Before you bake a cake, you follow a recipe. Manufacturing works the same way — it needs a “product recipe” to ensure nothing is missed. That’s exactly what a Bill of Materials (BOM) is. Whether you’re assembling a piece of furniture, crafting a pizza, or building complex machinery, a BOM keeps everything organized: the parts, the quantities, and the steps.

In this guide, we’ll explain what a BOM is, who needs it, how to create one, and why Excel may not be your best option anymore.

- What is a Bill of Materials (BOM)?

- Why is BOM Important?

- Who Should Use the Bill of Materials — and When?

- Types of Bills of Materials

- Why You Shouldn’t Manage BOMs in Excel

- Free Bill of Materials Templates

- How to Create a BOM in Kladana

- Software for BOM Management: Kladana vs Alternatives

- Benefits of Using a BOM

- Frequently Asked Questions on Bill of Materials

- List of Resources

🎯 Managing materials or WIP manually?

🧊 4 Free Inventory Ckecklists

Learn how to manage stock, set up your warehouse, track barcodes, and build product cards for e‑commerce — even if you’ve never done it before

✅ Inventory management

✅ Warehouse setup

✅ Barcode tracking

✅ E-commerce product cards

What is a Bill of Materials (BOM)?

Before you build a product, you need a plan — a clear list of everything that goes into it. That’s what a Bill of Materials is: a detailed “product recipe” used in manufacturing. Just like a cake recipe lists flour, sugar, and eggs in precise amounts, a BOM lists every part, component, and material needed to make a finished product — and in what quantities.

For example, to assemble a wooden IKEA shelf, your BOM would include side panels, screws, wall brackets, pegs, glue — even the instruction manual and packaging materials. Everything must be documented to avoid missing steps, wasting materials, or delaying production.

A well-structured BOM includes:

- Raw materials

- Semi-finished components or subassemblies

- Final packaging elements

- Quantities and measurement units

- Reference codes or SKUs

Beyond tracking parts, a BOM plays a critical role in:

- Costing (estimating total product cost)

- Inventory control (ensuring stock is available)

- Compliance (especially in electronics, food, and pharma)

- Workflow coordination between engineering, procurement, and production teams

Why is BOM Important?

A well-structured Bill of Materials (BOM) is more than a checklist — it’s a core operational document that supports product development, cost control, supply chain coordination, and team collaboration. Without it, even the most advanced manufacturing process risks miscommunication, delays, and wasted resources.

Here’s why a BOM in manufacturing is essential for business success:

- ✅ Streamlines Inventory Management

A clear BOM enables real-time stock planning, helps avoid overstocking or shortages, and supports better warehouse coordination.

- ✅ Supports Cost Control

With accurate quantity tracking and component listings, you gain full visibility into material costs and can better forecast production budgets.

- ✅ Improves Cross-Team Communication

A centralized bill of materials keeps engineering, procurement, production, and quality teams aligned with a single source of truth.

- ✅ Enhances Supply Chain Resilience

When sourcing becomes unpredictable, a structured BOM helps identify interchangeable parts and secondary suppliers faster.

- ✅ Speeds Up Product Development

Using existing components listed in your BOM helps teams prototype faster and reduce time to market for new products.

- ✅ Reduces Production Errors

By eliminating guesswork around materials and assemblies, a BOM ensures consistency and compliance in every batch.

💡 Tip: Integrate your BOM with MRP or ERP software to automate updates and reduce manual entry errors.

Who Should Use the Bill of Materials — and When?

A Bill of Materials plays a vital role throughout the entire product lifecycle: from initial design to production, and even during maintenance or repair. It’s not just for the shop floor. A BOM acts as a shared reference that keeps cross-functional teams aligned on what goes into a product, how much is needed, and how it’s assembled.

🔄 When is a BOM used?

- Design phase: Engineers define product structure and materials

🔍 Historically, it is widely accepted in scientific literature that up to 80% of a product’s cost is determined at the design stage.

- Production phase: Teams build the product according to the BOM specifications

- Repair and maintenance: Technicians use the BOM to replace parts accurately

👥 Who uses a BOM?

- Engineers and Product Designers

Use BOMs to document every required part, material, and subassembly during product development. Helps visualize dependencies and design constraints. - Production Managers

Plan the manufacturing process, assign tasks, and ensure every unit follows the correct component structure — whether in-house or via subcontractors. - Procurement Specialists

Rely on the BOM to purchase the right materials at the right quantities and specifications, avoiding overstocking or misorders. - Inventory Controllers

Monitor stock levels based on BOM requirements to prevent shortages, delays, and bottlenecks in production. - Cost Analysts

Use BOMs to calculate total production costs and develop accurate pricing and budgeting strategies. - Sales and Marketing Teams

Refer to BOMs to understand product variations, offer accurate quotes, and emphasize product features during customer engagement. - Quality Assurance (QA) Teams

Cross-check the final output against the BOM to ensure compliance with design and quality standards.

✅ A structured BOM ensures that every team speaks the same language — making product planning, costing, and delivery smoother and more reliable.

Types of Bills of Materials

Different types of BOMs are available to suit the specific requirements of different stages in the product lifecycle and across various departments. Knowing and understanding these different types of BOMs helps leverage them to their full potential and optimize product development, manufacturing, sales, and support.

Let’s explore different types of BOMs in detail.

