E-commerce brands often hit a growth ceiling — not due to lack of demand, but because their operations can’t keep up. As orders scale across channels, managing inventory, returns, suppliers, and fulfillment manually leads to delays, errors, and rising costs. This is where supply chain management in e-commerce becomes essential. It ensures your entire backend — from purchase orders to delivery — is coordinated and scalable.

In this guide, we’ll break down how e-commerce supply chains work, when to invest in SCM, what tools and workflows to use, and how systems like Kladana help streamline operations at every stage.

- What Is Supply Chain Management in E‑commerce?

- What Operational Problems Hold E‑commerce Brands Back?

- How Does E‑commerce Supply Chain Management Start?

- E‑commerce vs. Traditional Supply Chains: Key Differences

- Components of an Effective E‑Commerce Supply Chain

- Do All E-commerce Businesses Need Supply Chain Management?

- E‑commerce Supply Chain Strategy: How to Scale Smart

- Kladana as a Tool for E‑commerce Supply Chain Visibility

- Conclusion

- Frequently Asked Questions on Supply Chain Management in E‑Commerce

- List of Resources

What Is Supply Chain Management in E‑commerce?

Supply chain management (SCM) in e-commerce is about controlling and coordinating everything from purchasing or producing a product to its delivery to the customer.

A solid e-commerce SCM system helps you:

- To know exactly what inventory you have in cross-functional channels such as retail stores, Amazon, Flipkart, warehouses, etc.

- To avoid overselling or stockouts, which cost you money, reviews, and ranking

- To manage orders based on real-time availability, location, and SLA (Service Level Agreement) commitment

- To work with suppliers to ensure replenishment and raw material timelines

- To handle returns and exchanges smoothly and transparently

- To adapt quickly to demand spikes, sales, etc.

What Operational Problems Hold E‑commerce Brands Back?

E-commerce growth starts strong — driven by a few winning SKUs, marketplaces, and marketing — but often slows down due to operational chaos. Here’s what typically happens:

- Inventory is spread across locations (own warehouse, Amazon FBA, 3PLs), making it unclear what’s in stock and where.

- Returns don’t update in one place, making it hard to restock or refund quickly.

- Order spikes lead to overselling or delays because stock data isn’t synced in real time.

- Supplier delays or quantity mismatches leave you understocked or with excess.

As a result:

- You sell more but fulfill less efficiently.

- Operational costs increase.

- Delays become frequent.

- Customers complain.

- Your team spends more time firefighting than scaling.

And this isn’t just your story — it’s the industry norm.

👉 According to Verified Market Research, the e-commerce logistics market was valued at $432.94 billion in 2024 and is projected to reach $1,946.17 billion by 2031 at a CAGR of 22.8%.

How Does E‑commerce Supply Chain Management Start?

When you start your e-commerce business, you probably don’t think it through regarding supply chain management. You mainly focus on your products, selling them, and shipping them out. But even those basic steps count. Your supply chain includes ordering stock from a supplier, storing it, fulfilling customer orders, and handling returns.

At first, this process might seem very simple and handy. However, that process becomes difficult to handle once your business grows with increasing SKUs, suppliers, and customer expectations. That is when supply chain management stops being optional and becomes a necessity.

Here is how e-commerce SCM typically evolves in three key stages.

Stage 1: Inventory Chaos

- You are growing, but your backend is still manual.

- You don’t have visibility into what’s in stock.

- Your products oversell or go out of stock without any warning.

- Your returns are disorganized and hard to track.

- You have to rely on memory, spreadsheets, and direct messages to reorder or check stock.

- You are constantly reacting to issues instead of preventing them.

Stage 2: Patchwork

- You start adding tools, but none are integrated, and you waste more time fixing issues.

- You install a basic order management or inventory plugin.

- Your stock syncing happens only for one or two channels instead of the whole.

- Your supplier communication and purchase orders are still manual.

- You may use automation for specific tasks, but your team still handles things manually again.

Stage 3: Operational Structure

- You define your fulfillment model in-house or hybrid.

- Your inventory, orders, returns, and supplier data flow through one connected platform.

- Your forecasting helps you order the right products at the right time.

