Managing inventory manually can only be effective until supply chains accelerate, customer expectations rise, and competition intensifies. With manual tracking, you are slowing down your business while putting it at the risk of stockouts, delays, and missed sales.

A blog by Fireworks reports that 43% of small businesses do not track inventory at all or use manual methods. The result is inefficiency and lost sales opportunities.

And then there’s a huge inventory management software market experiencing substantial growth globally. It is projected to reach $2.51 billion by 2025 and $4.79 billion by 2032, at a 9.6% compound annual growth rate (CAGR).

Such a surge highlights the growing reliance on automated inventory management systems to improve accuracy and efficiency.

With Automated inventory management, you save time, protect cash flow, and build an operational rhythm that small and mid-sized businesses need to scale.

Let’s find out more about this.

- What Is Automated Inventory Management?

- How Automated Inventory Management Differs from Digital Record-Keeping

- What Can Be Automated in Inventory Management?

- Use Cases by Business Type

- When Should You Automate Your Inventory?

- Real-World Stories: What Automation Looks Like (and When It’s Too Early)

- Key Benefits of Inventory Automation

- Choosing Automated Inventory Software

- Final Thoughts: Start with Smart Rules, Then Automate

- Frequently Asked Questions on Automated Inventory Management

- List of Resources

What Is Automated Inventory Management?

Automated inventory management means letting your system, not your staff, track, update, and coordinate your inventory activities. It replaces the manual checking of stock, filling out spreadsheets, and cross-referencing sales orders with an automated inventory system that updates in real-time.

For example, when an online customer buys the last blue T-shirt, your automated inventory tracking system deducts it from available stock and triggers a reorder when thresholds are crossed.

How Automated Inventory Management Differs from Digital Record-Keeping

Sometimes teams think they’re “automated” because they’ve transitioned from pen-and-paper to Excel or basic inventory apps.

But automation is another level altogether.

Here’s the real difference:

| Aspect | Manual Inventory Management | Automated Inventory Management |

Core Action |

Manually updating stock records |

Automatic updates based on triggers and transactions |

Human Dependency |

High |

Low |

Error Risk |

Still high (manual entry mistakes) |

Minimal (system-driven actions) |

Examples |

Filling a spreadsheet after shipment |

Stock auto-deducts when a shipment is confirmed |

Speed |

Depends on manual input |

Immediate, real-time changes |

Impact |

Data visibility only |

Data visibility + operational action |

Facing stock discrepancies and production delays, a Kazakhstani women’s clothing manufacturer moved from Excel-based tracking to Kladana’s automated inventory management system.

This shift improved real-time stock visibility, reduced manual errors, and helped turn the business profitable.

What Can Be Automated in Inventory Management?

Automating inventory management will prevent your business from chasing errors after they occur. They’ll stay two steps ahead by predicting needs, avoiding stockouts, and keeping your operations tight.

Here’s how automated inventory management can make a real difference:

Real-time stock updates

When an item is sold, your automated inventory tracking system updates stock levels instantly across all sales channels.

