You already track sales, monitor expenses, and review performance. But when was the last time you audited your inventory control system?

Inventory management is not just about having enough stock. It is about having the right stock levels at the right time. It affects how fast you fulfill orders, how much working capital you free up, and how efficient your supply chain is. According to Accenture, companies that utilize real-time inventory systems as part of their supply chain experience up to 23% higher profitability.

Missed reorders, expired stock, and shelves full of unsold products aren’t just mistakes. They are signs that your inventory process is reacting, not leading. Poor inventory control leads to stockouts, overstocking, and ultimately, lost revenue or locked-up capital. Good inventory management answers the real question — not what’s in stock, but what should be. It supports demand forecasting, improves inventory accuracy, and reduces the cost of inventory over time.

In this article, we will explore what inventory management is, its significance, its benefits, and how it contributes to overall warehouse optimization and scalable business operations.

- What Is Inventory Management?

- Why Inventory Management Is Important?

- Benefits of Inventory Management

- The Role of Inventory Control in Business Operations

- Significance of Inventory Management Matters in Different Industries

- Technology and Tools for Effective Inventory Management

- To Sum Up

- Frequently Asked Questions on Inventory Management

- List of Resources

What Is Inventory Management?

Inventory management is the process of controlling how your stock moves through your business, from purchasing and storage to usage and final sale. It involves tracking what you have, forecasting what you will need, and ensuring the right products are available at the right time, in the correct quantity.

But it goes beyond just counting items.

Effective inventory management helps you avoid stockouts, reduce overstocking, enhance cash flow, and make more informed decisions. It provides visibility into what’s working, what’s wasting, and what needs adjustment, so you can improve inventory accuracy and operate more efficiently.

Whether you are running a warehouse, a production floor, or a fulfillment centre, inventory management is the heart of your operations. If you utilise and implement your inventory properly, it will reduce the cost of inventory, improve supply chain efficiency, and help your business grow without chaos.

📍 New to inventory control? Check out our beginner’s guide to inventory management — covering key techniques, common challenges, best practices, and trends.

Why Inventory Management Is Important

Inventory management is one of the most crucial parts of your business. It not only supports efficient operations but also protects profits, improves inventory control, and provides a clearer path to scale.

Here’s how effective inventory management helps you run a smarter, more resilient business.

1. Avoid Stockouts and Overstock

When you lack visibility into stock levels or demand forecasting, you face two costly risks:

- Running out of key items or losing sales (stockouts)

- Holding excess inventory that doesn’t sell (overstocking)

A strong inventory control system helps strike the right balance. It ensures you can meet customer demand while minimizing waste due to markdowns, expired products, or unnecessary storage costs. This optimization improves inventory accuracy and frees up capital.

2. Protect and Improve Cash Flow

Inventory ties up working capital. Every unsold unit sitting on a shelf increases the cost of inventory and limits your ability to invest in growth. By setting smart reorder points and improving inventory turnover, a well-managed inventory system enhances cash flow and reduces reliance on emergency stock purchases.

3. Enable Accurate Forecasting

With reliable, real-time inventory data, it is always better to plan. You will be able to identify trends, anticipate seasonal demand, and prevent over-ordering or shortages.

Proactive demand forecasting saves you from emergency purchases, budget overruns, and wasted storage costs. It also improves inventory accuracy and strengthens your overall inventory control system.

4. Speed up Order Fulfillment

When you always know what’s in stock and where it is located, order processing becomes easier and more reliable. This leads to on-time deliveries and fewer customer complaints. Your team spends less time dealing with errors or misplaced items, and service quality improves — without added complexity or operational strain. It’s a key benefit of efficient warehouse optimization.

5. Strengthen Your Supply Chain

Inventory touches every link in your supply chain. From procurement and production to sales and shipping. Clean, real-time inventory management data ensures your suppliers know what to replenish and when. This strengthens supply chain efficiency, reduces last-minute disruptions, and helps internal teams stay aligned. It also supports better inventory audits and vendor accountability.

📍 Learn how to count inventory accurately with our step-by-step guide.

Benefits of Inventory Management

If you think inventory management is just about keeping your shelves in order, think again. When you manage inventory effectively, you’re not just staying organized — you’re unlocking powerful business advantages that impact your cash flow, your team, your customers, and your long-term growth.