- You track returns, sync stock in real time, and manage delays with clear visibility.

- Your operations team isn’t just responding to problems, but they plan ahead.

E‑commerce vs. Traditional Supply Chains: Key Differences

Supply chain management might sound like a fixed concept. Still, the difference between managing a B2B supply chain in traditional retail and an e-commerce-focused chain is like comparing a four-wheeler to a two-wheeler. Both get things from A to B. Still, everything is about how they do it, and what they require is fundamentally different.

Here is a side-by-side breakdown of the most critical differences:

| Aspect | E-commerce Supply Chain | Traditional Supply Chain |

Order type |

Thousands of small B2C orders |

Fewer, bulk B2B shipments |

Fulfillment channels |

Website, marketplaces, 3PL, own warehouse |

One or two primary channels |

Customer expectation |

Same day / two days delivery, live tracking |

3–7 days’ delivery is acceptable |

Inventory strategy |

Real-time, multi-location, SKU-level tracking |

Monthly or batch-level updates |

Returns volume |

High, the majority in apparel and home, reverse logistics is critical |

Very low, usually no customer-facing process |

Forecasting complexity |

Promo-driven, channel-variant demand spikes |

Predictable and seasonal |

Tech stack needs |

Order management system, warehouse management system, transportation management system, channel integration, auto PO, real-time sync |

ERP, freight scheduling, vendor portal |

Why Do These Differences Matter?

Traditional supply chains are built for efficiency at scale, moving large amounts of goods at the lowest cost per unit. They work great in manufacturing, wholesale, and retail.

On the other hand, the e-commerce supply chain is all about agility. You might ship one mug from different locations via Amazon FBA and customise a gift box for that mug from 3PL, all in one day.

Additionally, e-commerce buyers expect transparency. They want to see available stock online, get delivery estimates, and track their packages. This puts intense pressure on the back office system to sync perfectly across platforms.

Traditional SCM doesn’t deliver that out of the box, but e-commerce-focused SCM does.

Components of an Effective E‑Commerce Supply Chain

Modern e-commerce doesn’t hinge on great products alone. It hinges on whether you can deliver those products reliably, quickly, and profitably.

It requires an e-commerce supply chain built for speed, complexity, and customer expectations. Let’s break down the key components of a strong e-commerce SCM framework.

1. Warehouse Control and Bin-Level Management

As you scale, inventory doesn’t just stay in one place. Warehouse management means knowing what is in stock, where it is stored in the bin, and how to pick, pack, and ship efficiently.

Why does it matter?

- You will have on-time deliveries

- You will reduce pick and pack errors

- It will enable zone picking and bundling workflows

- Bin level control will help you minimize waste, mispicks, and confusion

2. Order Fulfillment Tracking

Every customer wants an email confirmation of the order and expects visibility from purchase to delivery. Businesses also need the same on the backend to track bottlenecks, missed SLAs, and delivery performance.

Key features to look for:

- You will get a centralized view of order status by channel

- You can track your carrier and delivery updates

- You have an exception on order delay, address issues, etc

- You will reduce complaints like — (where is my order) and help brands spot problems before they reach the customer

3. Returns and Reverse Logistics

Returns aren’t an afterthought in e-commerce; they are the reality of the business model. Most returns happen in verticals like fashion, home decor, or electronics, and poor return experiences kill repeat business.

What you need:

- You need to have return initiation portals

- You need to have condition tracking and restock workflows

- You need to have a policy of refund logic and reporting

- You need to have automated parts once you cross the monthly returns of 100–200

4. Supplier Coordination + Purchase Planning

Inventory issues are often unrelated to fulfillment but are primarily due to a delay in sourcing, late POs, poor lead time visibility, or reactive reordering.

Strong Supply Chain Management tools help you:

- To set your reorder points by SKU

- To automatically generate your purchase order

- To track your supplier performance

- To predict your future inventory needs based on trends

- To prevent you from missing deadlines and dead stock

5. Forecasting and Demand Planning

Real forecasting involves analyzing historical sales, seasonal trends, marketing calendars, and channel behaviour to more accurately project demand.