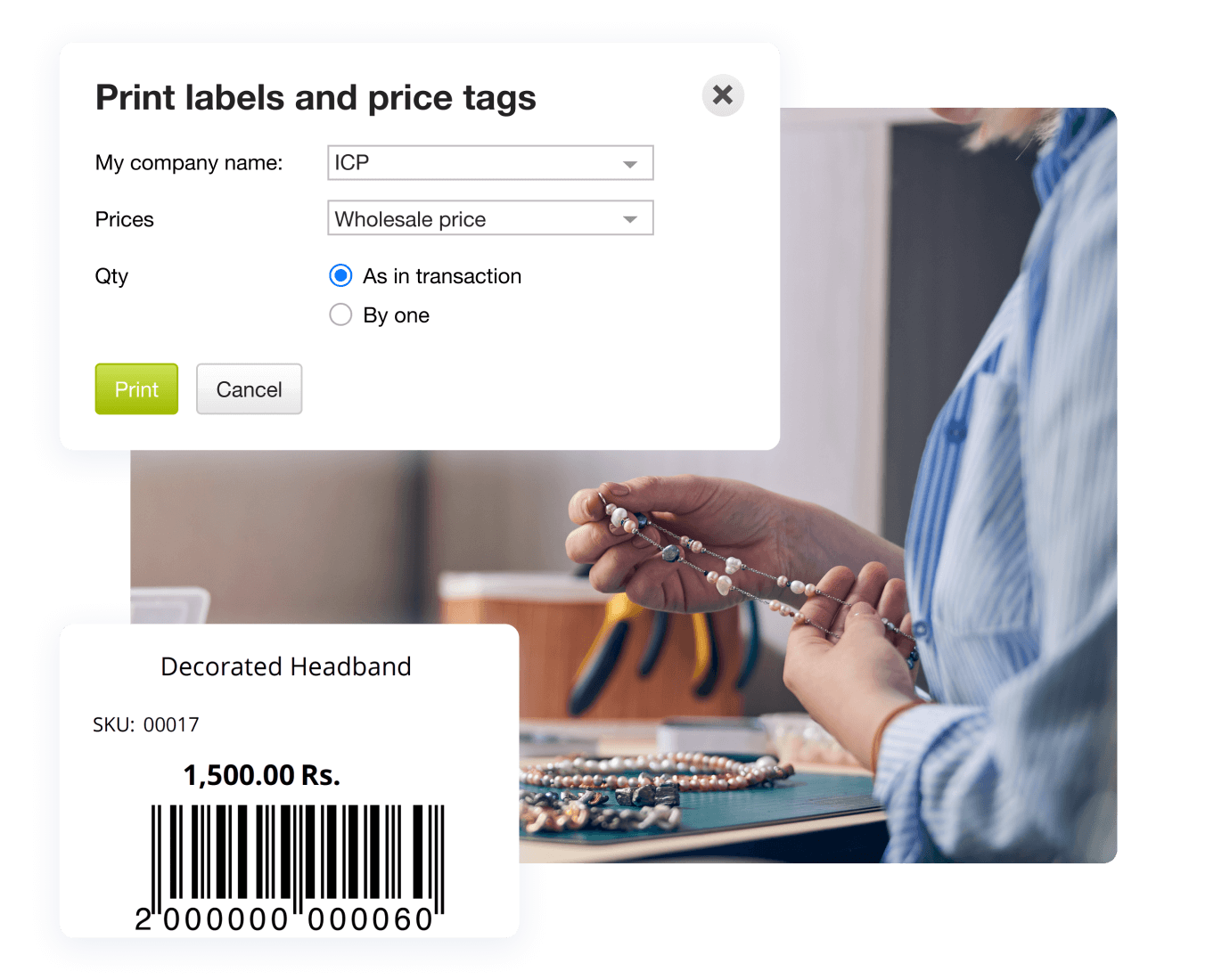

Barcode auto-generation

Automated inventory systems can automatically create and assign barcodes, making it easier to track incoming and outgoing stock without missing a beat.

Reorder point automation

Set minimum stock levels once, and after that, your automated inventory management software triggers reorder requests the moment thresholds are crossed.

Multi-location sync

When managing multiple warehouses or stores, automated inventory tracking systems update stock counts across locations in real-time, ensuring your numbers remain accurate.

Expiry/batch tracking

An automated inventory management system can track product batches, monitor expiry dates, and alert your team when items need to be rotated out.

Demand forecasting

Automated inventory software analyzes past sales patterns and seasonal trends to predict future demand. You make smarter purchasing decisions and avoid sitting on dead stock.

Thinking of automating soon?

If you already have repeatable processes but aren’t sure if you’re ready for automated inventory management, start here.

It covers the essentials your business should have in place before pivoting to an automated inventory management system.

Use Cases by Business Type

Automated inventory management is helpful for businesses across all industries. From D2C brands to traditional manufacturers, automation is transforming the way enterprises manage inventory, fulfill orders, and address customer needs.

E-commerce

E-commerce businesses using automated inventory tracking automatically synchronize their stock levels across Shopify, Amazon, Flipkart, and their brand website.

Manufacturing

When production begins, the automated inventory management system automatically deducts raw materials and generates purchase orders when supplies are low.