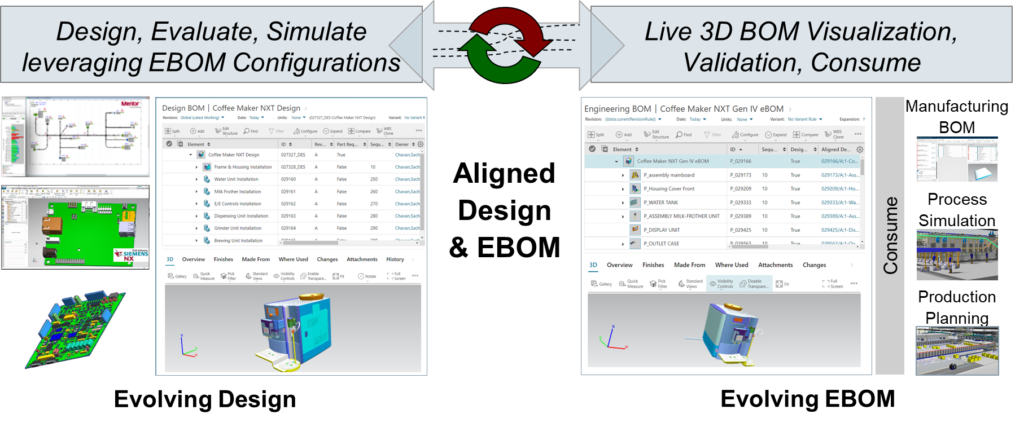

Engineering BOM (EBOM)

The Engineering BOM is like a product’s blueprint that defines the design and structure of the finished product. EBOM is often based on a detailed CAD (computer-aided design) drawing, making it an essential BOM in the product design phase.

EBOMs are intended to help engineers and designers outline exactly what components are needed as a product goes through its lifecycle. During this time, multiple EBOMs are created to reflect design changes and improvements.

Manufacturing BOM (MBOM)

MBOM contains a list of all the parts, assemblies, and materials necessary in an entire production lifecycle — from manufacturing a product to packaging sent to the customer. This is a critical bill that requires the use of manufacturing management software for production managers and assembly teams. It ensures that everything is accounted for during manufacturing.

Configurable BOM (cBOM)

What is CBOM? This BOM is particularly useful if a product has multiple iterations to manufacture and assemble (for instance, different colors, sizes, or features). It lets you define a base model and quickly create variations based on customer preferences to streamline the ordering and production process.

Modular BOM

You’d go with a modular BOM if your business needs to produce complex products with numerous subassemblies. This BOM helps break down the product into manageable chunks, making it easier to track changes and updates without reworking the entire BOM every time.

Sales BOM (SBOM)

The Sales BOM is tailored to specific customer orders and outlines the components and materials required to fulfill a particular sales order, including any special packaging or customization details. It is a necessary BOM for sales teams to help ensure that customer-specific requirements are met accurately and efficiently.

Service BOM

The Service BOM is the go-to document when repairing or servicing a product. It holds details of all the parts, components, and instructions required for maintenance and repairs. Service teams can use it to perform their tasks effectively since this BOM possesses details of the exact components used during repairs. In turn, this helps your teams maintain product integrity and performance.

Single-Level BOM

The Single-Level BOM provides a simplistic view of a product’s structure. It lists only the primary components required to build the product without diving into sub-assembly details. This BOM is highly useful for less complex products without a detailed breakdown.

Multi-Level BOM

Unlike a single-level BOM, a Multi-Level BOM offers a hierarchical view of the product’s structure, including all components and subassemblies. This BOM shows the relationships between each part. Manufacturing units use Multi-Level BOM to manage complex products with multiple layers of components.

In Kladana, we also offer BoMs, including multi-level ones:

Assembly BOM

Use assembly BOM when you need a bill highlighting a specific sub assembly within a larger product. It contains details of components and instructions required to build a particular subassembly, including the order in which components should be put together.

Software BOM (SBOM)

An SBOM is increasingly important in today’s digital world. The SBOM will list all the software components and dependencies within a software product to help in security and vulnerability assessments.

Repair BOM

You’d choose a repair BOM to track repair operations since it features all the components and parts needed to repair a product. This also contains detailed instructions for the repair process, which are essential for maintenance teams and service departments.

Packaging BOM

The PackagingBOM contains the materials and components required for packaging the final product.

Template BOM

The Template BOM is a predefined BOM acting as a starting point for creating new BOMs. Businesses that manufacture similar products often use a Template BOM, which allows them to quickly generate BOMs for new products by modifying an existing template.

Why You Shouldn’t Manage BOMs in Excel

Managing your Bill of Materials in Excel might seem convenient at first, but it comes with serious limitations that grow riskier as your operations scale.

❌ Common Issues with BOMs in Excel:

- No version control — Different team members may edit copies of the same file, leading to confusion, outdated data, or conflicting records.

- High risk of human error — One wrong cell, missed formula, or duplicated entry can throw off the entire production process.

- Lack of integration — Excel doesn’t connect with inventory, procurement, or production workflows, requiring manual updates and cross-checks.

- No collaboration tools — Teams working in silos risk miscommunication, especially during product updates or change requests.

🛠️ Real-world risks include production delays, incorrect procurement orders, stockouts, and inflated costs due to overlooked changes.