Why it matters:

- It prevents you from overstocking slow-moving SKUs

- It supports timed marketing campaigns

- It informs smart purchasing, not emotional guesses

6. Integrations with Storefronts and Marketplaces

SCM in e-commerce does not work in isolation. It must pull in data from sales and push updates to where fulfillment happens. That means you can have tight integrations with:

- Shopify, WooCommerce, Magento

- Amazon, Flipkart, Meesho

- Shipping and logistics carriers

- 3LPs and warehouse partners

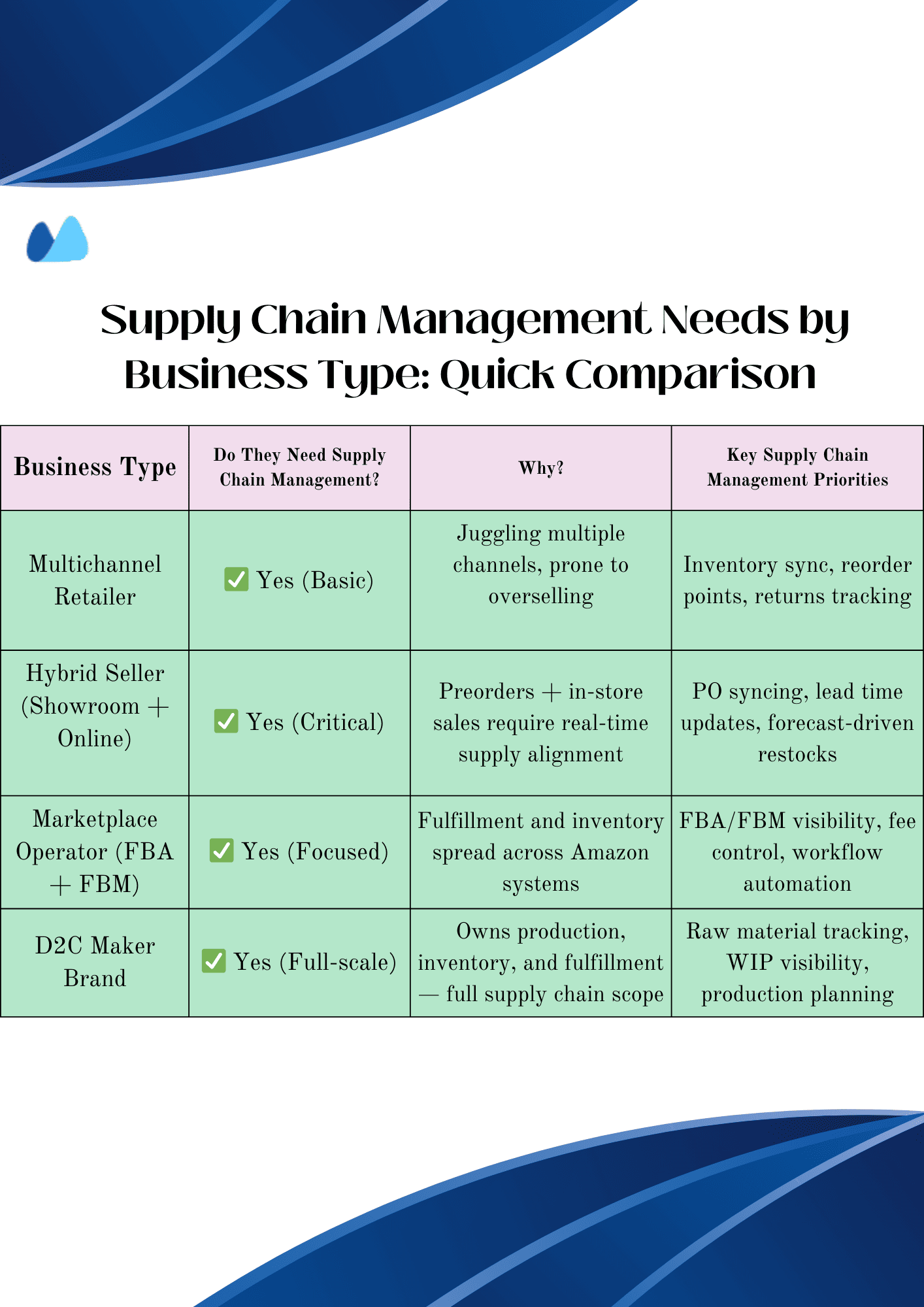

Do All E‑commerce Businesses Need Supply Chain Management?