Hey Baby!, a women’s clothing manufacturer in Kazakhstan, moved from Excel-based inventory tracking to Kladana’s automated system.

They were able to manage production processes more effectively, doubling their turnover from $125,000 to $262,000 within a year.

Distribution & Wholesale

Automated inventory systems help sync stock across warehouses and auto-generate replenishment orders based on sales velocity.

Elektronky, a wholesale distributor of portable gadgets, transitioned from manual order processing to Kladana’s Online Order App.

Enabling such a switch helped them create personalized digital catalogs for clients and automate the order intake process.

Food, Cosmetics, Chemicals (Expiry Tracking)

Industries like food, beauty, and chemicals require tracking expiration dates, and that’s where automated stock management systems track batch numbers, shelf lives, and alert the team before products expire.

More Ryadom, a seafood wholesaler and retailer, moved from manual stock handling to Kladana’s automated inventory system. An upgrade to Kladana gave them tighter control over fresh inventory, faster order processing, and stronger customer management.

When Should You Automate Your Inventory?

Automating inventory requires knowing when your business needs more intelligent systems to keep growing without chaos.

Moving too early can waste money. Waiting too long can cost customers.

Signs You’re Ready

Knowing when to automate inventory management often comes down to a few clear signals.

Watch for:

- Tracking stock across multiple channels or locations

Manual updates can’t keep up when orders come from websites, marketplaces, and physical stores simultaneously.

- Inventory discrepancies

If monthly stock counts rarely match records, manual processes are no longer reliable.

- Reactive reordering

In case your team scrambles to replenish stock after it runs out, you’re missing opportunities for smooth, uninterrupted sales.

- Losing sales due to stockouts

When customers can’t buy because items are marked unavailable, it’s time to fix the gap.

- Spending more than an hour a day on inventory tasks

Instead, use that time to grow your business, not manually checking and updating stock.

What Should Be in Place Before Automation?

Automated inventory management doesn’t fix broken processes. It amplifies whatever already exists — good or bad.

Before you automate, your business needs a strong base that makes automation useful, not chaotic.

Here’s what should already be working:

- Rules: Clear rules for stock handling, reorder points, safety stock levels, and returns must be set. If the system doesn’t know when to act, you’ll end up firefighting manually again.

- Processes: Basic workflows, such as receiving, quality checks, stock audits, and purchase order approvals, should already exist and be followed consistently.

- Team Roles: Everyone involved in inventory, from warehouse staff to purchasing, must know their role, as unclear responsibilities can create more confusion with automation.

- Metrics: Key inventory metrics, such as turnover rates, holding costs, and stockout frequencies, should already be measured since you can’t automate what you don’t track.

If these pieces are missing, automation won’t save you — it will expose the gaps faster.

Before plugging in a system, fix the structure behind it.

Real-World Stories: What Automation Looks Like (and When It’s Too Early)

Automation can transform inventory management just as it has helped companies in real-world examples. It lets you see where automation drives growth, where businesses prepare patiently, and where rushing in without the basics backfires.

Food and beverage retailer with automated purchasing from vendors

Space, a lemonade manufacturer, transitioned from manual processes to Kladana’s inventory management system.

This move enabled them to transfer 1,500 bottles between warehouses with just two clicks, significantly improving efficiency and reducing reliance on spreadsheets.

Fashion brand still using Excel but building internal logic

Neytt Homes, a high-fashion brand specializing in rugs and carpets, began managing inventory across its locations using Excel.

While retaining Excel, they also transitioned to Kladana’s automated inventory management system, enabling them to implement barcode tracking, faster counts, and real-time stock visibility.

Early-stage D2C brand rushing into software without inventory policies

Webvan, a dot-com era D2C grocery, invested heavily in fully automated warehouses and inventory systems from day one. They built multiple $35 million warehouses and stocked them with groceries before proving the model in a single city.

Such a lack of phased inventory rollout resulted in massive overcapacity and waste, ultimately leading to bankruptcy after only three years.