✅ A better alternative: ERP software like Kladana

With ERP tools, your BOM:

- Automatically syncs across inventory and procurement modules

- Is version-controlled and accessible by multiple teams in real time

- Can be duplicated, edited, or adjusted quickly for new product variants

- Keeps your business audit-ready and scalable

🔍 The global Bill of Materials (BOM) software market was valued at USD 8.2 billion in 2023 and is projected to reach USD 25.69 billion by 2033. The Asia-Pacific region is expected to be the fastest-growing market during this period.

Free Bill of Materials Templates

To help you get started with preparing the Bill of Materials, we’ve compiled some formats.

| Format | Best For | Features |

Excel |

Beginners |

Editable, simple formulas |

Google Sheets |

Collaborative teams |

Real-time editing |

Word |

Documentation |

Easy to share with vendors |

Printing & sharing |

Locked formatting |

Choose your preferred format and download or make a copy of the BOM template. Only in this case you’ll be able to edit it.

BOM Template in Excel (.xls) Format

Free download BOM template that helps with raw material inventory management in Excel format. You can paste your company logo, enter details of the bill, and edit it according to your branding style.

Single Level BOM Template

Multi Level BOM Template

BOM Template in MS Word (.docx) Format

Click the link below to download the Free MS Word Bill of Material template. Use it to edit and enter the details in the shared BOM.

BOM Template in PDF (.pdf) Format

Below is the free BOM template in PDF for the download. You can use it to enter the necessary details as required.

BOM Template in Google Sheets

This is the link for you to access the free BOM template in Google Docs format.

Single Level BOM Template

Multi Level BOM Template

BOM Template in Google Docs

Straightaway started editing this free bill of materials (BOM) template in Google Docs. Just log in to Google Docs and start preparing BOM.

Learn how to run a manufacturing business in Kladana. Plan your production operations, manage supplies and inventory, calculate cost of goods, and monitor employees’ activity.

🧮 Connect Your BOM to Profitability

Want to see exactly how your materials & component costs translate into profits?

Try Kladana’s Free Break-Even Point Calculator:

- Enter your fixed expenses, and selling price

- Instantly learn the number of units or revenue needed to break even

- Make data-backed decisions before changing components or launching new product lines

How to Create a BOM in Kladana

Let’s now drill down into some of the key steps involved in creating a Bill of Materials with the help of Kladana.