Here’s how solid inventory control directly benefits your business.

1. You’ll Save Money in Places You Didn’t Expect

This isn’t just about spending less on stock. It’s about lowering the cost of inventory across your entire operation.

- No more emergency restocking that kills your margins

- Lower storage costs because you are not keeping dead stock around “just in case”

- Less spoilage and obsolescence, especially if you are dealing with perishable goods, seasonal items, or fast-moving tech products

- Fewer returns and refunds due to improved inventory accuracy

By staying on top of your stock, you reduce costs not only at the point of purchase but also throughout storage, movement, and sales — minimizing inventory shrinkage and waste.

2. Your Customers Get a Better Experience

Customers will not know how hard it is to manage an inventory. They will just want their orders to be on time.

With a proper inventory control system in place you:

- Always know what’s available to sell

- Can confidently offer same-day or next-day shipping without fail

- Minimize “out of stock” messages that drive shoppers to competitors

- Deliver on the promised date, and that builds your loyalty

Today’s customer expects precision. According to Accenture’s Empowered Consumer Research, 78% of shoppers want real-time product availability across all channels, and nearly half will switch to a competitor after just one poor stock-related failure.

That’s why inventory accuracy is no longer an option. It is make-or-break for customer loyalty.

3. Improves Warehouse Efficiency and Accuracy

Poor inventory control leads to wasted time, picking errors, and unnecessary manual fixes. Your team spends more time searching and double-checking than actually moving orders out.

With a proper inventory system, everything changes:

- Items are stored in the correct location

- Barcode scanning replaces manual entry

- Alerts help you restock before stockouts happen

- Picking lists that are accurate and up to date

So, instead of operating reactively, your warehouses become well-organized and have a responsive environment.

4. Gives You Accurate Data for Smarter Business Decisions

When inventory data is scattered, outdated, or manually updated, you are forced to make decisions based on assumptions, and those assumptions cost money.

With real-time inventory visibility, you always know:

- What’s in stock, and where is it located

- Which products are selling fast and which are stalling

- When to reorder and how much to restock based on actual turnover

- Which suppliers are consistent, and which are causing delays

This empowers leadership to make informed decisions on pricing, promotions, reorder points, discontinuations, and expansions, all backed by data rather than assumptions.

5. You Stay Compliant and Improve Reporting Accuracy

Whether you are running a food business, a healthcare company, or an e-commerce store, you have legal and financial responsibilities. An inaccurate inventory system makes inventory audits a nightmare.

Good inventory management helps you:

- Track batch numbers and expiration dates

- Keep accurate logs for inventory audits

- Stay compliant with tax, safety, and industry regulations

- Avoid penalties, spoilage, or legal issues from poor tracking

Compliance doesn’t have to be stressful when your records are clean and your numbers match your shelves.

6. You Reduce Inventory Shrinkage

Inventory shrinkage refers to the loss of stock due to theft, error, or damage. It is a silent killer of profit, and it usually goes unnoticed until it’s too late,

But having inventory management system helps you to track items such as:

- Theft is easier to detect

- Errors are spotted faster

- Losses are minimized

Even a small drop in shrinkage can significantly lower your cost of inventory. Therefore, having effective inventory management is essential for better control and visibility.

📦 Case in Point: NeyttHomes

NeyttHomes, a luxury carpet brand, struggled with limited visibility while managing stock across multiple locations using Excel. After implementing Kladana:

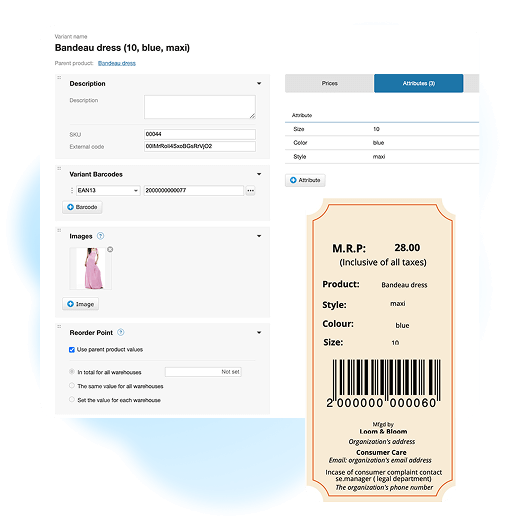

- They assigned unique barcodes to 270+ SKUs

- Completed a full inventory count with scanners in under 60 minutes

- Achieved real-time stock tracking across 10 locations

- Integrated a new store’s inventory in just 30 minutes

Result? Lower shrinkage, fewer errors, and better stock level control.