A supply chain is not needed at the beginning of the business. But as sales grow and complexity starts, many patterns change, such as stockouts, overselling, late deliveries, high return rates, and endless manual fixes.

Let’s walk you through four standard e-commerce business models to see how supply chain needs evolve at different stages and where structured systems make a real difference.

Example 1: Multichannel Retailer

Profile: Buys inventory in bulk, sells through Shopify + Amazon

Order Volume: 300–600 per month per channel

This seller already manages two demand streams and has its own D2C website. Fulfillment is in-house or handled by a small third-party logistics company.

Inventory is managed manually. When a product sells out on Amazon or Shopify, the store might still show it as “in stock.” This is because of their disconnected system and lack of supply chain management.

Pain points:

- Manual stock updates = overselling risk

- No real-time visibility into marketplace returns or unsellable inventory

- Reordering is reactive, even when the product is not in stock

Do they need supply chain management?

✅ Yes, at a basic level

What they need:

- One system to track inventory across all sales channels

- Automatic alert to reorder popular items

- Better tracking for returns, especially from marketplaces

💡Tip: Once this seller adds forecasting and Point-of-Sale automation, their supply chain management becomes light-touch but highly efficient, freeing them to focus on growth rather than firefighting.

Example 2: Hybrid Seller

Profile: Sells in showrooms, offers full catalog online

Model: Popular SKUs are stocked, others made to order

This business has both an online and a physical store. They can’t stock all the items and rely on supplier orders after customer purchases. Their timing, visibility, and customer communication are critical.

Pain Points:

- PO delays = delivery delays = loss of trust

- No link between online orders and supplier planning

- Customer support is overloaded with the same complaints, such as “Where is my order”?

Do they need Supply Chain Management?

✅ Yes, Critically

What they need:

- A system that connects online orders to supplier orders

- Real-time updates on delivery timelines

- Extra stock planning for items that sell fast

Example 3: Marketplace Operator (FBA+FBM)

Profile: Sells on Amazon with SKUs split between FBA and FBM

Order Volume: Steady, with seasonal spikes

This seller depends only on Amazon for reach but uses fulfillment and storage. Some products are stored and shipped by Amazon (FBA), while others are handled by others (FBM). They aim to stay in stock and keep fulfillment smooth without paying too many storage fees.

Common problems:

- It’s hard to track inventory across FBA and FBM

- Amazon charges extra for storing products for too long

- Labeling, prep, and returns vary between fulfillment types

Do they need Supply Chain Management?

✅ Yes, for warehouse and fulfillment flow control

What they need:

- Clear inventory for both FBA and FBM

- A plan to restock FBA without triggering long-term storage fees

- Automation for returns, labeling, and packaging

📦 For this type of business, SCM is not about procurement. It is about execution, speed, and cost control.

Example 4: D2C Maker Brand (Own Production + Multichannel Sales)

Profile: Manufactures small furniture, sells through its store and various marketplaces

Model: Mix of made-to-order and ready stock products

This type of business doesn’t just sell. It manufactures its products. That means it has to manage every step from buying raw materials, making the products, storing them, updating listings, shipping orders, and handling returns. It is a whole supply chain that has to stay in sync across functional teams and tools.

Common Problems:

- Ordering the materials without knowing the real demand

- Made-to-order items take longer than expected

- No visibility and real-time tracking

Do they need Supply Chain Management?