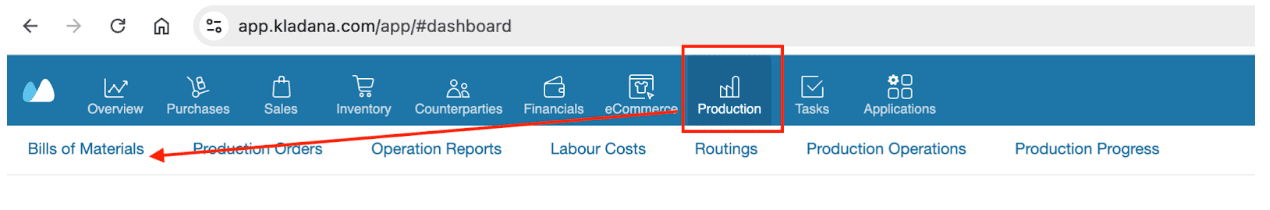

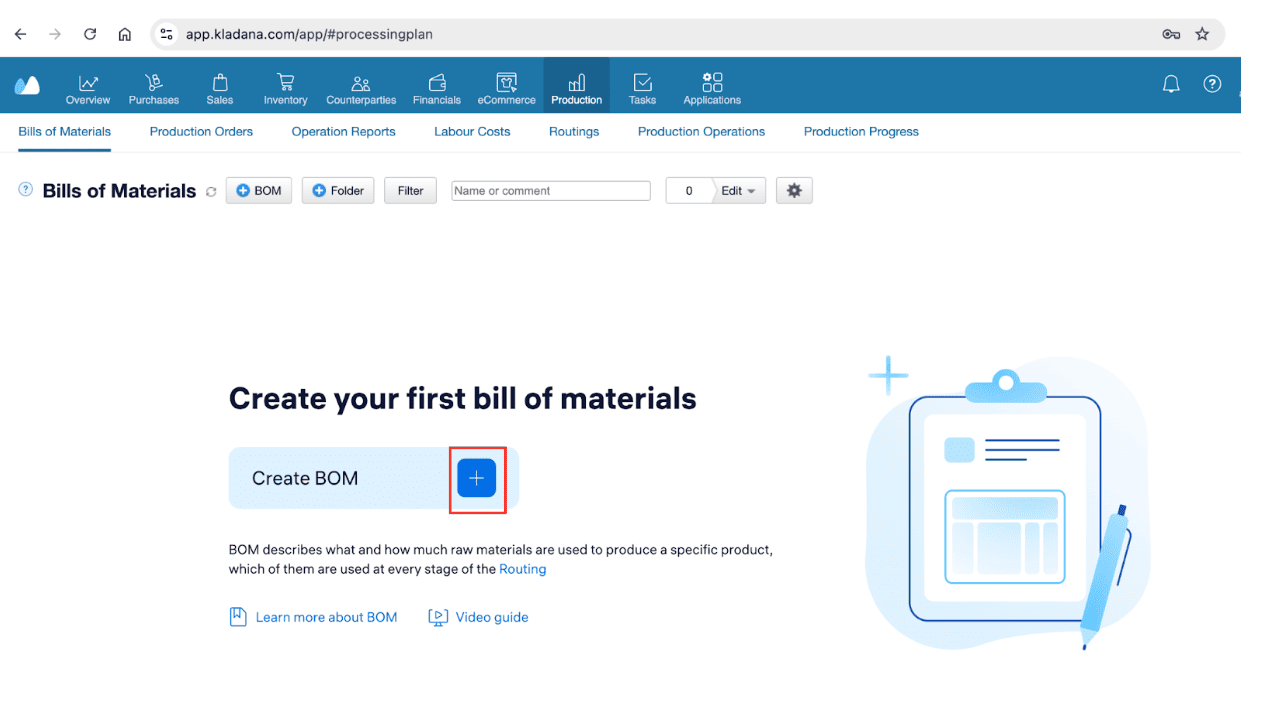

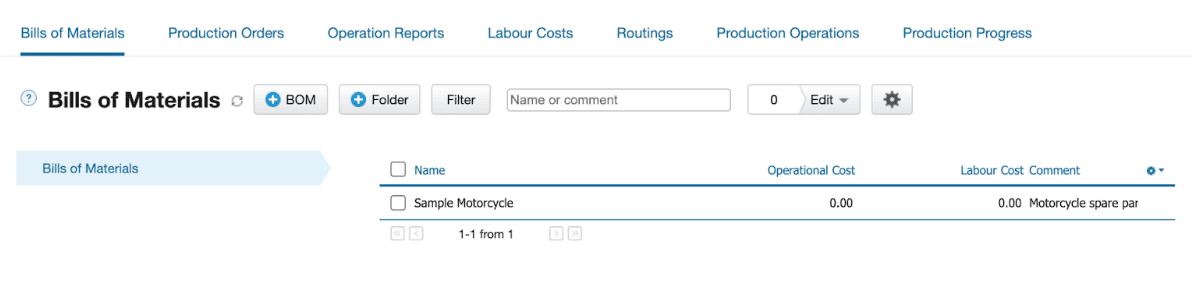

Step1: Navigate to the Production > BOM

Login to Kladana, and from the top main menu, select Production.

A sub-menu will open. From there, choose Bill of Materials.

Step 2: Create a BOM

Next, you’ll see an option to start creating BOM.

Click the ‘+’ sign to enter BOM build mode.