7. You Create Room to Grow

Scaling a business without solid inventory systems is like building a house without iron rods. It might stand for a while, but it won’t last.

The right inventory management practices let you:

- Expand into new sales channels such as online, wholesale, and retail without losing control over stock levels

- Add new SKUs without breaking your system

- Open new locations with centralized oversight

- Automate what used to take hours of manual tracking

The Role of Inventory Control in Business Operations

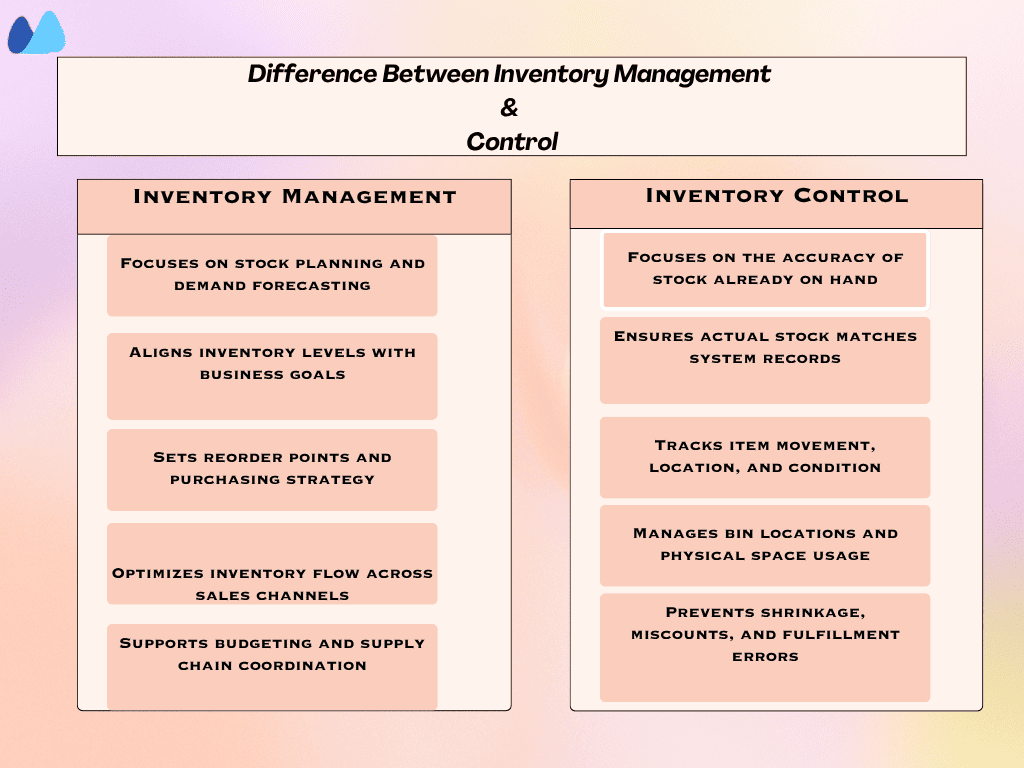

Inventory management and inventory control are closely related but distinct concepts.

- Inventory management is strategic: aligning stock with demand forecasting and sales trends.

- Inventory control is tactical: ensuring what’s in your warehouse matches what’s in your records through real-time tracking, inventory audits, and system accuracy.

One sets the direction, the other keeps it grounded. Without control, even the best inventory plans fall apart. And without management, control becomes reactive instead of purposeful.

Now, let’s examine closely why inventory control matters to your bottom line.

1. You Get Real Inventory Accuracy

If your system shows 20 units, but your shelf is empty — that’s not just an error, it’s a financial risk. Accurate inventory control eliminates these discrepancies by syncing physical stock with your system.