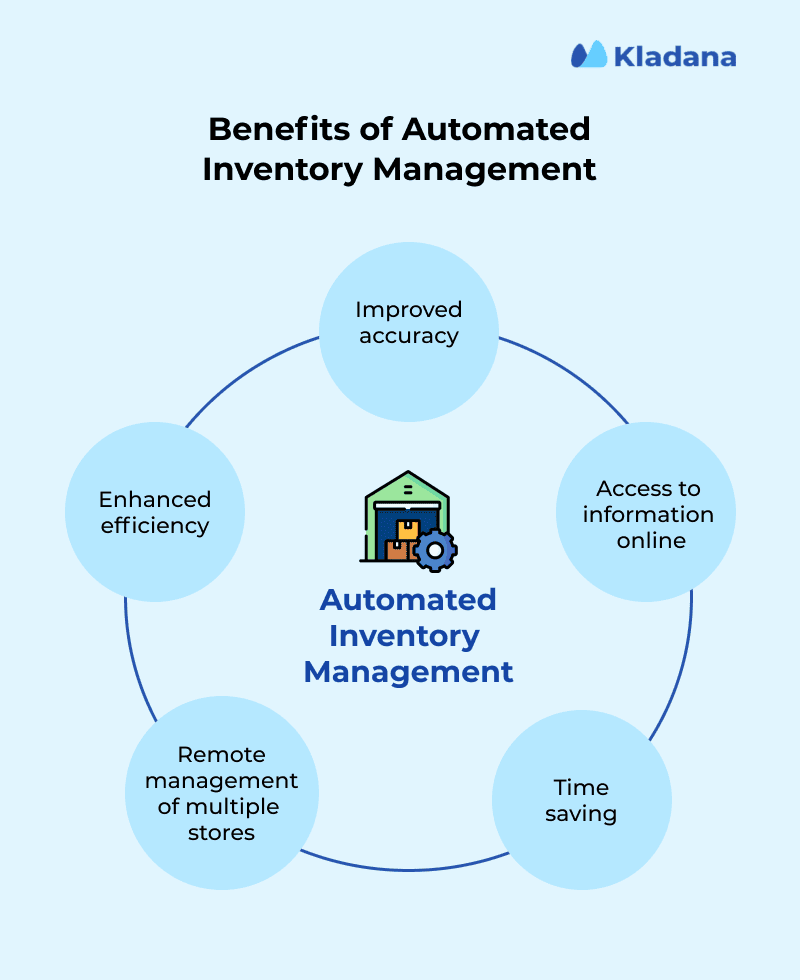

Key Benefits of Inventory Automation

Automated inventory management significantly impacts the speed of your business operations, customer satisfaction, and your ability to compete effectively. Adopting such a system brings operational improvements across daily operations.

Here’s what automation changes:

Time savings

Automated inventory management frees your team from low-value tasks. Stock adjustments, order updates, and reporting occur automatically, allowing teams to focus on selling and scaling.

Better stock accuracy

An automated inventory system adjusts stock levels automatically with every sale, purchase, or return. It leads to fewer errors during audits, fewer customer complaints about “out-of-stock” surprises, and improved financial reporting.

Fewer lost sales

Automated stock level alerts, reorder point automation, and real-time stock updates make sure you restock at the right time, minimizing missed sales opportunities.

Higher customer satisfaction

With accurate inventory visibility and faster fulfillment, you can consistently meet customer expectations, driving strong brand loyalty.

Improved decision-making via analytics

Effective inventory management can forecast future demand by tracking demand patterns, identifying fast-moving SKUs, recognizing slow movers, and anticipating seasonal spikes. It leads to more intelligent forecasting, fewer clearance sales, and healthier margins.

Choosing Automated Inventory Software

Making the right choice for an automated inventory management system begins with getting the basics right and ensuring the system grows with you.

So here are the features to look for:

Integrations

Your inventory software must integrate seamlessly with your online store, accounting software, CRM, and shipping partners to eliminate the need for manual syncing.

Scalability

The system should not only meet your current needs but also be able to handle double or triple the load as you expand products, sales channels, and locations.

Real-time stock updates

Automatic stock updates across all points of sale and warehouses, ensuring you never sell an item you don’t have or miss an item that’s overstocked.

Multi-location inventory tracking

When operating across multiple stores, warehouses, or fulfillment centers, your system must give you a real-time, unified view of stock everywhere.