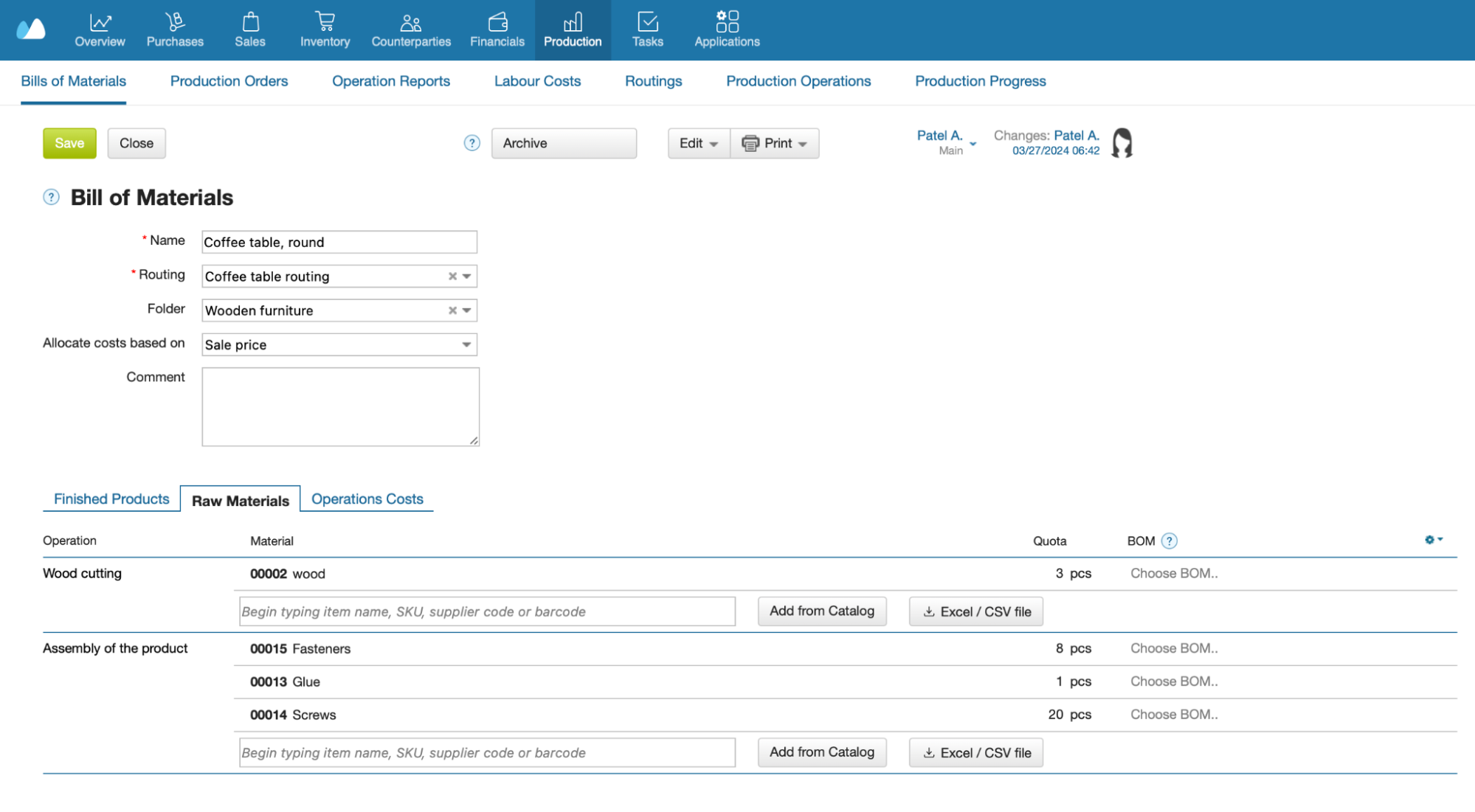

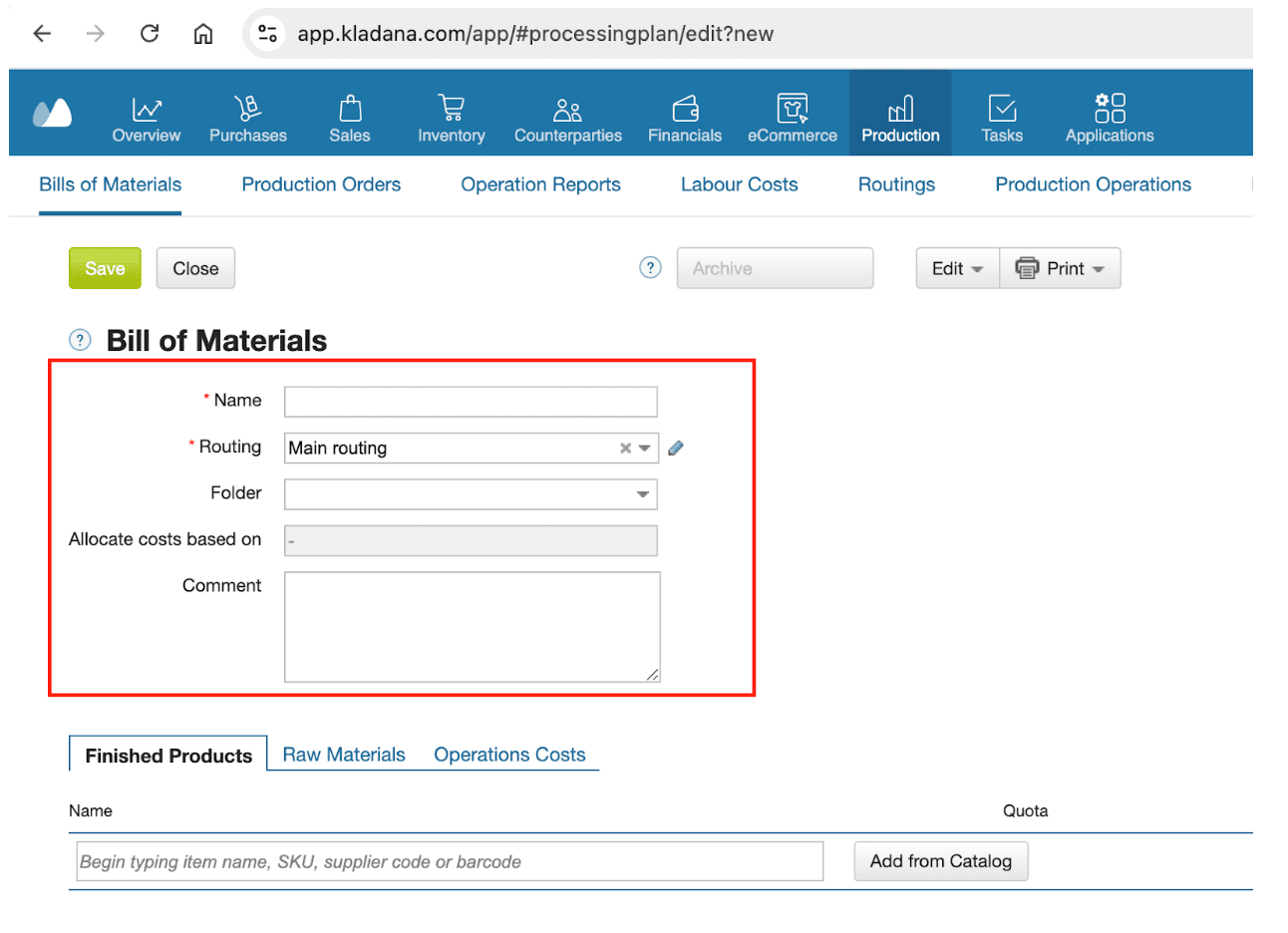

Step 3: Add Details

Enter the name of the BOM, select routing, and choose the BOM folder. Routing is the sequence of production operations that must be completed to produce a finished product. You can also opt to add a comment on that particular BOM.