Whether it’s barcodes, RFID, or cycle counting, having better control leads to better decisions.

2. You Prevent Inventory Shrinkage

Inventory shrinkage doesn’t just mean theft. It includes:

- Misplaced items

- Supplier shortfalls

- Damaged goods

- Unrecorded transfers

All of these eat into your profit margins over time.

Inventory control detects and prevents shrinkage by:

- Real-time tracking ensures that every time it is scanned and logged

- Cycle counts and audits highlight discrepancies before they grow

- Clear stock movement history makes it easier to identify patterns, such as recurring damage in a specific zone or missing items from certain shipments.

3. Importance of Audit and Tax Compliance

Accurate inventory records aren’t just crucial for operations, but they are equally important for financial reporting and compliance as well.

Whether you are preparing for an internal audit, external inspection, or filing taxes, your inventory data must reflect what’s actually on hand. Discrepancies between physical stock and system records can raise a red flag, lead to penalties, or delay audits.

Inventory control provides the transparency auditors need:

- Stock movements are time-stamped and traceable

- Adjustments and write-offs are documented with clear reasons

- Historical data is available for review at any time

Significance of Inventory Management Matters in Different Industries

Every industry faces different inventory challenges. You may be shipping high-volume SKUs across cities or tracking expiration dates down to the hour. That’s why one-size-fits-all inventory systems don’t work. The importance of inventory management is deeply industry-specific — affecting operations, margins, and customer experience.

Here’s how the significance of inventory management plays out across five key industries.

1. Retail

If you are in retail, your entire customer experience hinges on product availability. People walk in or log on expecting to make a purchase. If it’s not there, they move on.

Without real-time inventory tracking:

- You risk stockouts during peak seasons

- Your overstocking leads to markdowns and wasted shelf space

- Your promotions fail when stock doesn’t match demand

But with the right Inventory management system:

- You sync online and in-store stock levels instantly

- You spot trends early and adjust before they become problems

- You cut down on carrying costs by ordering smarter

2. E-commerce

In e-commerce, your window to impress is just about 30 seconds. Customers expect instant availability, transparent delivery timelines, and no hiccups.

Challenges include:

- Managing multiple SKUs and warehouse locations

- Handling flash sales and seasonal spikes

- Maintaining inventory accuracy across channels

An optimized inventory management system enables:

- Real-time stock visibility across platforms like Shopify, Amazon, and WMS

- Livestock level visibility across all channels

- Tighter control over fulfillment, so you don’t lose time fixing mistakes

3. Manufacturing

In manufacturing, delays aren’t just inconvenient — they’re expensive. Shortages of raw materials lead to downtime. Excess work-in-progress (WIP) creates bottlenecks.

Inventory management in manufacturing supports:

- Just-in-time (JIT) delivery of raw materials

- Visibility into WIP inventory to improve flow

- Timely shipping of finished goods

A strong inventory control system lets you:

- Set accurate reorder points based on real demand

- Optimize your inventory control system around production workflows

- Avoid stockouts of critical inputs

- Align your inventory with production cycles to boost supply chain efficiency

4. Healthcare

In healthcare, inventory isn’t just about efficiency — it’s about safety. You’re managing:

- Expiration dates, batch numbers, and lot tracking

- Regulatory compliance

- Life-critical supplies where stockouts are unacceptable

And if you can’t find a product when you need it on time, it’s not just a customer issue; it directly impacts patients’ health and safety concerns.

An accurate inventory management system helps:

- Track inventory turnover and batch usage

- Enable fast response in case of product recalls

- Maintain compliance with audit and safety regulations

5. Food and Beverage

In food and beverage, your products have a ticking clock. Managing inventory turnover and minimizing spoilage is everything.