Inventory reporting and analytics

Get insights like stock turnover rates, low-stock alerts, and sales velocity at your fingertips for smarter purchasing and pricing decisions.

How Kladana Helps to Automate Your Inventory Management:

✅ Real-Time Stock Tracking — Monitor inventory levels across multiple warehouses and sales channels in real-time, ensuring accurate stock counts and reducing the risk of stockouts or overstocking.

✅ Automated Reorder Alerts — Set minimum stock levels for products, and Kladana will automatically notify you when it’s time to reorder, helping maintain optimal inventory levels without manual checks.

✅ Batch and Expiry Date Management — Track product batches and their expiration dates efficiently, allowing for timely write-offs of expired goods and ensuring compliance with industry standards.

✅ Barcode Generation and Scanning — Automatically generate barcodes and print labels for products, making stock operations faster and reducing manual data entry errors.

✅ Comprehensive Reporting Tools — Access detailed stock and stock movement reports to analyze inventory on hand, committed, or in transit, and make informed business decisions.

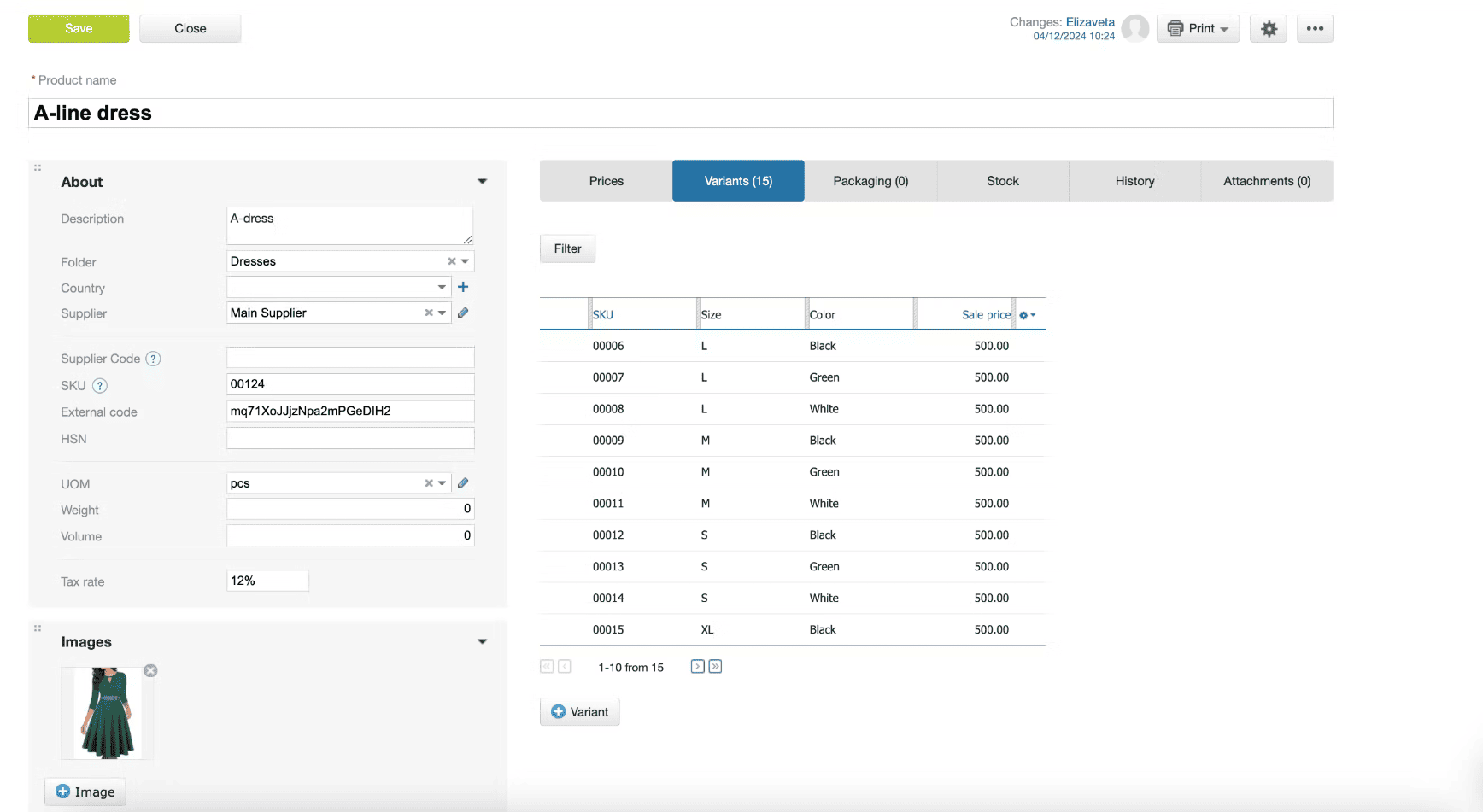

✅ Customizable Product Cards — Create detailed product cards with variants, pricing, and tax information, and organize items into groups or bundles for better inventory categorization.

If you want to know about other options, you can review our list of the best free inventory software in 2026.

Final Thoughts: Start with Smart Rules, Then Automate

Automation is a force multiplier for businesses that already have clarity in their processes.

It’s all about your team knowing when to reorder, how stock audits happen, and what roles everyone plays.

Once done, automation makes those processes faster, cleaner, and more scalable.

Before you automate, check:

- Are your basic workflows documented?

- Are your inventory responsibilities assigned?

- Are you manually tracking key stock KPIs, even if roughly?

When the answer to these is yes, your business is ready to move inventory management into automation — and to the next stage of growth.

Ready to manage your inventory on autopilot?

If you already have repeatable processes but aren’t sure if you’re ready for automated inventory management, start here.

Frequently Asked Questions on Automated Inventory Management

Below are answers to common questions businesses have about automating their inventory processes, including benefits, timing, and practical steps.

What exactly is automated inventory management?

Automated inventory management means using software and technology to track and update your stock levels automatically, without manual intervention. It ensures real-time accuracy, automatic reorder triggers, and synchronization across multiple sales channels and locations.

How does automated inventory management save time?