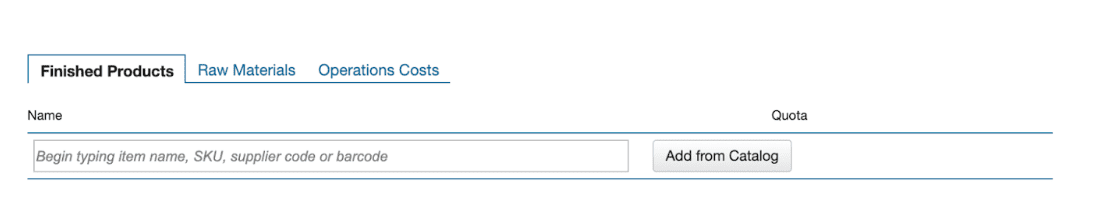

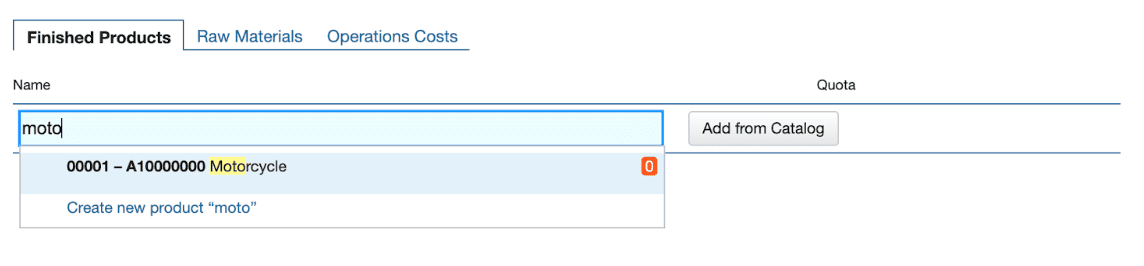

Step 4: Choose Expenditure Type

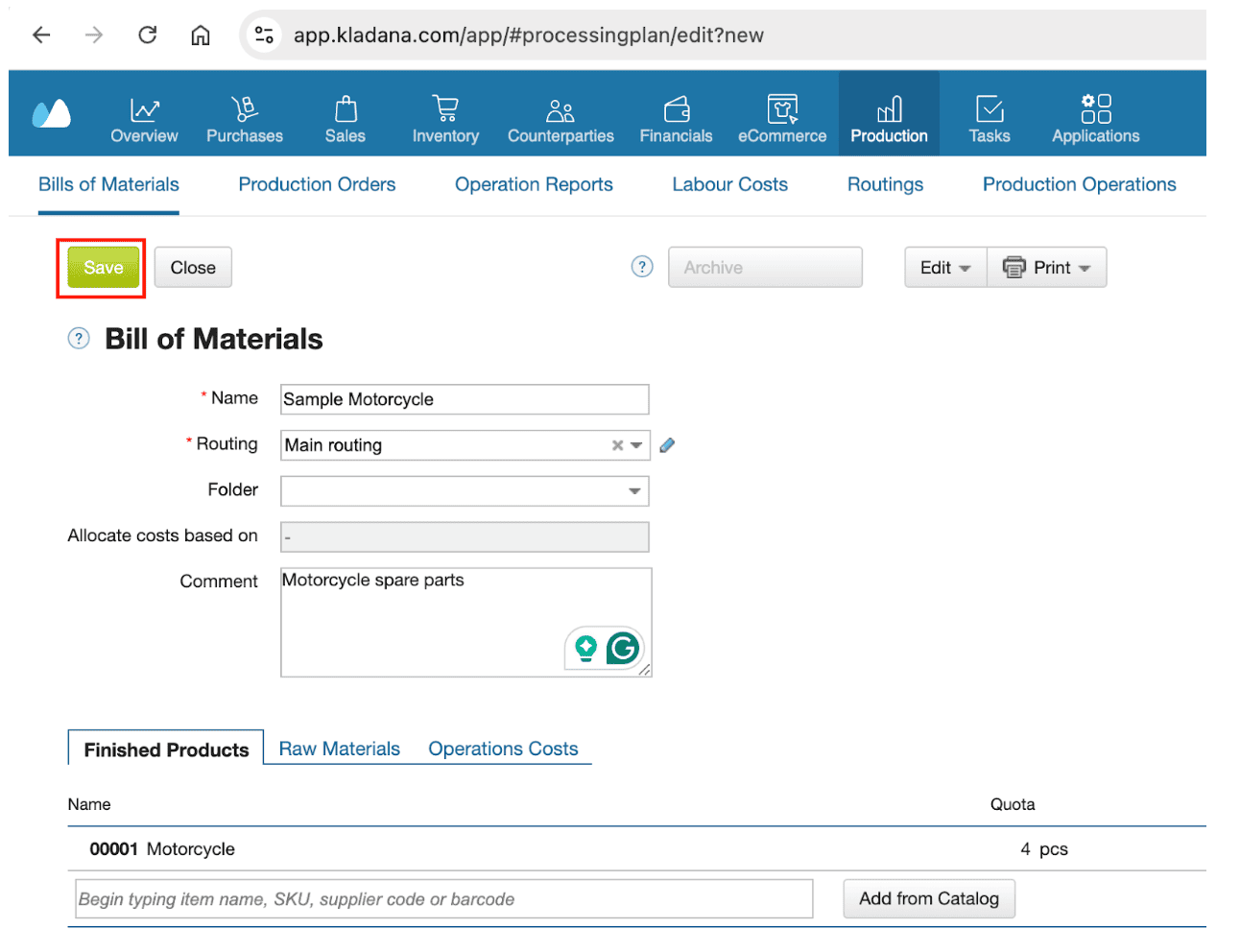

So, is the BOM for finished products, raw materials, or operations costs like machine maintenance? Each of the options will require you to add details as follows.