✅ Yes, Critically

What they need:

- A system to track everything and plan production

- Real-time visibility into work-in-progress and stock

- Data to help decide what to make in advance versus on demand

- One place to manage inventory, orders, and production

Here is a quick summary table for your reference of all four ecommerce business types and when SCM in e-commerce becomes necessary:

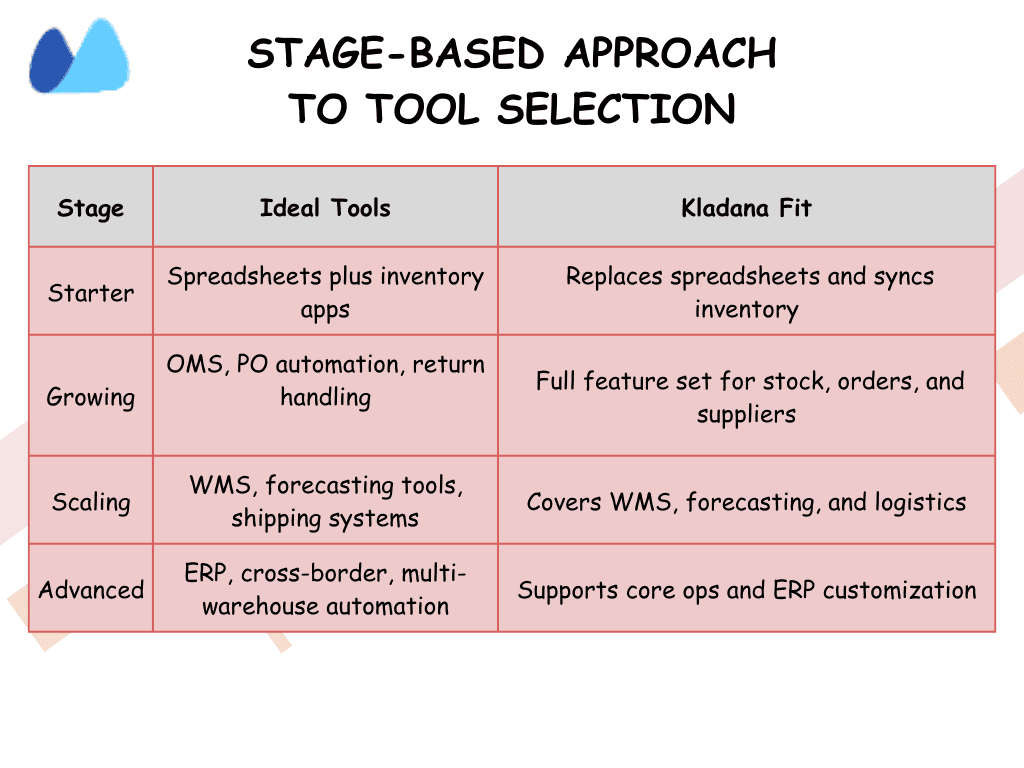

E‑commerce Supply Chain Strategy: How to Scale Smart

Most e-commerce businesses don’t fail because they can’t sell. They mostly fail because they can’t deliver. The backend breaks before the front-end does.

The good news? You don’t need to build Amazon-like operations. Innovative supply chain management is not like having to do everything simultaneously. It is about knowing when to upgrade, what to prioritize, and how to avoid overkill.

Step 1: Start Small

Most businesses hit an inflection point when order volume crosses 200–300 per month, or when you sell in multiple channels. At this stage, your priority should be:

- To set your reorder points on high-volume SKUs

- To sync your inventory between the store and the marketplace

- To define SLAs (Service Level Agreements) for fulfillment speed

- To map basic workflows, such as how orders get picked, packed, and shipped

Step 2: Automate Intelligently

Once you are past survival mode, scale with purpose. It means choosing automation that reduces your manual effort and improves consistency.

You should automate:

- PO generation based on forecast or stock levels

- Order routing by region, channel, or fulfillment type

- Returns workflows, including restock logic

- Customer notifications for delays, backorders, or delivery updates

Step 3: When to Outsource

Initially, many growing startups make the mistake of holding onto fulfillment for too long or outsourcing it too early. Here is a smarter rule of thumb:

- If you are fulfilling 400 orders a month, in-house might still be cheaper

- If you are spending 25% of your time troubleshooting fulfillment, it is time to look at 3PLs

- If your delivery times vary wildly by region, use regional 3PLs to reduce delays

Step 4: Use the Right Tools at the Right Time

Do not just jump straight to enterprise software. Instead, use a stage-based approach tool selection.

