new garment businesses face?

Inconsistent orders, cash flow gaps, labor turnover, fabric delays, and founder burnout are standard, but they are solvable with proper planning and systems.

How long does it take to break even in a garment manufacturing business?

Most small businesses aim to break even in 12–24 months, depending on demand, margins, and how well you manage your costs.

List of Resources

- IBEF — Textile Industry & Market Growth in India

- PIB — How Make in India is Shaping the Future of the Textiles and Apparel Industry

- SAI — Industrial Acts and Registration

- Statista — Apparel India Reports

- PM MITRA Parks — Mega Integrated Textile Region And Apparel PM Mitra

- PLI Scheme — Production Linked Incentive (PLI) Scheme Upgradation Fund

- Technology Upgradation Fund — Ministry of Textiles

- MUDRA Loan — Pradhan Mantri MUDRA Yojana (PMMY)

- PMEGP — Prime Minister’s Employment Generation Programme

- SAMARTH — Scheme For Capacity Building in Textile Sector

- Ministry of Textile Portal — Website of the Ministry of Textiles

- PLI application portal — Registration portal for PLI

- SIDBI and nodal banks — Registration Portal

- Apply via banks, Micro Finance Institutions — Registration Portal

- Non-Banking Financial Companies — Registration Portal

- Apply via KVIC or DIC portal — Registration Portal

- Apply via training centres and the textile ministry website — Registration Portal

- Udyam registration — Registration Portal

- GST Registration — Registration Portal

- Director General Of Foreign Trade — Registration Portal