Without proper tracking, here is what can happen:

- You stock too much and throw half of it away

- You miss expiration windows and lose sales

- You waste labour moving products you can’t even sell

But an inventory management system helps you with:

- Implement FIFO to prioritize fresh stock

- Track inventory shrinkage due to spoilage or misplacement

- Ensure batch-level visibility across storage locations

📍 Recommended Read: Smart Food Inventory Management: Slash Waste and Maximize Profits

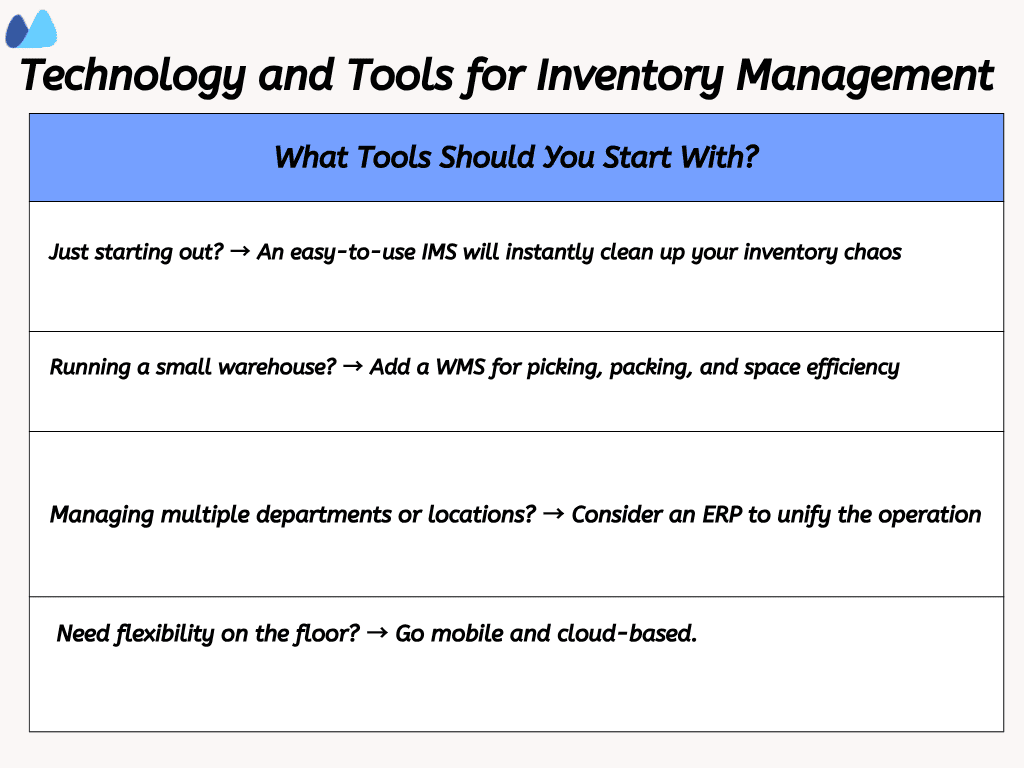

Technology and Tools for Effective Inventory Management

As Inventory demands become more complex, businesses can no longer rely on spreadsheets or manual processes. The right technology not only improves accuracy but also transforms how you plan, track, and scale your operations — minimizing risks like stockouts, overstocking, and inventory shrinkage.

Here is a breakdown of the key tools powering the importance of inventory management.

1. Inventory Management System

An inventory management system is designed to track stock levels, movements, and product locations. It’s ideal for SMEs needing tighter inventory control without managing large production flows or complex warehouse setups.

With the right system, you can:

- Set reorder points to automate reordering and avoid stockouts

- Reduce human error and improve inventory accuracy

- Create purchase orders and receipts automatically

2. Warehouse Management System

A warehouse management system (WMS) helps you optimize your space, people, and processes — a must for achieving true warehouse optimization.

What it does:

- Organizes your layout for faster picking and packing

- Guides your team to the right bin, shelf, or zone

- Tracks incoming and outgoing stock with barcodes or RFID

- Reduces time wasted hunting for items

That means

- More orders are shipped per day

- Fewer picking errors and inventory discrepancies

- Better warehouse optimization without hiring more people

3. ERP System

ERP (Enterprise Resource Planning) system integrates your inventory control system with other business-critical functions like finance, procurement, sales, and HR — ensuring smoother workflows and better supply chain efficiency.

If you’re juggling inventory, procurement, and accounting across separate tools, chances are you’re duplicating work and introducing errors.