👉 According to PwC’s 2025 Digital Trends in Operations Survey, leading brands are turning supply chain management into a competitive edge. With over half already using AI to predict disruptions, driving supply chain management is shifting from a cost center to a strategic advantage, need, resilience, and better customer experiences.

🚨What You Risk When You Ignore Supply Chain Management

Most e-commerce businesses don’t feel the pain of weak operations until they start scaling. And when they face problems simultaneously, such as delays, refunds, and negative reviews, the root problem is already deep.

Here is what you risk by ignoring supply chain management.

1. You Can’t Control Margin at Scale

- Your economic unit starts to shift

- Your shipping cost rises

- Your storage fees eat into profits

- Your stockouts lead to emergency restocking at higher prices

- Without supply chain management, you can’t optimize the cost per unit, and even a profitable product becomes unprofitable at volume.

2. You Lose Leverage with Suppliers and Partners

- You can’t negotiate better terms with vendors without precise purchase data, lead time visibility, and fulfillment tracking

- You are the one absorbing delays and inconsistencies due to a lack of supply chain management

- You will get leverage, not just logistics, if you implement a proper supply chain management system

3. You Delay Expansion into New Channels or Regions

- You can’t expand domestic or cross-border shipping if you don’t have a centralized system for stock and order flow

- Your operational gaps will block your ability to scale into new opportunities

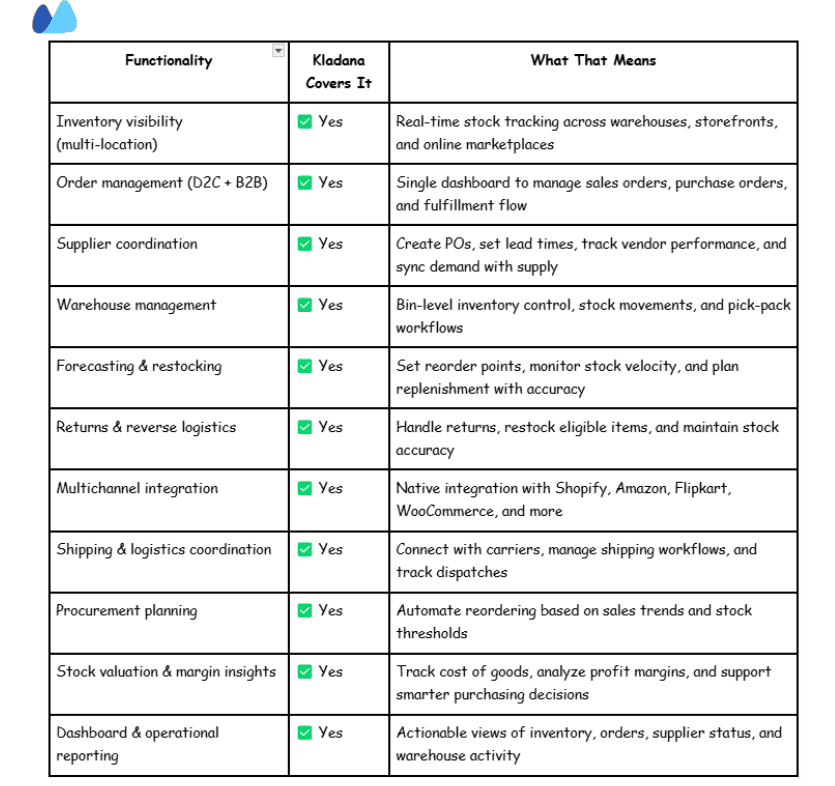

Kladana as a Tool for E‑commerce Supply Chain Visibility

Kladana will help you grow in e-commerce and D2C brands without the weight or cost of an ERP. It will centralize your inventory, orders, procurement, and warehouse logic into one powerful, accessible platform.

Whether managing in-house fulfillment, coordinating with suppliers, or syncing multiple sales channels, Kladana gives you the tools to stay in control.

Here is a breakdown of what it covers:

Who Is It Best for?