-

Finished Products

Choose this, and you’ll be able to search for the finished products for which BOM needs to be generated.

Also, you can choose the Add from Catalog option if you need to add a product that is not entered in the inventory.

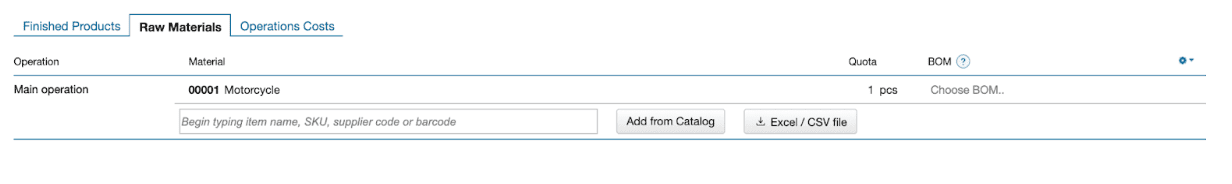

-

Raw Materials

Add raw materials that are needed for finished goods production.

Here, you can again choose to navigate and add from the catalog or import from an external Excel/CSV file.

-

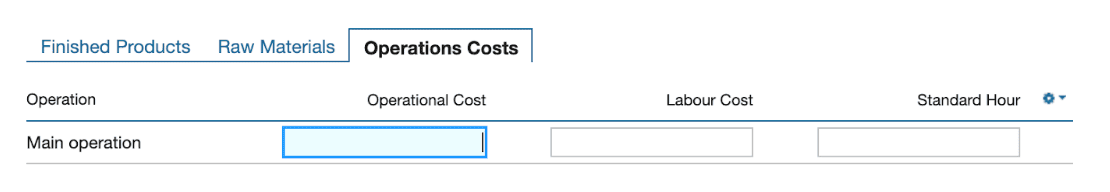

Operations Cost

In order to keep track of operational costs, use this option and add cost for operations and labor while mentioning the standard hours.

Step 5: Save the BOM

Lastly, save the BOM you created after entering the necessary details.

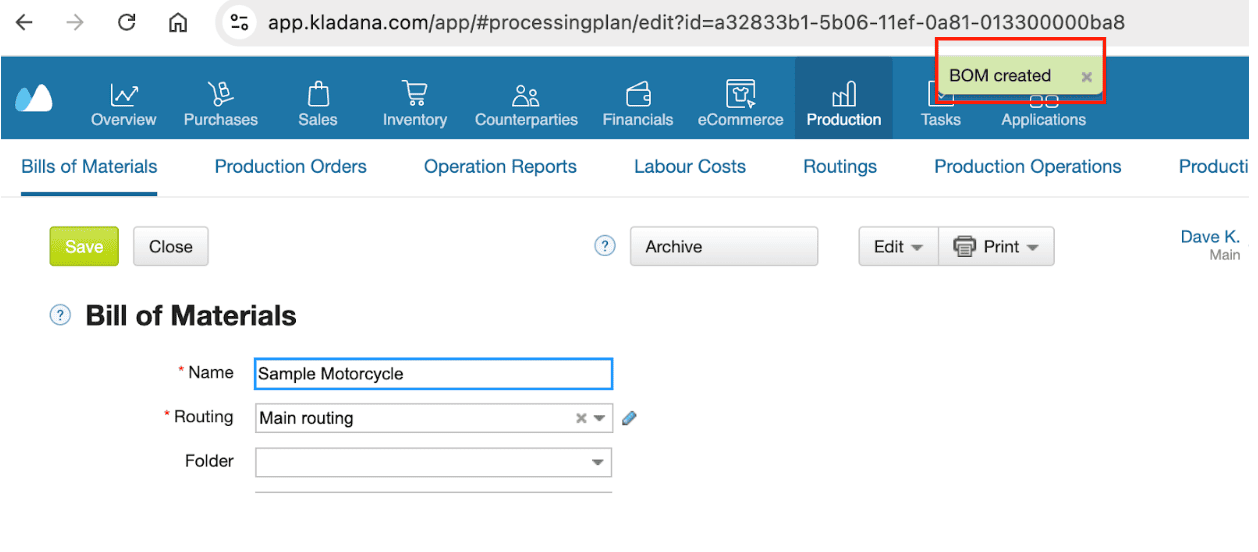

Click on the Save button, and you should be able to see the text: BOM created.

Step 6. Check The BOM Entry

Finally, you can click on the close option, and you’ll then be able to see the entry you created in a BOM.

Moreover, you can also choose the Filter and Edit buttons to find and bulk edit your BOM, respectively.

To explore Kladana in-depth, browse through our video tutorial on creating BOMs, Routings, and Production Orders:

Use Kladana to create and track BOMs, and streamline production, minimize downtime, and reduce costs.

We have our own BOM template. Log in to Kladana, then go to Production → BoM → Print → Template Settings → BoM Download

Software for BOM Management: Kladana vs Alternatives

From the above example, we learned how to use the software Kladana to create a BOM. Also, there are other software programs that you can use to create BOM.