ERP helps:

- Combine your inventory data with financial records

- Show your actual cost of inventory and margin

- Forecast demand using real-time sales and purchase data

- Help with audit preparation, regulatory compliance, and tax filing

4. Mobile Apps and Cloud Dashboards

Your team isn’t always at a desk. Mobile inventory apps let them:

- Scan products instantly on the floor

- Adjust stock levels after a count

- Fulfill orders from anywhere in the warehouse

- Track stock movements across multiple locations

Meanwhile, cloud-based dashboards allow you to:

- Monitor inventory operations from anywhere

- Make data-driven decisions without waiting for someone to pull the report

- Give different teams access to what they need without sharing your entire system

5. Automation Tools and Real-Time Tracking

Inventory automation is no longer just for large enterprises. Small and medium businesses can now use tools like barcoding, label printers, and real-time tracking systems to streamline operations and minimize errors.

Even simple automation can:

- Flag low stock and auto-generate purchase orders

- Notify when a shipment is delayed — boosting supply chain efficiency

- Update stock across sales channels when a purchase is made

These tools reduce manual workloads and prevent inventory shrinkage, while ensuring your inventory control system is always up to date.

To Sum Up

Inventory is connected to every part of your operations. Managing it effectively is not just about having systems in one place, but about how well those systems work together to support daily decisions.

Throughout this guide, you’ve explored the importance of inventory management — from reducing stockouts and improving inventory accuracy to enabling faster decisions and smarter growth.

You have also explored the difference between inventory control and inventory management, the impact of poor visibility, and the role of technology in building a system that’s fast and scalable.

Now’s the time to audit your current process, identify the gaps, and implement tools that help you control your inventory, reduce costs, and unlock growth with confidence.

Frequently Asked Questions on Inventory Management

Here are some common questions and answers to help you understand and improve your inventory management.

Why is inventory management Important for business success?

Because it directly impacts your profitability, cash flow, and customer experience. When you implement strong inventory practices, you can avoid stockouts, reduce overstocking, and make smarter purchasing decisions that improve overall inventory control.

What are the five main benefits of Inventory management?

The top five include:

- Cost savings through better stock planning

- Customer satisfaction with timely fulfillment

- Warehouse optimization for faster operations

- Supplier relationship management based on performance data

- Accurate reporting for compliance and better forecasting

What’s the difference between inventory management and inventory control?

Inventory management is strategic — forecasting demand, managing reorder points, and optimizing stock across your business.

Inventory control is operational — ensuring inventory accuracy, conducting inventory audits, and maintaining real-time stock level data in your inventory control system.

How does poor inventory management affect profitability?

It causes overstocking, stockouts, and delays in order fulfillment. These issues reduce sales, increase waste, and strain cash flow, ultimately hurting your bottom line.

What is inventory shrinkage, and how can it be reduced?

Inventory shrinkage happens when actual stock doesn’t match records — usually due to theft, miscounts, or damage. To reduce shrinkage, use:

- Barcode scanning

- Regular cycle counts

- Strong inventory policies

- A reliable inventory control system

What are the benefits of using inventory software?

You gain:

- Real-time visibility into inventory levels

- Fewer stock errors

- Faster picking and packing

- Accurate forecasting

- Integration with accounting, e-commerce, and procurement systems for end-to-end control

What’s the role of Inventory management in supply chain efficiency?

Inventory acts as a buffer between supply and demand. If it’s mismanaged, it creates bottlenecks. With proper control, your entire supply chain runs faster and more smoothly.

Which industries and business types rely most on inventory management?

Industries such as retail, e-commerce, manufacturing, healthcare, and food and beverage rely heavily on effective inventory management. Why? Because their operations depend on having the right products available at the right time.

Why is inventory control critical to profitability?

Because it directly impacts your costs, revenue, and efficiency. Without inventory control, you risk:

- Overstocking products that don’t sell

- Running out of high-demand items

- Wasting time and labor fixing fulfillment errors

- Losing money to shrinkage, spoilage, or theft

How does inventory management impact cash flow?

Inventory ties up capital. Poor planning leads to excess stock and locked cash. Effective inventory management ensures faster turnover, optimized reorder points, and improved cash flow — so your funds work for growth, not sit idle on the shelf.

List of Resources

- Accenture: New Research from Accenture

- Accenture: The empowered Consumer