It is best for fast-moving teams that need visibility, order control, and inventory accuracy without overhead, such as:

☑️ D2C brands scaling from 1 to 3+ sales channels

☑️ Marketplace-first sellers starting to manage in-house stock

☑️ Retailers blending offline + online inventory in a single system

☑️ B2B ecommerce platforms expanding into direct-to-consumer

☑️ Operations leads looking to automate procurement and reduce manual work

📍Example: If your business handles 200–1,000 orders per month across Shopify and Amazon, and you spend 6–9 hours resolving mismatch orders, returns, and stock updates, Kladana will simplify your entire process.

🛒Who Should Use Kladana?

- A D2C brand managing its warehouse or third-party logistics

- A multichannel seller syncing Shopify, WooCommerce , Flipkart, and Amazon

- A B2B business expanding into D2C

- A team struggling with restocking delays, overselling, or return tracking

Integrations That Matter

Kladana integrates with key ecommerce platforms and services out of the box to unify data across your tech stack without costly development work.

These allow you to:

- Sync your order and inventory in real time

- Push product and stock updates to all platforms

- Track performances across channels from a unified view

⚙️ Check out Kladana for Ecommerce ➡️

Conclusion

Therefore, smart e-commerce brands treat supply chain management like marketing or product as a driver of outcomes, not overhead.

Whether you are a D2C furniture maker, a drop shipper evolving into in-house warehousing, or a multichannel seller juggling Shopify and Amazon, supply chain management is no longer optional. It is the cost of scaling well.

You don’t need everything at once. You need the right next step, whether setting reorder points, syncing channels, automating POs, or bringing in a tool like Kladana to unify the pieces.

Frequently Asked Questions on Supply Chain Management in E‑Commerce

Let’s look at some common questions that often come up when exploring the topic of supply chain management.

What is SCM in e-commerce?

Supply chain management involves coordinating suppliers, manufacturers, distributors, and retailers to minimise cost, maximize quality, and meet customer demands. It is also the backbone of any business, ensuring that products reach consumers on time and in the best possible condition.

What are the five pillars of supply chain management?

- Planning

- Sourcing

- Making

- Delivering

- Returning

What is the process of e-commerce supply chain management?

E-commerce supply chain management analyzes customer orders and generates a report based on them. Businesses leverage this report to understand customer demand and plan their manufacturing processes accordingly.

What are the benefits of effective e-commerce SCM?

- It reduces your cost by optimizing the process and minimizing waste

- It streamlines your operations and reduces bottlenecks

- It provides a seamless and positive shopping experience

- It helps in managing inventory

What are the tips for Improving Supply chain management in e-commerce?

- Implement systems like ERP, WMS, and TMS to automate and streamline

- Build a trustworthy relationship with the supplier to ensure quality and on-time delivery

- Optimize your Inventory management system

- Focus on customer experience

- Develop a contingency plan to minimize the impact of unexpected events

What are the key challenges in e-commerce SCM?

Common challenges include inventory inaccuracies, delayed deliveries, high return rates, lack of real-time visibility, and difficulties in demand forecasting. These issues can lead to customer dissatisfaction and increased operational costs.

How is the e-commerce supply chain different from traditional retail?

Unlike traditional retail, which deals with bulk shipments to physical stores, E-commerce deals with smaller, more frequent orders and direct delivery to customers.

What technologies are essential for modern supply chain management?

Essential technologies include AI, IoT, for real-time tracking, cloud-based platforms, and integrations with e-commerce platforms.

What metrics should I track to evaluate supply chain performance?

Key metrics include order accuracy, delivery times, inventory turnover, and return rates, which help assess and improve supply chain efficiency.

How do I choose the right fulfillment strategy for my business?

Assess factors like order volume, product type, and customer location to decide between in-house fulfillment, third-party logistics, or a hybrid approach.

List of Resources

- Verified Market Research — Global E-commerce Logistics Market Report

- PWC — Digital Trends Operations Survey 2025

Read‑alikes

Shopify ERP Guide: How to Pick the Right System for Your Business

ERP System for eCommerce: Key Features, Benefits, Trends, and Implementation Guide

Top eCommerce Business Ideas and Trends to Fuel Growth

Crafting Compelling Product Cards for E‑Commerce: a Tutorial with Product Descriptions and Examples