Here’s a quick overview comparing the available BOM software with Kladana, which should help you make the right choice.

| Software | Features | Ratings | Pricing (USA) | Ideal for Business Size |

Kladana |

|

5/5 |

Starts at $563/year |

Small to Medium Businesses |

Arena PLM |

|

4.3/5 |

Custom pricing |

Medium to Large Enterprises |

OpenBOM |

|

4.1/5 |

$1,200/Year /month (per user) |

Small to Medium Businesses |

Odoo MRP |

|

4.2/5 |

Starts at $345/year (per user) |

Small to Large Enterprises |

Upchain (By Autodesk) |

|

4.0/5 |

Custom pricing |

Medium to Large Enterprises |

Sage 100cloud |

|

4.2/5 |

Custom pricing |

Small to Medium Businesses |

MRPeasy |

|

4.5/5 |

Starts at $488/year (per user) |

Small to Medium Businesses |

Fishbowl Manufacturing |

|

4.2/5 |

Custom Pricing |

Small to Medium Businesses |

SAP BOM Management |

|

4.2/5 |

Custom Pricing |

Large Enterprises |

When choosing the right software to help you create BOM, it is ideal to understand your business needs, size, and scope of further scalability.

Try Out the Easiest Manufacturing Process Management Software

- Manage multi-level BOM with ease

- Create production orders straight from BOM

- Outsource sub-contracts to vendors seamlessly

- Access cloud software without downloads

- Forever free plan for basic features

Benefits of Using a BOM

A well-structured BOM is more than a technical document. It’s a powerful tool for boosting efficiency, reducing costs, and improving collaboration across your manufacturing workflow.

Here’s how it helps:

- 💰 Cost Control and Budgeting

Gain visibility into material costs and identify savings opportunities by comparing suppliers or replacing high-cost components. - 📦 Inventory Accuracy

Ensure the right quantities of raw materials and components are available — no overstocking, no shortages. - 🏭 Streamlined Production

Reduce errors, rework, and delays with a clear roadmap for each production step, from materials to assembly. - 🔗 Stronger Supply Chain Resilience

Identify single-source dependencies and proactively plan alternative sourcing strategies to minimize disruptions. - 🔍 Product Lifecycle Management (PLM)

Track each component across the product’s life — from design and sourcing to service and disposal. - 👥 Better Cross-Department Collaboration

Create a shared language for engineers, procurement, production, and quality assurance teams. - ✅ Compliance and Standards Adherence

Maintain audit trails, ensure certifications are in place, and meet regulatory requirements effortlessly. - 🌱 Sustainability Improvements

Use your BOM to highlight opportunities to switch to eco-friendly materials and reduce your environmental footprint.

📌 Tip: Pair your BOM with ERP software to automate tracking and reporting for even more impact.

Frequently Asked Questions on Bill of Materials

Having various questions when introducing your first or a new inventory management technique is normal. Here are some of the most common BOM questions you may have.

What is a BOM used for?

A BOM helps manage the production process by listing all the parts and components needed to build a product. It’s used by manufacturing, engineering, procurement, and design teams.

Can a BOM be used for service and maintenance?

Yes, you can use a service BOM that specifically lists the components, parts, and instructions required for servicing or repairing a product. This helps maintenance teams identify the correct components and perform effective repairs.

Is a BOM only applicable to physical products?

No, BOMs are also applicable to software products. A Software BOM (SBOM) lists the software components, libraries, and dependencies within a software product that help in security assessments and license compliance.

What is a Software BOM (SBOM)?

An SBOM lists all software components used in a digital product or application. It helps manage cybersecurity and version control.

How does a BOM help new product development?

A BOM can expedite new product development by allowing the reuse of existing components or subassemblies from previous products, saving time and resources.

Can BOM help reduce costs?

Definitely! With BOM, you get transparency into material costs, which allows for the analysis of component pricing. In turn, this reveals opportunities for cost reduction through supplier negotiations, material substitutions, or design optimizations.

What are common BOM management mistakes?

Using outdated spreadsheets, duplicating parts, and ignoring version control can lead to production delays and quality issues.

How often should I update BOM?

A BOM will need an update in case of a change in the product design, materials, or manufacturing process so as to accurately reflect the current state of the product.

Should small businesses use software for BOMs?

Yes — especially growing manufacturers. Software offers better accuracy, collaboration, and integration with inventory and procurement systems.

How does a BOM contribute to product compliance and regulatory requirements?

With BOM, you can track all the materials and components that are used in the product. You can use these details to showcase compliance with industry regulations like environmental standards, etc. to avoid potential legal issues and penalties.

🤩 Free Business Templates by Kladana

Looking for ready-to-use business templates? Explore our collection designed to simplify everything from production planning to invoicing.

Download, customize with your company details and logo, and use them right away — no sign-up required.

✔ Production Scheduling Templates — Organize production tasks and track progress

✔ Printable Bill Books — Use standard bills or tax-ready invoices in mobile-friendly formats

✔ Excel Inventory Tracker — Start managing stock with a simple spreadsheet

✔ Purchase Order Templates — Streamline your purchasing routines

✔ Proforma Invoice Templates — Share estimated costs with clients before final billing

👌 No forms, no phone numbers. Just download or make a copy.