Automation removes the need for manual counting, spreadsheet updates, and stock checks. It instantly updates inventory after every transaction, giving your team more time to focus on sales, customer service, and strategic growth.

When should a business start automating inventory?

Consider automating your inventory when you notice frequent discrepancies, stockouts, reactive ordering, or when manual tracking consumes more than an hour per day. These signs indicate your business is ready for automation.

Can small businesses benefit from automated inventory management?

Yes, small businesses can significantly benefit. Automated inventory management reduces manual errors, saves time, improves customer satisfaction, and provides accurate data for better decision-making, making it easier to scale operations smoothly.

What types of businesses typically automate inventory management?

Businesses across various industries, including e-commerce, manufacturing, wholesale, distribution, and industries requiring batch or expiry tracking (like food, cosmetics, and chemicals), commonly adopt automated inventory management systems.

What’s the difference between automated inventory management and digital record-keeping?

Digital record-keeping (like Excel spreadsheets) still relies on manual input, whereas automated inventory management updates automatically based on defined triggers, significantly reducing errors and enhancing real-time operational accuracy.

How does automation improve decision-making?

Automated systems provide detailed analytics, including sales patterns, stock turnover rates, demand forecasting, and seasonal trends. These insights help businesses make smarter purchasing decisions and optimize inventory to minimize holding costs and waste.

What should be set before automating inventory management?

Before automating, establish clear stock-handling rules, consistent inventory processes, defined team roles, and essential inventory metrics. Solid foundations ensure that automation enhances your operations instead of amplifying existing issues.

Is automated inventory management software scalable?

Yes, good automated inventory software is scalable. It adjusts seamlessly as your business grows, supporting expanded product lines, multiple sales channels, additional warehouses, and increased transaction volumes.

What essential features should automated inventory software have?

Key features include real-time updates, multi-location tracking, seamless integrations, automated reorder alerts, barcode generation, detailed reporting, batch and expiry date management, and customizable product categorization.

List of Resources

- Firework — 33+ Crucial Inventory Management Statistics for E-commerce Success in 2024

- Fortune Business Insights — Inventory Management Software Market Size

- TechCrunch — Where Webvan Failed And How Home Delivery 2.0 Could Succeed